Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Easy cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technical formula of rubber plastic wood-like pencil and manufacturing process therefor

The invention relates to a pencil, in particular to a technical formula and a preparation method of a rubber plastic wood-like pencil thereof. The invention mainly provides the technical formula and the preparation method of the rubber plastic wood-like pencil which has the characteristics of reasonable design, good toughness, high lead core concentration, easy cutting, etc. The formula of the invention is mainly that: the pencil core is made from the components with the following weight ratio of 10 to 40 percent of polystyrene, 4 to 20 percent of sbr, 50 to 80 percent of graphite powder, 0.5 to 2 percent of ammonium stearate and 0.4 to 3 percent of calcium stearate; the penholder is made from the components with the following weight ratio of 5 to 50 percent of polystyrene, 10 to 70 percent of sbr, 20 to 65 percent of talc, 0.1 to 3 percent of foaming agent, 0.3 to 10 percent of white oil and 0.02 to 0.2 percent of antioxidant.

Owner:方波

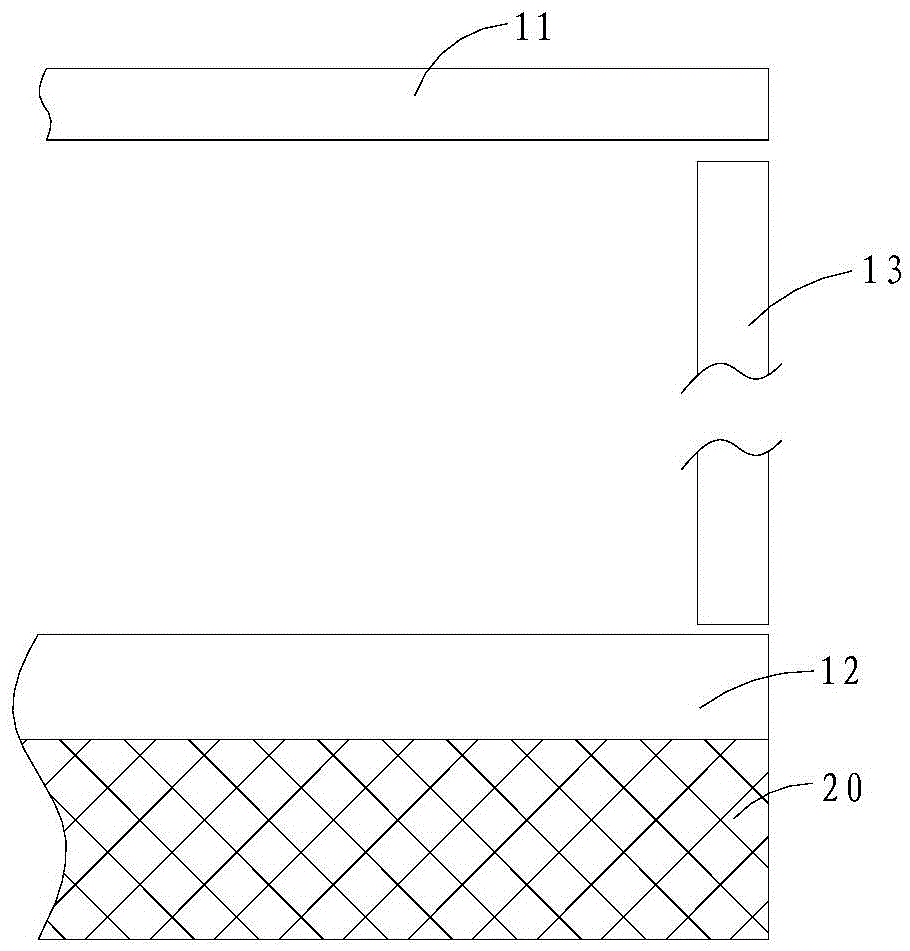

Square adhesive structure and manufacturing method thereof

The invention discloses a square adhesive structure. The square adhesive structure comprises a black and white adhesive, a heavy industry adhesive, a first protective film and a second protective film. The black and white adhesive comprises an upper adhesive strip, a lower adhesive strip and side adhesive strips on the two sides, wherein the upper adhesive strip, the lower adhesive strip and the side adhesive strips are spliced to define a rectangular area, and the lower adhesive strip is the widest. The heavy industry adhesive is attached to one face of the lower adhesive strip in the manner that the end face of the heavy industry adhesive is flush with the lower adhesive strip, and the heavy industry adhesive is narrower than the lower adhesive strip. The first protective film is attached to the other face, relative to the heavy industry adhesive, of the black and white adhesive. The second protective film is attached to the outer surface of the heavy industry adhesive and the black and white adhesive at the same time. The invention further discloses a manufacturing method of the square adhesive structure. The square adhesive structure is formed by splicing sectional structures, so that cutting is convenient, and the utilization rate of the black and white adhesive is high; besides, when the protective films on the outer surfaces of the black and white adhesive are torn off, the black and white adhesive is prevented from being torn up along with the protective films, so that the situation that the black and white adhesive deviates, and consequently dislocation or light leak occurs is avoided, and the optical grade is ensured.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Wheat straw preprocessing cutting device

The invention discloses a wheat straw preprocessing cutting device. The device comprises a connection support, a straw sliding barrel is welded to the upper end of the connection support, an opening is formed in one end of the straw sliding barrel and connected with a through hole, corresponding to the opening of the straw sliding barrel, of one side of the connection support, and a third electricretractable rod is connected to the right end in the straw sliding barrel through bolTS; a push plate can be driven to move through the third electric retractable rod, wheat straw can be pushed out of the opening of the straw sliding barrel through the push plate, a cutting blade can be driven to move up and down through a first electric retractable rod, the cutting sheet can be driven to rotatethrough a second motor, and accordingly the wheat straw is cut more conveniently; an adjustment baffle can be driven to move left and right through a second electric retractable rod, and the cutting length can be adjusted through the adjustment baffle. The wheat straw preprocessing cutting device is simple in structure and convenient to operate, cutting is more accurate, convenience is provided for people, and a large amount of labor is saved.

Owner:吾家农场成都农业有限公司

Method for synthesizing high-molecular-weight thermoplastic phenol resin

The invention relates to a method used for sp synthesis of phenolic resin. A synthesis method for thermoplastic phenolic resin of high molecular weight is characterized in that the invention comprises four following steps: 1) the selection of raw materials: the weight portion of each raw materials: water: 50 to 250, phenol: 90 to 160, formaldehyde liquid: 60 to 120, hexamethylene tetramine:15 to 35, gum Arabic powder: 3 to 10, aluminum oxide powder:2 to 8, the mass concentration of the formaldehyde liquid is 37 percents. 2) some water, the phenol and the formaldehyde liquid are taken and added to a stirring reaction vessel, and the reaction time is ranging from three hours to five hours after adjusting pH value to 2 to 5 and increasing the temperature to 85 DEG C to 95 DEG C. 3) some gum Arabic powder and some hexamethylene tetramine are uniformly mixed, the remained gum Arabic powder and the aluminum oxide powder are added after the reaction time ranging from a half hour to one and a half hours and uniformly mixed with the water, and the remained hexamethylene tetramine is dissolved in the some water and is added into the reaction vessel after five minutes to 30 minutes, the heating is stopped after the reaction time ranging from 25 minutes to 40 minutes, and the temperature of a reactor is decreased to the room temperature. 4) the product is obtained after water washing, filtering and drying. The product obtained by the synthesis method has the advantages of high molecular weight, high heat-resistance, high toughness; the technique is simple and the cost is low.

