Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Reasonable design process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

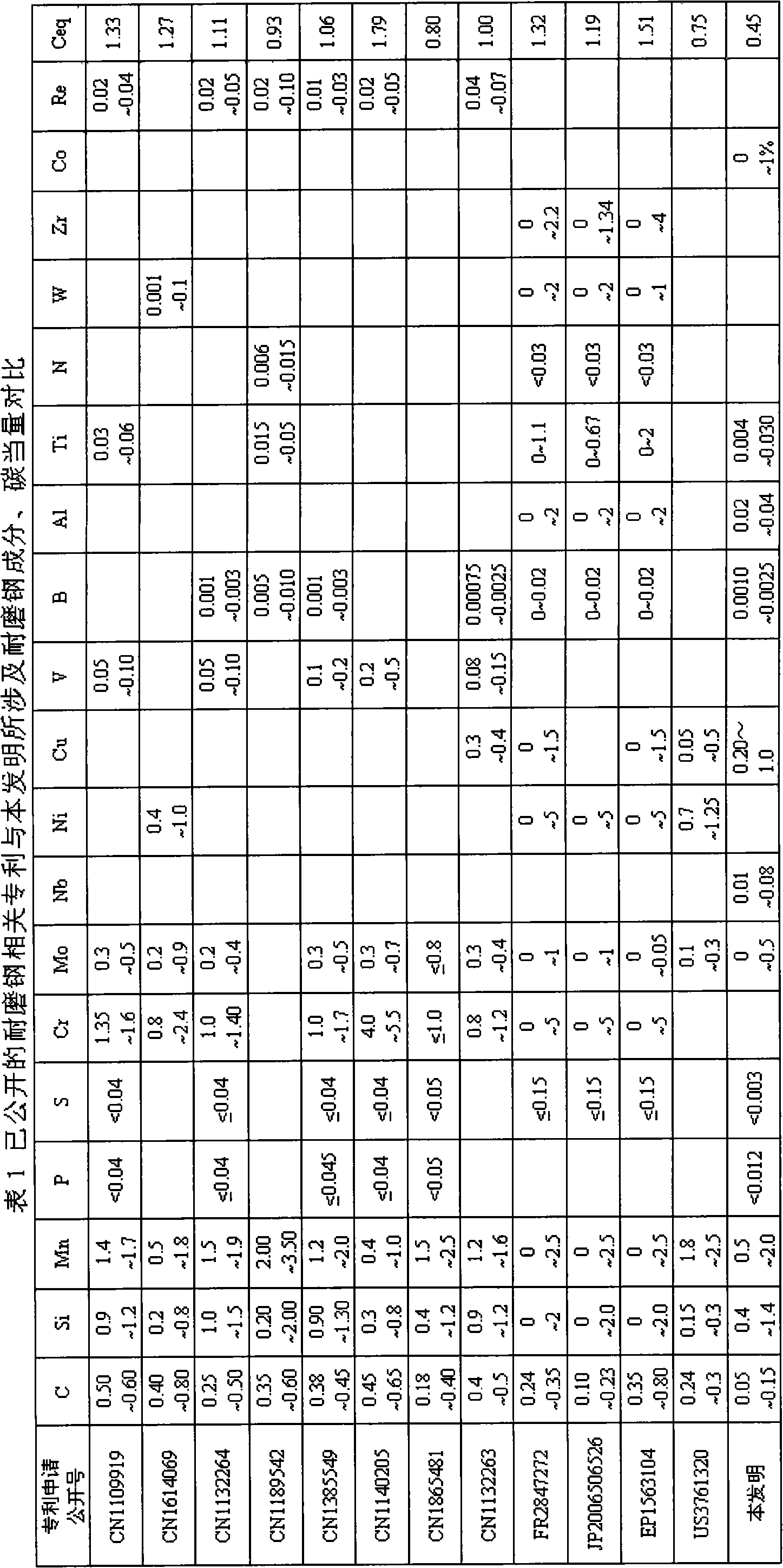

600HB-grade wear resistant steel plate and its manufacturing method

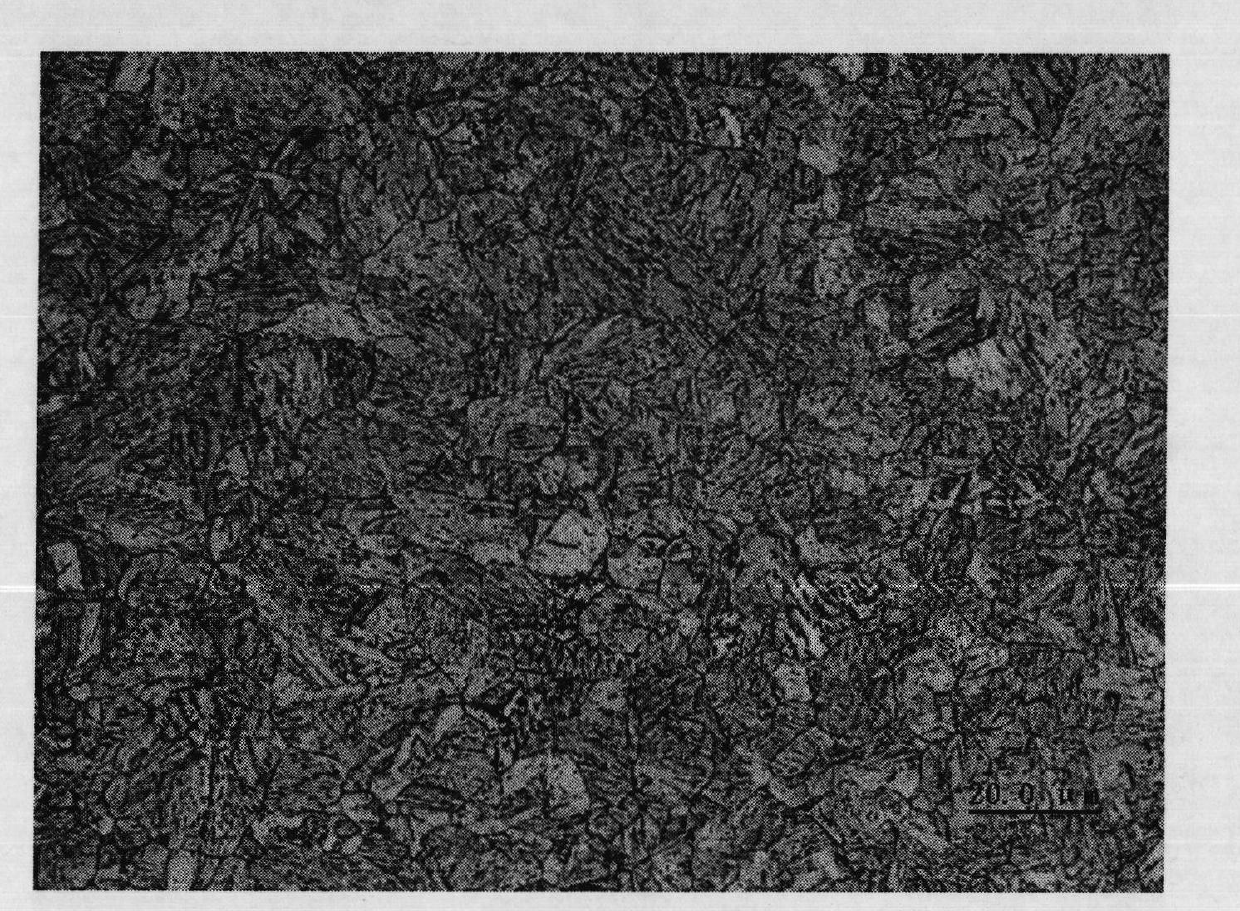

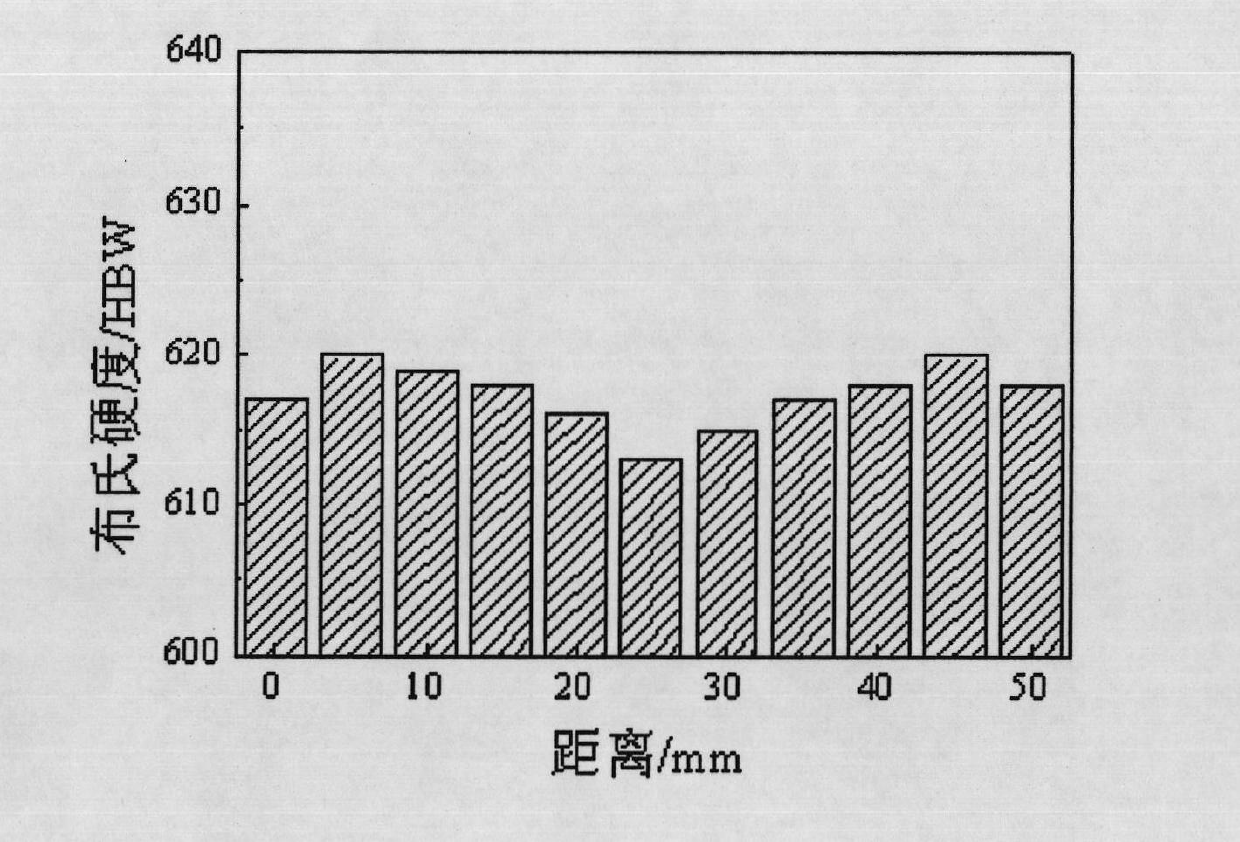

