600 MPa-grade-and-above high strength steel bars and reinforced concrete application method thereof

A technology of reinforced concrete and high-strength steel bars, applied in the field of steel bar manufacturing, can solve problems such as hidden dangers in engineering quality, low yield strength, and inability to meet the protection thickness of reinforced concrete, etc., achieve good trampling resistance, reduce diameter, and avoid excessive corrosion rate and the effect of hardness exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

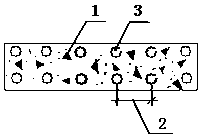

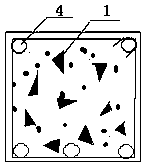

Image

Examples

Embodiment 1

[0034] A high-strength steel bar of 600 MPa grade and above provided in this embodiment, the weight percentage composition of the high-strength steel bar is: C: 0.2%, Mn: 0.45%, Si: 0.62%, Cr: 0.7%, Mo: 0.15%, Ni: 0.65%, V: 0.3%, S: 0.0075%, P: <0.01%, the balance is Fe and unavoidable impurities.

[0035] The production process of the high-strength steel bar is:

[0036] (1) Put the steel bar in the heating furnace and heat it to 1300°C. After leaving the heating furnace, use water cooling to cool the steel bar to 950°C at a cooling rate of 23°C / s, then quench it with water or quenching liquid in the quenching device, and then temper it Heating in the heating furnace to 600°C for tempering, and then cooling to room temperature through the first cooling process; the first cooling process is: using water cooling and air cooling, first using water cooling at a cooling rate of 1.5°C / s to water-cool the steel bar to 460 °C, then air-cooled to 290 °C, then water-cooled to 200 °C a...

Embodiment 2

[0042] A high-strength steel bar of 600 MPa grade and above provided in this embodiment, the weight percentage composition of the high-strength steel bar is: C: 0.15%, Mn: 0.4%, Si: 0.75%, Cr: 0.6%, Mo: 0.2%, Ni: 0.5%, V: 0.25%, S: 0.009%, P: 0.009%, the balance is Fe and unavoidable impurities.

[0043] The production process of the high-strength steel bar is:

[0044] (1) Put the steel bar in the heating furnace and heat it to 1350°C. After leaving the heating furnace, use water cooling to cool the steel bar to 920°C at a cooling rate of 24°C / s, then quench it with water or quenching liquid in the quenching device, and then temper it Heating in the heating furnace to 600°C for tempering, and then cooling to room temperature through the first cooling process; the first cooling process is: use water cooling and air cooling, first use water cooling to cool the steel bar to 430°C at a cooling rate of 3°C / s °C, then air-cooled to 320 °C, and then water-cooled to 180 °C at a cool...

Embodiment 3

[0050] A high-strength steel bar of 600 MPa grade and above provided in this embodiment, the weight percentage composition of the high-strength steel bar is: C: 0.18%, Mn: 0.65%, Si: 0.69%, Cr: 0.65%, Mo: 0.3%, Ni: 0.59%, V: 0.4%, S: 0.008%, P: 0.011%, and the balance is Fe and unavoidable impurities.

[0051] The production process of the high-strength steel bar is:

[0052] (1) Put the steel bar in the heating furnace and heat it to 1400°C. After leaving the heating furnace, use water cooling to cool the steel bar to 940°C at a cooling rate of 25°C / s, then quench it with water or quenching liquid in the quenching device, and then temper it Heat to 610°C in the heating furnace for tempering, and then cool to room temperature through the first cooling process; the first cooling process is: use water cooling and air cooling, first use water cooling to cool the steel bar to 420°C at a cooling rate of 2.5°C / s °C, then air-cooled to 300 °C, then water-cooled to 190 °C at a coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com