Thermal treatment process for 40CrNiMoA core rod and 40CrNiMoA core rod obtained through process

A mandrel and process technology, which is applied in the field of forging, can solve the problems of difficult impact toughness and other problems, and achieve the effects of improving grain size, avoiding cracking of workpieces, and reducing quenching stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

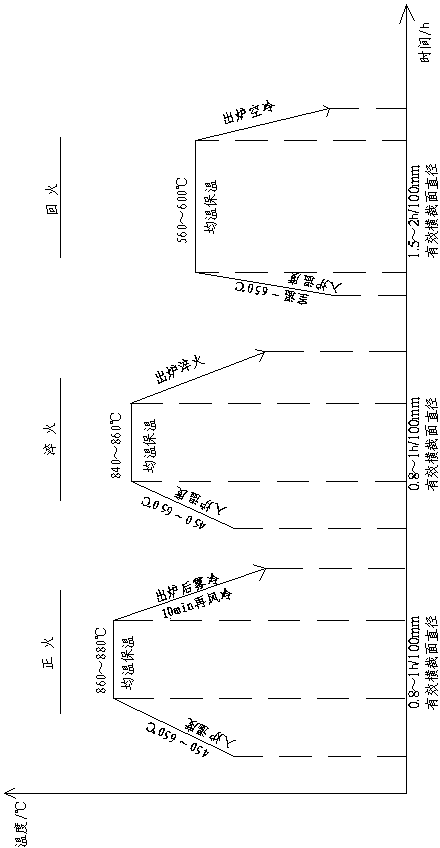

[0025] Such as figure 1 Shown, a kind of heat treatment process of 40CrNiMoA mandrel, it comprises the following steps:

[0026] Step 1. Normalizing treatment: Put the 40CrNiMoA mandrel into the furnace with a furnace temperature of 450°C, heat it to the normalizing temperature of 860°C with full power, and keep it warm for 1 hour per 100mm of the effective cross-sectional diameter of the 40CrNiMoA mandrel. After 10 minutes, air-cool to room temperature;

[0027] Step 2, quenching treatment: put the 40CrNiMoA mandrel after the normalizing treatment in step 1 into the furnace at a furnace temperature of 450°C, then heat it to the quenching temperature of 840°C with full power, and keep it warm for 1 hour per 100mm of the effective cross-sectional diameter of the 40CrNiMoA mandrel , the furnace is cooled to the surface temperature of the 40CrNiMoA mandrel at 100-140°C by the gap cooling method of water ~ air ~ water to obtain the martensitic structure;

[0028] Step 3, temperi...

Embodiment 2

[0040] A kind of heat treatment process of 40CrNiMoA mandrel, it comprises the steps:

[0041] Step 1. Normalizing treatment: Put the 40CrNiMoA mandrel into the furnace with a furnace temperature of 620°C, heat it to the normalizing temperature of 870°C with full power, and keep it warm for 0.9h per 100mm of the effective cross-sectional diameter of the 40CrNiMoA mandrel. After cooling for 10 minutes, air-cool to room temperature;

[0042] Step 2, quenching treatment: put the 40CrNiMoA mandrel after the normalizing treatment in step 1 into the furnace at a furnace temperature of 600°C, then heat it with full power to the quenching temperature of 850°C, and keep it warm for an effective cross-sectional diameter of 0.9 per 100mm of the 40CrNiMoA mandrel. h, after being released from the furnace, the surface temperature of the 40CrNiMoA mandrel is 100-140° C. to obtain a martensitic structure;

[0043] Step 3, tempering treatment: put the 40CrNiMoA mandrel after the quenching tr...

Embodiment 3

[0055] A kind of heat treatment process of 40CrNiMoA mandrel, it comprises the steps:

[0056] Step 1. Normalizing treatment: Put the 40CrNiMoA mandrel into the furnace with a furnace temperature of 650°C, heat it to the normalizing temperature of 880°C with full power, and keep it warm for 0.8h per 100mm of the effective cross-sectional diameter of the 40CrNiMoA mandrel. After cooling for 10 minutes, air-cool to room temperature;

[0057] Step 2, quenching treatment: put the 40CrNiMoA mandrel after the normalizing treatment in step 1 into the furnace at a furnace temperature of 650°C, then heat it at full power to the quenching temperature of 860°C, and keep it warm for an effective cross-sectional diameter of 0.8 per 100mm of the 40CrNiMoA mandrel. h, after being released from the furnace, the surface temperature of the 40CrNiMoA mandrel is 100-140° C. to obtain a martensitic structure;

[0058] Step 3, tempering treatment: Put the 40CrNiMoA mandrel after the quenching trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com