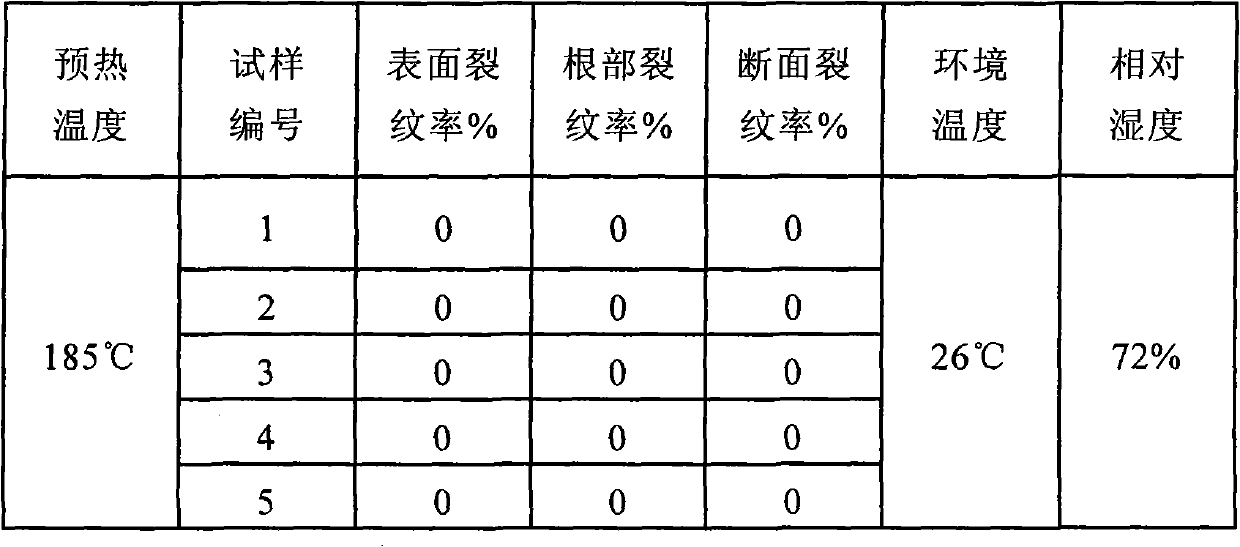

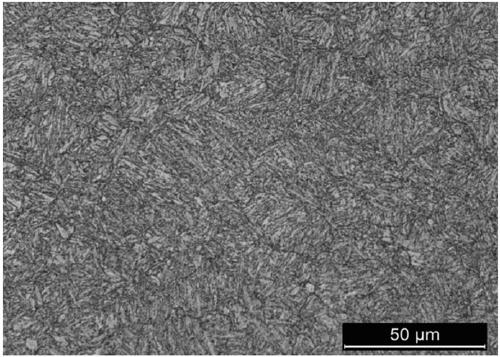

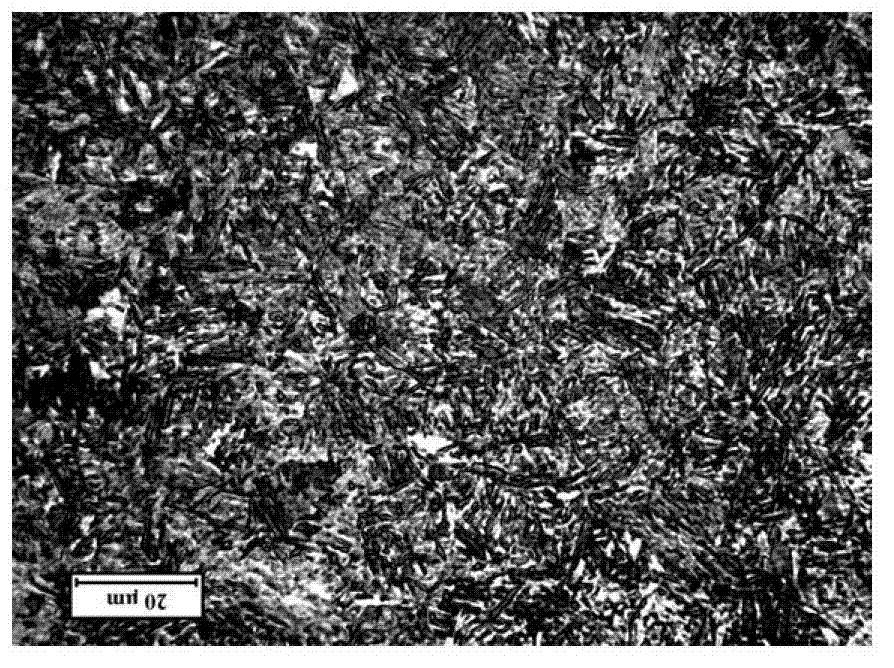

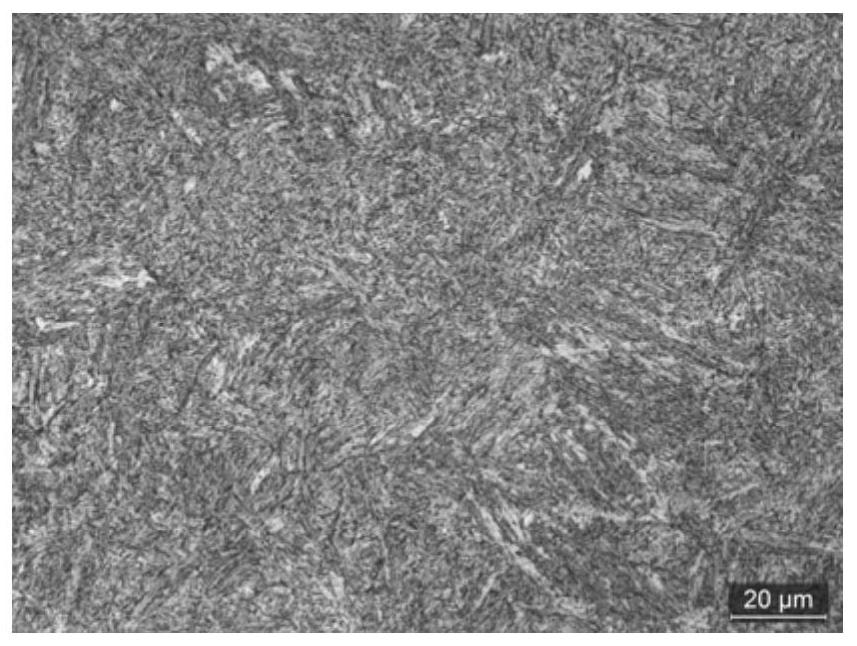

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balance Fe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance and excellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