Owner:WUHAN UNIV OF TECH

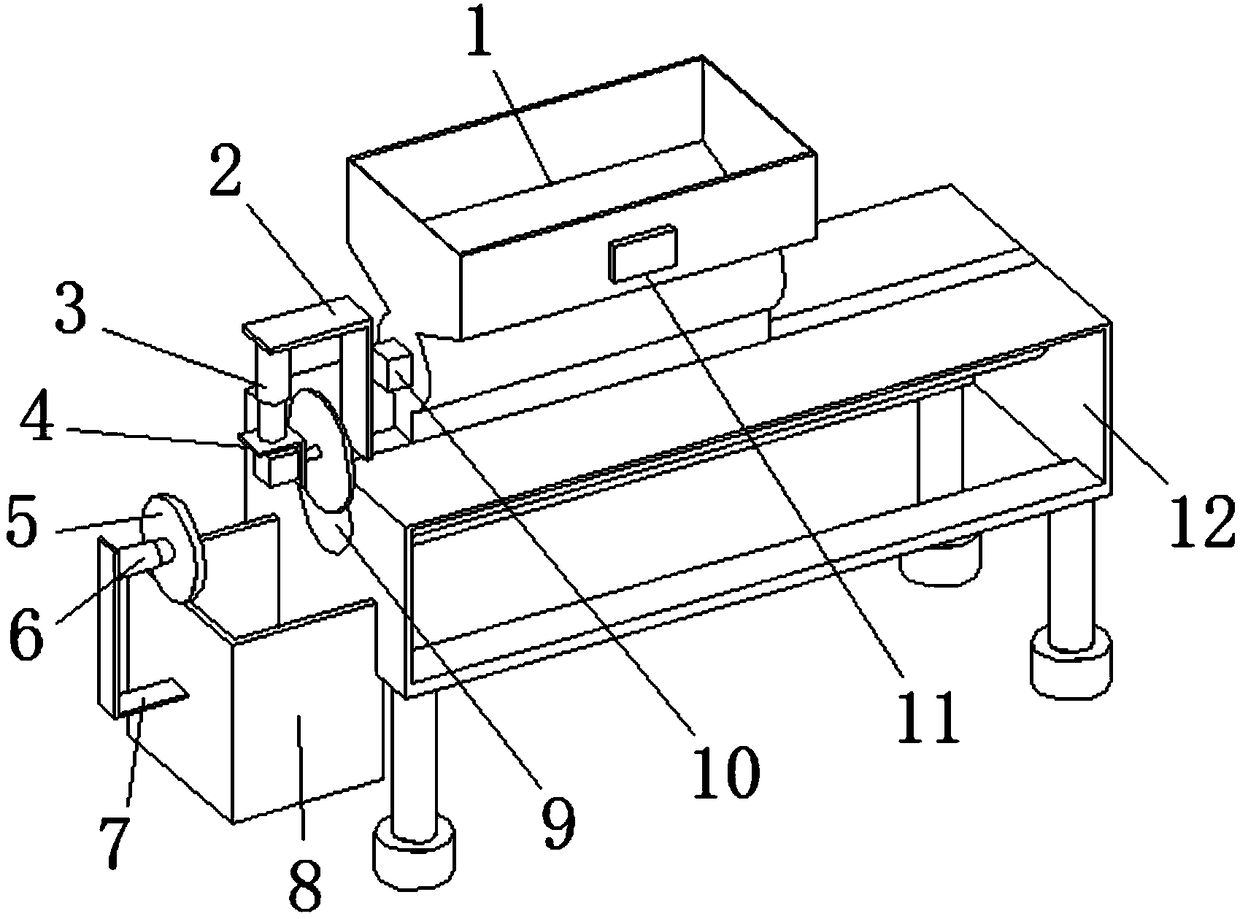

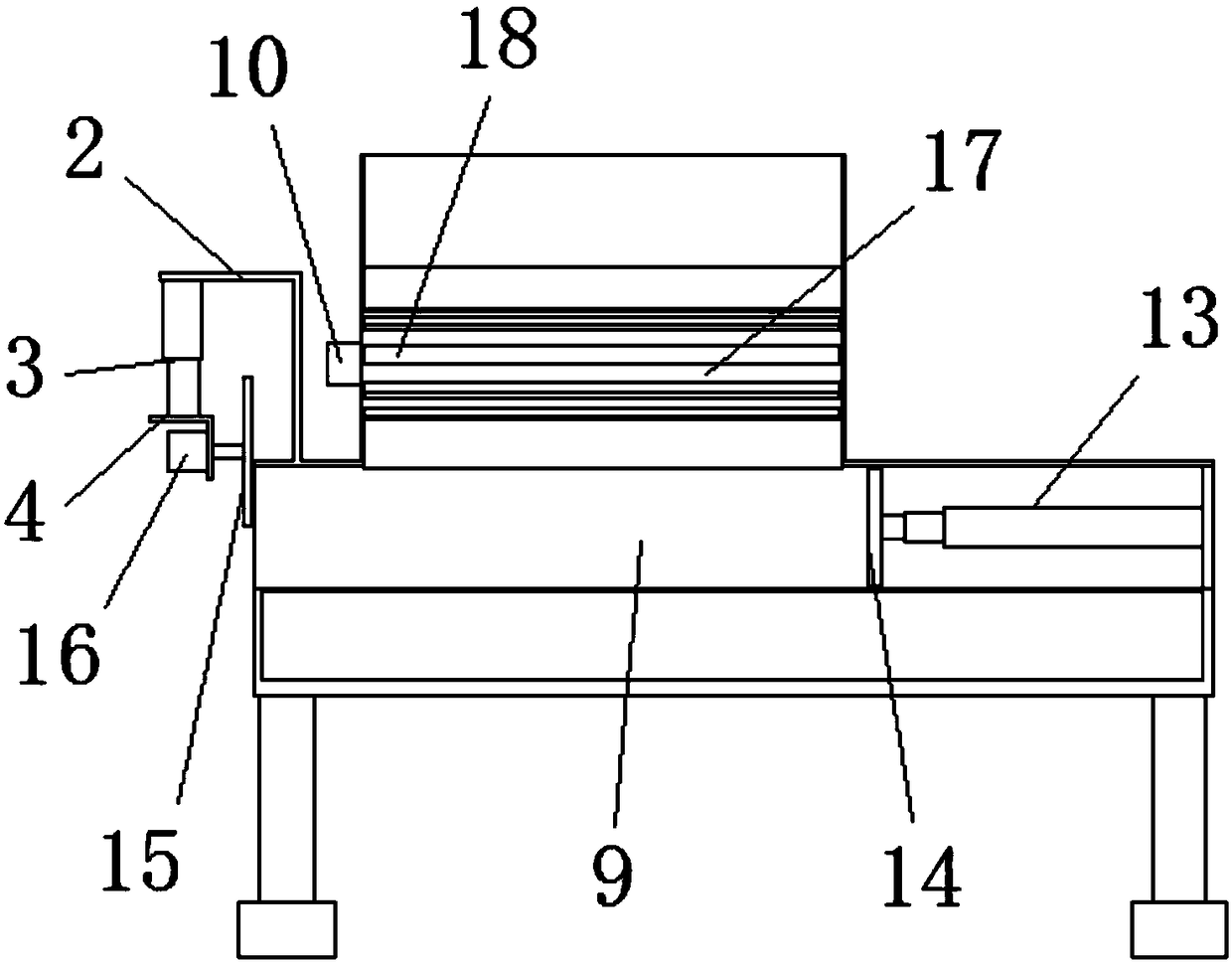

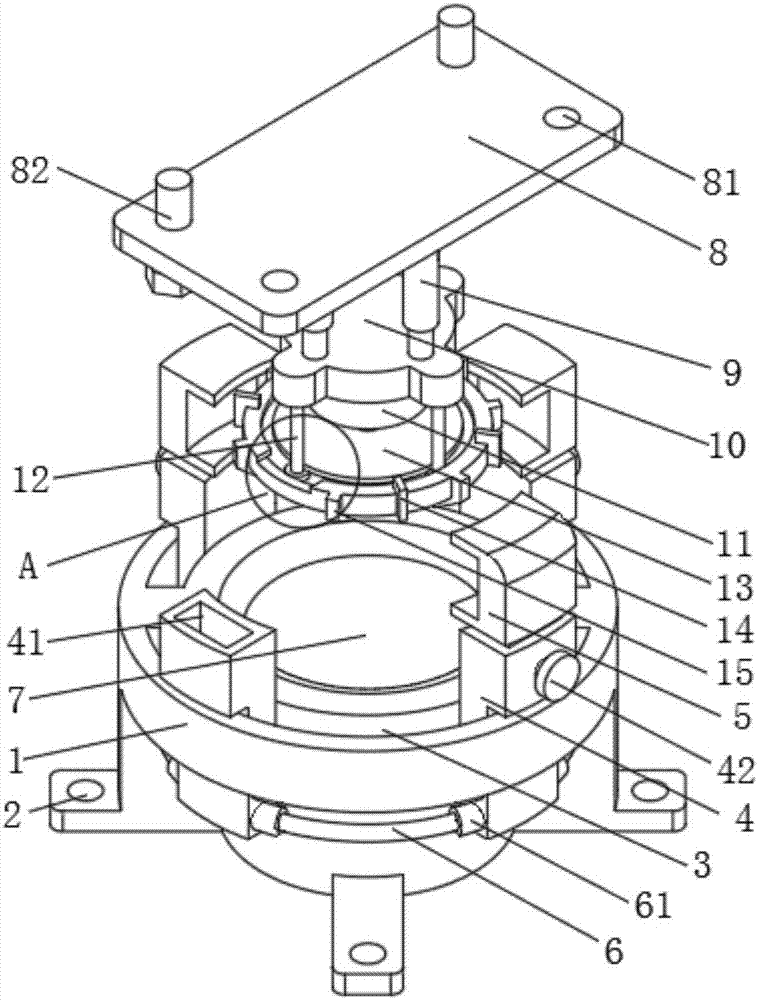

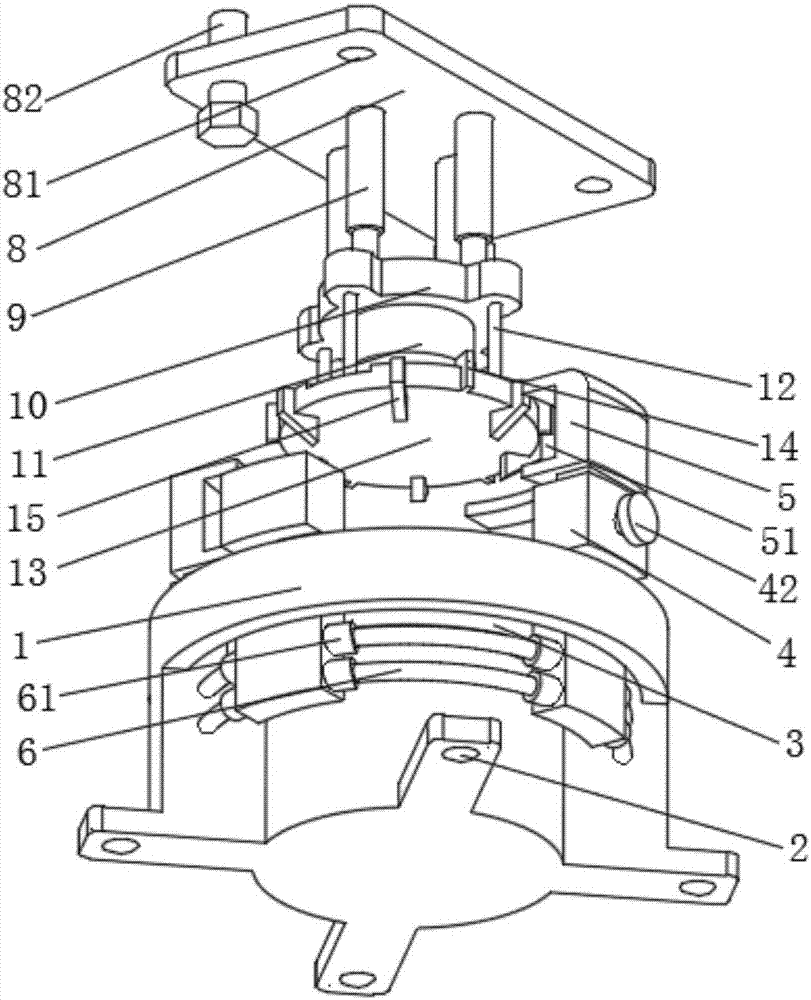

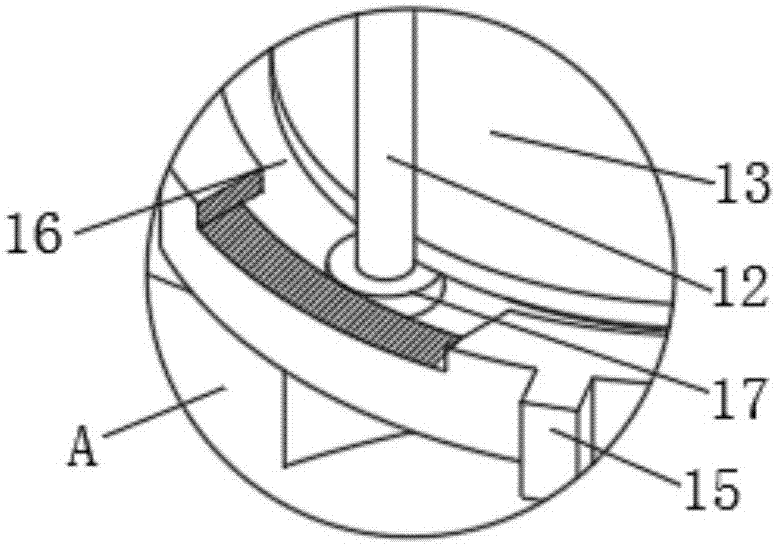

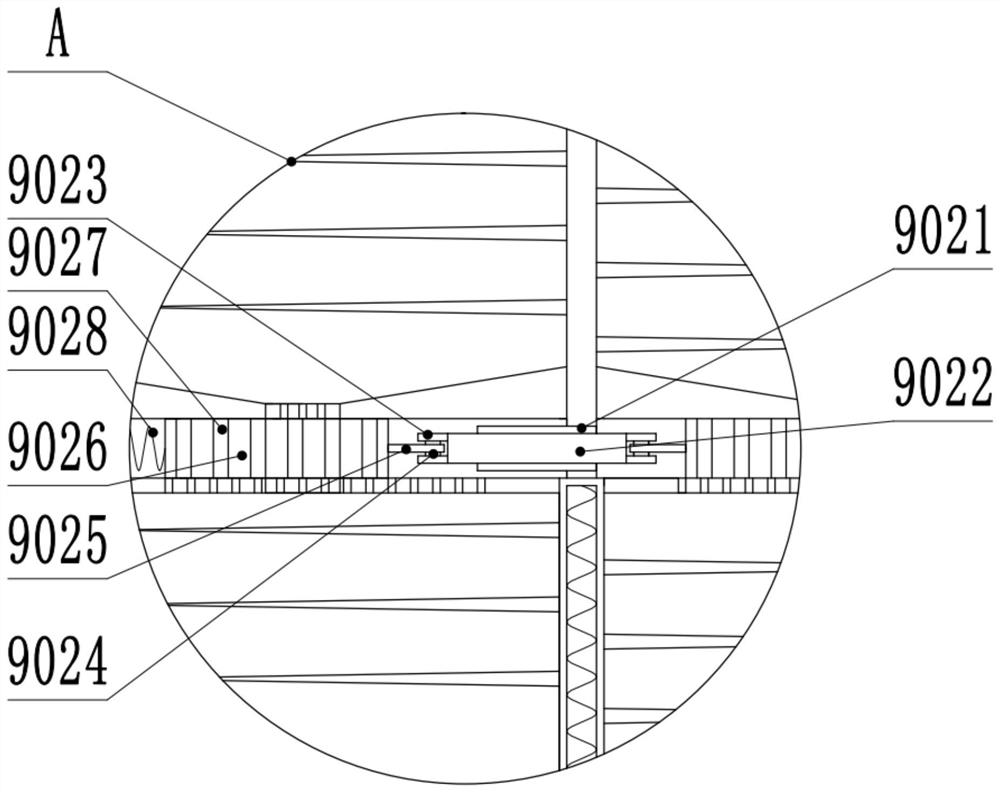

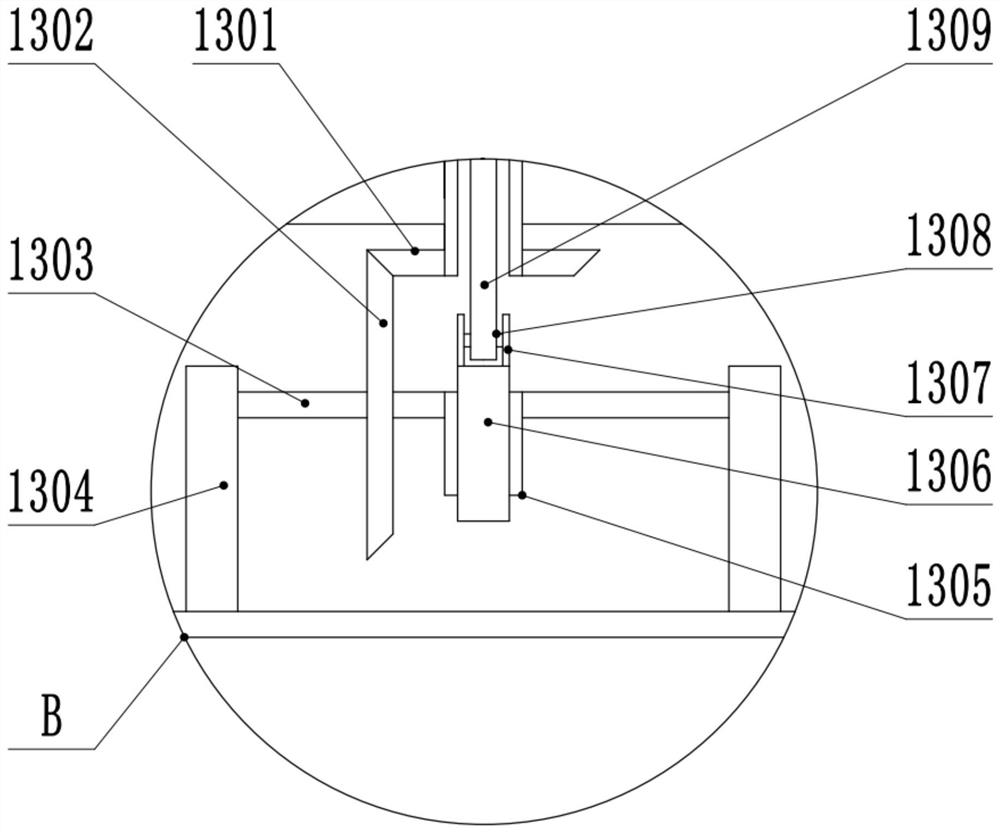

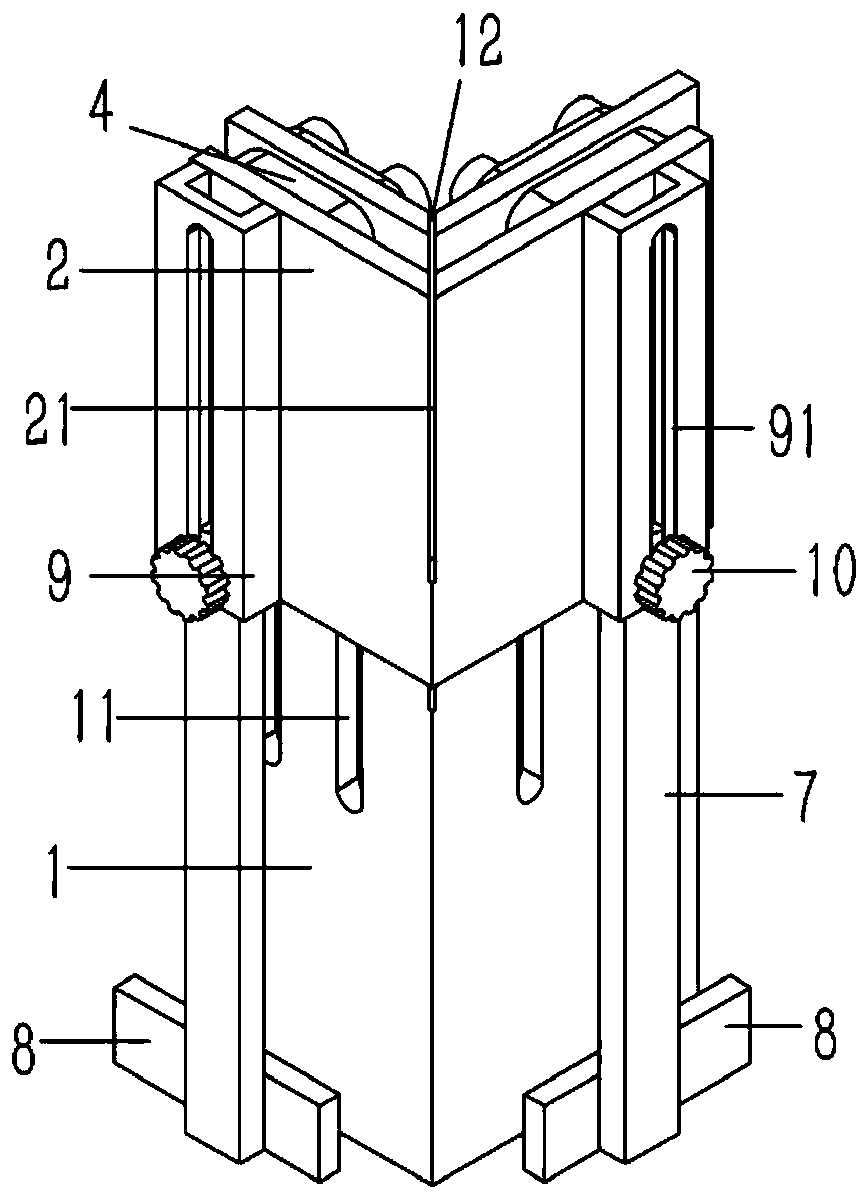

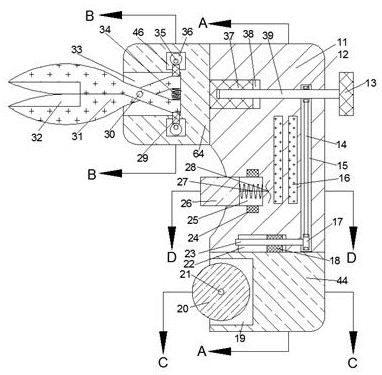

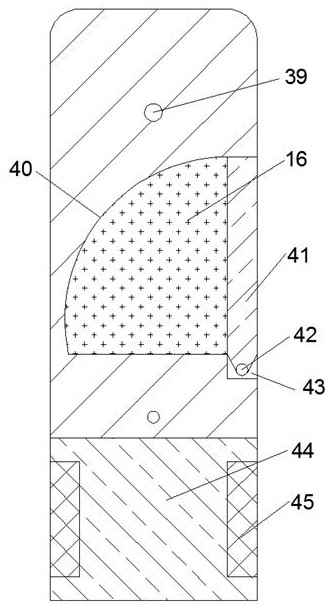

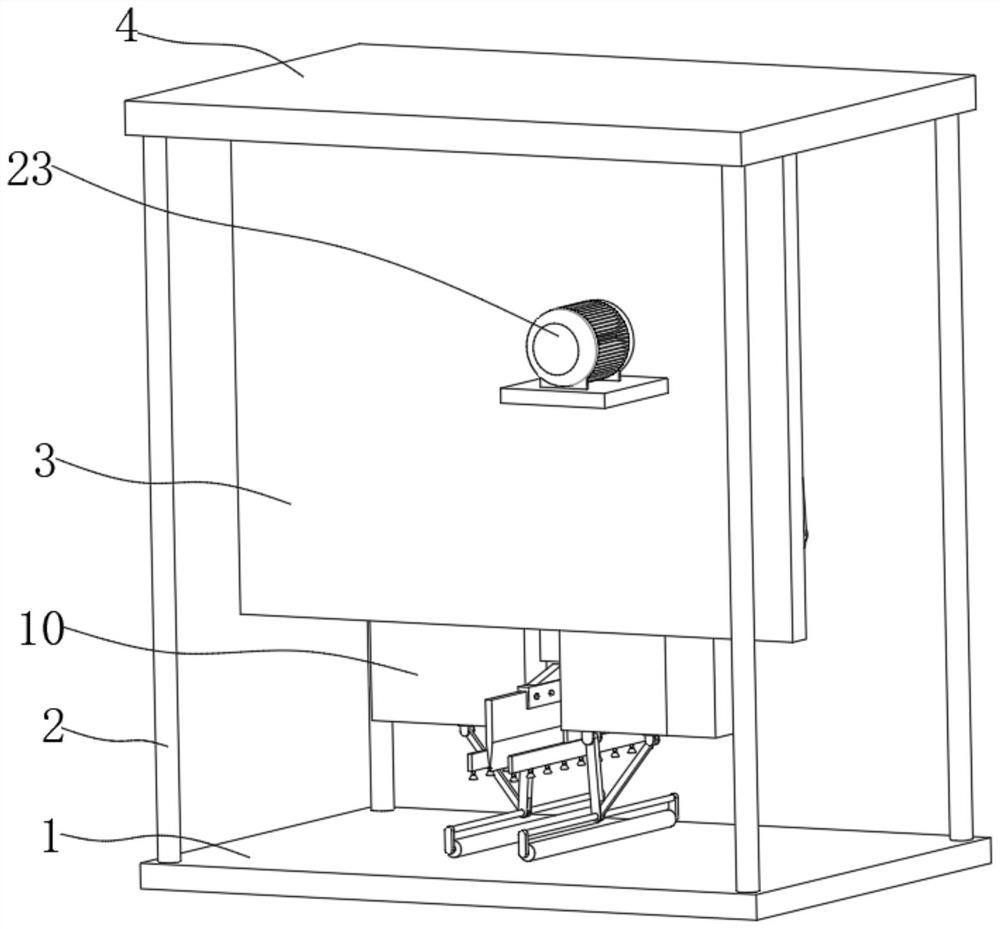

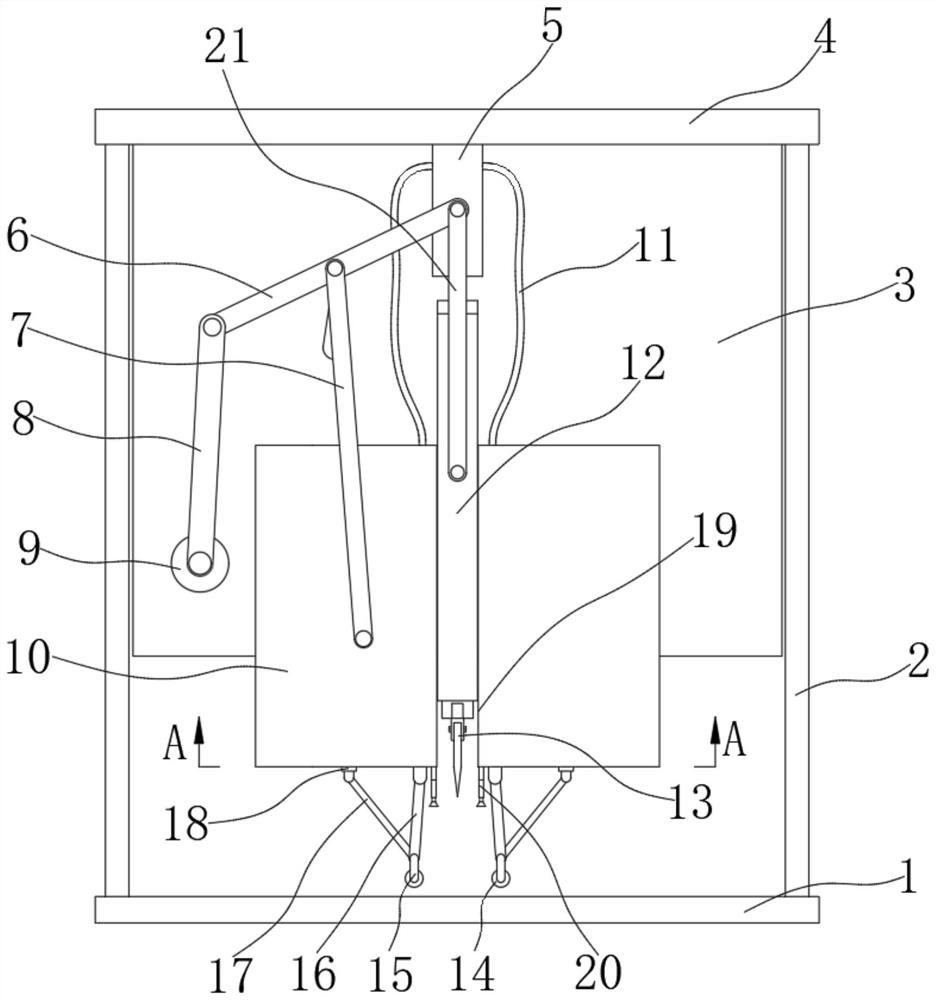

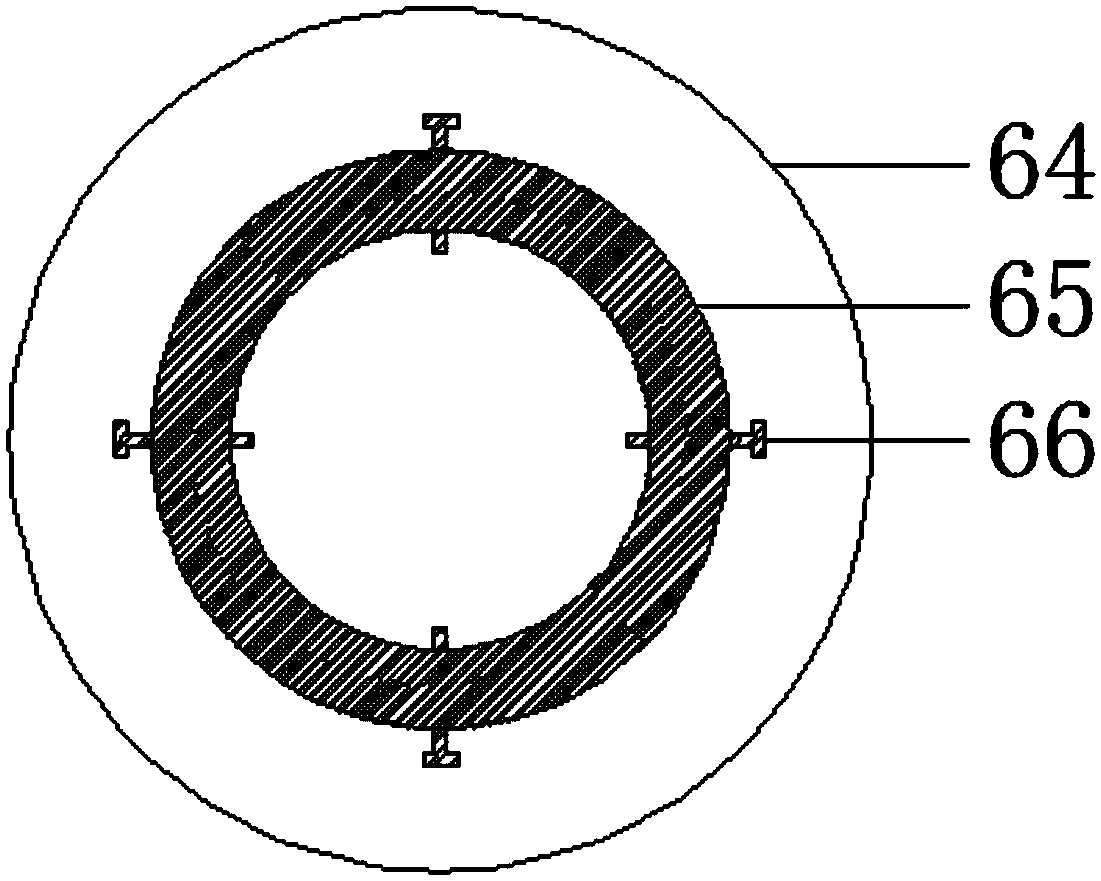

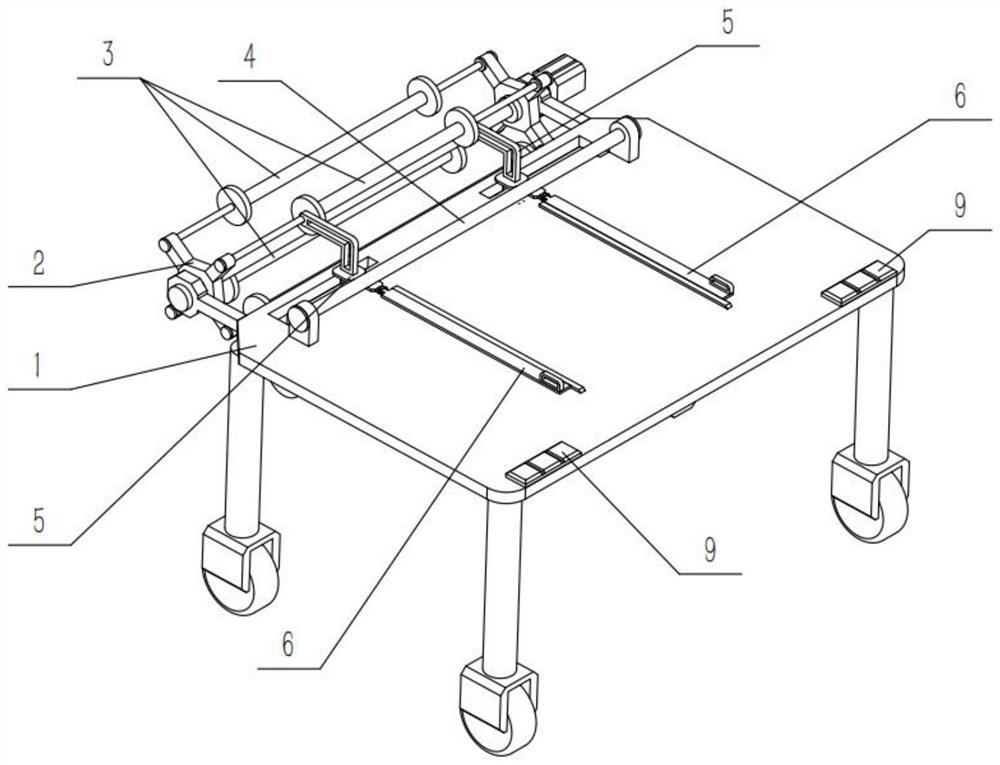

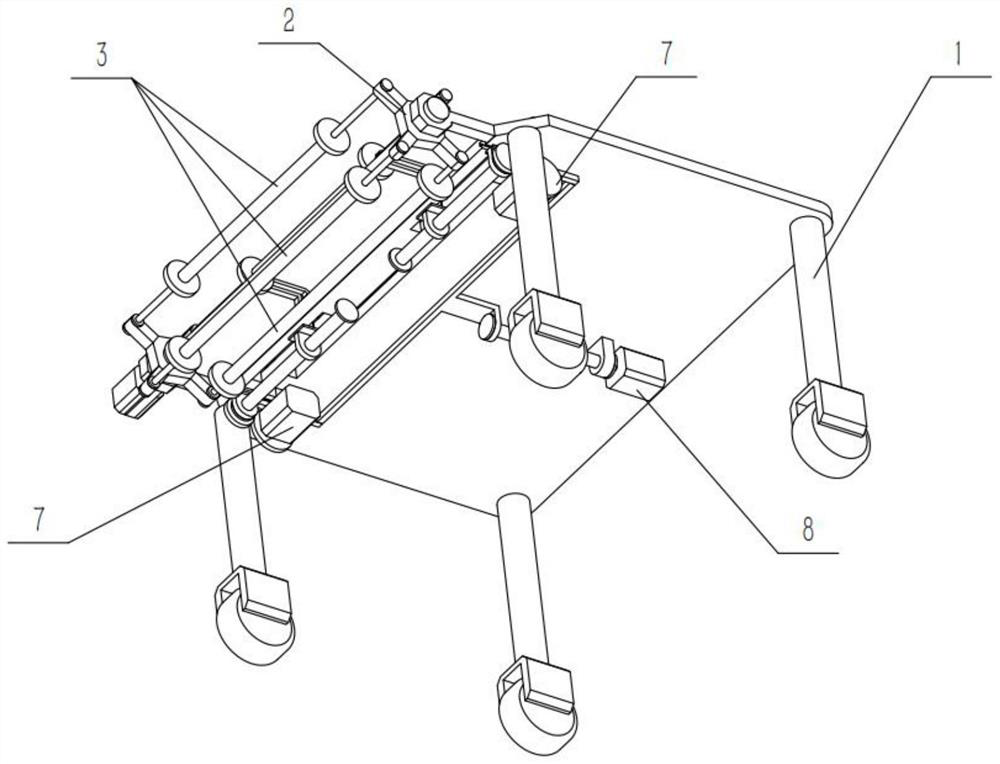

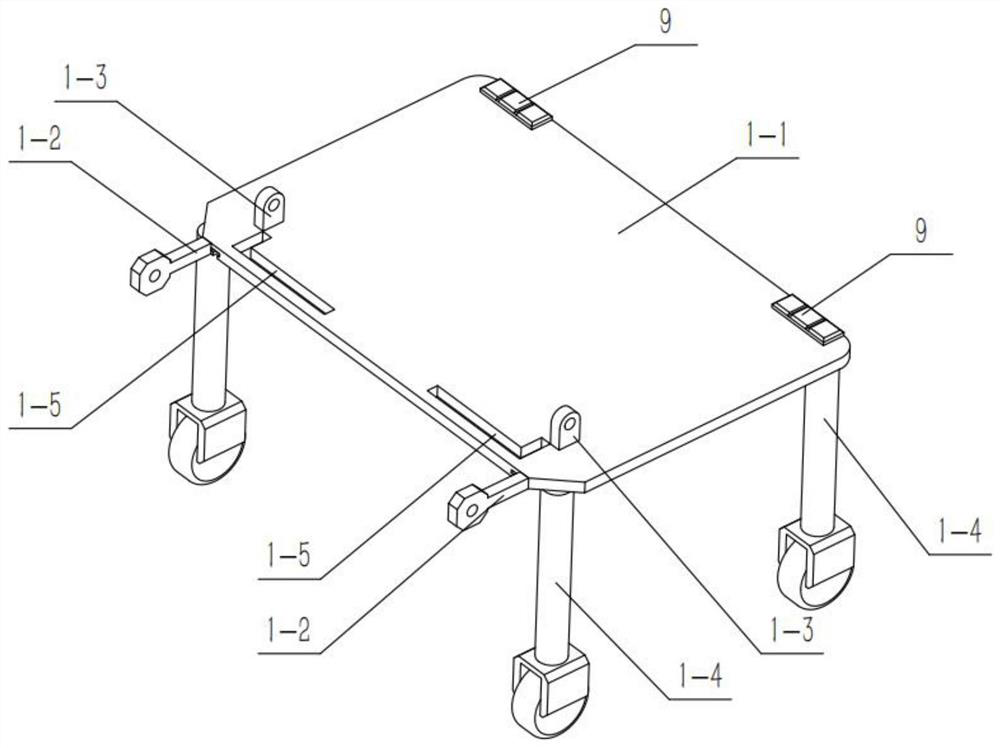

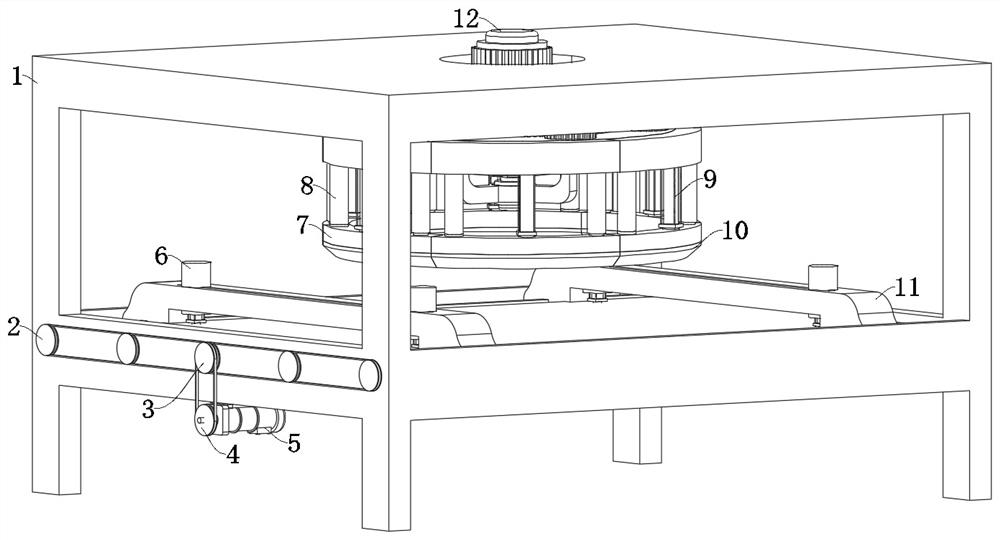

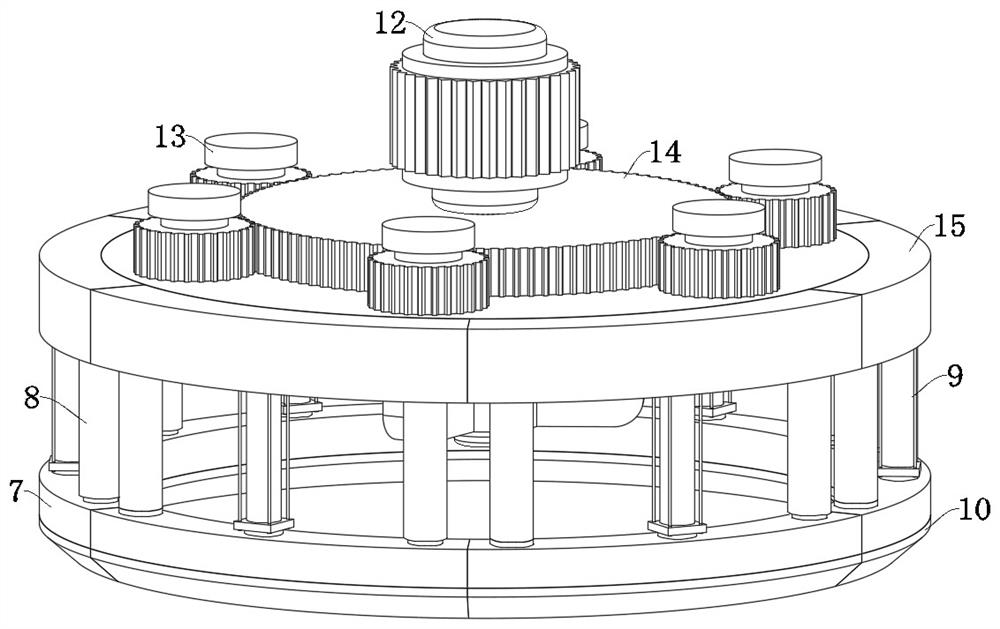

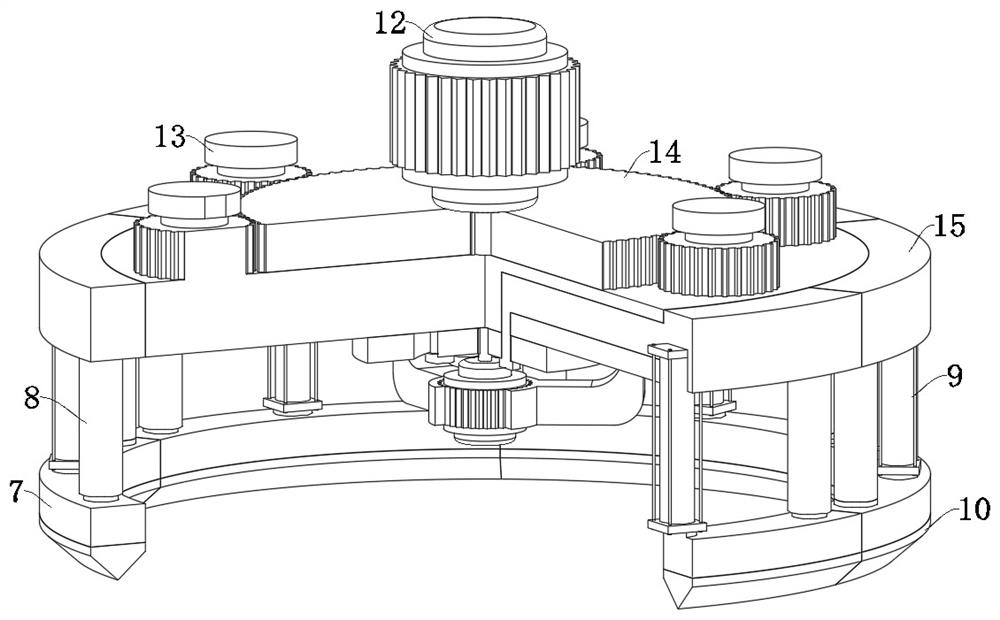

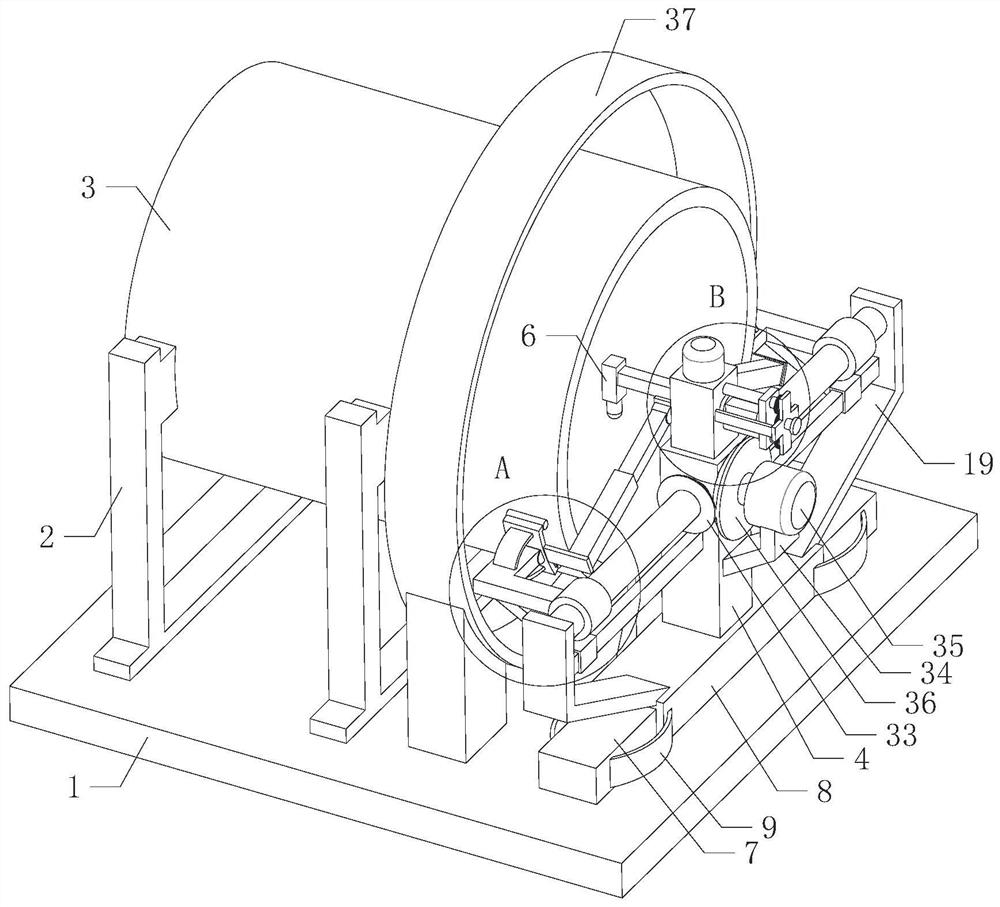

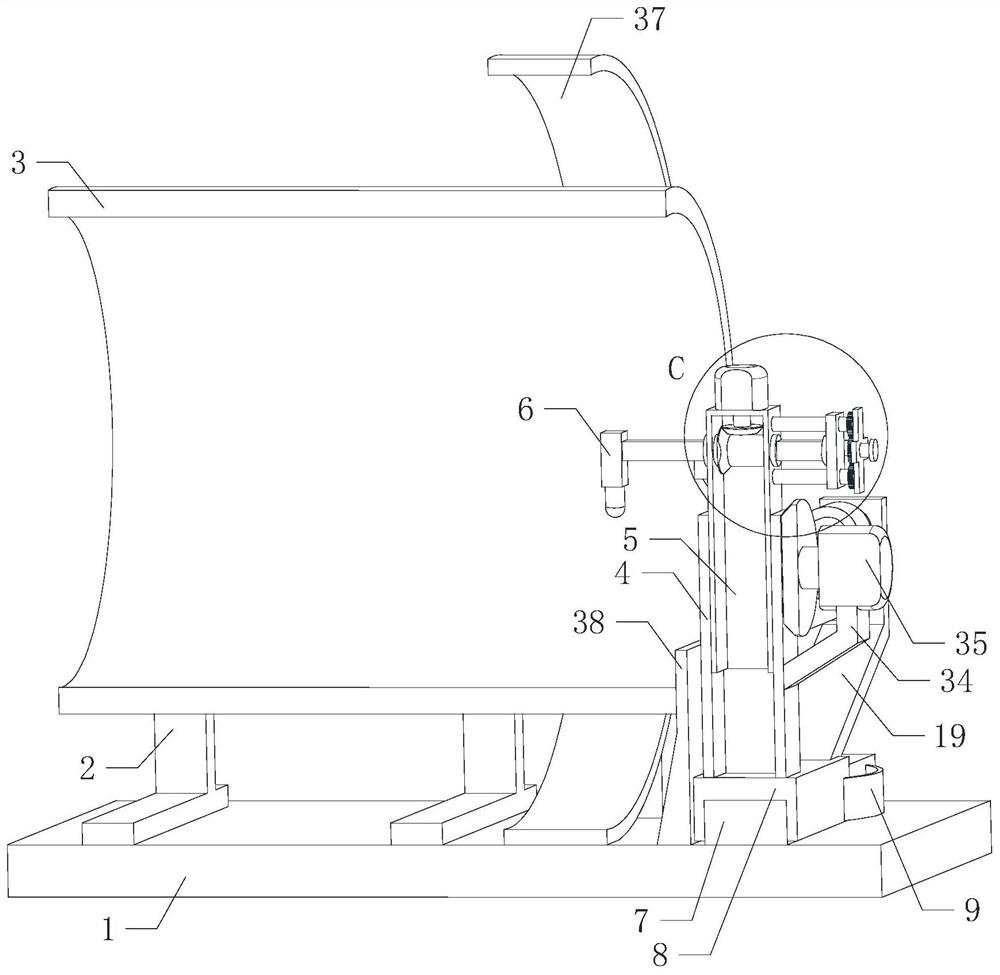

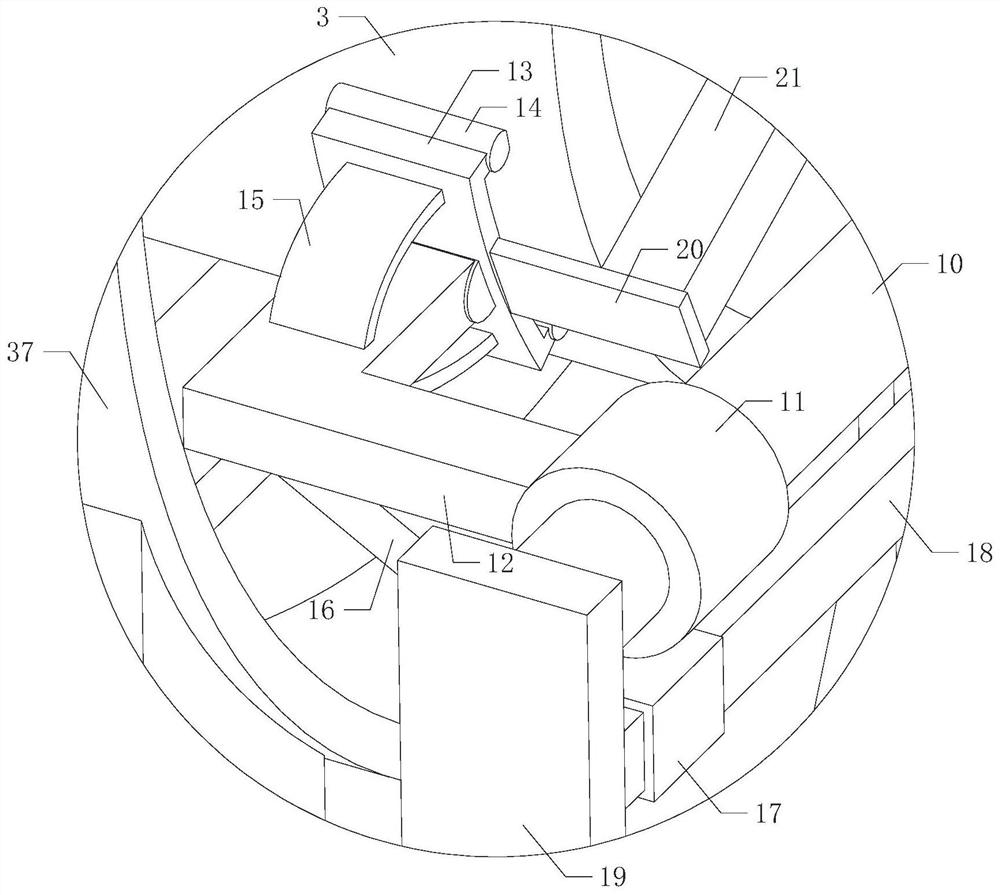

Large annular blank cutting equipment with automatic chip breaking function

InactiveCN107398603AEasy cuttingAvoid leaningPositioning apparatusMaintainance and safety accessoriesEngineeringElectrical and Electronics engineering

The invention discloses a large-scale ring blank cutting device with automatic chip breaking function, which includes a base, the lower surface of the base is provided with a first installation hole, and the edge of the upper surface of the base is provided with two symmetrically arranged arcs. A through groove, the interior of the arc-shaped through groove is provided with a fixed seat, and the fixed seat is slidably connected with the arc-shaped through groove, the upper surface of the fixed seat is provided with a clamp, and the side of the clamp is provided with a clamping groove, A collecting tank is provided in the middle of the upper surface of the base, and a top plate is provided on the upper side of the base. This large-scale ring blank cutting