New energy battery side plate film pasting device

A new energy, battery-side technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, transportation and packaging, etc., can solve the problem of inconvenient replacement of film drums, and achieve the effect of easy replacement and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

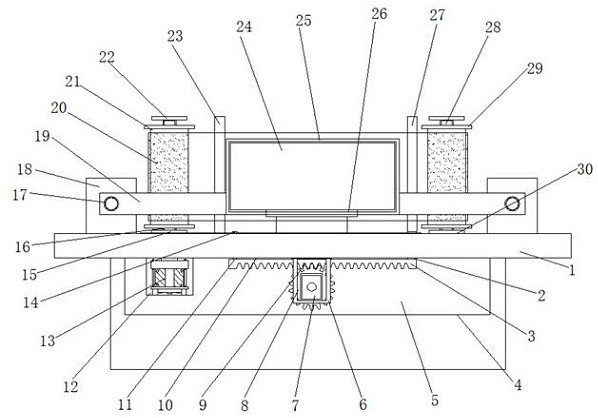

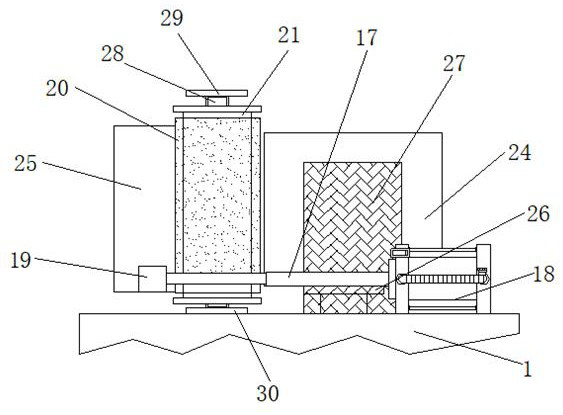

[0026] Example 1: See Figure 1-6 , a new energy battery side panel film sticking device, including a fixed platform 1 and a base 4, the bottom of the fixed platform 1 is fixedly connected with the base 4, the top of the fixed platform 1 is fixedly installed with a support seat 26, and one side of the support seat 26 is set There is a first fixed plate 23, a new energy battery body 24 is provided on the top of the support seat 26, a cylinder 18 is fixedly installed on one side of the top of the fixed table 1, a guide groove 10 is provided inside the top of the fixed table 1, and a guide groove 10 is provided inside the base 4. There is a first reserved groove 5, a first base 15 is fixedly installed on one side of the top of the fixed platform 1, a second base 30 is fixedly installed on the other side of the top of the fixed platform 1, and a second base 30 is fixedly installed on one side of the base 4 inside. Two reserved slots 12;

[0027] The inside of the second reserved ...

Embodiment 2

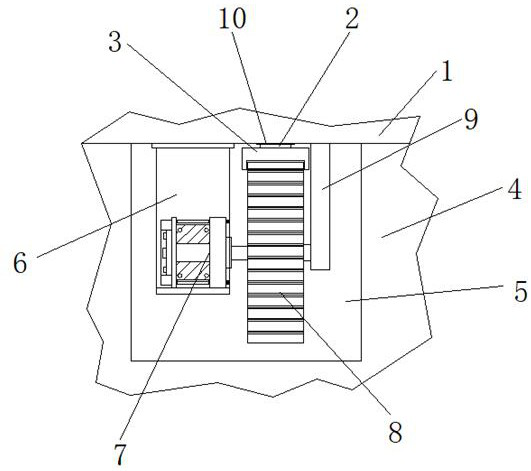

[0029] Embodiment 2: the inside of the first reserved groove 5 is fixedly installed with a fixed frame 6, and the inside of the fixed frame 6 is fixedly installed with a first drive motor 7, and the output end of the first drive motor 7 is fixedly connected with a gear 8 through a transmission shaft. One end of the gear 8 is movably connected with a mount 9, and the top of the mount 9 is fixedly connected with the bottom of the fixed table 1;

[0030] Specifically, such as figure 1 , image 3 and Image 6 As shown, open the first driving motor 7, and drive the gear 8 to rotate through the transmission shaft. Because one end of the gear 8 is provided with a mounting seat 9, at this moment, one end of the gear 8 will rotate in the interior of the mounting seat 9 one end.

Embodiment 3

[0031] Embodiment 3: the top of the gear 8 is provided with a toothed rod 3, one side of the top of the toothed rod 3 is fixedly connected with the first connecting rod 2, and the other side of the top of the toothed rod 3 is fixedly connected with the second connecting rod 11, and the first connected The top end of the rod 2 passes through the inside of the guide groove 10 and is fixedly connected with a second fixing plate 27;

[0032] The top end of the second connecting rod 11 runs through the inside of the guide groove 10 and is fixedly connected to the limit block 14. The width of the limit block 14 is greater than the width of the guide groove 10. The first connecting rod 2 and the second connecting rod 11 can be placed in the guide groove 10. The internal sliding of the gear rod 3 and the gear 8 are meshed;

[0033] Specifically, such as figure 1 , image 3 and Image 6As shown, because the top of the gear 8 is meshed with the gear rod 3, when the gear 8 rotates, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com