Nano zinc oxide modifying chloroprene rubber spraying type adhesive and preparation method thereof

A technology of nano-zinc oxide and chloroprene rubber, which is applied in the direction of chloroprene adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of poor heat resistance and achieve improved heat resistance and oxidation probability The effect of reducing and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

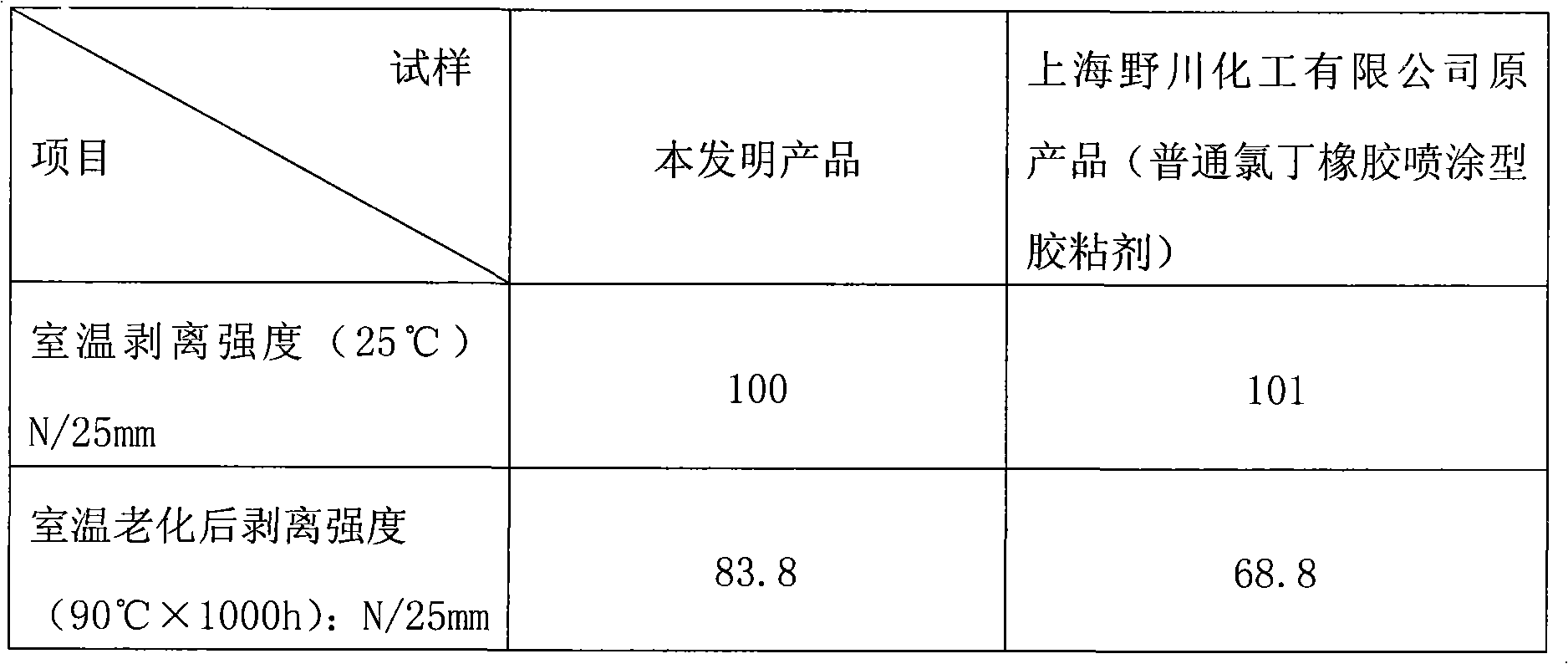

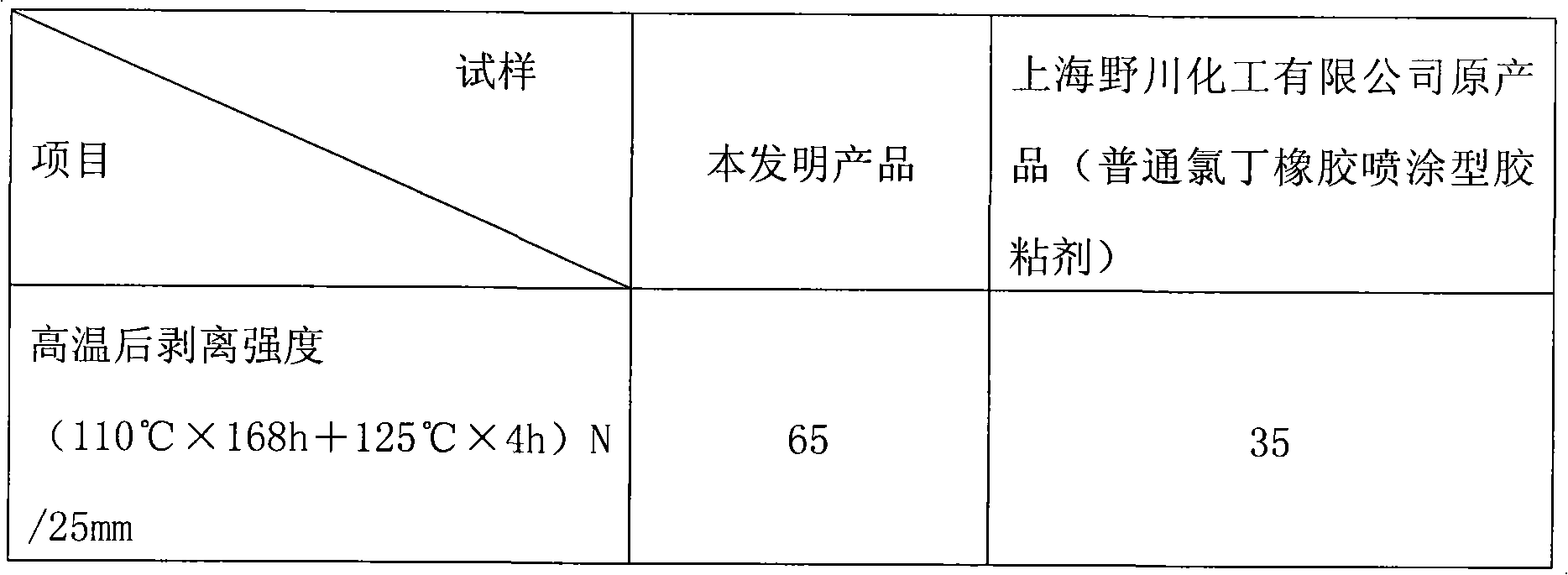

Examples

Embodiment

[0029] The formula and content of the present embodiment:

[0030] TA-85 Neoprene 72g produced by Nippon Denki Chemical Co., Ltd.

[0031] Nano Zinc Oxide 3g produced by Shanghai University Nanotechnology Center

[0032] Magnesium oxide 150# 3g produced by Kyowa Chemical Co., Ltd.

[0033] Magnesium Oxide 3g from Shanghai Dunhuang Chemical Plant

[0034] Calcium silicate produced by Shandong Weifang Hongyuan Technology Co., Ltd. 4.2g

[0035] Liquid resin produced by Jiangxi Mashan Chemical Co., Ltd. 6g

[0036] FRJ-551 Alkyl Phenolic Resin produced by Tena Chemical (Shanghai) Co., Ltd. 36g

[0037] Anti-aging agent BHT 2.4g

[0038] Toluene 72g

[0039] Cyclohexane 186g

[0040] n-hexane 102g

[0041] Acetone 119.2g

[0042] Water 0.2g.

[0043] Specific preparation methods and steps:

[0044] Step 1. First masticate TA-85 neoprene and 1 / 2 antioxidant BHT on a small rubber mixing machine for 3 minutes, then add nano-zinc oxide, magnesium oxide, remaining antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com