equipment with automatic chip breaking function, the fixed seat can be adjusted, the clip can be replaced, and can fix large rings of different sizes. It has good stability, and the cutting knife and scraper can move up and down, which is convenient for large-scale The scraps of the ring blank are cut and cut to improve the machining accuracy, and the scraps can be collected for easy cleaning and strong practicability.

Owner:魏斌达

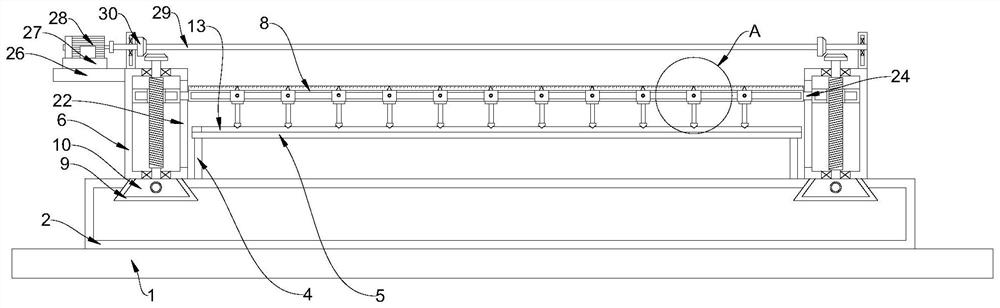

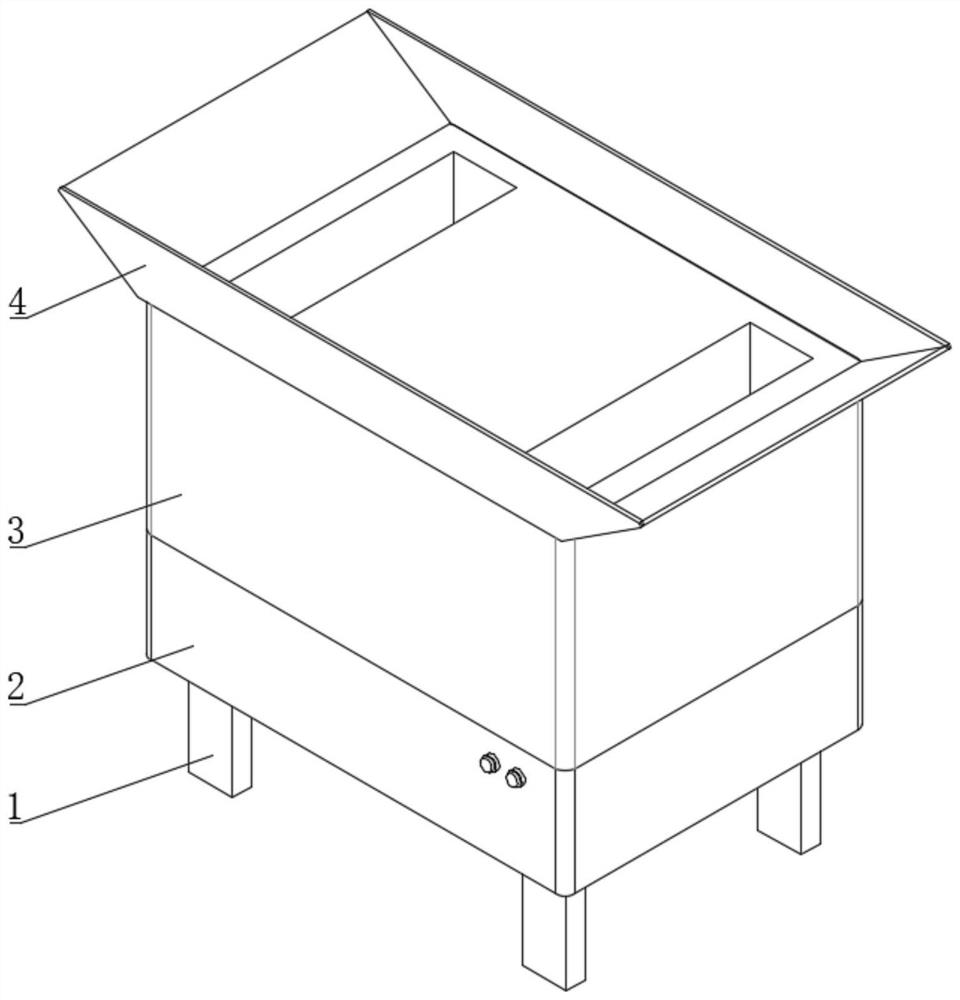

Rapid cutting equipment for glass curtain wall and cutting method of the rapid cutting equipment

PendingCN112939437ABatch cutting is fast and efficientAdjustment works preciselyGlass severing apparatusManufacturing engineeringMechanical engineering

The invention discloses rapid cutting equipment for a glass curtain wall and a cutting method of the rapid cutting equipment, relates to the technical field of glass curtain wall cutting, and aims to solve the problems that an existing glass curtain wall plate is generally cut manually through a glass cutting knife to form scratches, only one glass panel can be cut through one-time operation when the cutting knife is used for cutting, but a high number of the glass curtain wall plates are required, and time is consumed during batch processing. A fixing seat is fixedly arranged on the upper end face of a base, connecting seats are fixedly arranged at the front end and the rear end of the fixing seat, the connecting seats are fixedly connected with the base, four supporting rods are fixedly arranged above the fixing seat, and a placing plate is fixedly arranged above the four supporting rods. First fixing boxes are arranged on the two sides of the placing plate correspondingly. Second fixing boxes are arranged above the connecting seats, and cutting mechanisms are arranged between the first fixing boxes and between the second fixing boxes correspondingly.

