CrMnTi series gear steel and processing technique thereof

A processing technology and technology of gear steel, applied in the field of CrMnTi series gear steel and its processing technology, can solve the problems of unsuitable mass production, good surface quality and high manufacturing cost, and achieve the effects of easy processing, reasonable composition and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare CrMnTi gear steel according to the following method:

[0023] (1) Preliminary smelting: prepare the materials according to the following ratio: molten iron (68~72t) + scrap steel (6~7t), first add scrap steel and then mix with molten iron; send the raw materials into the primary smelting furnace for smelting at 1660℃, and the end of smelting When adjusting the content of C to 0.06%, the sliding plate is used to stop slag tapping to achieve slag-free tapping, and the tapping process adopts a combination of strong deoxidation and pre-deoxidation;

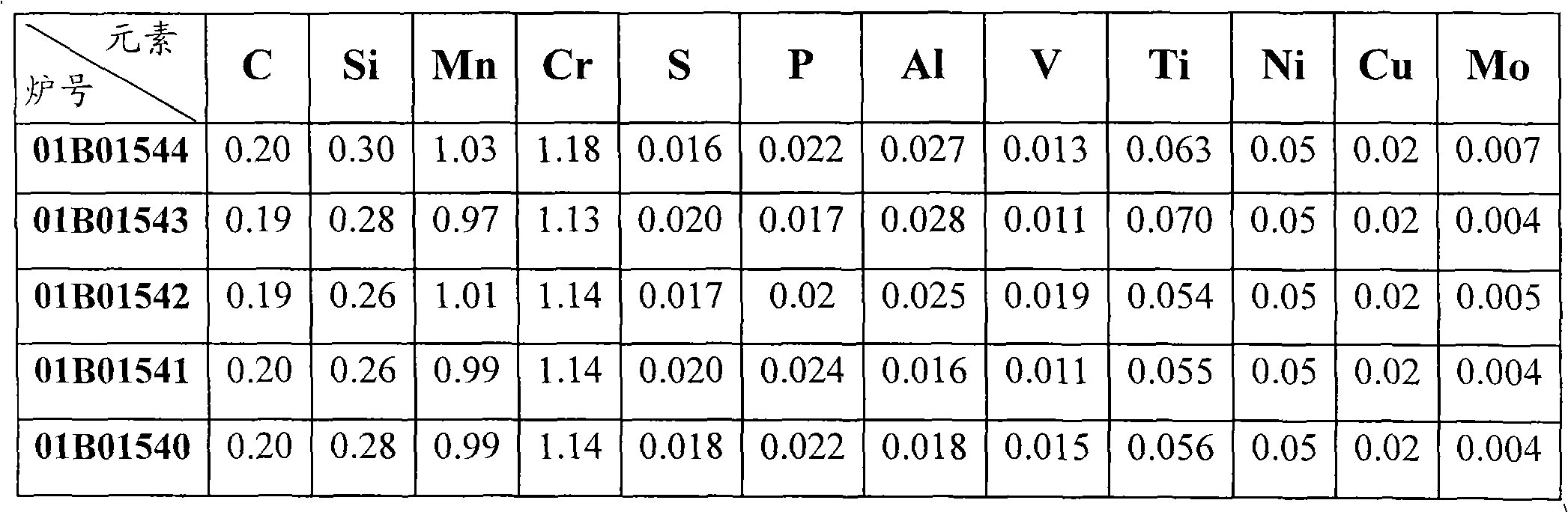

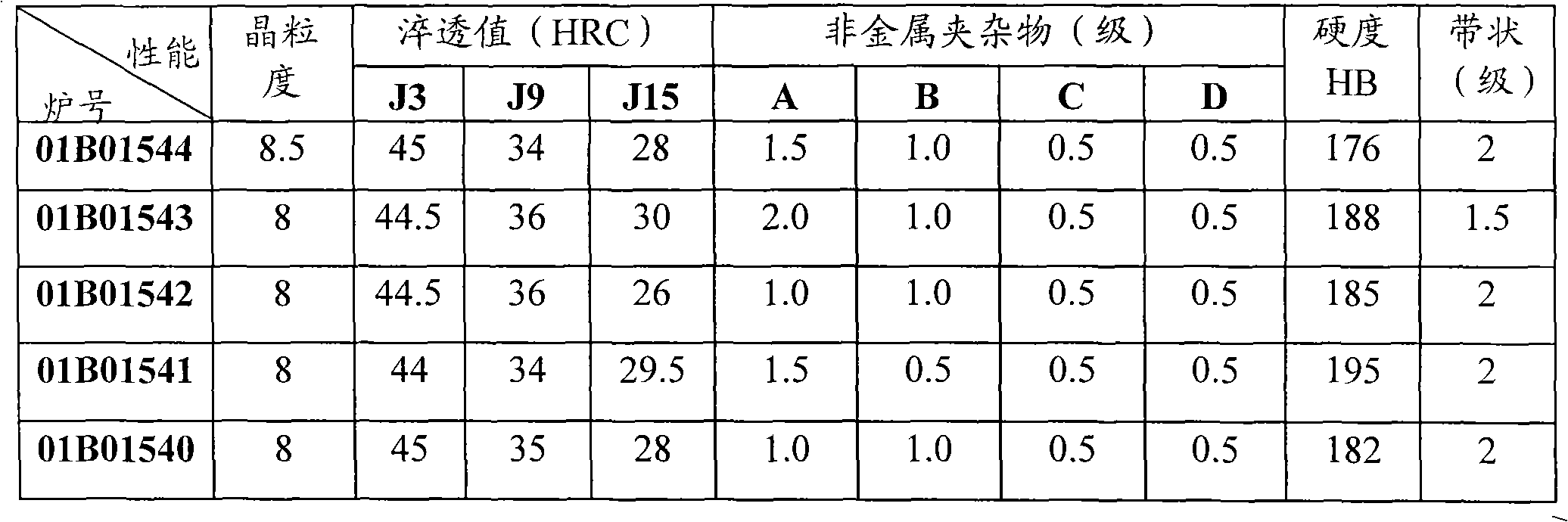

[0024] (2) Refining: The surplus produced in step (1) is sent to the molten steel to be refined in the ladle refining furnace (LF furnace) numbered D1801544, D1801543, D1801542, D1801541, D1801540, and reheated and refined. 150Kg deoxidizer (AD powder: Al: 18-23%, Al2O3: 55-70%, MgO: <3%, SiO2: <8%, H2O: <0.5%, S: <0.05%, P: <0.05% ), quickly produce white slag, control steel slag basicity to 2.5, sulfur content of 0.026%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com