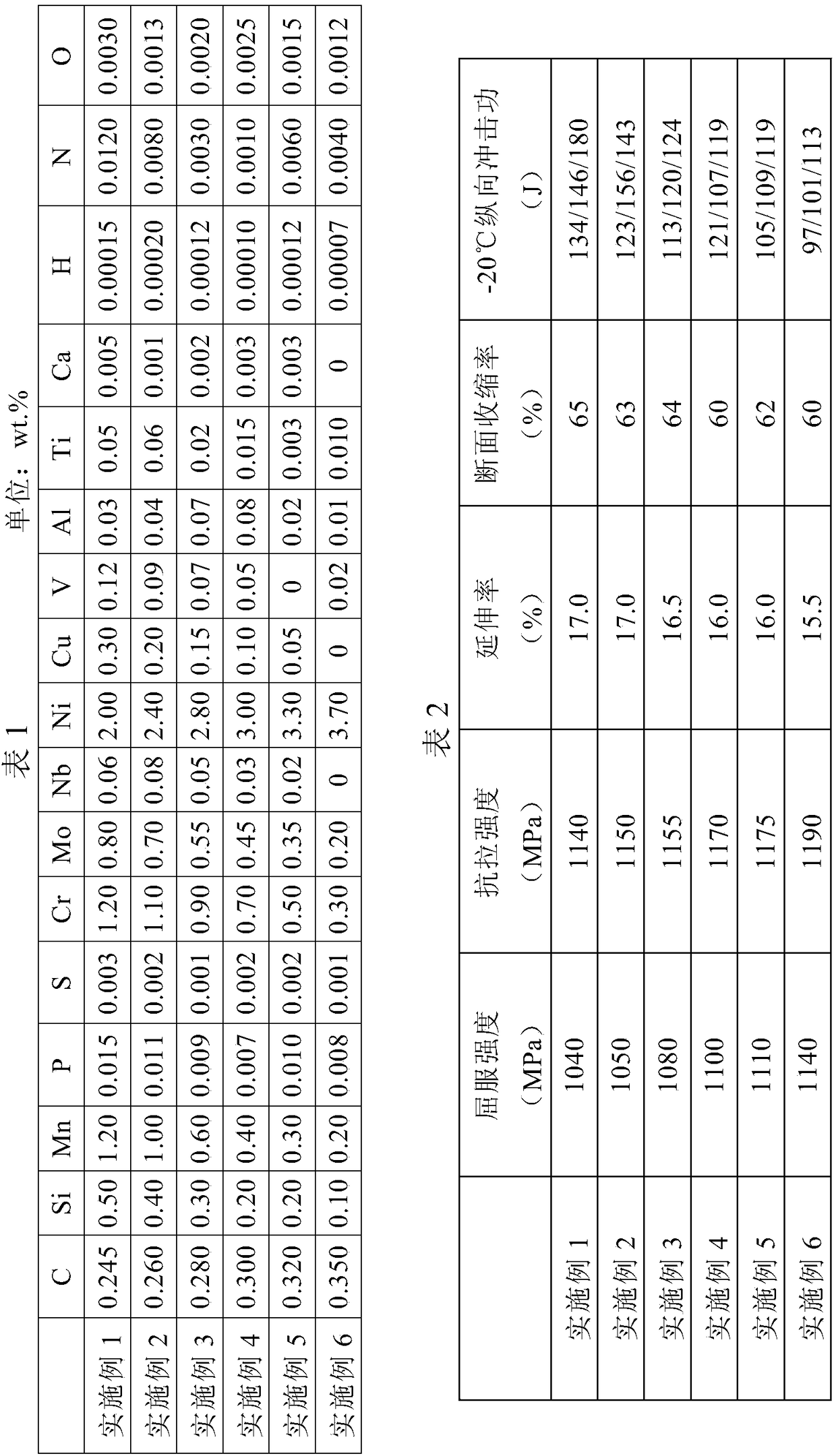

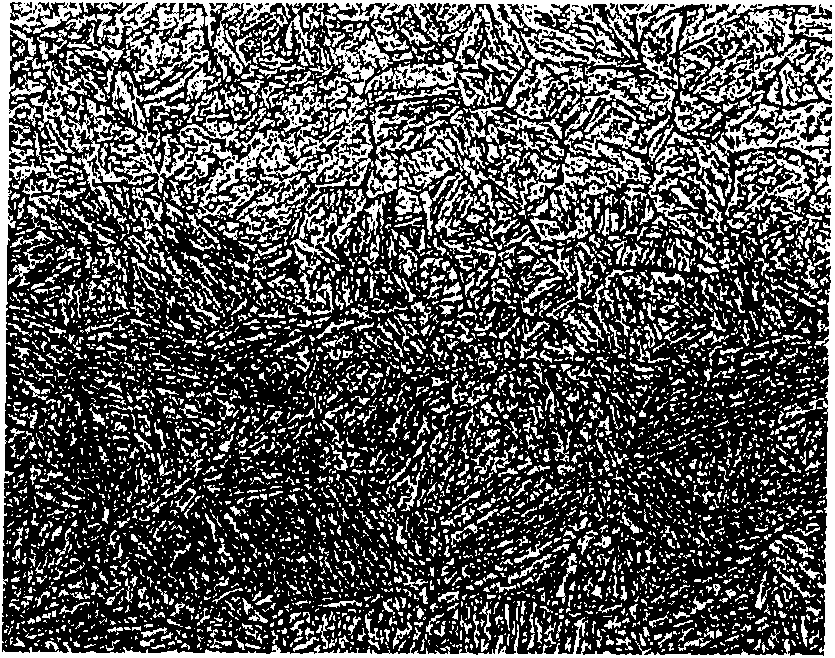

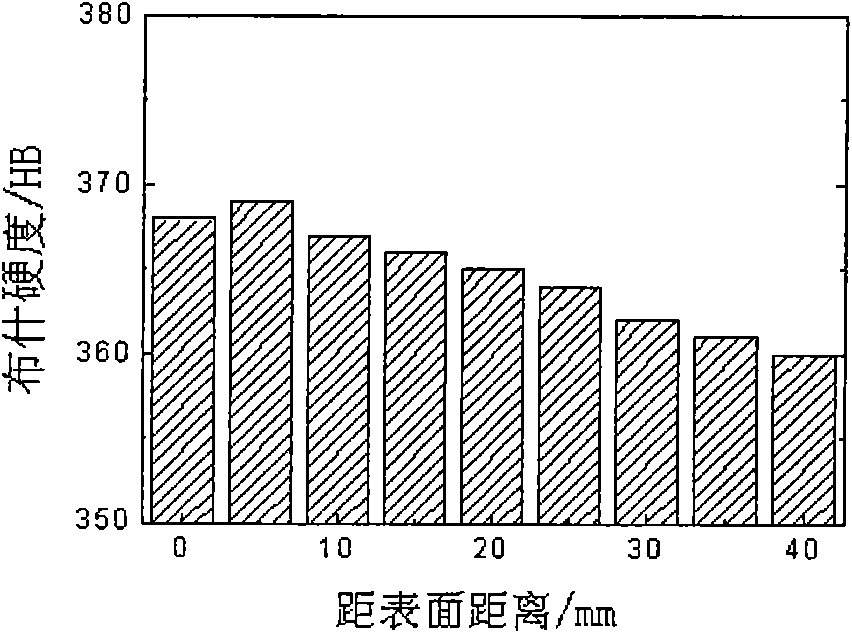

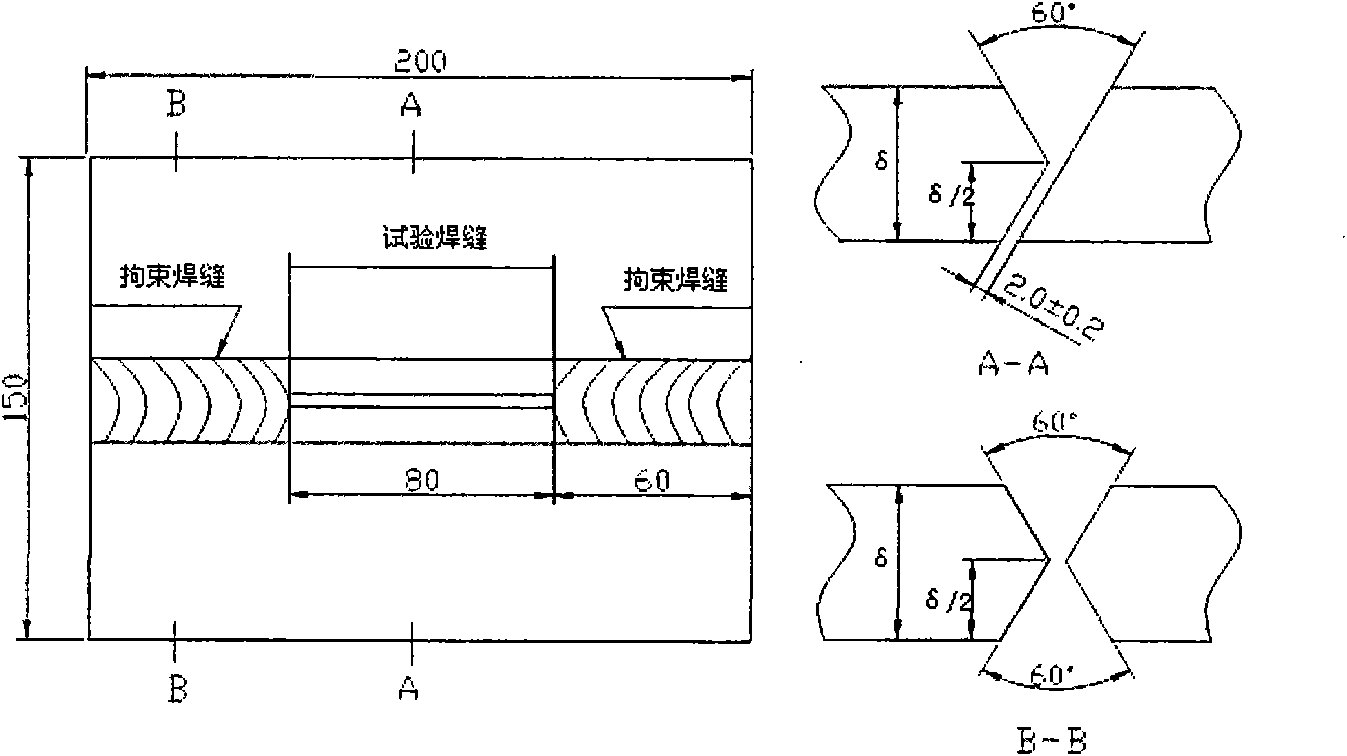

Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

InactiveCN109136737AImprove low temperature impact toughnessImprove tensile propertiesShrinkage rateUltimate tensile strength

