Pre-cold pressing quenching correction technology for die steel

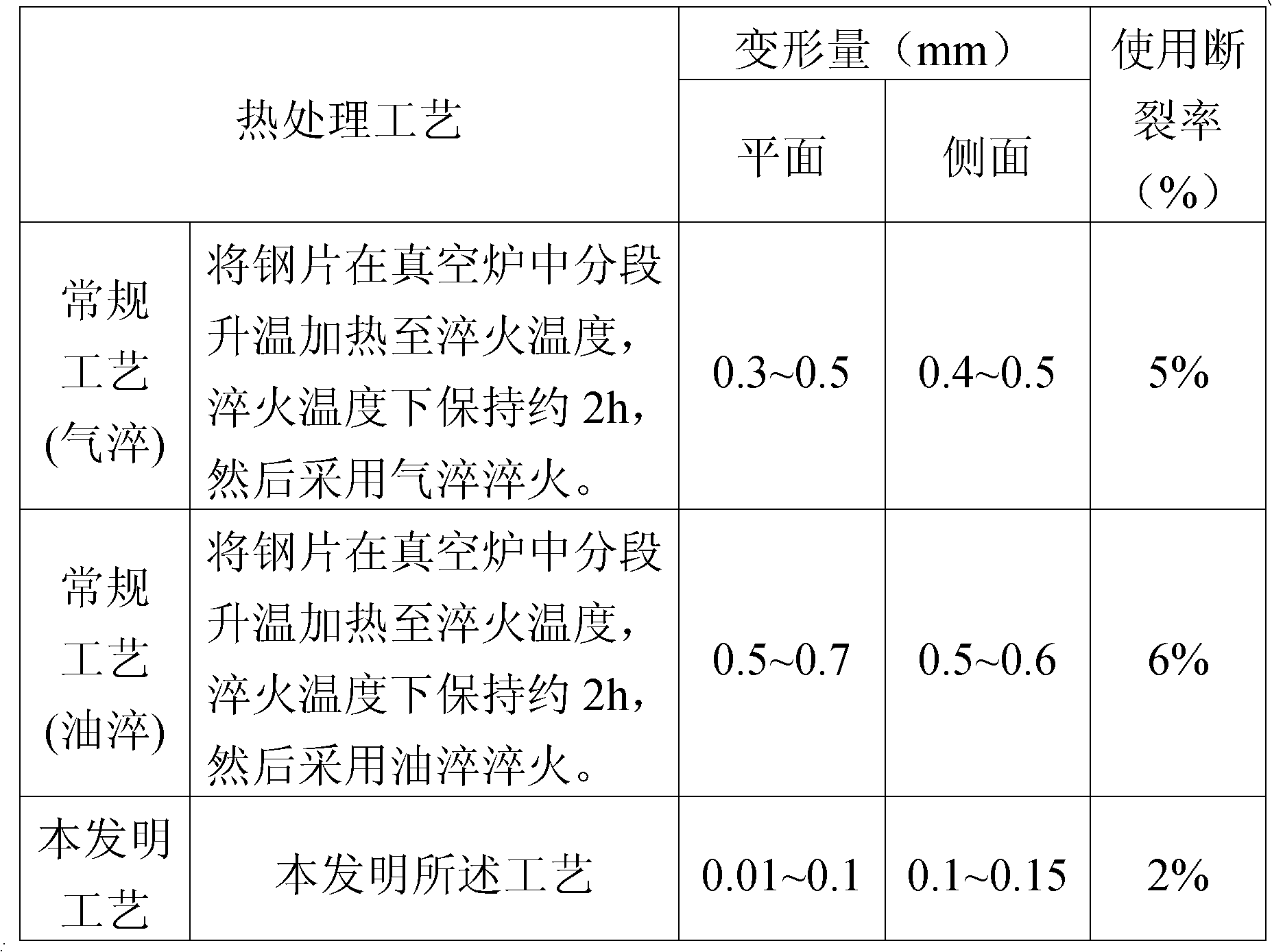

A die steel and pre-cooling technology, applied in quenching devices, manufacturing tools, furnaces, etc., can solve the problems of increased difficulty, deformed metal workpiece performance, time-consuming and labor-intensive, etc., and achieves the effects of small deformation, low quenching stress, and easy correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