Owner:江苏华幕建筑科技有限公司

Wheat seed quality detection method

InactiveCN109115955AIncrease the average rate of particle sizeEasy cuttingTesting plants/treesStainingGranularity

The invention discloses a wheat seed quality detection method. The wheat seed quality detection method comprises the following steps: S1, selecting seeds; S2, performing the imbibitions; S3, cutting the seeds; S4, staining the seeds; S5, examining the staining; S6, sampling the neatness; S7, calculating the neatness; S8, sampling weight of 1,000 wheat grains; S9, weighing weight of 1,000 wheat grains; S10, sampling the germination vitality; S11, seeding; and S12, judging the germination vitality. According to the method, the vitality, neatness, weight of 1,000 wheat grains and germination vitality of the wheat seeds are separately detected, the imbibitions are performed for the wheat before the staining, so that the average rate of the wheat granularity can be increased, the detection error caused by non-uniformity in slicing due to the excessive hardness can be avoided, the paper is used for performing the tensile strength test for the wheat seeds, the germination vitality of the wheat can be determined, the practical application is facilitated, the germination rate of the wheat sowed in the soil of different hardnesses can be determined, evidence and guarantee can be provided forthe practical application, the germination of the wheat can be known, and the wheat seed quality detection method is suitable for wide popularization.

Owner:徐长斌

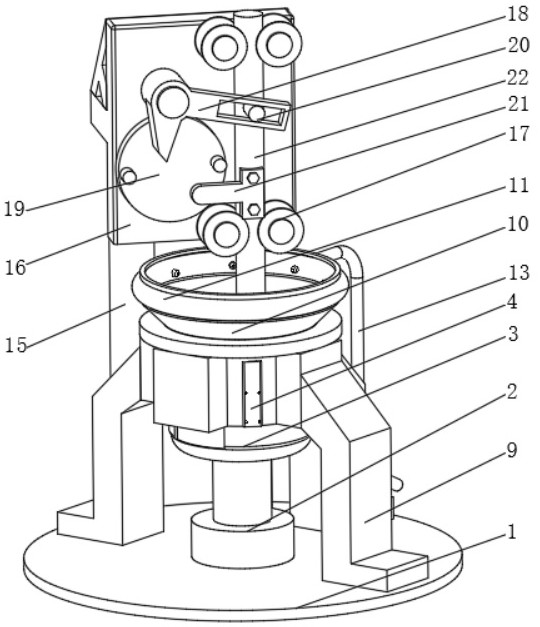

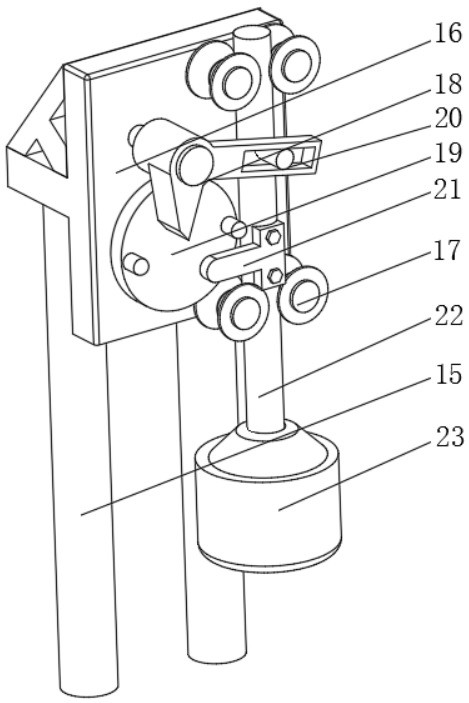

Intermittent working food pounding mechanical device

InactiveCN112588354AEasily brokenNo excessive churnHollow article cleaningFood shapingElectric machineryStructural engineering

The invention belongs to the technical field of food processing, and discloses an intermittent working food pounding mechanical device. The mechanical device comprises a bottom disc, wherein a supporting column is fixedly mounted at the rear end of the top of the bottom disc, a fixed plate is fixedly mounted on the front face of the upper end of the supporting column, guide rollers are fixedly mounted at the upper end and the lower end of the right end of the front face of the fixed plate respectively, a motor is fixedly mounted at the left end of the front face of the fixed plate, a rotatingdisc is fixedly mounted on the front face of the motor, and a guide device is fixedly mounted at the upper end of the left end of the front face of the fixed plate. According to the mechanical device,the purpose for a good pounding effect is achieved by arranging the rotating disc, a lifting rod, a hammering block and the like, the rotating force of the motor can be well converted into reciprocating lifting work through structural cooperative work of the rotating disc, the guide device and a stop block, the whole lifting rod is of a light metal structure, the hammering block is of a wooden structure, the overall stress is not very large, and meanwhile the motor rotates at a relatively low speed.

Owner:韩冬

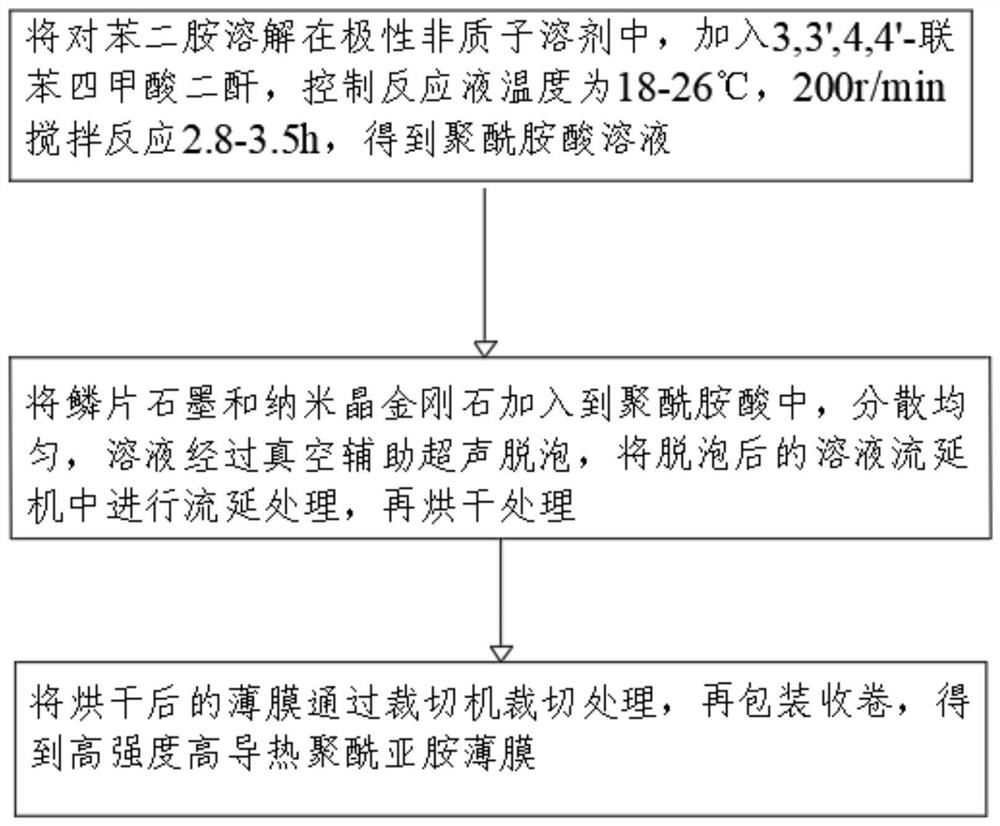

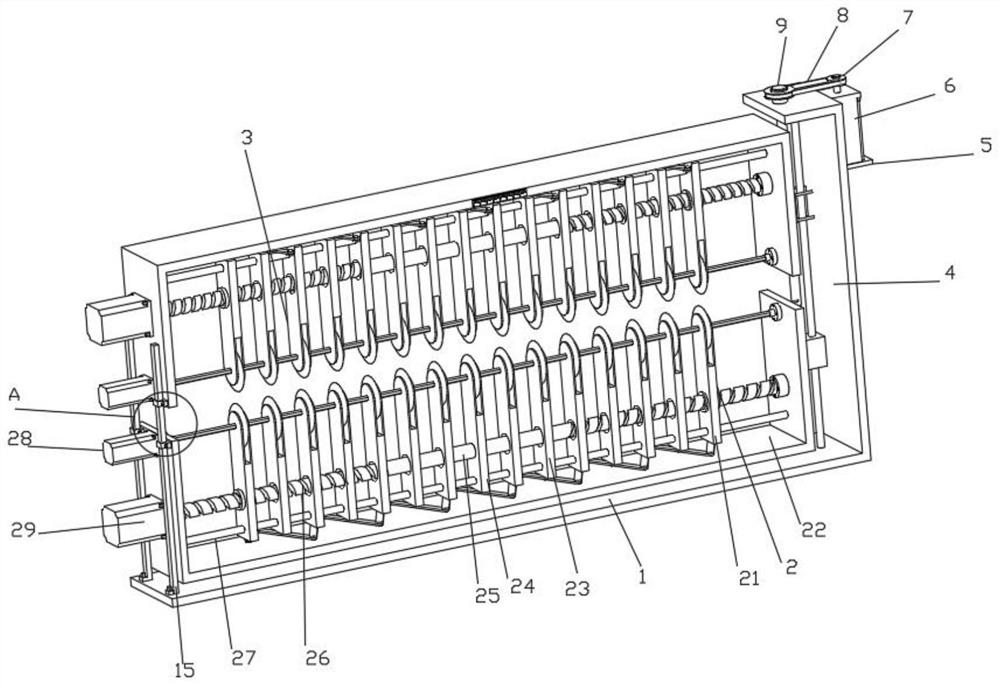

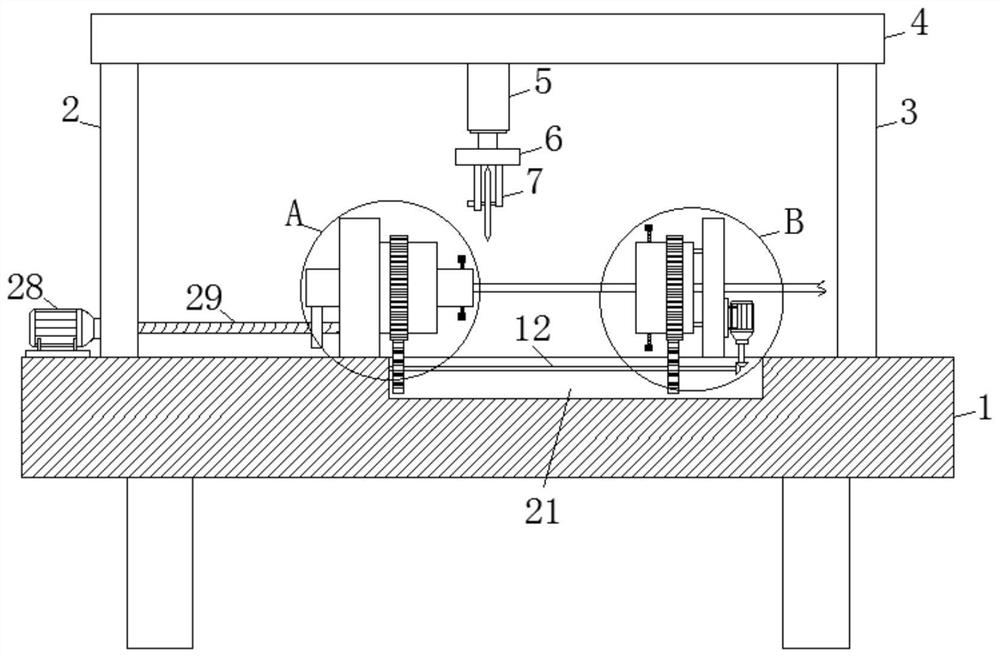

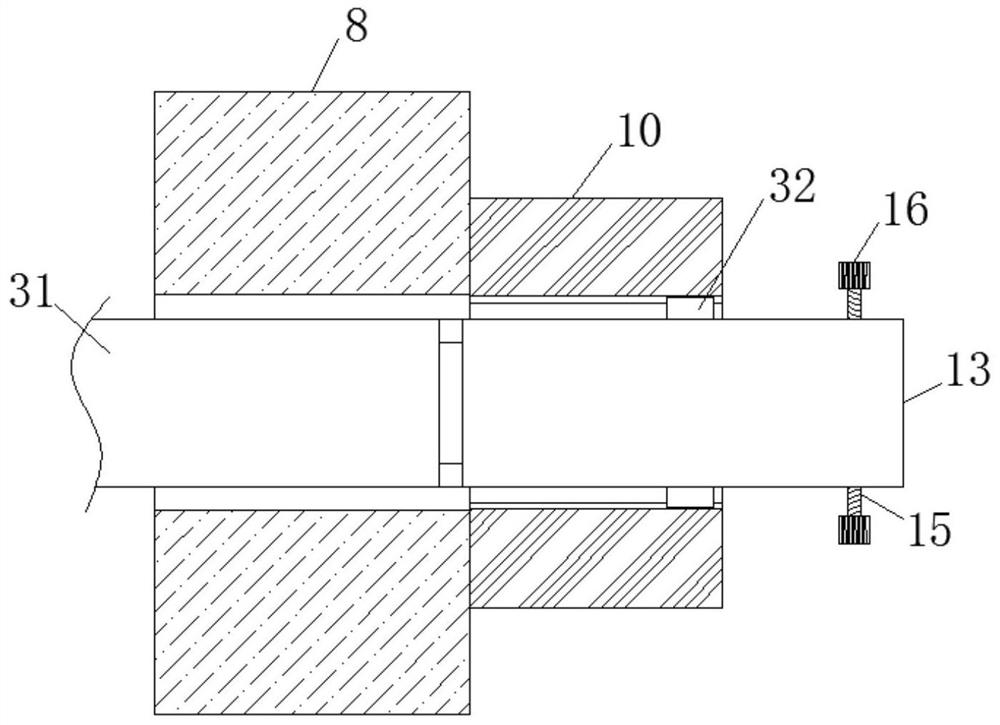

High-strength and high-thermal-conductivity polyimide film and preparation method and cutting equipment thereof

PendingCN113061339AEasy cuttingAdjust adjustment processFlat articlesMetal working apparatusP-PhenylenediaminePolyimide

The invention discloses a high-strength and high-thermal-conductivity polyimide film and a preparation method and cutting equipment thereof, and relates to the field of polyimide films. The high-strength and high-thermal-conductivity polyimide film comprises the following raw materials in parts by mass: 45-65 parts of 3,3',4,4'-biphenyl tetracarboxylic dianhydride, 32-48 parts of p-phenylenediamine, 5.5-6.2 parts of crystalline flake graphite and 3.6-4.8 parts of nanocrystalline diamond. Through the scheme, 3,3',4,4'-biphenyl tetracarboxylic dianhydride and p-phenylenediamine serve as raw materials of the high-strength and high-thermal-conductivity polyimide film, the crystalline flake graphite and the nanocrystalline diamond are added into the raw materials, when the crystalline flake graphite is added, the crystallinity of the nanocrystalline diamond is reduced, crystallization and activation of the nanocrystalline diamond are facilitated, and the tensile strength is improved; meanwhile, the nanocrystalline diamond is beneficial to improvement of the heat conductivity coefficient of the composite material; in addition, the preparation method is simple, and the production requirements of enterprises are reduced.

Owner:常熟市方舟绝缘材料有限责任公司

Automatic slicing machine for insulating layer of power cable

ActiveCN112857858AEasy cuttingImprove efficiencyWithdrawing sample devicesElectric machineryWorkbench

The invention discloses an automatic slicing machine for an insulating layer of a power cable. The machine comprises a workbench, the top of the workbench is fixedly connected with a first side plate and a second side plate, the top of the first side plate and the top of the second side plate are fixedly connected with the same top plate, the bottom of the top plate is fixedly connected with an electric push rod, a fixing plate is fixedly connected to the bottom of the electric push rod, a cutting device body is fixedly connected to the bottom of the fixing plate, and a first mounting plate and a second mounting plate are fixedly connected to the top of the workbench. The two ends of a cable are clamped and fixed through a first fixing mechanism and a second fixing mechanism, then a first motor drives a rotating shaft to rotate, the rotating shaft drives a first bevel gear and a supporting rod to rotate through a second bevel gear so as to enable the clamped cable to rotate, and the electric push rod drives the cutting device body to cut the insulating layer of the cable. The cutting operation is simple and convenient, and the efficiency is high.

Owner:江苏新汇烽塑胶有限公司

New energy battery side plate film pasting device

InactiveCN114148812AEasy to replaceEasy cuttingFinal product manufactureElectrolyte accumulators manufacturePhysicsElectric machinery

The invention discloses a new energy battery side plate film pasting device which comprises a fixing table and a base, the base is fixedly connected to the bottom end of the fixing table, a supporting seat is fixedly installed at the top end of the fixing table, a first fixing plate is arranged on one side of the supporting seat, and a new energy battery body is arranged at the top end of the supporting seat. And an air cylinder is fixedly mounted on one side of the top end of the fixed table. According to the new energy battery side plate film pasting device, parts such as a film rolling barrel are arranged, a first positioning sleeve and a second positioning sleeve are screwed, the film rolling barrel can be detached, the film rolling barrel is installed outside a first connecting shaft and a second connecting shaft, a second driving motor is started, the first connecting shaft is driven to rotate through a transmission shaft, and the film rolling barrel can be detached; and when the first connecting shaft rotates, the film rolling barrel is driven to rotate, at the moment, a film body is conveyed, so that film pasting is more convenient, waste films can be conveniently and timely rolled, and the problem that the film rolling barrel is inconvenient to replace during film pasting is solved.

Owner:深圳安博智控科技有限公司

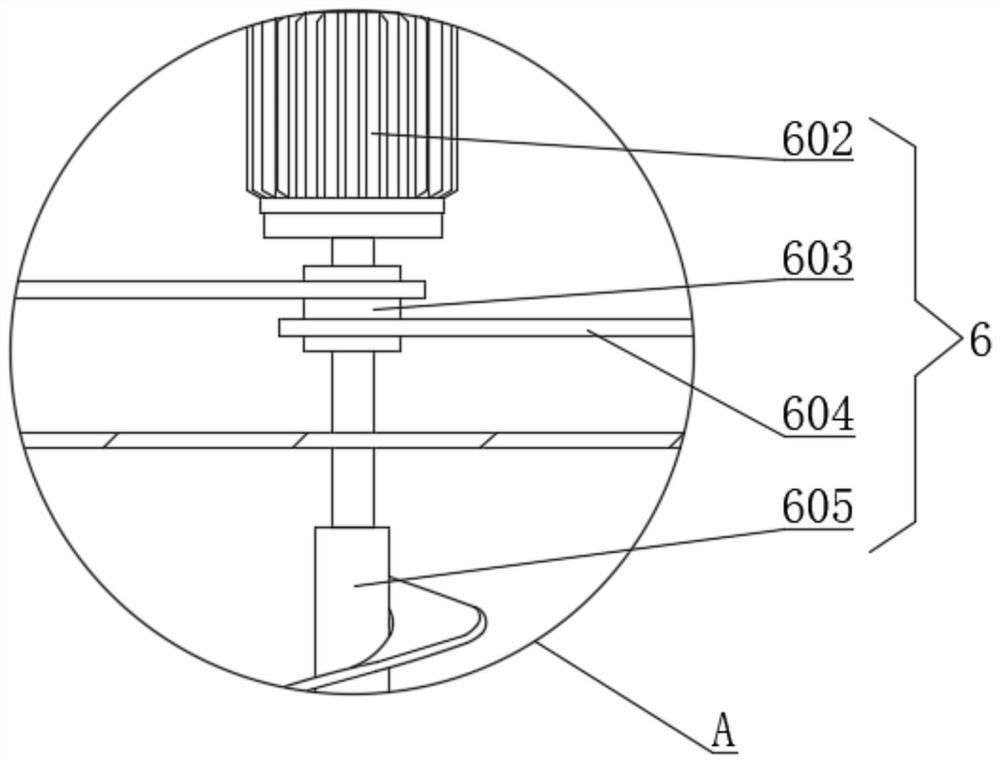

Food processing crushing and stirring device with screening function

InactiveCN112387385AEasy cuttingImprove efficiencySievingScreeningElectric machineryProcess engineering

The invention discloses a food processing crushing and stirring device with a screening function, and relates to the field of food processing equipment. The food processing crushing and stirring device comprises a box body, the lower surface of the box body is fixedly connected with a damping mechanism, the upper surface of the box body is fixedly connected with a feeding port, the side edge of the box body is fixedly connected with a discharging port, and the top outside the box is fixedly connected with a motor support; the motor support is fixedly connected with a motor, a motor output shaft is fixedly connected with a rotating shaft, the rotating shaft is fixedly connected with a crushing mechanism and a plurality of first crushing blades, the lower end of the rotating shaft is fixedlyconnected with a rotating sleeve, and the rotating sleeve is fixedly connected with a plurality of second crushing blades and stirring rods; and a partition plate is fixedly connected in the box body, the rotary sleeve is fixedly connected with a reciprocating mechanism, and the reciprocating mechanism is rotationally connected with a screening mechanism. According to the food processing crushingand stirring device, through the arrangement of the damping mechanism, vibration generated and borne by the whole device can be buffered, through the arrangement of the crushing mechanism, materialscan be crushed in a reciprocating mode, the food crushing and screening efficiency is improved, and meanwhile the labor cost is reduced.