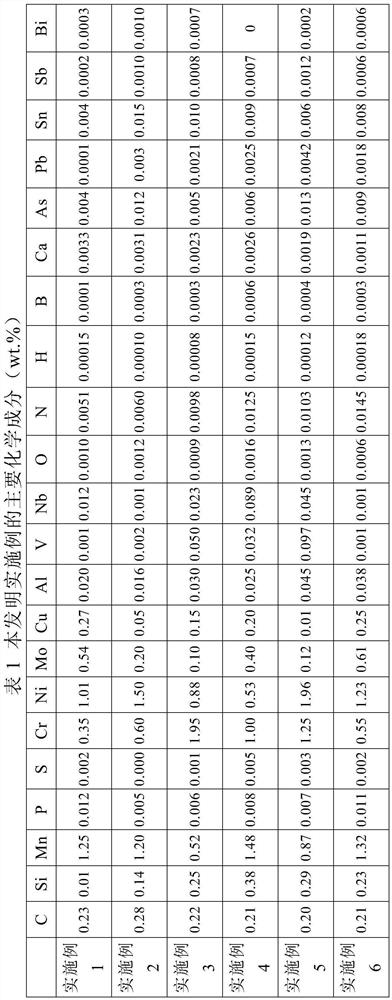

The invention discloses ultrahigh tough steel with tensile strength of 1100 Mpa and a manufacturing method thereof. Chemical components of the tough steel comprises, by weight, 0.245-0.350% of C, 0.10-0.50% of Si, 0.20-1.20% of Mn, P less than or equal to 0.015%, S less than or equal to 0.003%, 0.30-1.20% of Cr, 0.20-0.80% of Mo, 2.00-3.70% of Ni, 0-0.30% of Cu, 0-0.08% of Nb, 0-0.12% of V, 0.01-0.08% of Al, 0.003-0.06% of Ti, Ca less than or equal to 0.005%, H less than or equal to 0.002%, N less than or equal to 0.0120%, O less than or equal to 0.0030%, Fe and inevitable impurities. The preparation method adopts quenching plus tempering heat treatment, and tempered martensites plus tempered bainites and residual austenite tissue are obtained. The yield strength of steel is greater than or equal to 900 Mpa, the tensile strength is greater than or equal to 1100 Mpa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 70 J, the elongation rate is greater than or equal to 15%, the shrinkage rate of a fracture surface is greater than or equal to 50%, good strength, low-temperature toughness and plasticity are achieved, and the ultrahigh tough steel can be used for manufacturing high-performance ocean platform mooring cables of R6 grade and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

High-flexibility wear-resistant steel plate and manufacturing method thereof

ActiveCN101775539AImprove wear resistanceImprove low temperature toughnessMicro structureForeign matter

The invention provides a high-flexibility wear-resistant steel plate, which is characterized by comprising the following chemical components by weight percent: 0.04 to 0.11 percent of C, 0.10 to 0.50 percent of Si, 0.50 to 1.50 percent of Mn, less than 0.015 percent of P, less than 0.010 percent of S, 0 to 0.60 percent of Cr, 0 to 0.50 percent of Mo, 0 to 0.80 percent of Ni, 0 to 0.050 perent of Nb, 0.005 to 0.0040 percent of B, 0.010 to 0.060 percent of Al and 0.005 to 0.060 percent of Ti, and the surplus is Fe and inevitable foreign matters; and the content of Si, Mn and Cr satisfies that: Si+Mn+Cr is less than or equal to 2.4 percent and more than or equal to 1.30 percent; and the content of Mo, Ni and Nb satisfies that: Mo+Ni+Nb is less than or equal to 1.10 percent more than or equal to 0.10 percent. The hardness of the high-flexibility wear-resistant steel plate is more than 350 HB, the longitudinal impact power is more than 100J at the temperature of minus 40 DEG C, the micro-structure is of bainite or martensite, and the welding performance is excellent. The wear-resistant steel plate has simple and easy production technology and excellent low-temperature flexibility and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