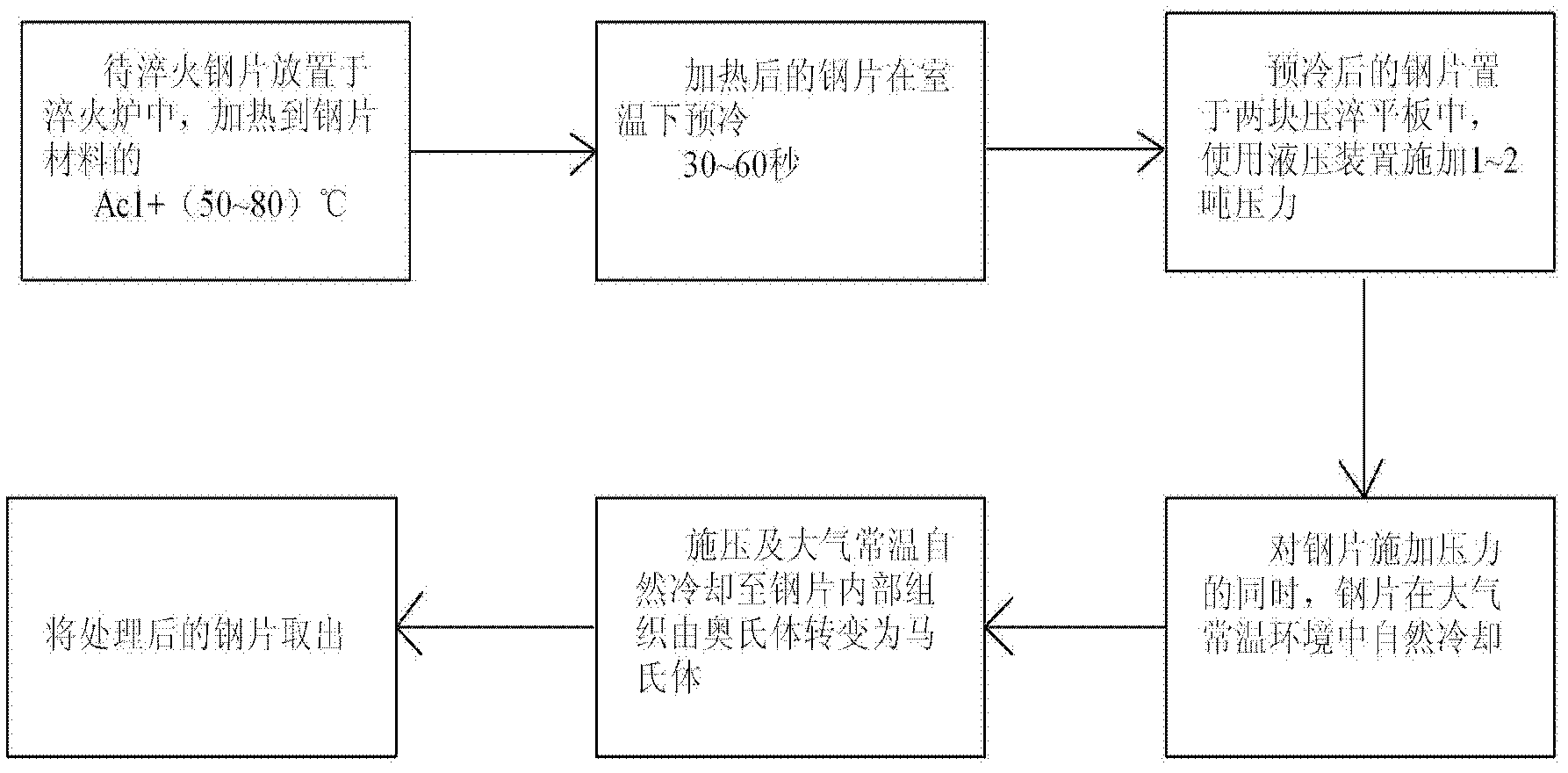

[0015] combine figure 1 The present invention is described in further detail.

[0016] The size specification of the steel sheet selected in this embodiment is 500×100×20 mm; the material of the selected steel sheet is one of hypereutectoid steel.

[0017] A pre-cooling and press-quenching correction process for die steel: comprising the following steps:

[0018] Step (1): Place the steel sheet to be quenched in a quenching furnace and heat to the Ac1+(50-80)°C of the steel sheet material;

[0019] Step (2): precooling the steel sheet heated in step (1) at room temperature for 30 to 60 seconds;

[0020] Step (3): Place the pre-cooled steel sheet in step (2) quickly on two press-quenched plates, start the hydraulic device, and the hydraulic device applies a pressure of 1 to 2 tons to the press-quenched plate, while the steel sheet is Natural cooling is carried out in the ambient temperature environment of the atmosphere, and the internal structure of the steel sheet material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com