Double-liquid double-metal oil quenching hammer and machining method thereof

A dual-liquid bimetallic and oil quenching technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high cost, high manufacturing difficulty, inability to meet performance requirements, etc., achieve reasonable ingredients, reduce production costs, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

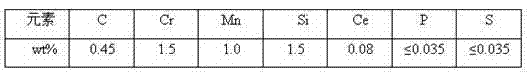

[0049] The hammer head part is made of high chromium cast iron and added with modifier. The chemical composition of high chromium cast iron is shown in Table 1 in terms of weight percentage:

[0050] Table 1

[0051]

[0052] Modifiers are 0.8 wt% ferroboron, 1.0 wt% ferrotitanium, 0.8 wt% ferrovanadium, 1.0 wt% rare earth silicon, and the balance is iron.

[0053] The hammer handle part is made of low-carbon alloy steel and added with modifier. The chemical composition of low-carbon alloy steel is shown in Table 2 in terms of weight percentage:

[0054] Table 2

[0055]

[0056] The modificator is 3.0 wt% lanthanum cerium rare earth, 1.5 wt% ferrosilicon particles, 2.0 wt% rare earth magnesium, 0.3 wt% ferroboron, and the balance is iron.

[0057] 1. Melting of some materials of the hammer head

[0058] 1.1. In terms of weight percentage, scrap steel, pig iron, ferrochrome, ferromanganese and ferrosilicon are used as furnace materials according to the carbon content...

Embodiment 2

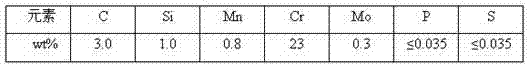

[0070] The hammer head part is made of high chromium cast iron and added with modifier. The chemical composition of high chromium cast iron is shown in Table 3 in terms of weight percentage:

[0071] table 3

[0072]

[0073] Modifiers are 0.5 wt% ferroboron, 1.5 wt% ferrotitanium, 0.5 wt% ferrovanadium, 1.5 wt% rare earth silicon, and the balance is iron.

[0074] The hammer handle part is made of low-carbon alloy steel with modifier added, and the chemical composition of the low-carbon alloy steel is shown in Table 4 in terms of weight percentage:

[0075] Table 4

[0076]

[0077] The modificator is 2.0 wt% lanthanum cerium rare earth, 2.0 wt% ferrosilicon particles, 1.5 wt% rare earth magnesium, 0.5 wt% ferroboron, and the balance is iron.

[0078] 1. Melting of some materials of the hammer head

[0079] 1.1. In terms of weight percentage, scrap steel, pig iron, ferrochrome, ferromanganese and ferrosilicon are used as furnace materials according to the carbon cont...

Embodiment 3

[0091] The hammer head part is made of high chromium cast iron and added with modifier. The chemical composition of high chromium cast iron is shown in Table 5 in terms of weight percentage:

[0092] table 5

[0093] element C Si mn Cr Mo P S wt% 3.1 0.6 0.9 22 0.4 ≤0.035 ≤0.035

[0094] The modificator is 0.6wt% ferroboron, 1.2wt% ferrotitanium, 0.6wt% ferrovanadium, 1.2wt% rare earth silicon, and the balance is iron.

[0095] The hammer handle part is made of low-carbon alloy steel and added with modifier. The chemical composition of low-carbon alloy steel is shown in Table 6 in terms of weight percentage:

[0096] Table 6

[0097] element C Cr mn Si Ce P S wt% 0.4 1.8 0.9 1.6 0.06 ≤0.035 ≤0.035

[0098] The modificator is 2.5 wt% lanthanum cerium rare earth, 1.8 wt% ferrosilicon particles, 1.8 wt% rare earth magnesium, 0.4 wt% ferroboron, and the balance is iron.

[0099] 1. Melting of some materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com