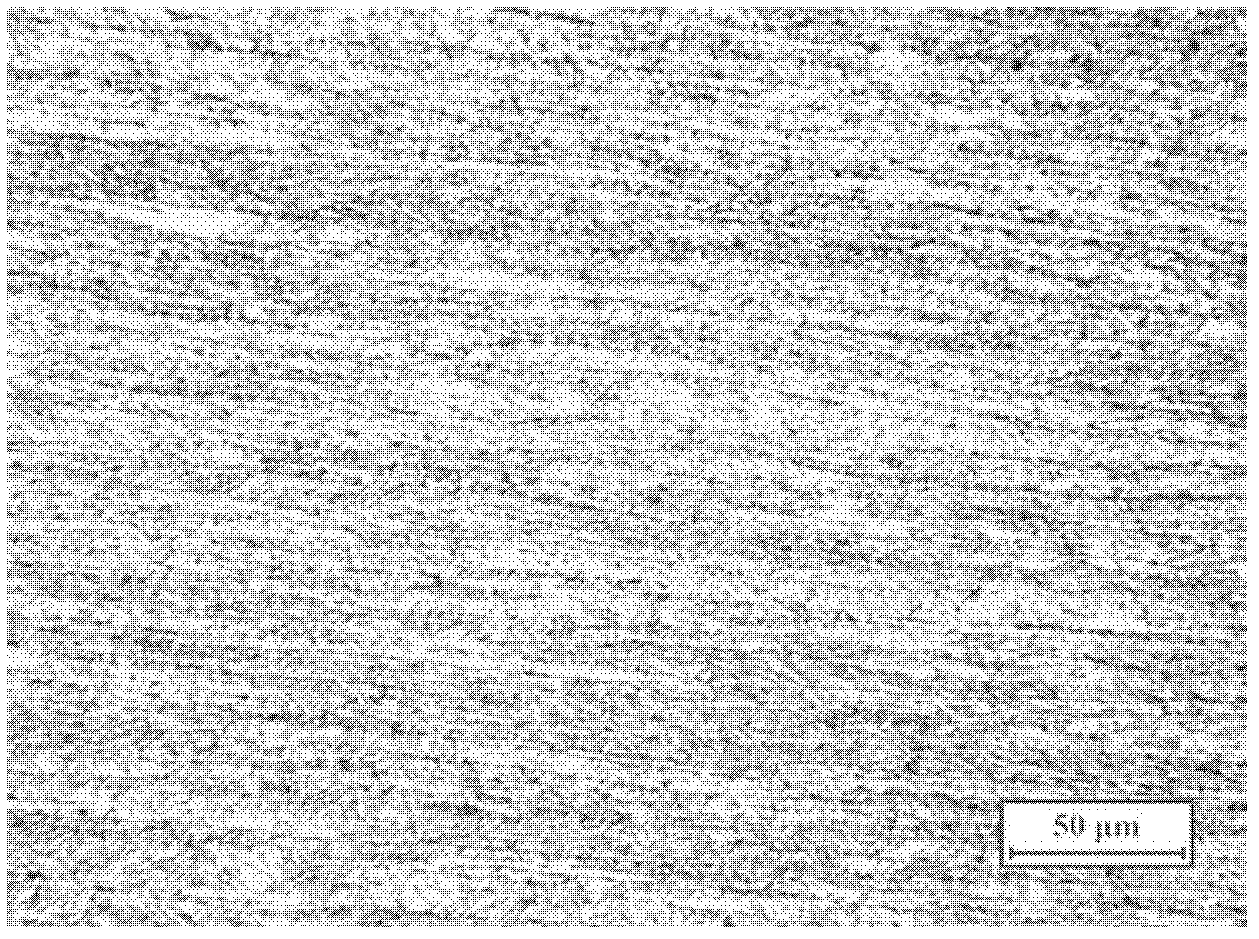

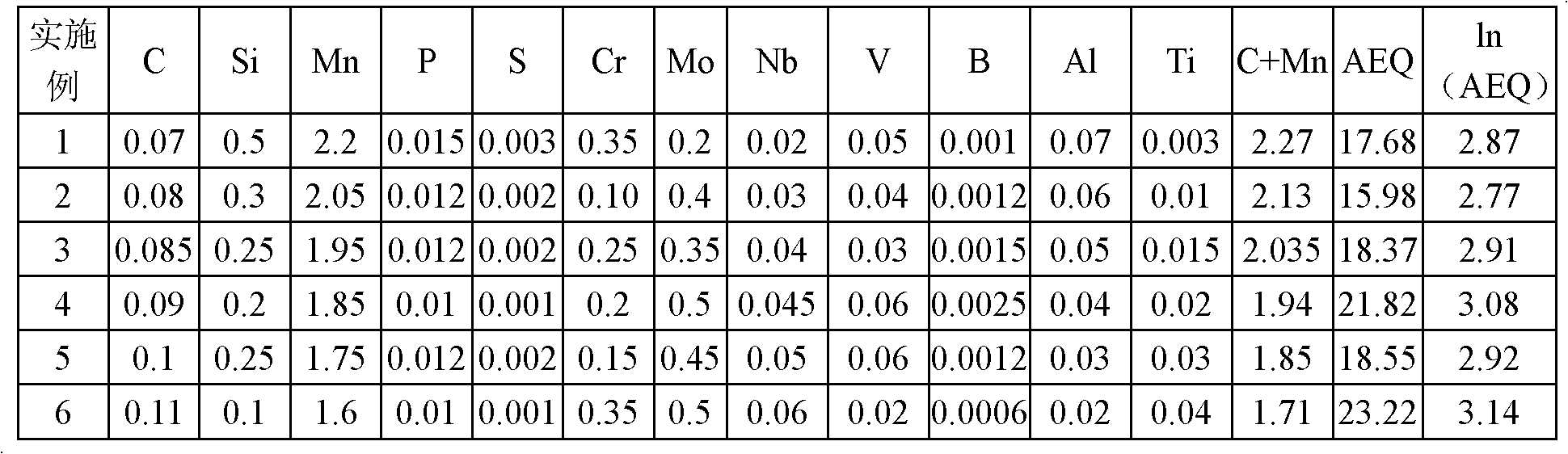

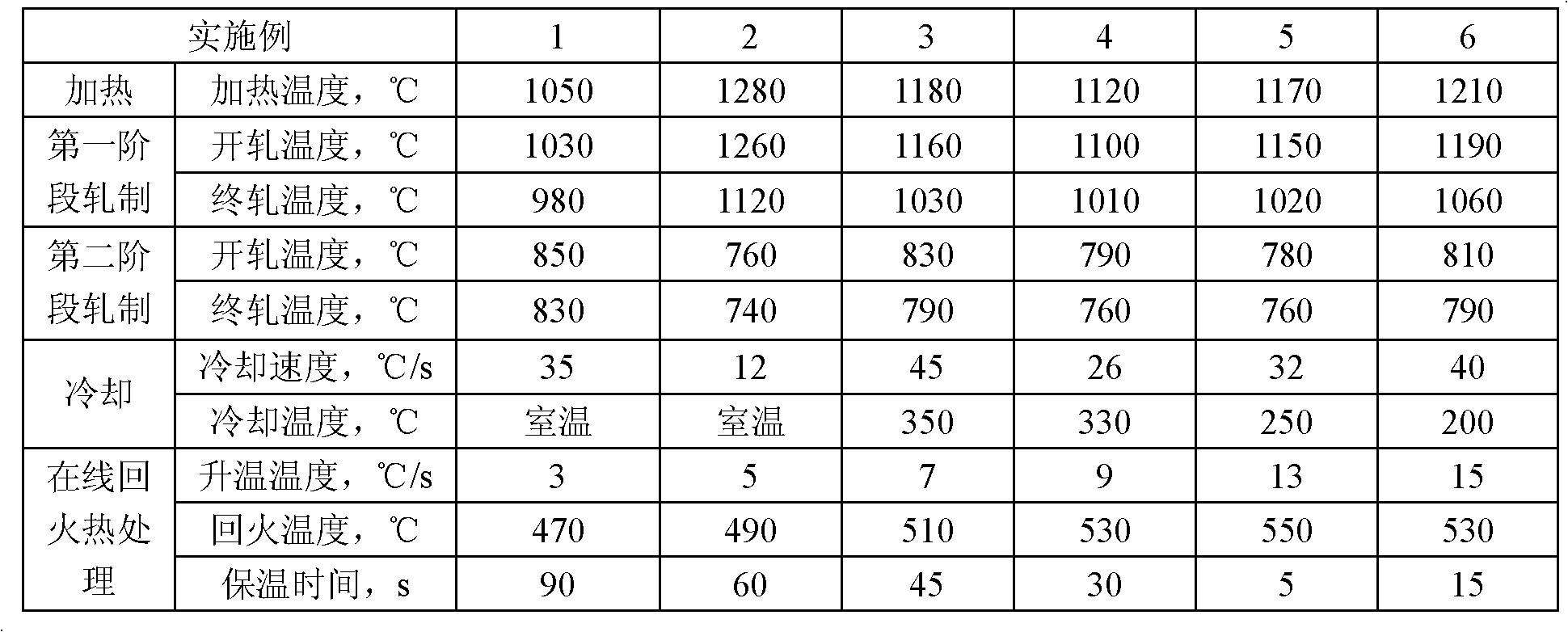

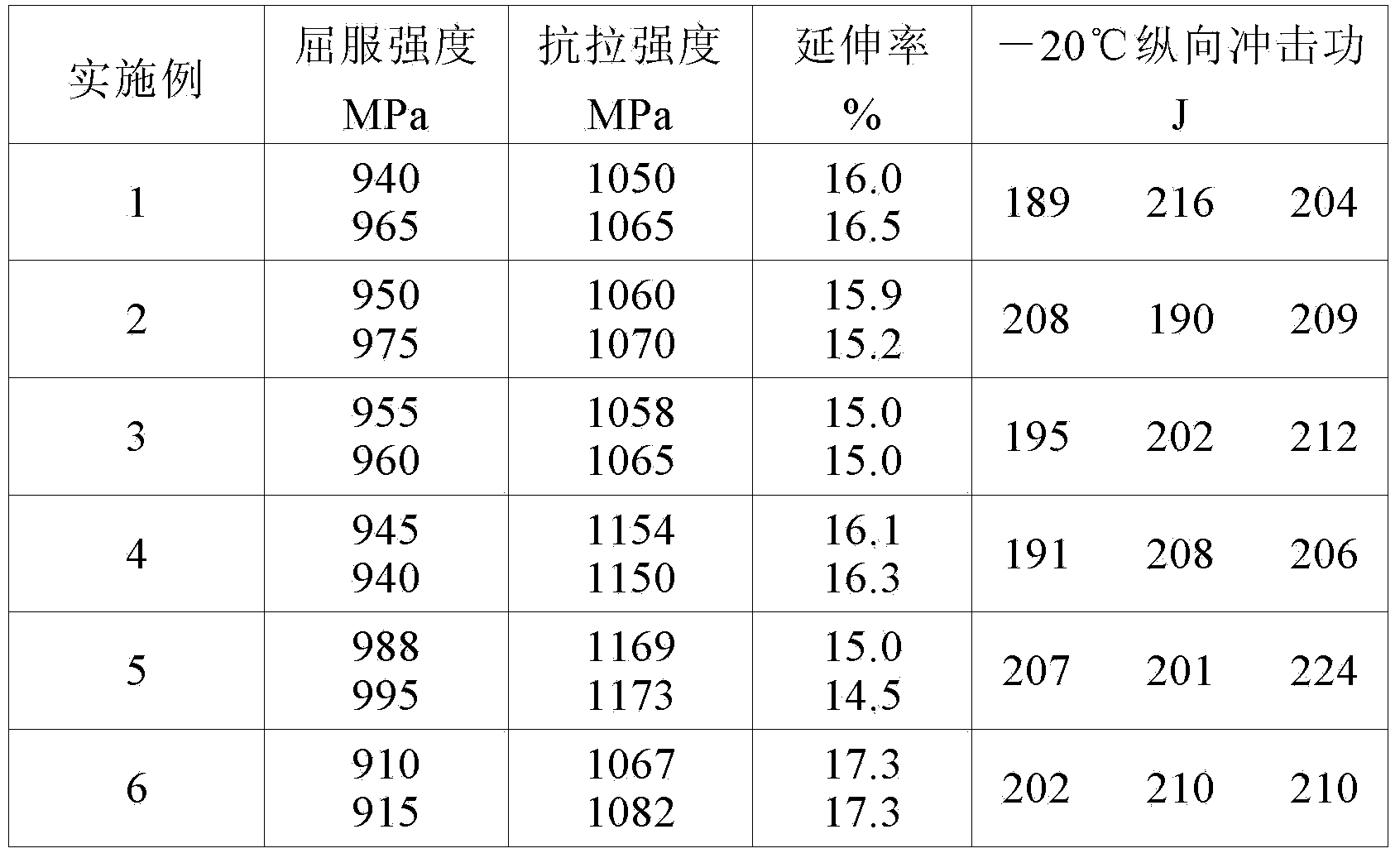

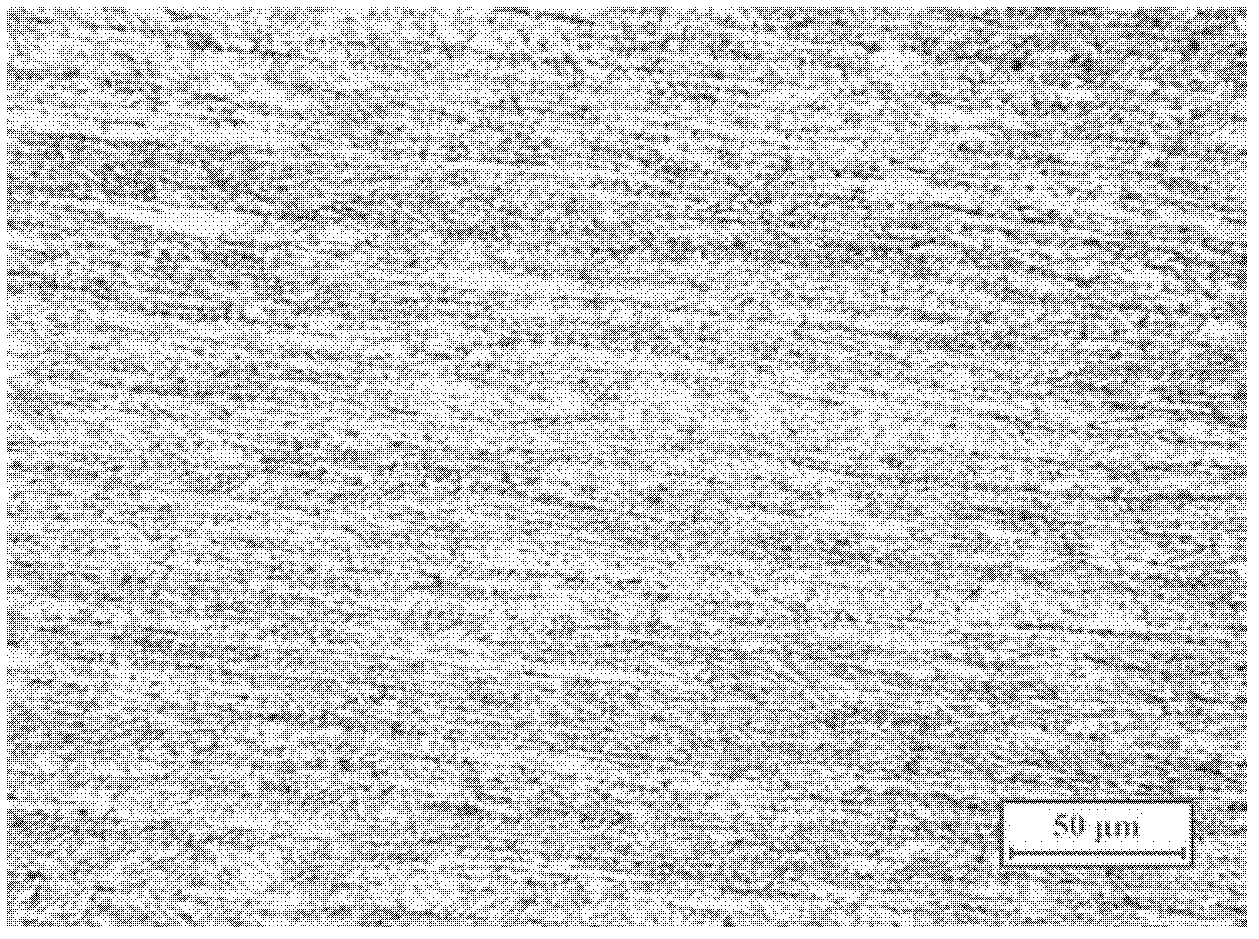

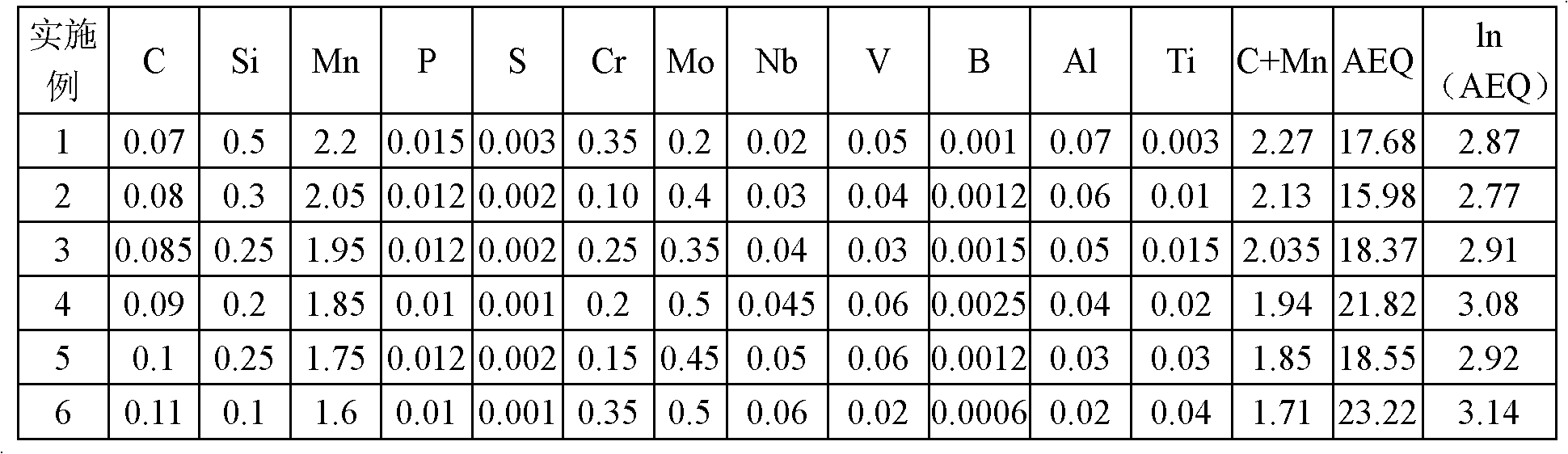

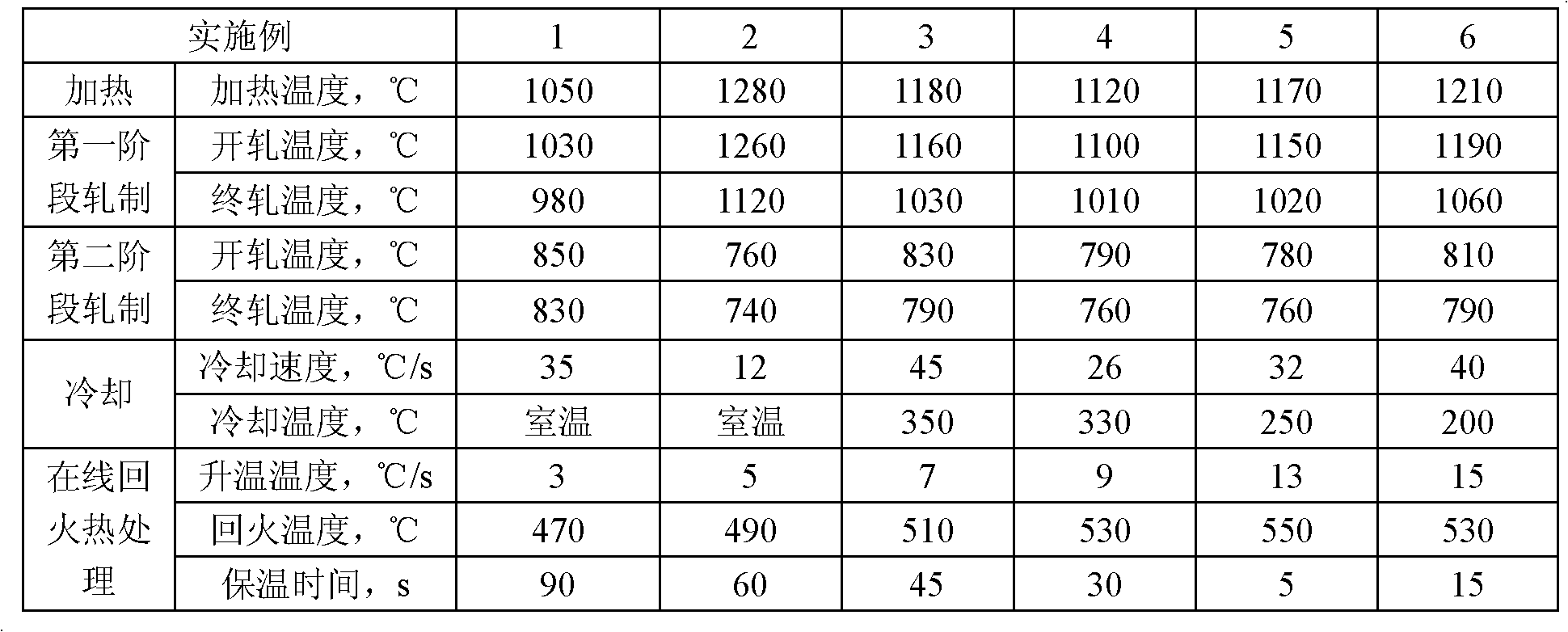

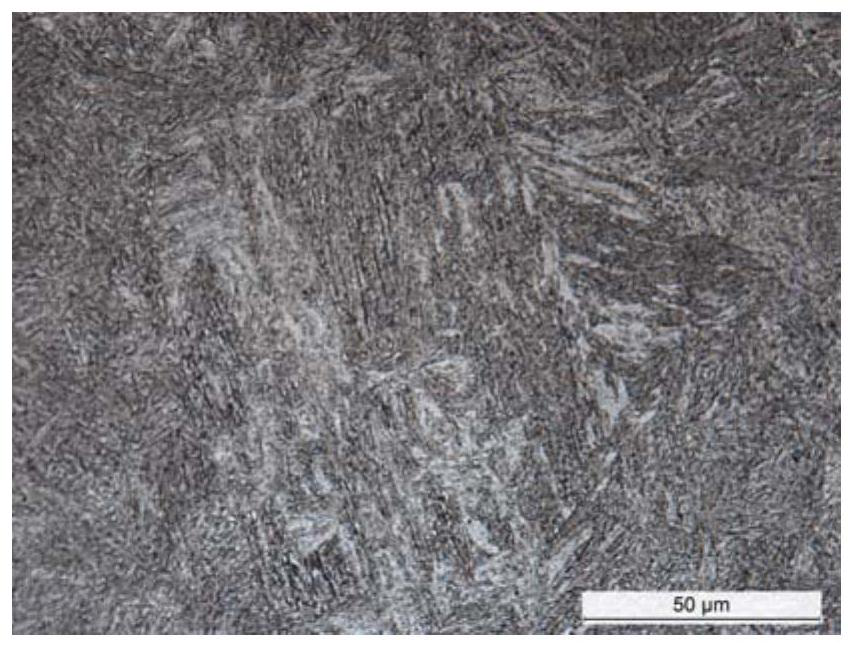

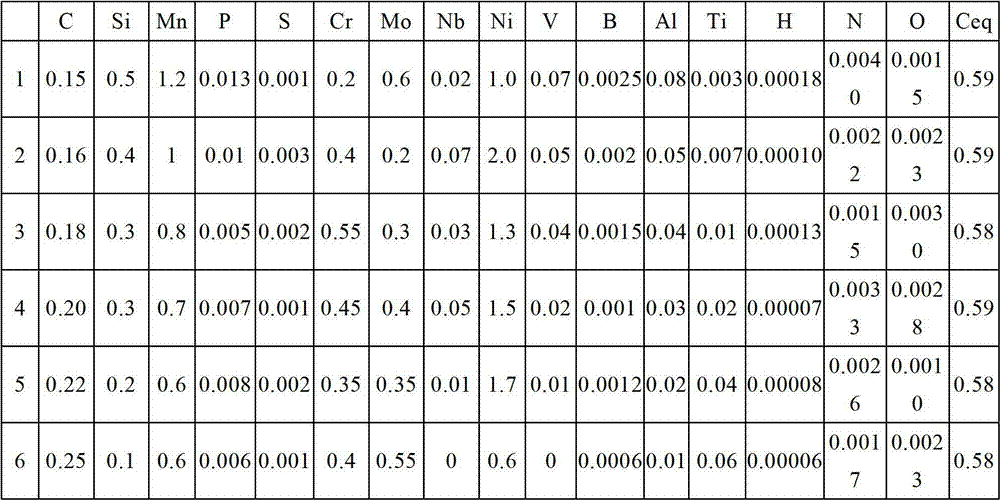

Steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing polystyrene extruded sheet with compressive strength larger than 700 kPa

InactiveCN101890782AReasonable productivityReasonable design processFlat articlesPolymer scienceFire retardant

The invention relates to a method for producing a polystyrene extruded sheet with compressive strength larger than 700 kPa, in particular to a production formula and a process method for high-strength polystyrene extruded sheet (XPS) with compressive strength larger than 700 kPa. The method for producing the polystyrene extruded sheet with the compressive strength larger than 700 kPa of the invention is characterized by comprising the following steps: taking general purpose polystyrene (GPPS), high impact polystyrene (HIPS), a foaming agent, a nucleating agent, color master batches and a fire retardant in certain weight proportion as raw materials; utilizing a plastic extruding machine 1 to heat the raw materials so as to melt and mix polystyrene materials to form polymer melt; utilizing a plastic extruding machine 2 and