High-nitrogen pearlitic steel

A pearlitic steel, high nitrogen technology, applied in the field of metal materials, can solve the problem of the blank of high nitrogen structural steel patents, and achieve the effect of increasing the strength to yield ratio, reducing the cost, and increasing the strength

Inactive Publication Date: 2014-12-17

CENT IRON & STEEL RES INST

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are few researches on high nitrogen in structural steel at home and abroad, and the patent on high nitrogen structural steel is blank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

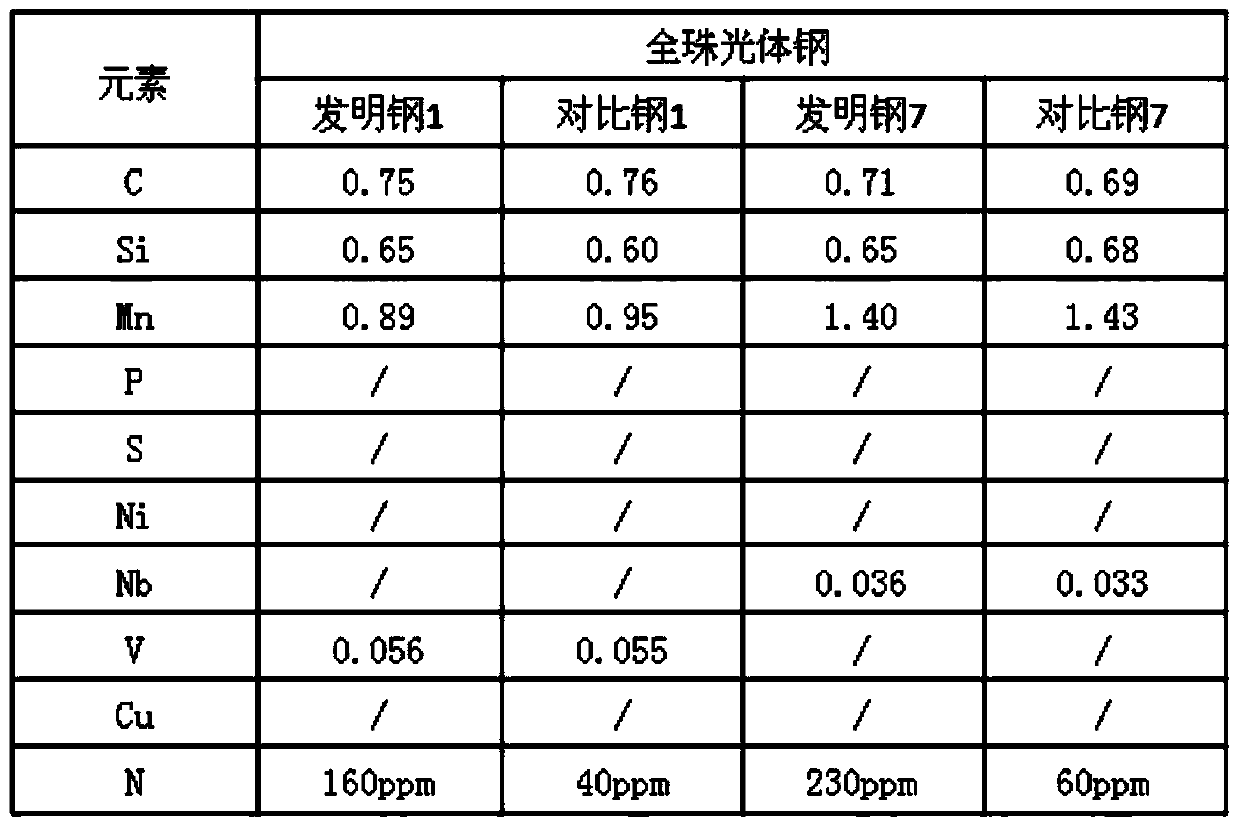

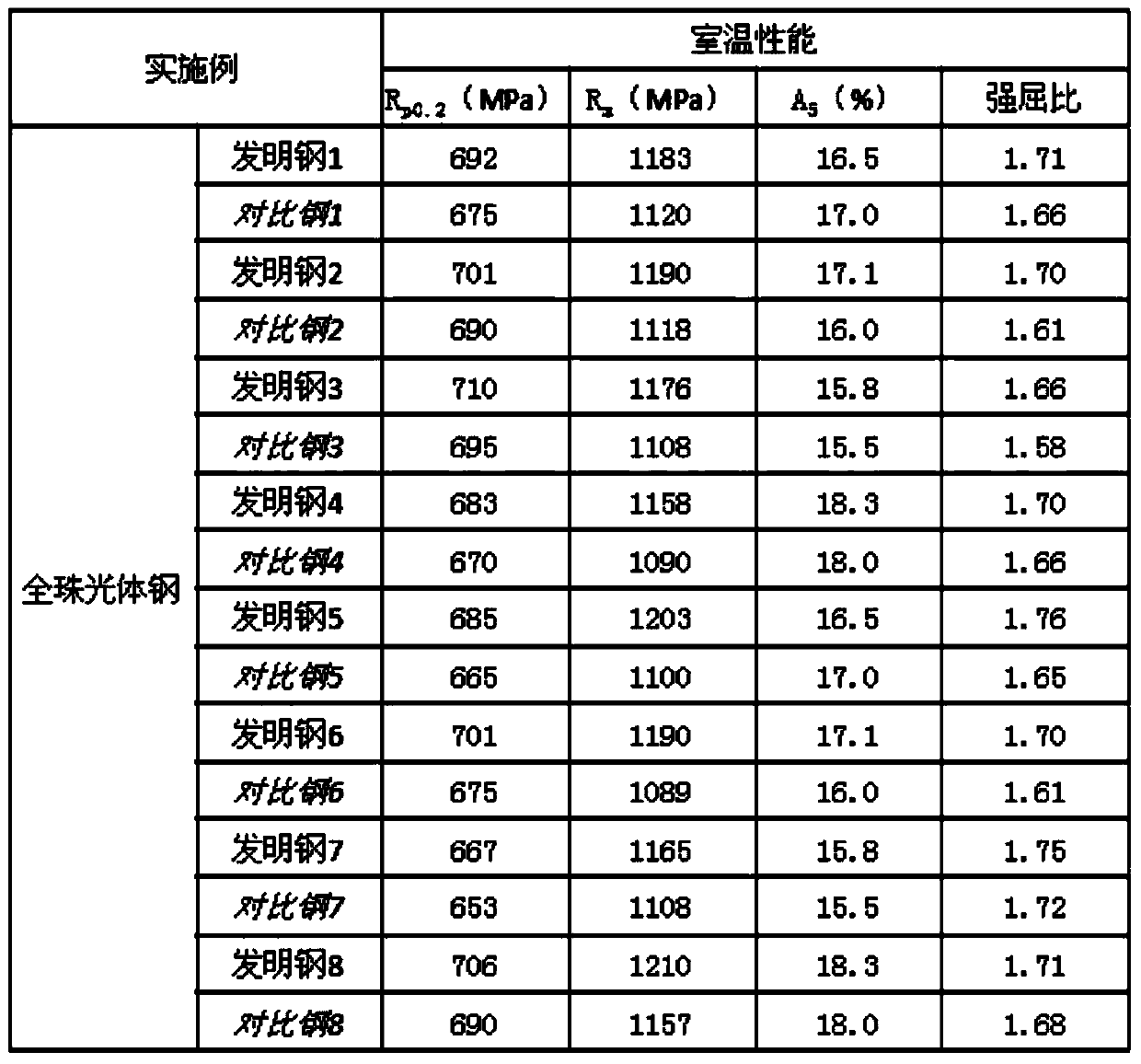

Embodiment 1

[0011] Chemical composition ratio, by weight percentage: C: 0.75, Si: 0.65, Mn: 0.89, P≤0.035, S≤0.035, V: 0.056, N: 160ppm, others are Fe.

Embodiment 2

[0013] Chemical composition ratio, by weight percentage: C: 0.65, Si: 0.8, Mn: 1.10, Cu: 0.3, Nb: 0.03, Cr: 0.25, N: 180ppm, others are Fe.

Embodiment 3

[0015] Chemical composition ratio, by weight percentage: C: 0.70, Si: 0.35, Mn: 1.40, Nb: 0.036, V: 0.062, Cr: 0.55, Cu: 0.30, Ni: 0.30, N: 300ppm, others are Fe.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-nitrogen pearlitic steel, and belongs to the technical field of metal materials. The high-nitrogen pearlitic steel comprises the following components in percentage by weight: 0.60-0.80% of C, 0.3-0.8% of Si, 0.80-1.40% of Mn, P not higher than 0.045%, S not higher than 0.035%, N not higher than 300 ppm and not lower than 120 ppm, and the balance of Fe and impurity elements, wherein