Owner:常伟丽

Auxiliary jig for detaching and recombining carton

InactiveCN111546695AEasy to repackageEasy cuttingEnvelopes/bags making machineryBags/boxes manufactureEngineeringStructural engineering

The invention discloses an auxiliary jig for detaching and recombining a carton. The auxiliary jig comprises a right-angled interior lining panel and a right-angled exterior lining panel. The exteriorlining panel is located on the outer side of the interior lining panel, a plurality of vertical adjusting slots are formed in edge boards on two sides of the interior lining panel, a plurality of studs are formed on edge boards on two sides of the exterior lining panel, the studs are spirally connected to swivel nuts by penetrating a partition block, the adjusting slots of the interior lining panel and a base plate successively, and the swivel nuts lean against the base plate. A first cutting groove and a second cutting groove are separately formed at a corner point of the interior lining panel and at a corner point of the exterior lining panel, separately. The auxiliary jig can position folded corrugated paper and is convenient to recombine and package the detached carton and cut a turnup at the top end of the carton.

Owner:苏州超烁再生资源有限公司

Production device for preparing environment-friendly water permeable bricks by utilizing industrial smelting waste residues

InactiveCN113715168AEasy cuttingStir wellSolid waste managementDischarging apparatusElectric machineryPulley

The invention relates to the technical field of water permeable brick production, and discloses a production device for preparing environment-friendly water permeable bricks by utilizing industrial smelting waste residues. The production device comprises supporting legs, a discharging box is fixedly connected to the tops of the supporting legs, a stirring box is fixedly connected to the top of the discharging box, and a leakage-proof cover is fixedly connected to the top of the stirring box; a connecting mechanism is arranged on the left side of the top in the stirring box, a stirring mechanism is arranged in the middle of the top in the stirring box, a discharging mechanism is arranged in the middle of the top in the discharging box, and the stirring mechanism comprises a power box, a first motor, a first belt pulley, a belt, a first stirring shaft, a second belt pulley and a second stirring shaft. According to the production device for preparing the environment-friendly water permeable bricks by utilizing the industrial smelting waste residues, raw materials are conveyed into the stirring box through a feeding pipe at the top in the stirring box, then the first motor is started, the first motor drives the first stirring shaft and the second stirring shaft to rotate when working, and the raw materials in the stirring box can be stirred more uniformly.

Owner:砀山县华洁环保科技有限公司

Flexible metal sheet cutting and processing method

ActiveCN113547166AImprove clippingEasy cuttingShearing machine accessoriesEngineeringMetallic materials