a static mixer or a heat exchanger to carrying out mixing and cooling; enabling cooled gel to enter into a pressure lowered or decreased area through a die to form a foaming structure; leveling and typing by utilizing a bump-cutter machine; cooling by utilizing a cooling fan; and removing edges and carrying out fix-length cutting to prepare the high-strength polystyrene extruded sheet (XPS) with the compressive strength larger than 700 kPa.

Owner:南京法宁格节能科技股份有限公司

Automated hot-stamping production line

ActiveCN103920780ALow costGuaranteed uptimeMetal-working feeding devicesPositioning devicesProduction lineHot stamping

The invention discloses an automated hot-stamping production line. An unstacking device is arranged on the production line and used for being docked with a heating feeding manipulator in a heating furnace feeding and discharging device after metal plates are separated, transferring the plates onto the heating furnace feeding manipulator and supporting the plates into a heating furnace, a heating furnace discharging manipulator in the heating furnace feeding and discharging device is docked with a press feeding manipulator in a press feeding device after supporting high-temperature plates out of the heating furnace and transfers the high-temperature plates onto a stamping machine to realize forming of the high-temperature plates through stamping, and finally the high-temperature plates are picked out by a press discharging manipulator in a press discharging mechanical device, so that the automated hot-stamping production line is reliable and stable in performance and high in production efficiency.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

Steel plate with 890MPa-grade yield strength and low welding crack sensitivity and manufacturing method thereof

ActiveCN103898406AReduce C contentLow costFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

The invention discloses a steel plate with 890MPa-grade yield strength and low welding crack sensitivity and a manufacturing method thereof. The steel plate comprises the following components by weight percent: 0.06-0.13wt.% of C, 0.05-0.70wt.% of Si, 1.20-2.30wt.% of Mn, 0-0.25wt.% of Mo, 0.03-0.11wt.% of Nb, 0.002-0.050wt.% of Ti, 0.02-0.15wt.% of Al, 0-0.0020wt.% of B, no more than 8.5% of 2Si+3Mn+4Mo, and the balance being Fe and inevitable impurities. The tissue of taking a super-fine bainitic lath as a matrix is obtained by adopting a technology of controlling hot mechanical rolling and cooling, so as to improve the strength, the plasticity and the toughness of the steel plate. The yield strength of the steel plate with low welding crack sensitivity is greater than 800MPa, the tensile strength is greater than 900MPa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 150J, the welding crack sensitivity index Pcm is smaller than or equal to 0.20%, and the welding property is good.