such alloy elements as Nb, V, Cr, Ni and Cu can be properly added according to the comprehensive performance requirement of the steel. The high-nitrogen pearlitic steel has the following advantages: various technical measures for denitrification in the steel making process are avoided; pearlite in the steel is strengthened by using cheap nitrogen; the tensile strength of the steel is improved; the process is simple; and the cost is low.

Description

technical field [0001] The invention belongs to the technical field of metal materials, and is especially suitable for full pearlitic steel. Background technique [0002] Generally, nitrogen is considered a harmful element in steel. Free nitrogen in steel has adverse effects on the aging properties of steel. However, nitrogen absorption in various stages of steelmaking, such as molten iron, scrap steel, arc heating, and tapping, will increase the nitrogen content in steel. In order to reduce the nitrogen content in steel, it is often necessary to take many measures. Taking converter steel as an example, the nitrogen content can be reduced by using high-purity oxygen, increasing the feeding strength, reducing the diameter of the furnace mouth, and reducing the use of scrap steel with high nitrogen content. [0003] With the successful application of high-nitrogen stainless steel, the role of nitrogen as an alloying element has been paid more and more attention. Studies hav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/46C22C38/48C22C38/24C22C38/26C22C38/12C22C38/00

Inventor 杨忠民陈颖王慧敏

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com