Owner:安徽大东新材料科技有限公司

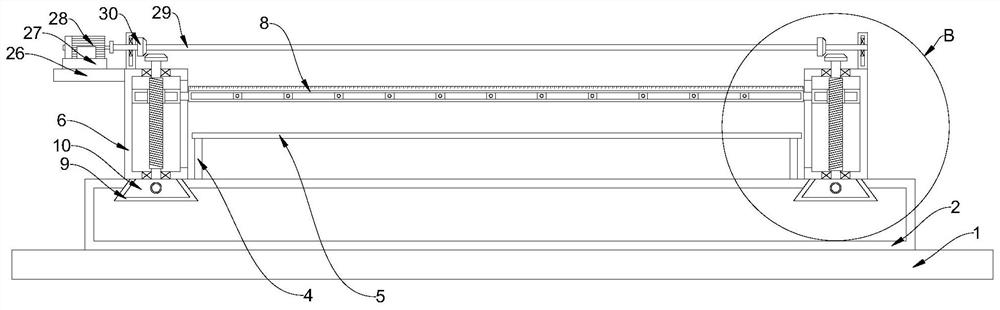

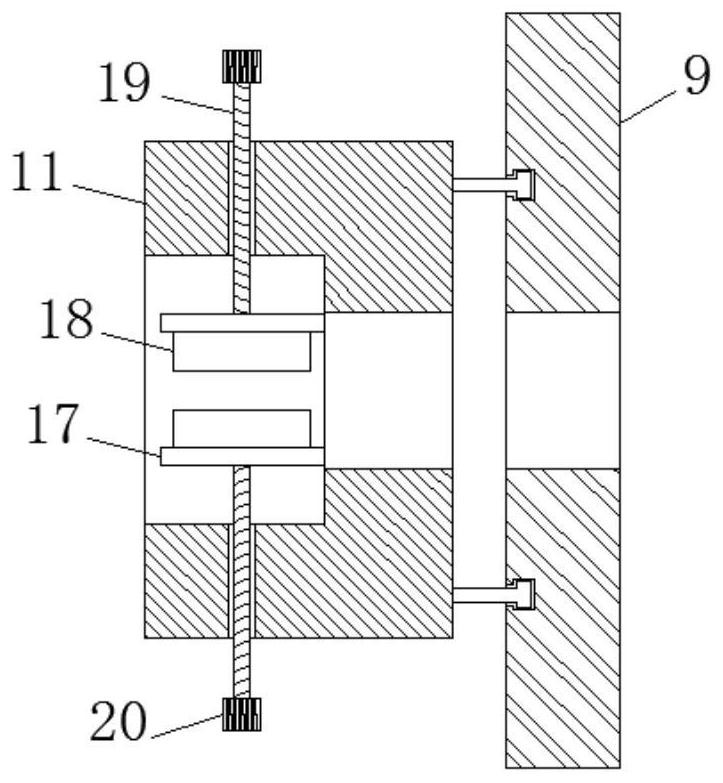

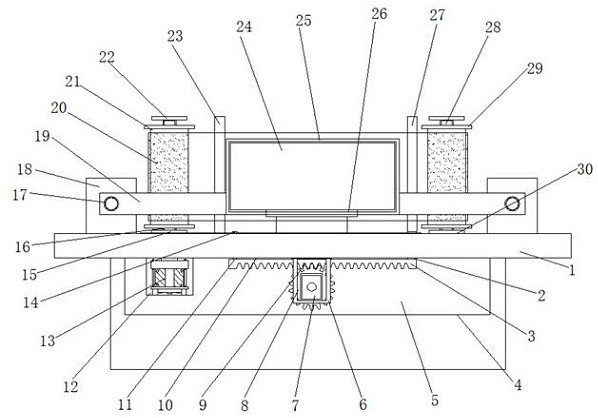

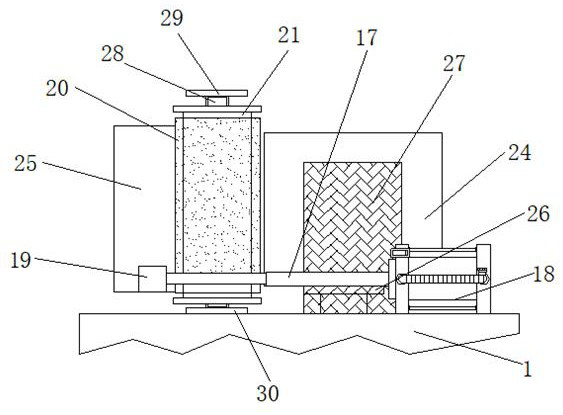

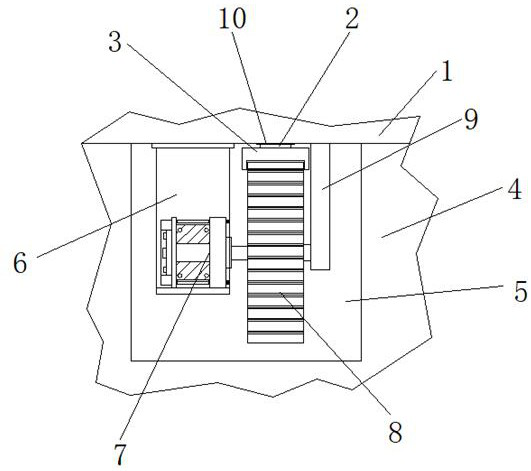

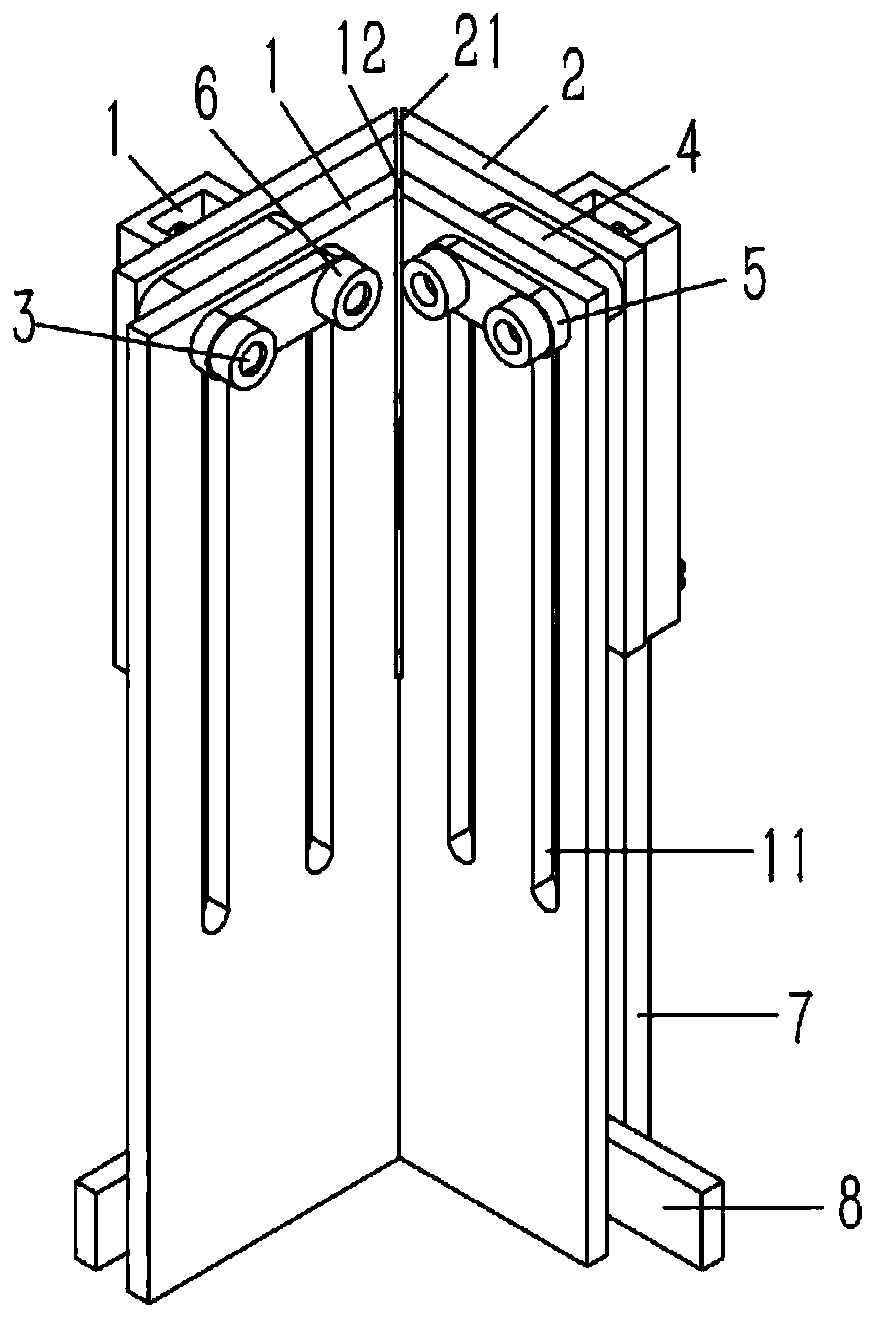

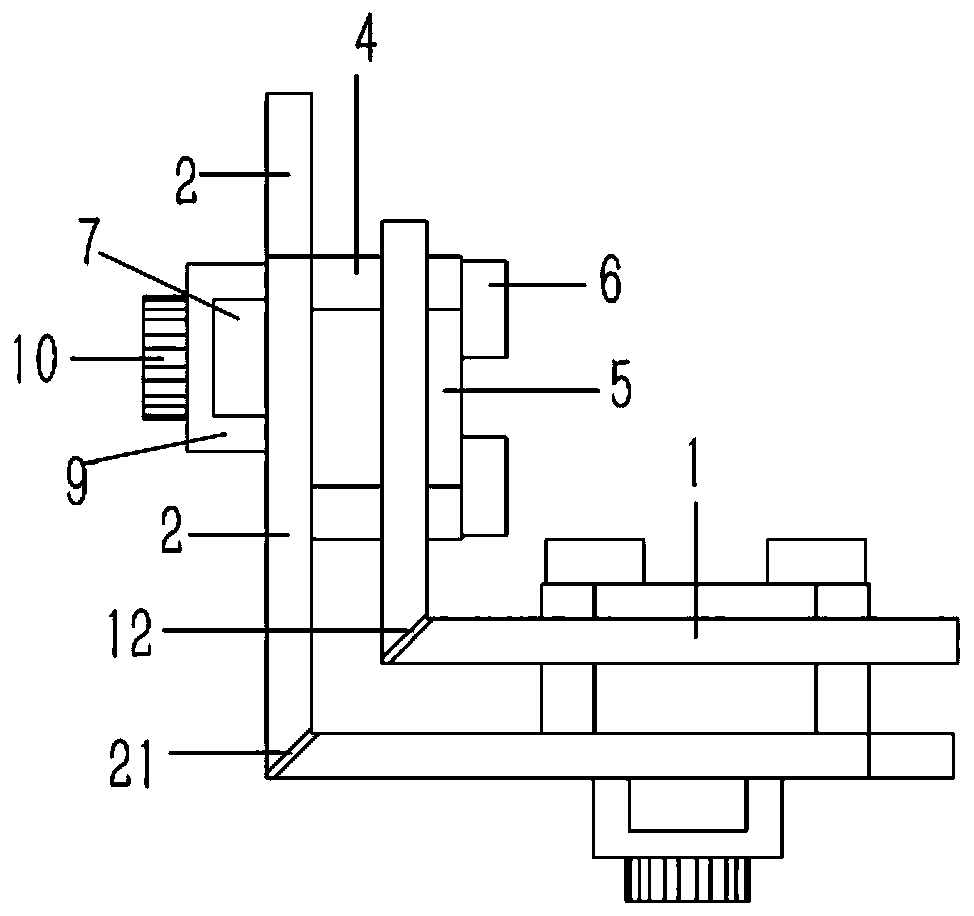

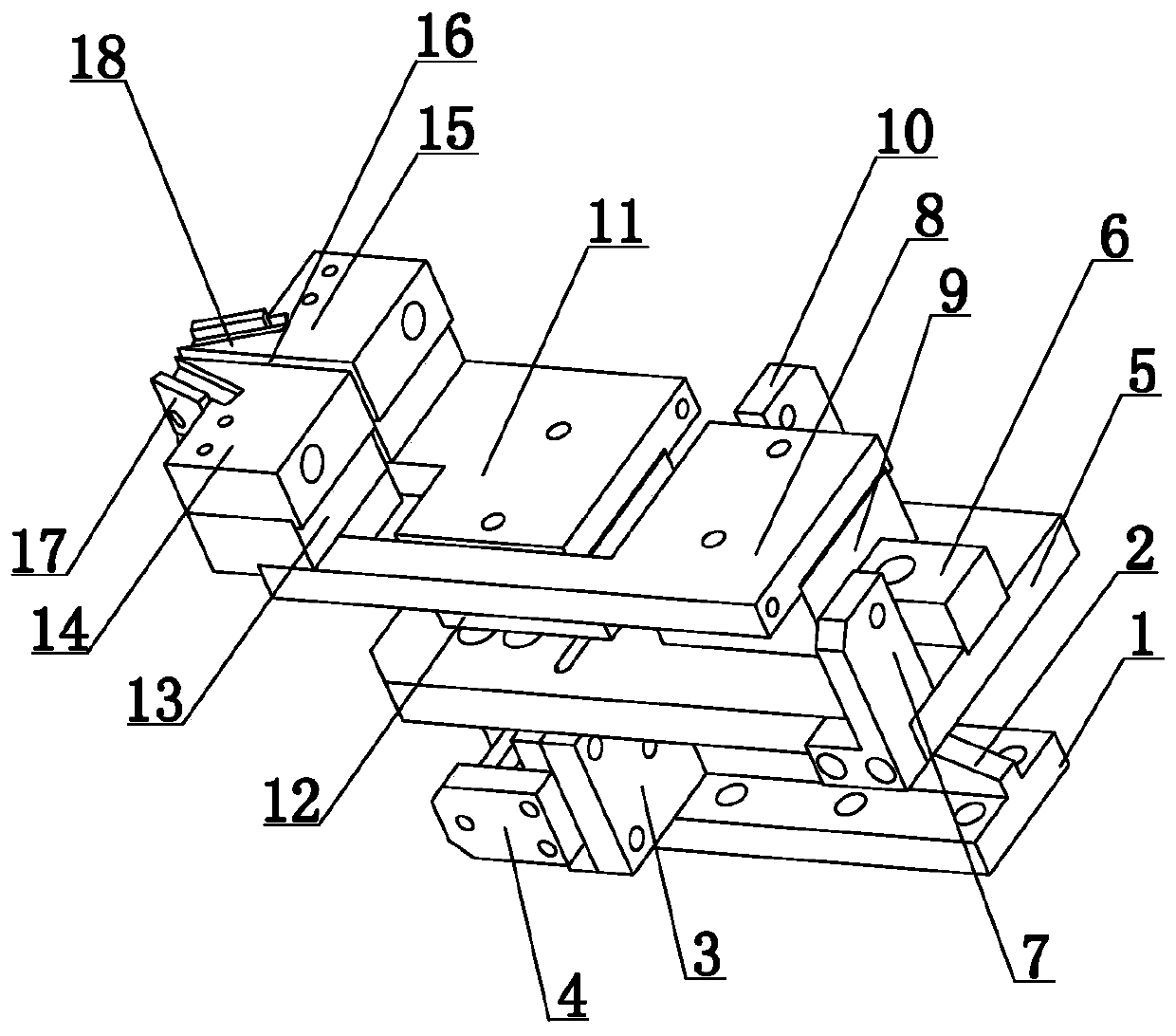

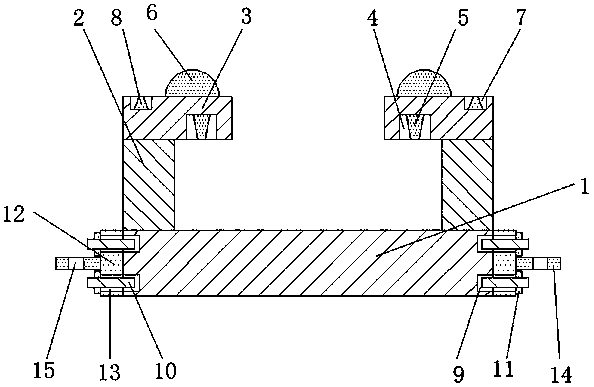

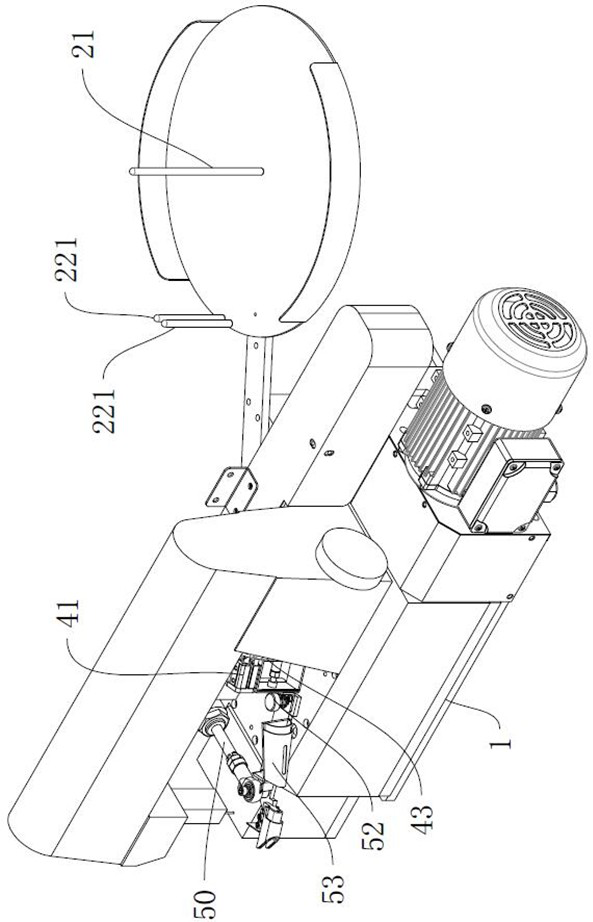

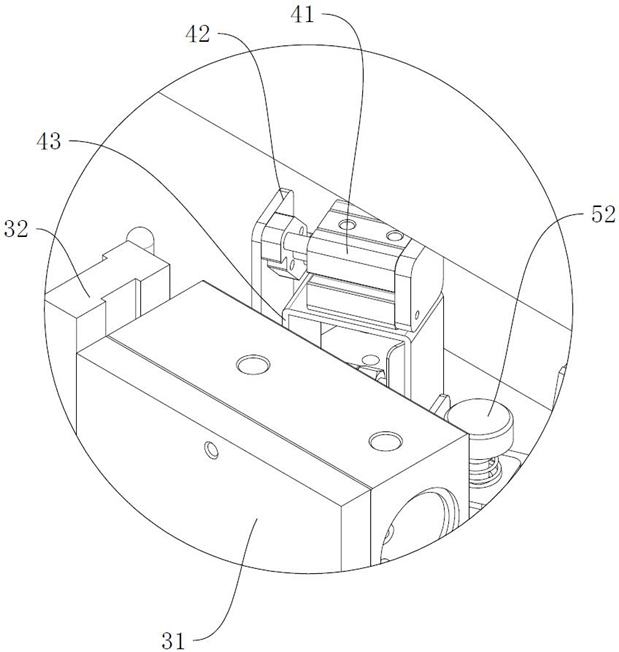

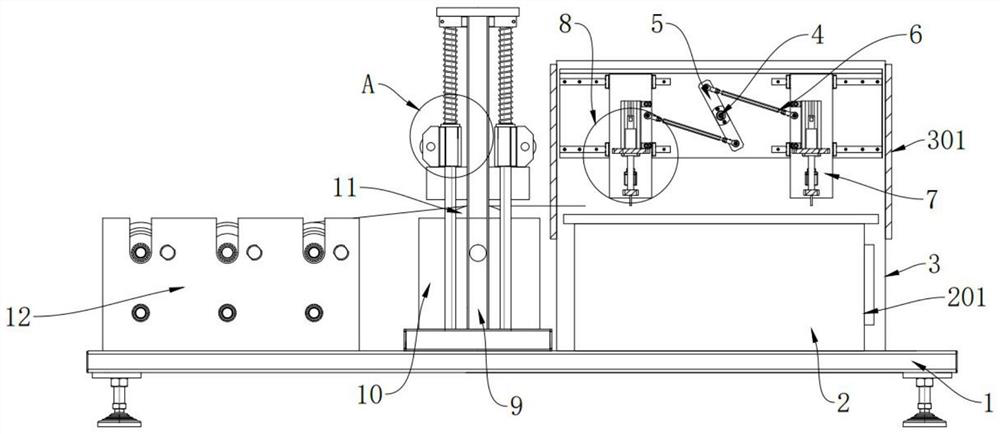

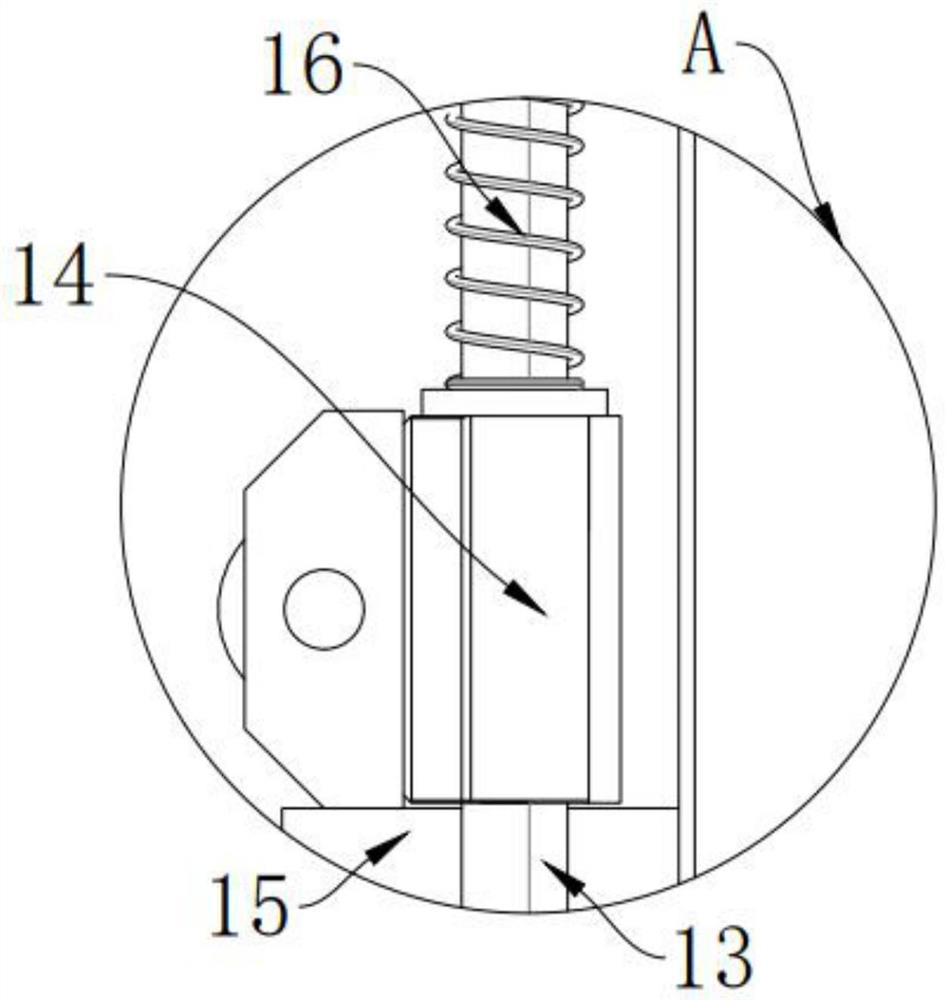

Paper cutting blade clamping device for numerical control machine tool

InactiveCN110142824AFlexible mobile adjustmentEasy cuttingMetal working apparatusPaper cutEngineering

The invention discloses a paper cutting blade clamping device for a numerical control machine tool. The paper cutting blade clamping device comprises a base, wherein a supporting seat and a side seatare arranged on the base, a fixing seat is arranged on the end parts of the supporting seat and the side seat, a guide rail is arranged on the fixing seat, a sliding adjusting plate is arranged on theguide rail, a pair of sliding seats are arranged at the bottom of the sliding adjusting plate, and the sliding seats are arranged on the guide rail; a base is arranged on the top surfaces of the sliding seats, and a fixing block is arranged at the bottom of the base; and a clamping plate is arranged on the front part of the base, a first clamping seat and a second clamping seat are arranged on the clamping plate, a clamping groove is formed between the first clamping seat and the second clamping seat, a first clamping part is arranged on the front part of the first clamping seat, and a secondclamping part is arranged on the front part of the second clamping seat. According to the device, the sliding adjusting plate realizes sliding adjustment through the sliding seats along the guide rail, so that the clamping plate can be conveniently moved, and a paper cutting blade can be flexibly moved and flexibly adjusted; and paper on a paper cutting machine can be conveniently and rapidly cutthrough the paper cutting blade.

Owner:颖德精密机械(南京)有限公司

Trimming device for producing non-woven fabric

The invention discloses a trimming device for producing a non-woven fabric. The trimming device includes a base. The outer wall of the top of the base is in connection with a first rotating shaft through a bolt, the first rotating shaft is of an annular structure, the inner wall of the periphery of the first rotating shaft is provided with sliding grooves, two symmetrically arranged rollers are slidably connected in the sliding grooves, the outer sides of the opposite sides of the two rollers are connected with an identical connecting rod through a bolt, the outer wall of one side of the connecting rod is connected with a rotating plate through a bolt, the outer wall of the top of the rotating plate is connected with a cushion plate through a bolt, one side of the outer wall of the top ofthe first rotating shaft is connected with a second rotating shaft through a bolt, and the outer wall of the top of the second rotating shaft is connected with a lower knife rest through a bolt. The cushion plate can rotate, the angle of a cutting knife can be adjusted, the position of the cutting knife relative to a non-woven fabric is adjusted conveniently, the cutting of the non-woven fabric next time is facilitated, and the cutting working efficiency is improved while the safety is improved.

Owner:河南聚力时刻环保科技有限公司

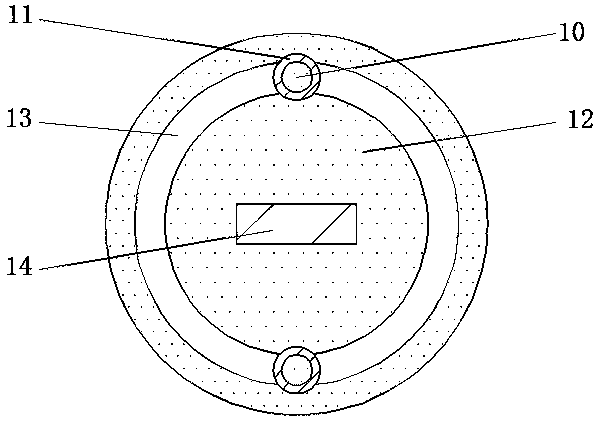

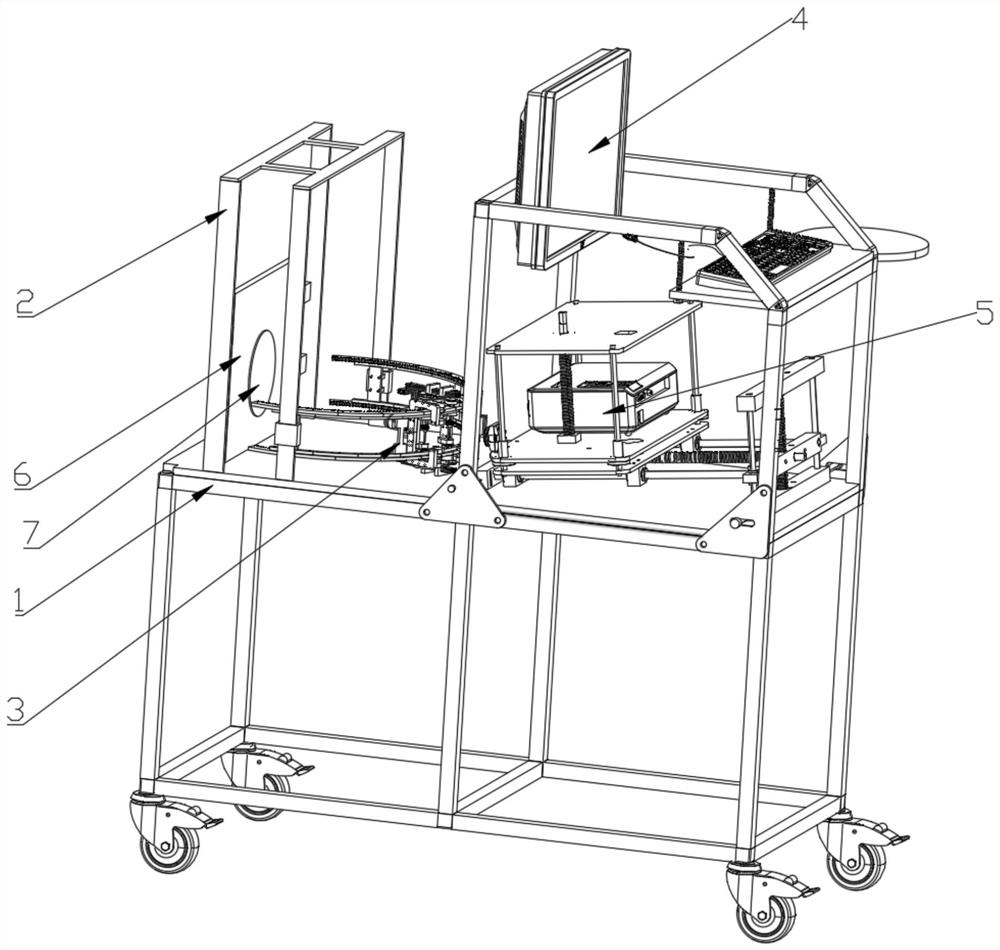

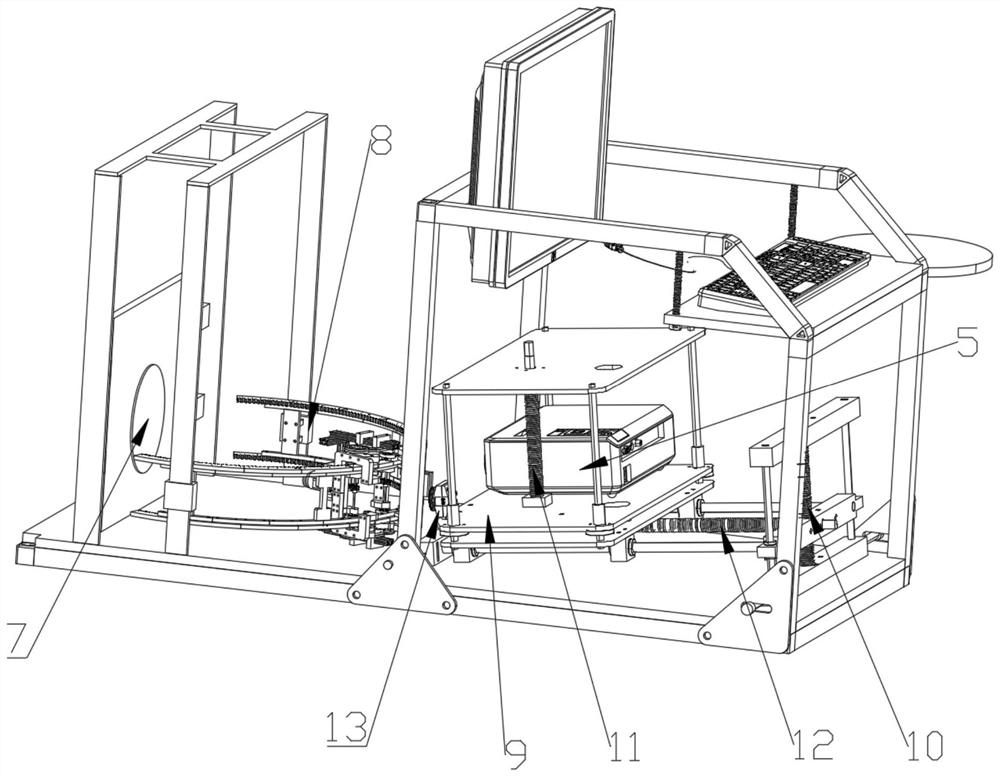

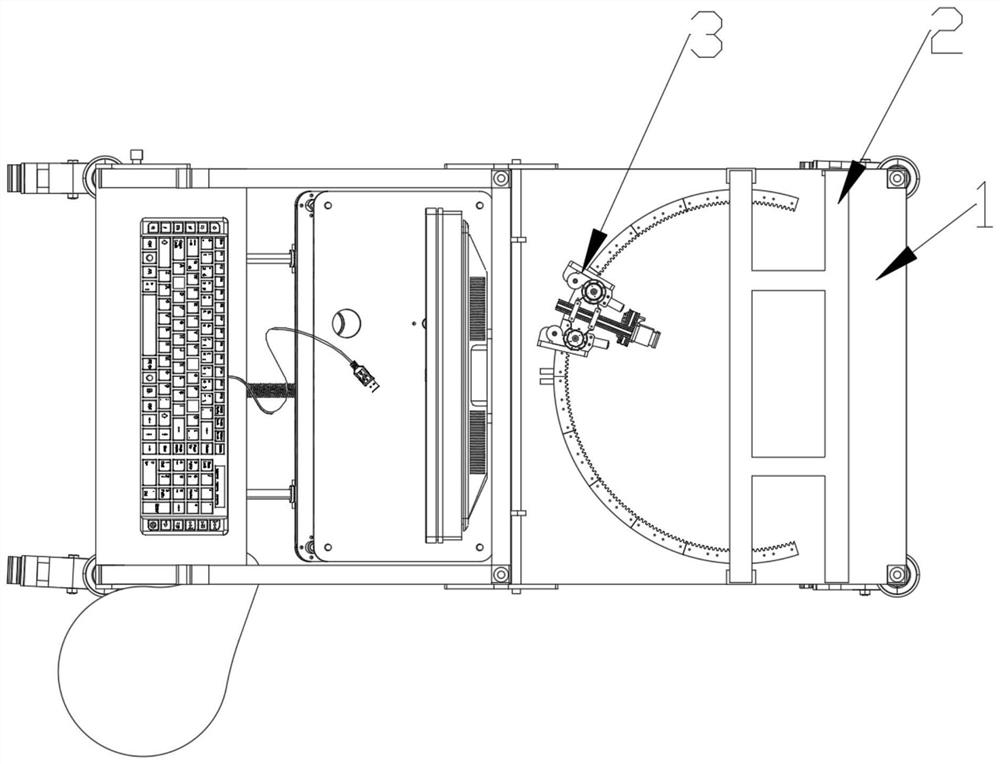

Pericardium screening system and method for artificial valve

PendingCN114533345AReduce additional damageEasy cuttingHeart valvesWater resource assessmentGraph generationBiomedical engineering

The invention relates to a pericardium screening system and method for an artificial valve, and belongs to the technical field of medical instruments. Comprising an operation table, a pericardium placement frame, a rail type three-dimensional scanner, a graphic processing computer and a projector, one end of the operation table is provided with a pericardium placing frame, and pericardium tissue to be measured is arranged on the pericardium placing frame. A track type three-dimensional scanner and a projector which face the pericardium tissue to be measured are arranged on the operation table on one side of the pericardium placing rack; a graphic processing computer is further arranged on the operation table and connected with the rail type three-dimensional scanner and the projector; and three-dimensional model generation software and thickness peak valley graph generation software are installed in the graph processing computer. The thickness of the pericardial tissue is measured through the three-dimensional scanner, and extra damage to the pericardial tissue is reduced to the maximum extent in a non-contact thickness measurement mode; and the thickness peak-valley graph is projected to the pericardial tissue through the projector, so that the cutting treatment is more convenient, and the screening efficiency is high.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV +1

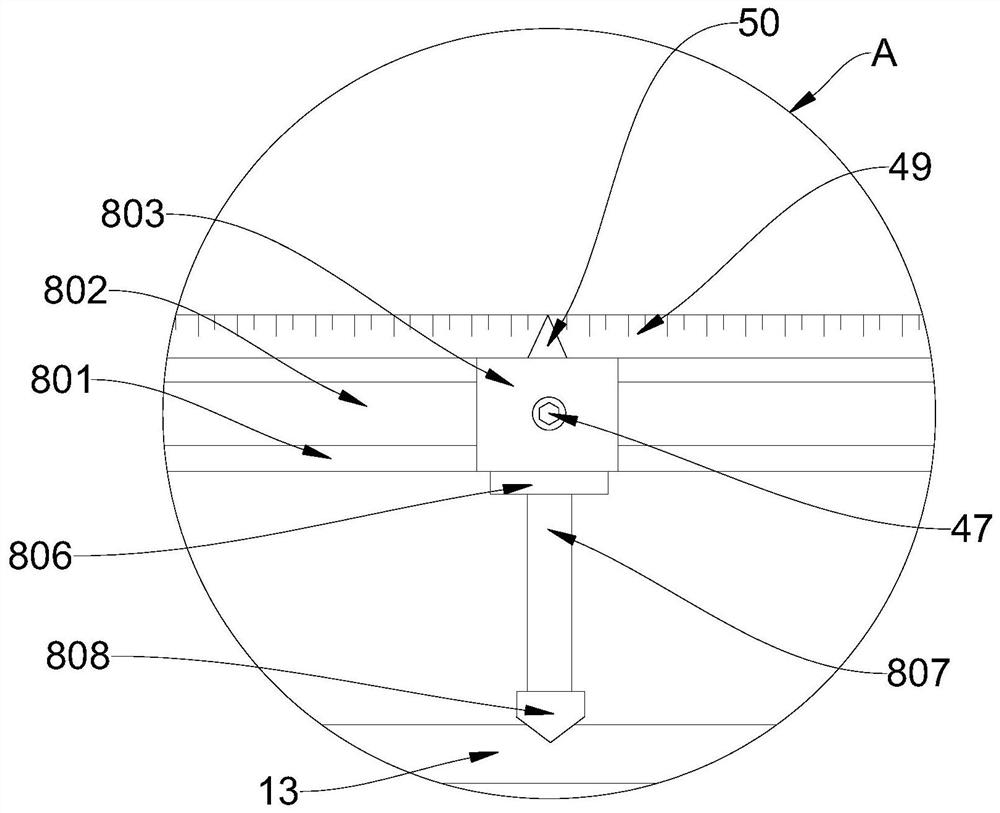

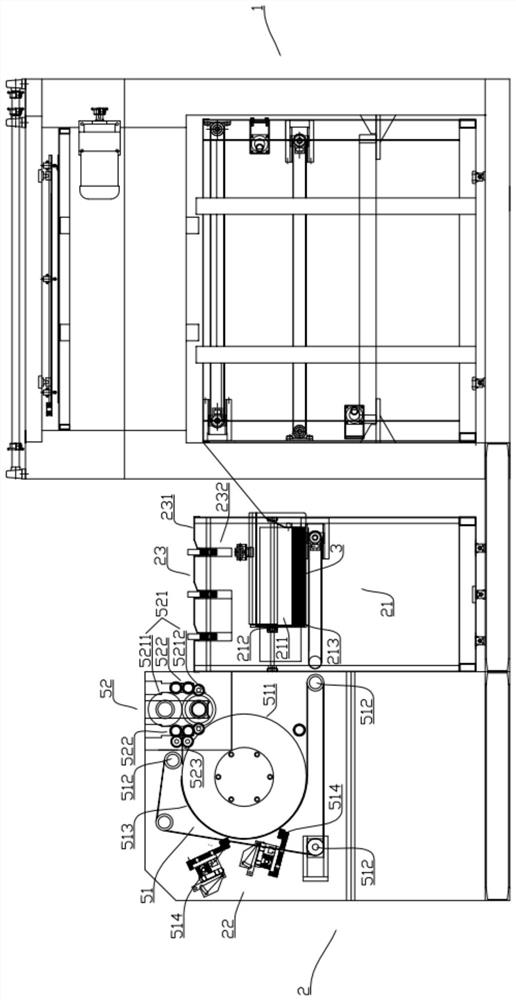

Cutting mechanism in aluminum coil laminating processing device

InactiveCN113291907AReduce air bubblesEasy cuttingArticle deliveryStructural engineeringMechanical engineering

The invention discloses a cutting mechanism in an aluminum coil laminating processing device. The cutting mechanism comprises a bottom plate, supporting legs are fixed to the tops of the two sides of the bottom plate, a top plate is fixed to the tops of the supporting legs, and a vertical fixing plate is fixed to the bottom of the top plate. The front outer wall of the vertical fixing plate is provided with a trowelling mechanism used for trowelling the aluminum coil and a cutting mechanism, and the rear outer wall of the vertical fixing plate is provided with a driving mechanism used for driving the trowelling mechanism and the cutting mechanism to move. A film covering mechanism used for covering the aluminum roll with a film is further arranged between the bottom of the top plate and a vertical mounting plate. According to the cutting mechanism, by arranging the trowelling mechanism, the cutting mechanism, the driving mechanism and the film covering mechanism, the effect that an aluminum plate is trowelled before being cut is achieved, a film at the cut position can be prevented from being lifted up after cutting, and the aluminum plate cutting effect is further improved.

