TMCP-state low-cost high-strength ship plate steel for high-heat input welding and manufacturing method of TMCP-state low-cost high-strength ship plate steel

A high-energy-input welding and low-cost technology, applied in the field of metallurgy, can solve the problems of decreased mechanical properties of welded joints, deterioration of low-temperature toughness, and high cost, and achieve the effects of stable production process, improved toughness, and reasonable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

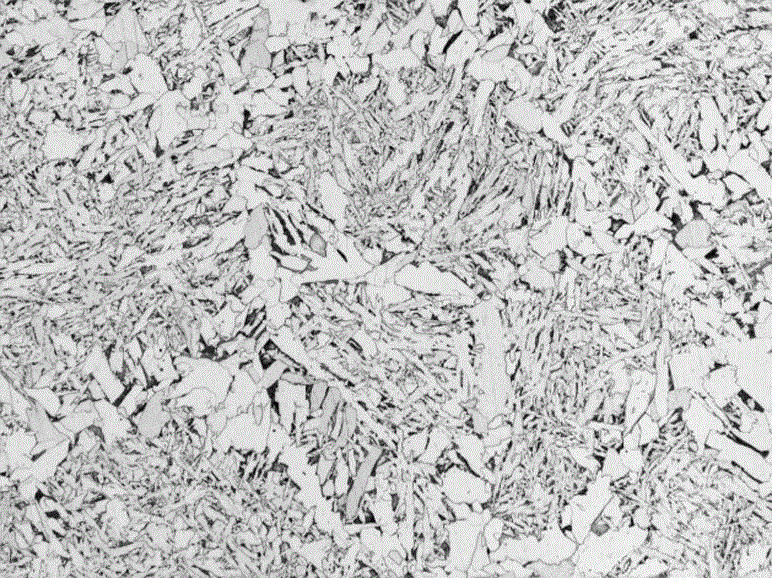

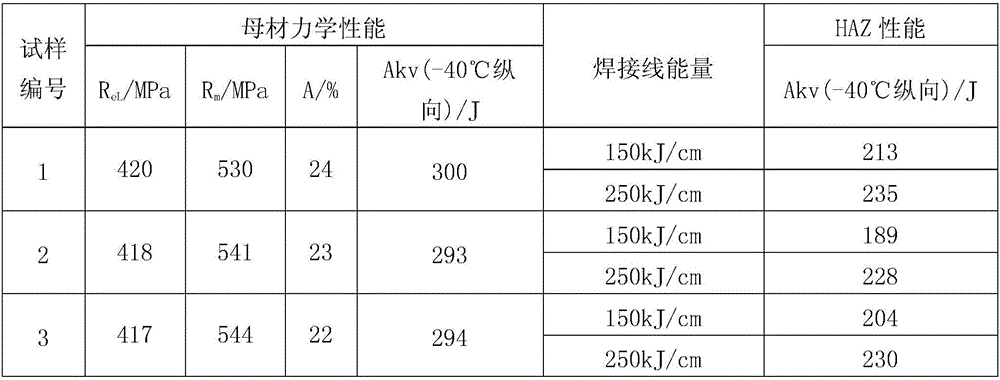

[0029] Examples 1-3 are the manufacturing method of high-strength ship plate steel for 60mm thick E40 high heat input welding, using low-carbon niobium-free, oxide metallurgical process, adding trace elements Ni and V, and using controlled rolling and controlled cooling technology.

[0030] The main chemical components of Examples 1-3 are shown in Table 1:

[0031] Table 1 The main chemical composition of the embodiment of the present invention (wt%)

[0032] ExampleC Si MnPS AltV Ti Ni Ceq Example 10.080.241.520.0080.00100.0220.0300.0120.330.36 Example 20.100.201.400.0100.00180.0250.0450.0220.250.36 Example 30.050.281.600.0140.00200.0400.0500.0200.280.35

[0033] The rolling cooling process parameters of each embodiment are shown in Table 2:

[0034] Table 2 Rolling cooling process parameters

[0035] Example Thickness mm Rough rolling final rolling temperature℃ Finish rolling opening temperature ℃ Final rolling temperature℃ Redness temperature ℃ Example 1601081835826640 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com