High-toughness mining chain steel and manufacturing method thereof

A manufacturing method, chain steel technology, applied in the direction of manufacturing tools, metal chains, furnaces, etc., can solve problems such as brittle fracture, safety accidents, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

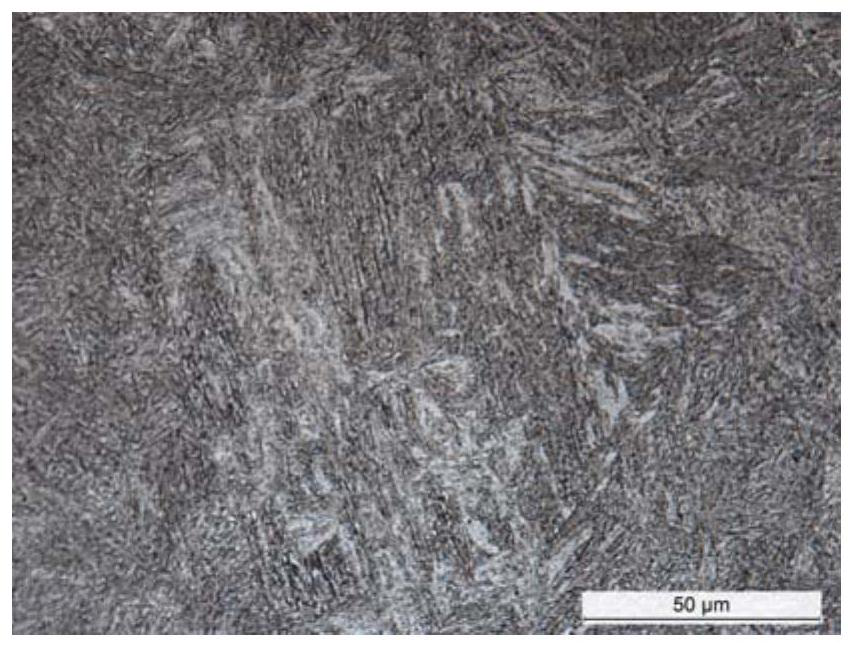

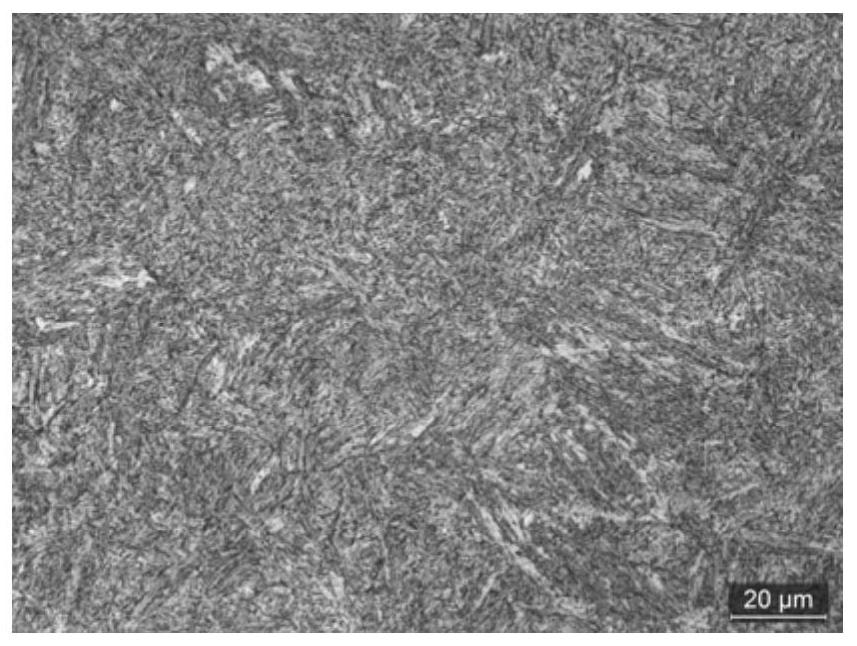

Image

Examples

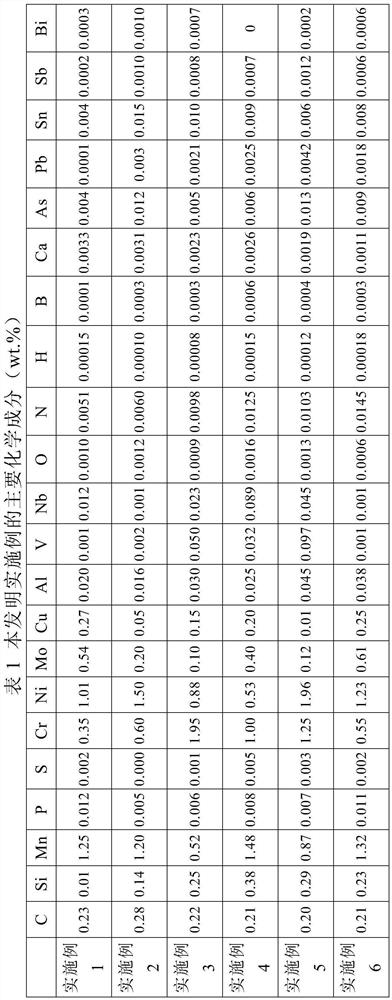

Embodiment 1

[0074] According to the chemical composition shown in Table 1, the electric furnace is smelted, and after refining and vacuum treatment, it is cast into a continuous casting slab, and the continuous casting slab is heated to 1050 ° C, and the holding time is 4 hours; The rolling temperature is 800°C, and the size of the middle billet is 200×200mm. The intermediate billet is heated to 1050°C, and the holding time is 24 hours. After being descaled by high-pressure water, rolling begins. The final rolling temperature is 850°C, and the finished bar size is φ50mm. Cool in air after rolling. The quenching heating temperature is 850°C, the heating time is 60min, the tempering temperature is 390°C, the tempering time is 90min, and air cooling after tempering.

Embodiment 2

[0076] The implementation is the same as in Example 1, wherein the heating temperature is 1080°C, the holding time is 3h, the final rolling temperature is 880°C, and the size of the intermediate billet is 220×220mm. The intermediate billet is heated to 1120°C, the holding time is ≥3h, the final rolling temperature is 850°C, and the specification of the finished bar is φ75mm. Cool in air after rolling. The quenching heating temperature is 870°C, the heating time is 100min, the tempering temperature is 550°C, the tempering time is 60min, and water cooling after tempering.

Embodiment 3

[0078] The implementation method is the same as that in Example 1, wherein the heating temperature is 1120° C., the holding time is 8 hours, the final rolling temperature is 940° C., and the size of the intermediate billet is 260×260 mm. The intermediate billet is heated to 1200°C, the holding time is 5h, the final rolling temperature is 880°C, and the specification of the finished bar is φ100mm. Cool in air after rolling. The quenching heating temperature is 890°C, the heating time is 150min, the tempering temperature is 430°C, the tempering time is 100min, and air cooling after tempering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com