Owner:高相会

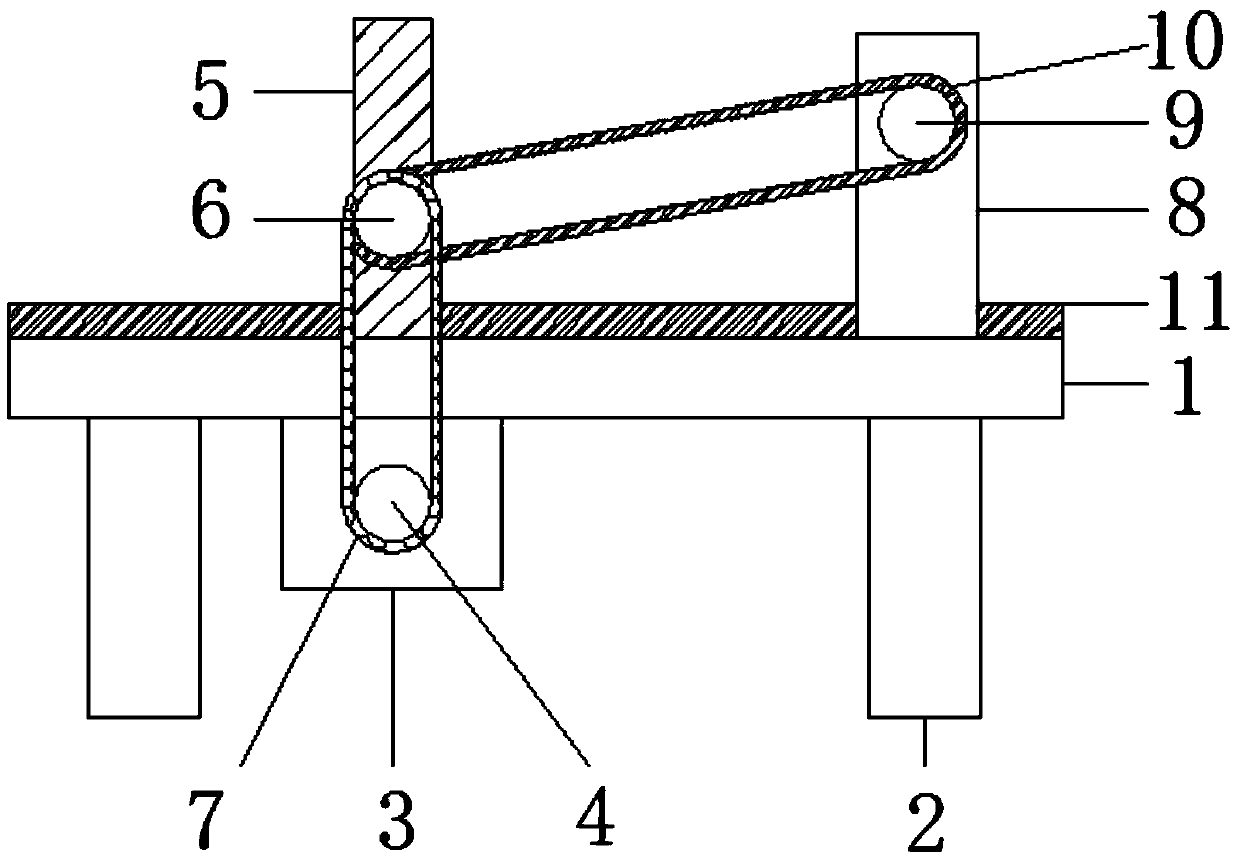

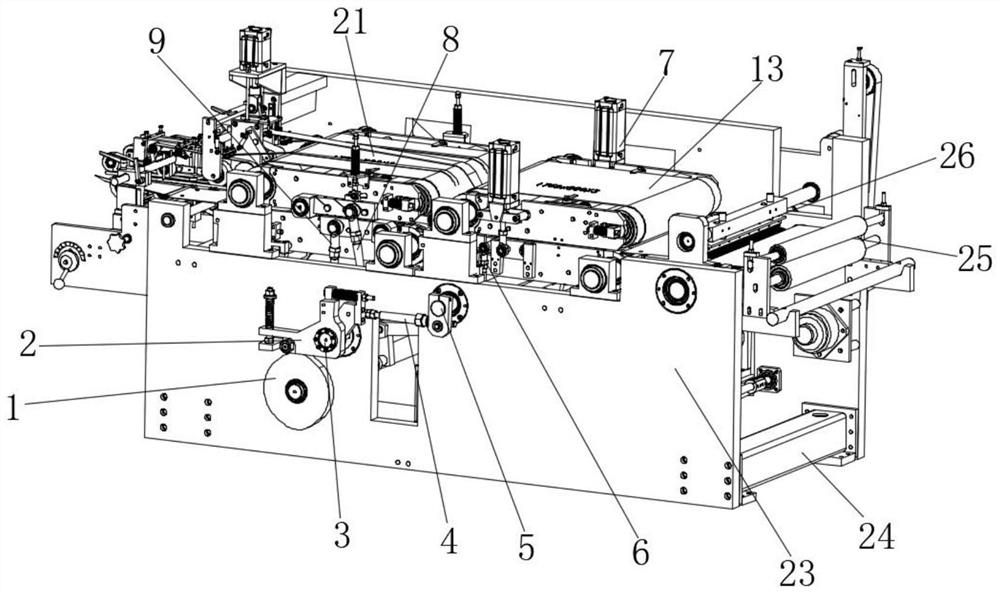

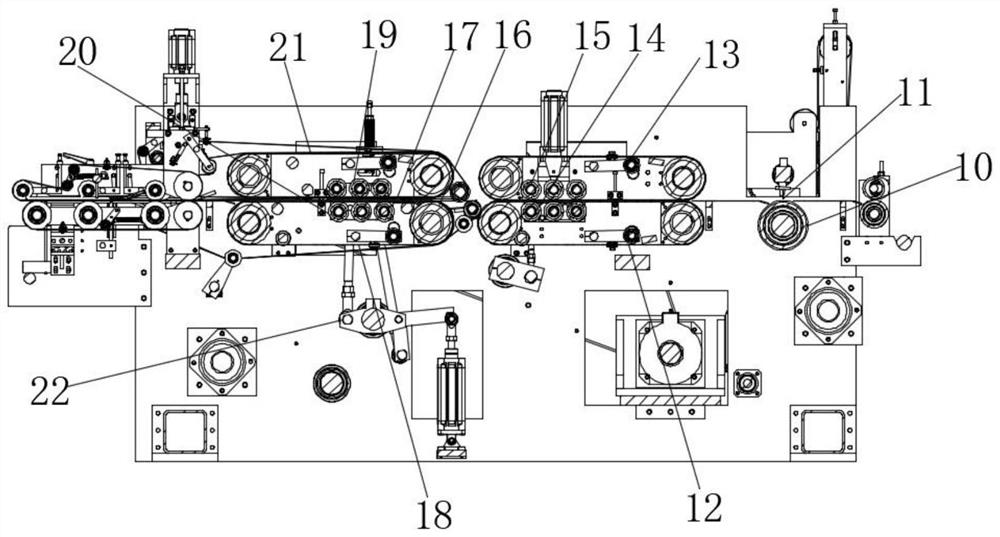

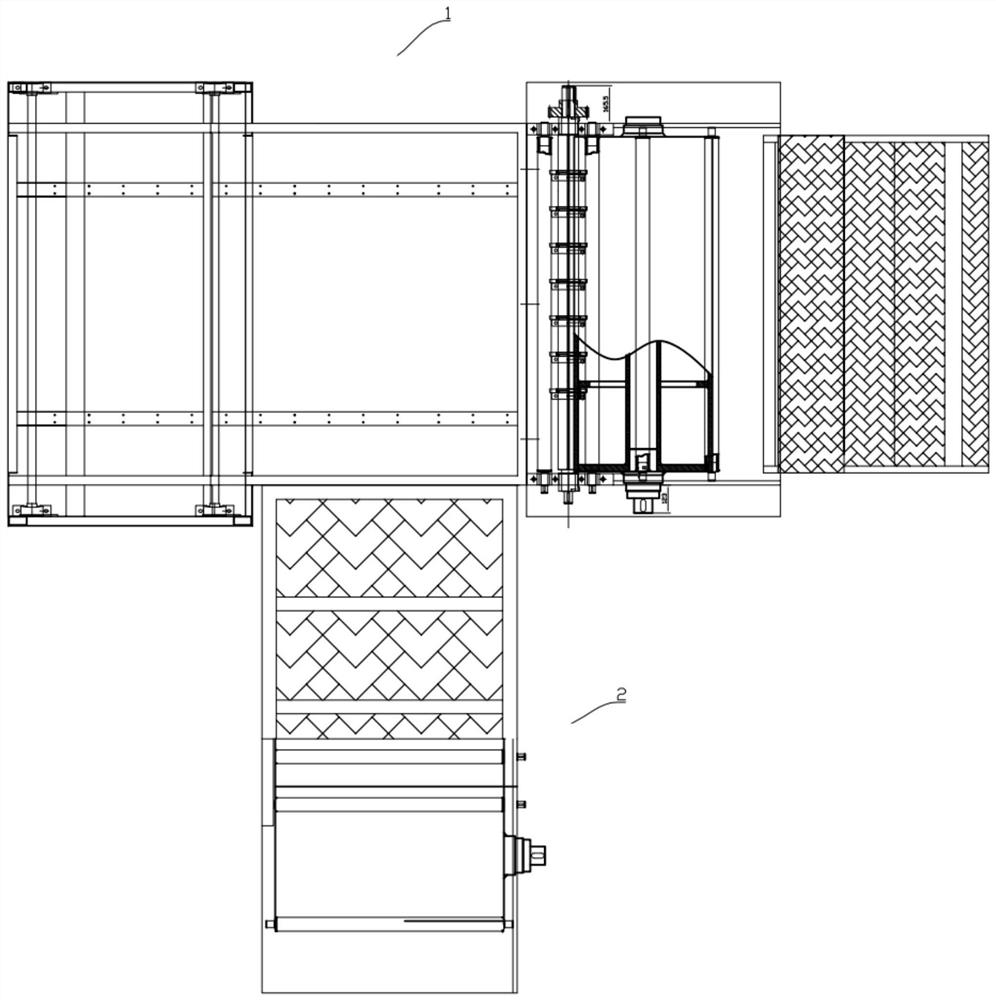

Sideband material cutting structure, edge surrounding machine comprising sideband material cutting structure, and sideband edge surrounding method

ActiveCN112501797AImpact deliveryAvoid the phenomenon of threadingWorkpiece carriersMattress sewingEngineeringSideband

The invention discloses a sideband material cutting structure, an edge surrounding machine comprising the sideband material cutting structure, and a sideband edge surrounding method. The sideband material cutting structure comprises a rack, a sideband feeding mechanism, a heating device, and a fixing mechanism; the sideband feeding mechanism is arranged on the rack, and the sideband feeding mechanism is used for placing a sideband; the heating device is arranged on the rack and used for heating the sideband, so that the sideband is heated and melted to form a recess for cutting off materials;and the fixing mechanism is arranged on the rack and used for clamping the sideband. The edge surrounding machine comprises the sideband material cutting structure. The provided structure, the edge surrounding machine and the method can conveniently cut off the sideband.

Owner:佛山市众联机械科技有限公司

Yarn cutting device for spinning

The spinning yarn cutting device comprises a bottom plate, vertical plates are fixed to the two sides of the top end of the bottom plate, a cutting table is fixed to the position, between the two vertical plates, of the top end of the bottom plate, a rotating shaft is rotationally installed on one side of the surface of each vertical plate, and a rotating plate is fixed to one end of each rotating shaft; connecting arms are movably installed on the two sides of the surface of the rotating plate, sliding plates are slidably installed on the two sides of the surface of the vertical plate, connectors are installed at the two ends of each connecting arm, the sliding plates are movably connected with the ends of the connecting arms, a cutting mechanism is installed on one side of the surface of each sliding plate, and a containing table is fixed to one side of the top end of the bottom plate. According to the yarn cutting device, the cutting requirements of different yarn lengths are met, the yarn lengths are unified, the cutting precision of the device is improved, automatic falling and rewinding of the yarn are avoided, workers can conveniently pull the yarn next time for cutting work, and the use convenience of the device is enhanced.

Owner:史经营

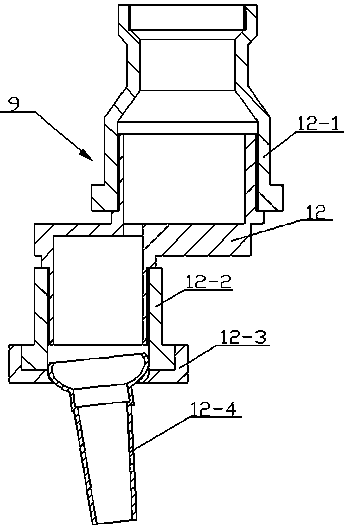

Forced-rinsing cooling mechanism of multi-sheet combined stone sawing machine

InactiveCN103921364AEasy cuttingFragmentation quality is goodWorking accessoriesBall valveEngineering

The invention provides a forced-rinsing cooling mechanism of a multi-sheet combined stone sawing machine. The forced-rinsing cooling mechanism comprises a multi-sheet combined stone saw. The forced-rinsing cooling mechanism is characterized by comprising a booster pump and an electric switch valve connected with the booster pump, the electric switch valve is sequentially connected with a water pressure gauge and a diversion water tank through a high-pressure pipe, the electric switch valve is connected with a transverse water spray pipe through the high-pressure pipe, a ball valve is installed on the portion, between the electric switch valve and the transverse water spray pipe, of the high-pressure pipe, a ball valve is installed on the portion, between the electric switch valve and the water pressure gauge, of the high-pressure pipe, the ball valves are used for adjusting the on-off and the flow of water, the diversion water tank is provided with a connector, the connector is connected with one end of the high-pressure pipe, and the other end of the high-pressure pipe is connected with an adjustable spray head through a connector on a water shield. Compared with the prior art, the forced-rinsing cooling mechanism of the multi-sheet combined stone sawing machine has the advantages that a disk saw can be rinsed and cooled sufficiently, deformation of the disk saw can be effectively reduced, the service life of the disk saw is prolonged, usage cost is reduced, and the quality of a stone slab obtained through cutting is improved.

Owner:杜泽忠

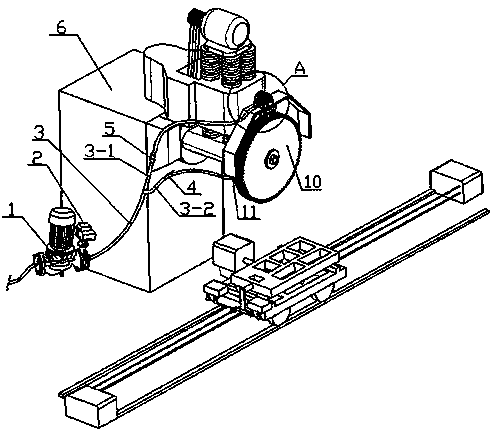

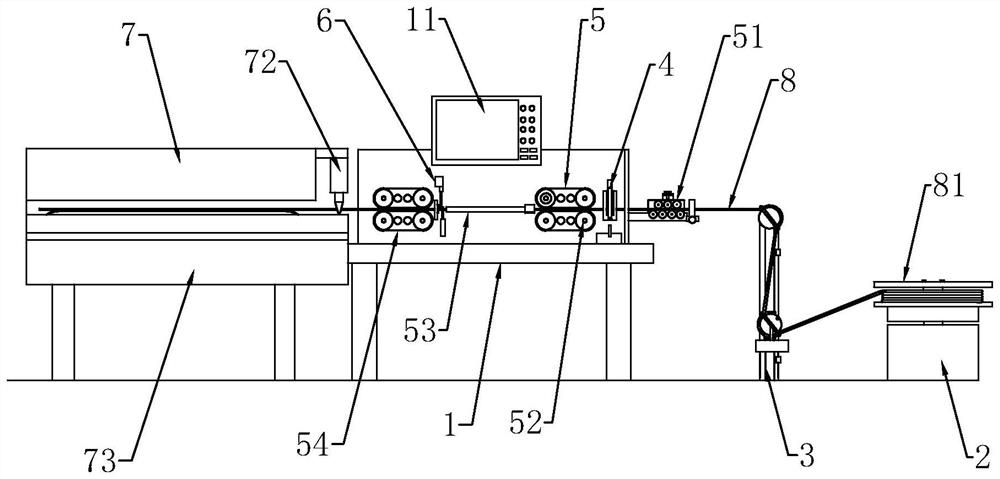

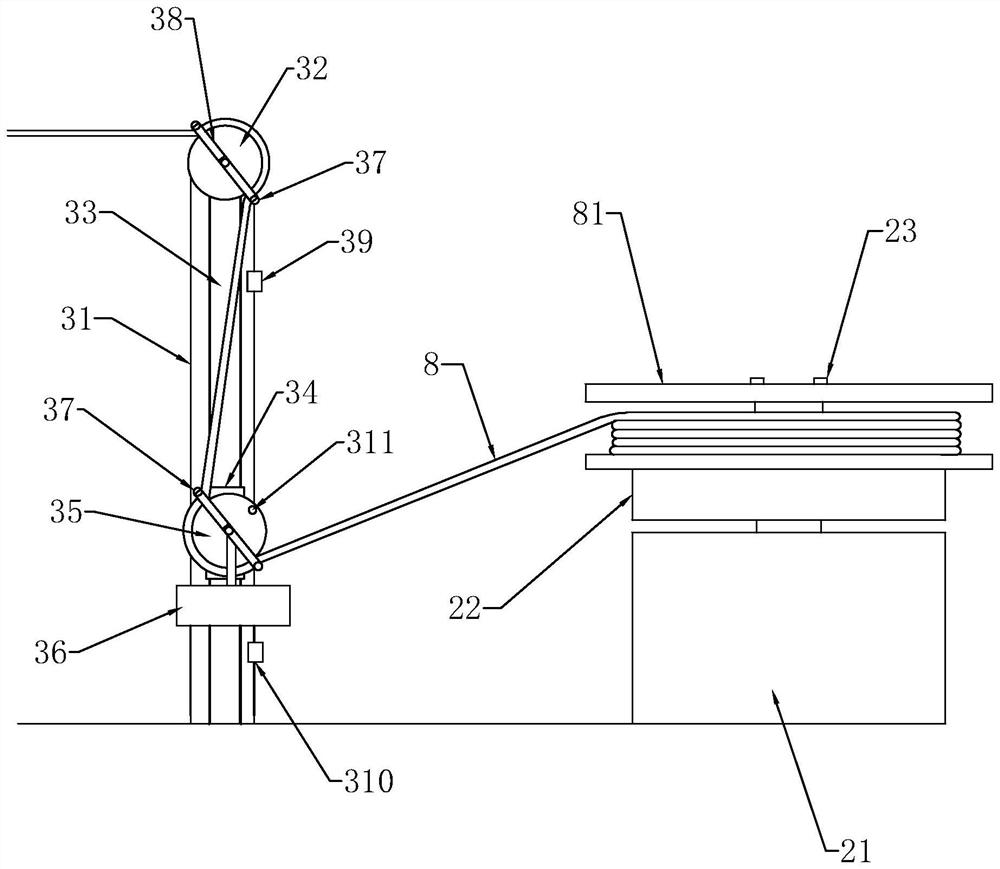

Automatic wire cutting equipment for cable connecting wire

PendingCN114275627AEasy cuttingImprove processing qualityFilament handlingMetal working apparatusWire cuttingRotation sensor

The invention discloses automatic wire cutting equipment for a cable connecting wire, which is characterized in that a tension adjusting assembly comprises a bracket, a first pulley is mounted at the top end of the bracket, a second pulley capable of moving up and down is arranged on the bracket, a high-position proximity switch and a low-position proximity switch are arranged on the side surface of the bracket, and induction magnetic steel is arranged on a sliding block; the switch is matched with the high-position proximity switch and the low-position proximity switch to work; the cable conveying assembly is sequentially provided with a guide roller group, a first wire pressing wheel group, a guide pipe and a second wire pressing wheel group, the first wire pressing wheel group is provided with a counting wheel which rotates synchronously with the first wire pressing wheel group, the counting wheel is provided with a rotation sensor, and the cable cutting assembly is arranged between the guide pipe and the second wire pressing wheel group. The feeding speed is controlled according to the position change information of the pulley, the cable conveying length is calculated according to the number of rotation turns of the counting wheel, and it is guaranteed that the lengths of cut cables are consistent.

Owner:嘉兴易瑞电子有限公司

Silk screen filler cutting machine with adjustable cutting width

InactiveCN110948548AEasy cuttingImprove work efficiencyMetal working apparatusElectric machineryLeather belt

The invention discloses a silk screen filler cutting machine with an adjustable cutting width, which belongs to the technical field of cutting machines. Supporting columns are mounted at the four corners of the bottom of a cutting table correspondingly. A motor is mounted on the left side of the bottom of the cutting table; an output shaft is arranged on the front end surface of the motor; cuttingframes are symmetrically arranged on the left side of the top of the cutting table; the two groups of cutting frames are connected through a cutting device; winding frames are symmetrically arrangedon the right side of the top of the cutting table; the tops of the two groups of winding frames are connected through a winding shaft; the winding shaft is connected with a cutting shaft through an auxiliary belt; the auxiliary belt is positioned in an inner cavity of the auxiliary belt groove; limiting plates are arranged on the front and rear end faces of the top of the cutting table. Through mutual cooperation of adjusting rings and adjusting bolts on the left side and the right side of the cutting knife, the distance between the cutting knives can be adjusted very conveniently, materials can be cut conveniently, the working efficiency is greatly improved, the materials can be limited through limiting plates on the front end face and the rear end face of the cutting table, and dislocation of the materials in the cutting process is prevented.

Owner:高邮市仁和机械配件厂

Cloth cutting machine for garment processing

ActiveCN111286959BEasy to cutEasy to cut and pick upSevering textilesEngineeringMechanical engineering

The present invention relates to the technical field of garment processing, and more specifically to a fabric cutting machine for garment processing. Before the cutting starts, the fabric rolls with different fabrics to be used can be placed on different bars of the turntable, and then press The button on the control button controls the motor Ⅰ, put the bar that needs to use the cloth roller against the positioning groove at the front end of the two bending plates, and then pull the cloth on the cloth roller by hand, and use the inner side of the two cloth pressing plates The inner pressure plate sticks the side of the fabric to the operating table to facilitate the cutting of the fabric. The cutting staff can pull out the appropriate length of the fabric according to the demand, so as to facilitate the cutting and save time. Fix the relative position of other cloth rollers for cutting, and control the bending plate through two motors II according to the cutting habit to adjust the relative position of the cloth rollers, which is convenient for the cutting work of cutting workers.

Owner:吴江桑尚丝绸有限公司

Umbrella fabric processing and cutting device

PendingCN114411404AStrong applicabilityEasy cuttingSevering textilesTool bitManufacturing engineering

The invention discloses an umbrella fabric processing and cutting device, and relates to the technical field of umbrella fabric cutting devices, the umbrella fabric processing and cutting device comprises a machine tool and a cutting mechanism arranged on the machine tool and used for cutting umbrella fabric, and the cutting mechanism comprises a mounting power part, a plurality of groups of telescopic parts, a cutting part, a driving gear, a plurality of driven gears, a suspension rotating block, a plurality of expansion rods and an expansion dispersion wheel. Through the use of the cutting device, cloth can be directly cut into regular circles, then the circular cloth is trimmed into triangles or sectors, the step of cutting the cloth into rectangles can be omitted, more time is saved, meanwhile, the size of the cutting mechanism can be adjusted according to the size of an umbrella, the cutting mechanism is more flexible and high in applicability, and through the use of the positioning mechanism, the cutting efficiency is improved. According to the cloth cutting device, the position can be limited according to the size of cut cloth, and the situation that the cloth is curled in the cloth cutting process, accidents occur in cloth cutting, the cloth is wasted, and meanwhile a cutting tool bit is possibly damaged is avoided.

Owner:福建优安纳伞业科技有限公司

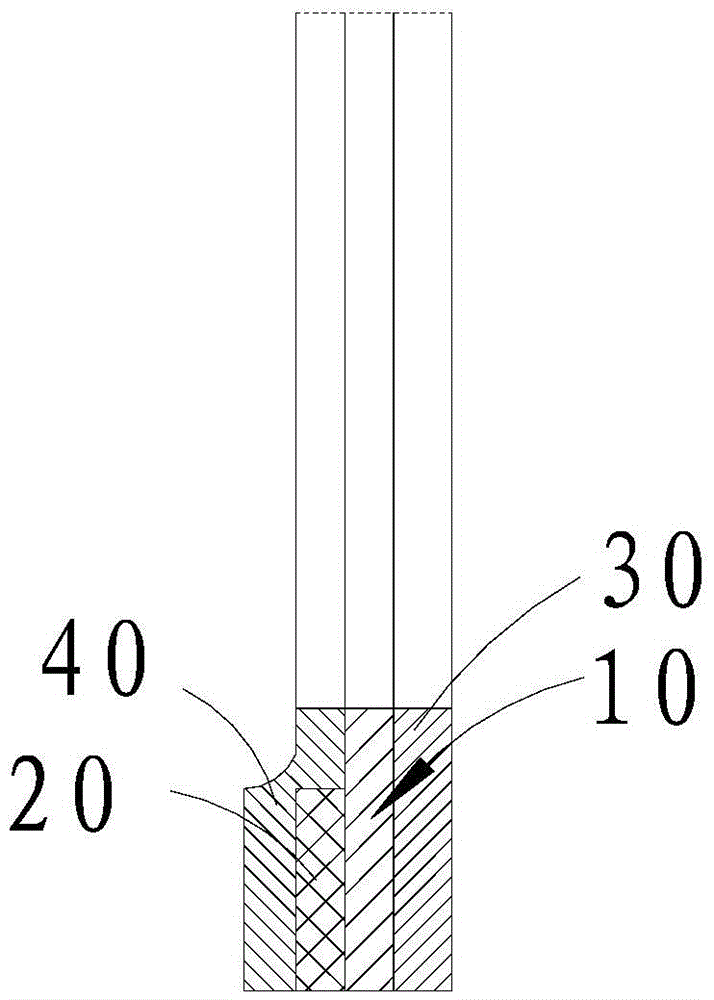

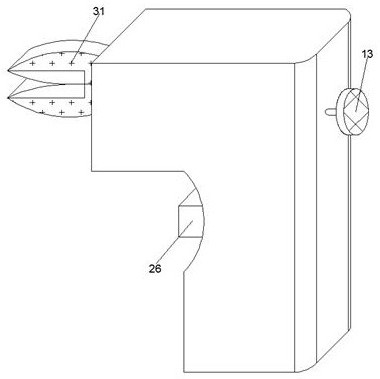

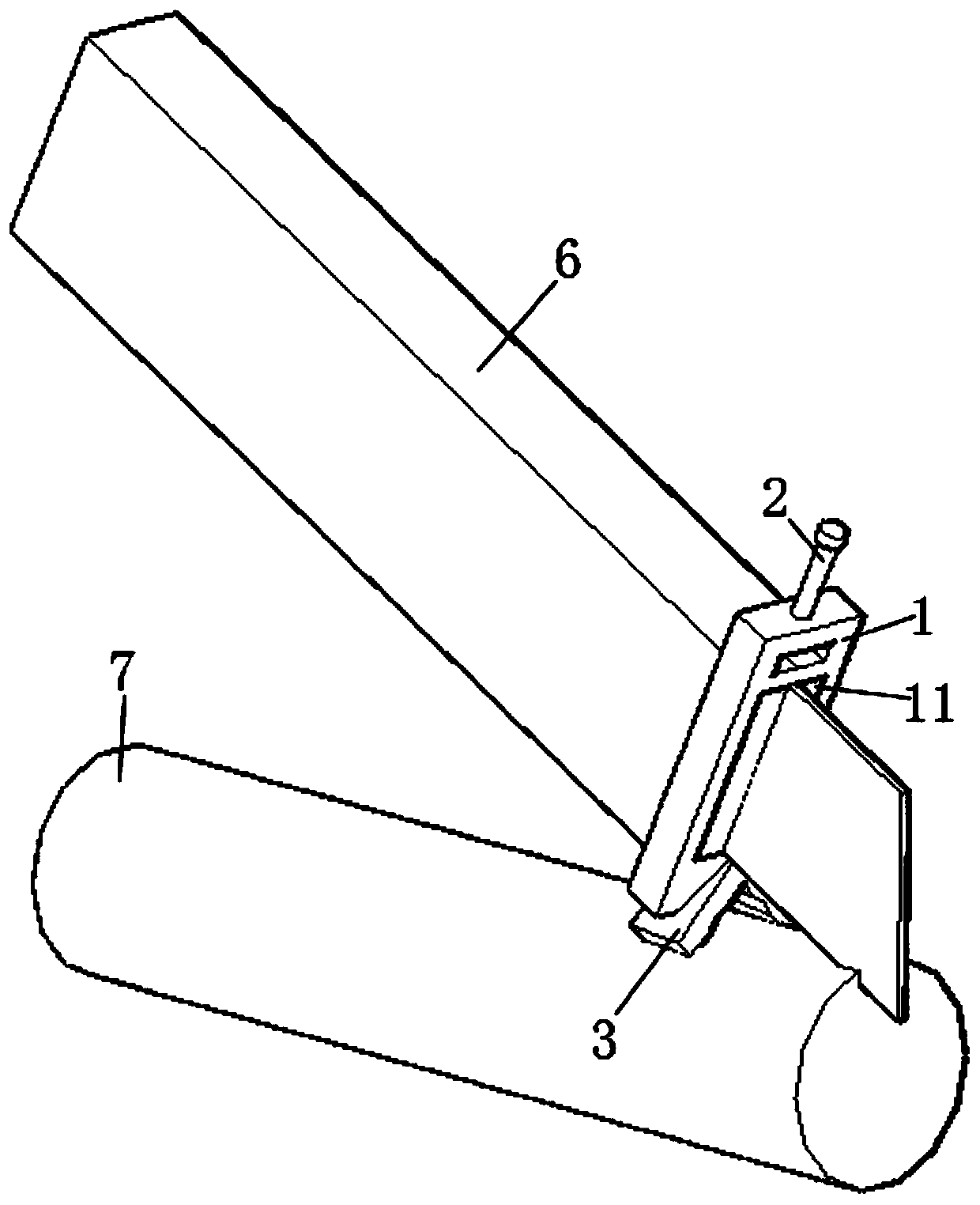

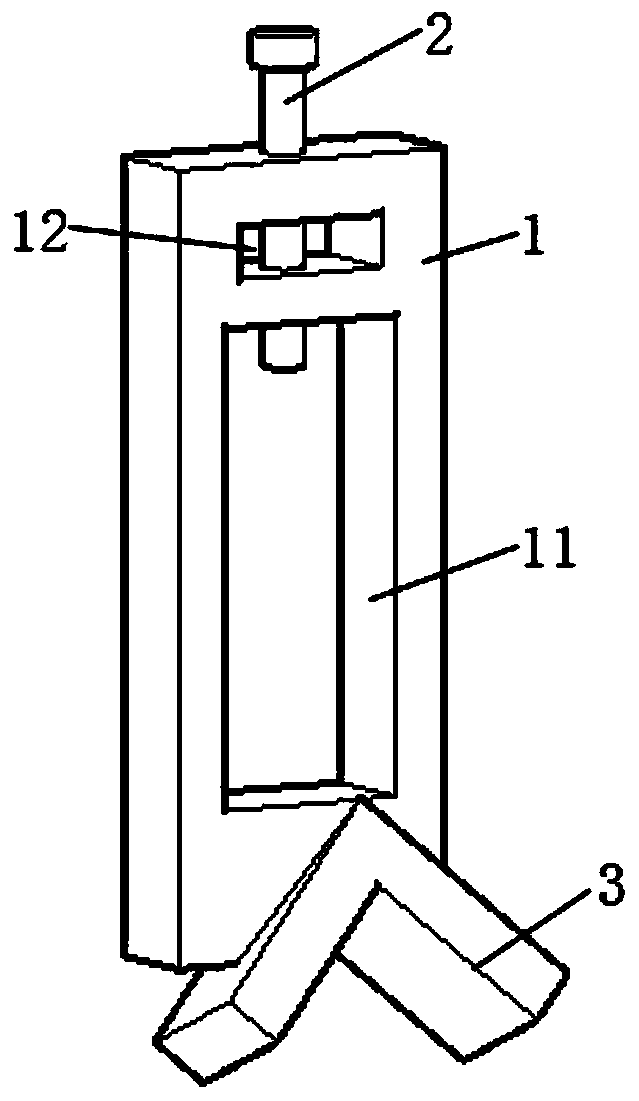

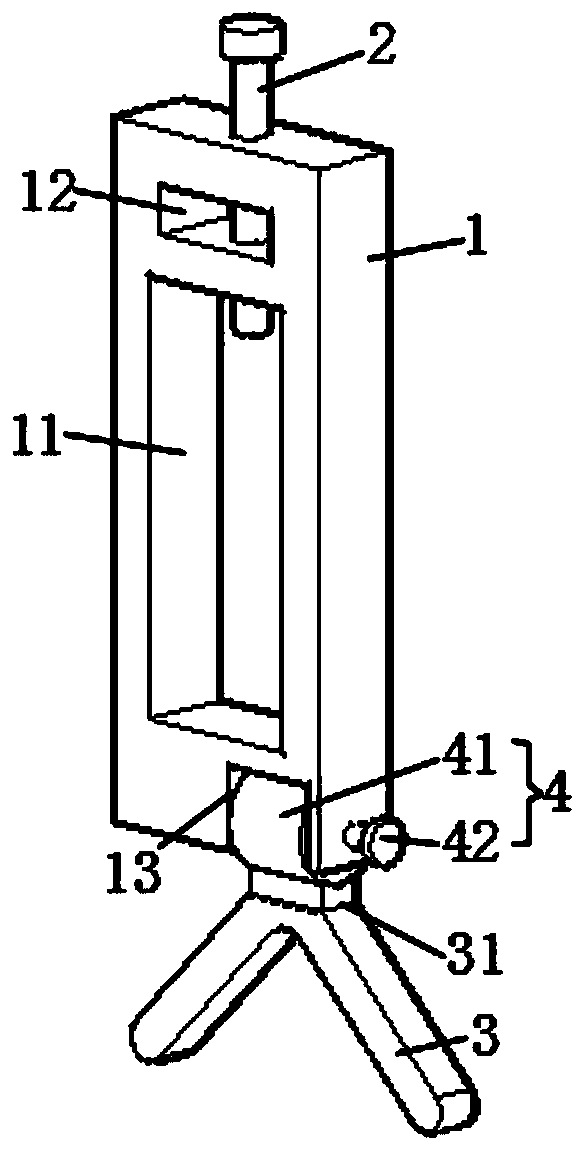

Anti-deviation device for cable cutting

PendingCN111293637AImprove the feelEasy cuttingApparatus for removing/armouring cablesApparatus for joining/termination cablesScrew threadElectric cables

The invention discloses an anti-deviation device for cable cutting. The anti-deviation device comprises an anti-deviation device body, a cutter locking bolt and a triangular clamp. The anti-deviationdevice body is fixed at the top of the triangular clamp; a cutter groove for mounting a cutter runs through the anti-deviation device body along the length direction of the cable; the opening of the clamping groove of the triangular clamp is arranged downwards, and the triangular clamp is vertically clamped at the top of a horizontally placed cable; the cutter locking bolt penetrates through a threaded hole in the anti-deviation device body and is matched with the threaded hole in the anti-deviation device body; and the extrusion end of the cutter locking bolt faces the cutter. The device is simple in structure, low in manufacturing cost and convenient to use.

Owner:HUAINAN MINING IND GRP

Breaking device for paper bag tube

The invention discloses a paper bag tube snapping device which comprises a device body, a cam, a swing arm, a swing arm shaft, a first connecting rod and a swing shaft are installed on the outer side of the device body, the cam is connected with the swing arm, the swing arm shaft is installed on the swing arm, and the first connecting rod is connected with the swing arm and the swing shaft. A fourth belt, a driven roller, a second belt and a first belt are arranged in the device body, an air cylinder is installed on the inner side of the upper end of the device body, a third connecting rod and a fourth connecting rod are connected to the outer side of the fourth belt, and a fourth clamping roller and a driving roller are arranged in the movable roller. According to the snapping device for the paper bag cylinder, the cutter does not need to be adjusted frequently, meanwhile, the tensioned paper bag cylinder is more convenient to cut, the front end of the paper bag cylinder enters the belt when the previous bag cylinder is snapped, the continuity of paper falling is guaranteed, the production efficiency is improved, the problem that the cutter is difficult to adjust is solved, and the production efficiency and the yield are improved.

Owner:苏州市易登机械有限公司

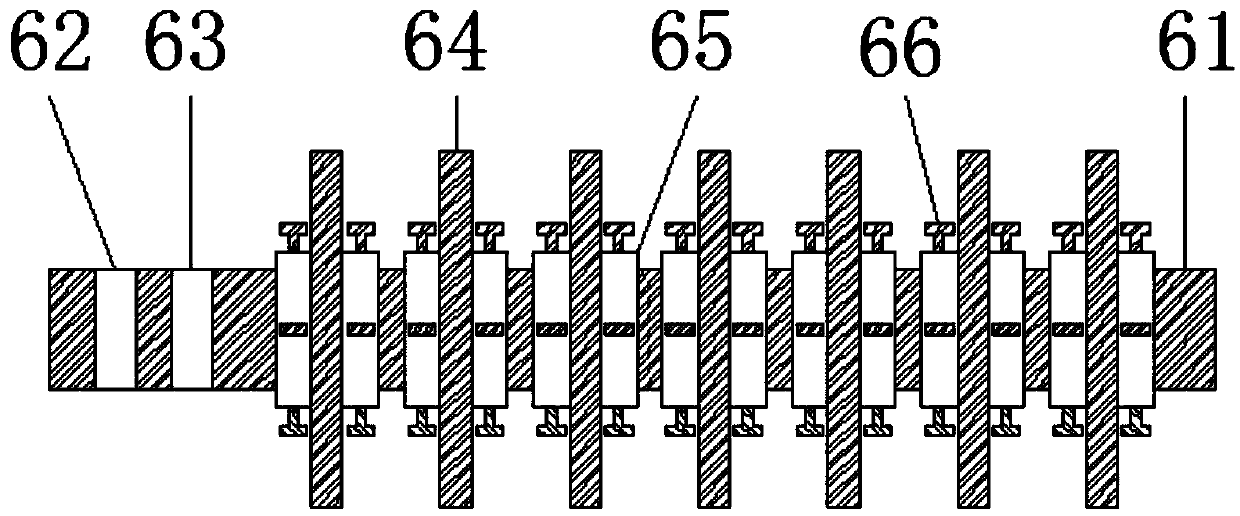

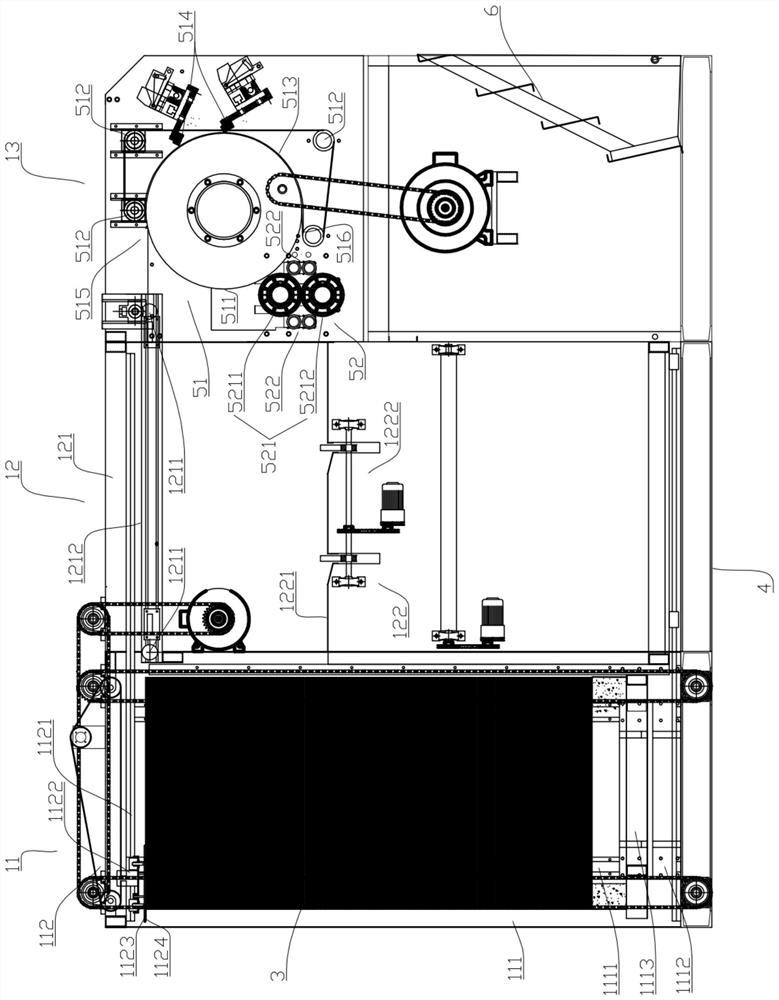

Paper board grooving and slitting all-in-one machine

InactiveCN112123866AOutstanding and Beneficial Technical EffectsIncrease productivityPaper-makingBox making operationsPaperboardMachining

The invention belongs to the technical field of paper box machining, and particularly provides a paper board grooving and slitting all-in-one machine. The all-in-one machine is composed of a longitudinal grooving and slitting machine and a transverse grooving and slitting machine. The transverse grooving and slitting machine is arranged on one side of the longitudinal grooving and slitting machine. The longitudinal grooving and slitting machine and the transverse grooving and slitting machine can carry out grooving and slitting work in the longitudinal direction and the transverse direction atthe same time, grooved portions and slit portions are mutually partitioned, grooving and slitting are not carried out at the same time, and the situation that due to mutual influence, machining precision is not high is avoided. The machine has a function of efficiently machining the lid and tray cover paper box, has the advantages of being high in machining precision and full automatic in whole process, and is particularly suitable for grooving and slitting operation of large-thickness paper boards such as grey paper boards and density boards.

Owner:温州市本色机械有限公司

Laser shearing equipment for assembling electric tower

InactiveCN113305452AEasy cuttingImprove work efficiencyLaser beam welding apparatusStructural engineeringIndustrial engineering

The invention relates to the technical field of cutting machinery, in particular to laser shearing equipment for assembling an electric tower. The laser shearing equipment comprises a bottom plate and a sliding mechanism, two groups of fixing tools are arranged at the top of the bottom plate, a pipe fitting is clamped on the two groups of fixing tools, and the pipe fitting is kept transverse. The sliding mechanism is mounted on the bottom plate, a square sliding barrel is arranged at the top of the sliding mechanism, a direction moving sleeve is slidably sleeved with the square sliding barrel, and the top of the direction moving sleeve extends out of the square sliding barrel. According to the equipment, the cutting mode can be effectively simplified, the working efficiency is improved, manpower is saved, meanwhile, the running stability of the equipment is improved, the cutting work of the pipe fitting is continuously carried out, the flatness of a notch and the cutting uniformity are effectively improved, the cutting precision and the machining quality are improved, and the practicability is improved.

Owner:SHANDONG LUNENG TAISHAN TOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com