Owner:BAOSHAN IRON & STEEL CO LTD

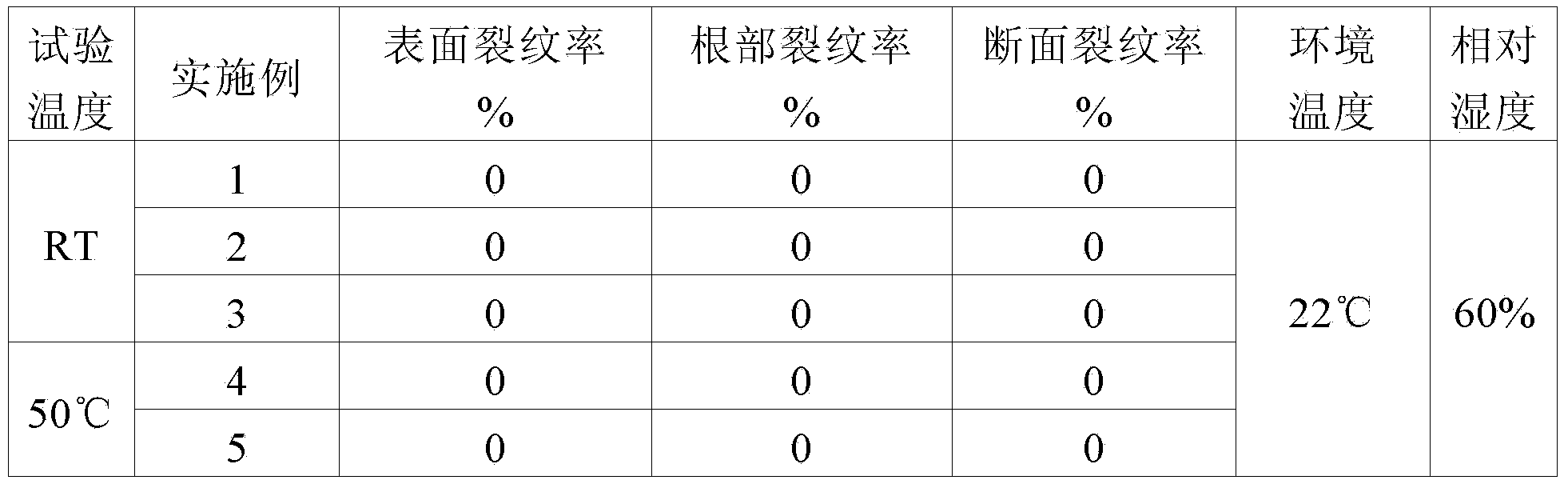

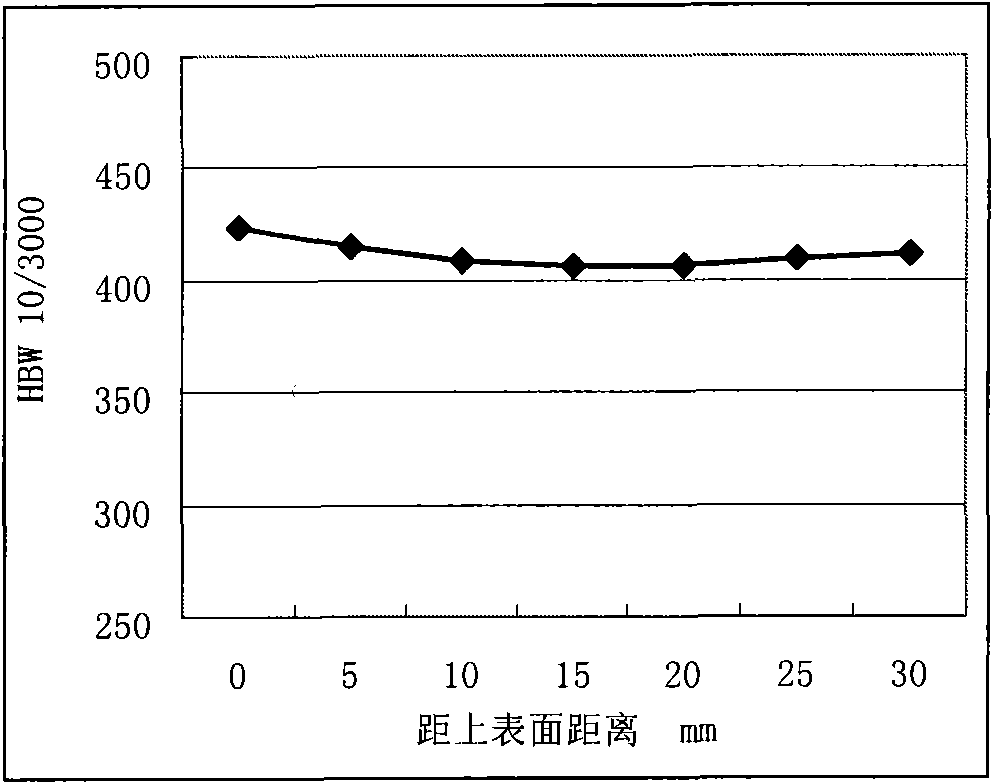

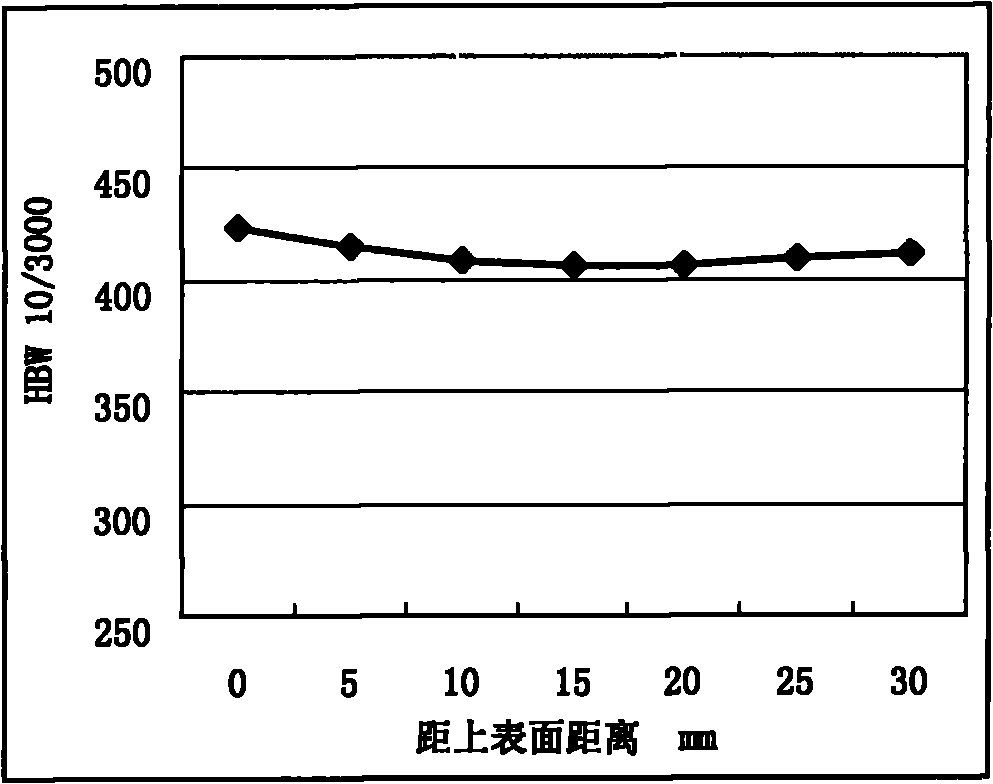

HB400-grade wear-resisting steel plate and production method thereof

The invention discloses an HB400-grade wear-resisting steel plate and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: C 0.05-0.15wt%, Si 0.4-1.4wt%, Mn 0.5-2.0wt%, P <0.012wt%, S <0.003wt%, Mo 0-0.5%, Nb 0.01-0.08%, Cu 0.20-1.0%, Co 0-1.0%, B 0.0010-0.0025wt%, Al 0.02-0.04wt%, Ti 0.004-0.030wt%, and the balance of Fe and inevitable impurities, wherein the content of Mo and Nb needs to satisfy the condition that the Mo+Nb is not less than 0.023C+0.059Ti+1.71B and not more than 2.574C+0.62Mn+10.36Ti +2.11B. The invention reduces production cost by adding some cheap alloy elements; and when the value of carbon equivalent Ceq is not more than 0.45, the HB400-grade wear-resisting steel plate has good welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

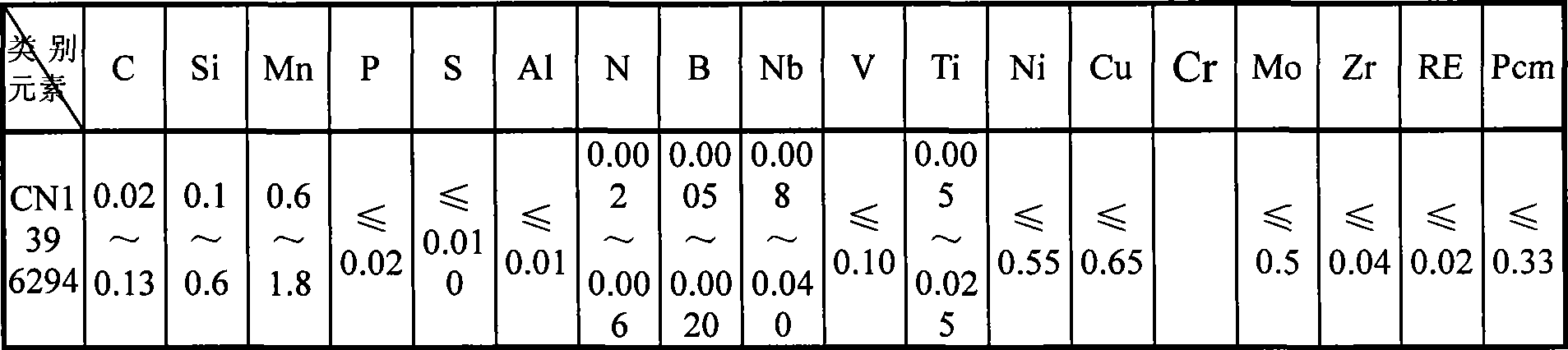

Low crack sensitivity steel plate with yield strength 500MPa and manufacturing method thereof

ActiveCN101481774ALow raw material costSimplify the manufacturing processFurnace typesHeat treatment furnacesSteel platesMetallurgy

The invention discloses a crack sensitivity steel plate with the yield strength of 500MPa, which is characterized by comprising the following chemical elements in terms of weight percentage: 0.010 to 0.09 percent of C, 0.10 to 0.65 percent of Si, 1.10 to 2.00 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.006 percent of S, 0.020 to 0.090 percent of Nb, 0.02 to 0.06 percent of Al, 0.004 to 0.030 percent of Ti, 0.0005 to 0.0025 percent of B and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: smelting and casting the raw materials into casting blank or steel ingot; 2) heating; 3) rolling; and 4) entering a cooling accelerator, cooling till the temperature of 450 to 560 DEG C, and air cooling after water drainage. The crack sensitivity steel plate has little sensitivity of welded crack, and the welding performance is good when the yield strength is more than 500MPa.

Owner:BAOSHAN IRON & STEEL CO LTD

Easy welding steel plate with yield strength of 550MPa and high toughness and manufacturing method thereof

The invention discloses an easy welding steel plate with yield strength of 550MPa and high toughness and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05 to 0.08 percent of C, 0.25 to 0.50 percent of Si, 1.65 to 1.90 percent of Mn, 0.03 to 0.07 percent of Nb, 0.03 to 0.07 percent of V, 0.0006 to 0.002 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, and the balance of Al and inevitable impurities, wherein the content of Fe accords with the following relation that: Mn is more than or equal to 3.01Si +12.8Nb+6.65V-12.12C and less than or equal to 4.78Si+13.8Nb+12.72V-10.13C. A tissue with a bainite strip serving as a substrate is obtained by a control rolling and control cooling technology. The yield strength of the easy welding thick plate with yield strength is more than 550MPa, the tensile strength is more than 670MPa, the Charpy impact power Akv(-20 DEG C) is more than 150 J, and the sensitivity index Pcm of welding cracks is less than or equal to 0.19 percent. The steel plate has high welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

High-hardness wear-resistant steel plate and manufacturing method thereof

ActiveCN103205643AImprove mechanical propertiesImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionWear resistant

The present invention provides a high-hardness wear-resistant steel plate and a manufacturing method thereof. The high-hardness wear-resistant steel plate comprises the following chemical compositions (wt%) of 0.60-0.75% of C, 0.10-0.40% of Si, 0.60-1.30% of Mn, 0-0.020% of P, 0-0.010% of S, 0.10-0.50% of Cu, 0.10-0.50% of Ni, 0.0030-0.0100% of N, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following steps of smelting, casting, hot rolling, annealing, pipe making, welding, quenching and tempering and other steps. The wear-resistant steel plate obtained by the above compositions and through the above process has high hardness and high wear resistance, with typical Rockwell hardness of HRC 62 to 66, and is suitable for easy-to-wear parts in various mechanical equipments, such as concrete pump delivery pipes.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing dispersion strengthening copper alloy materials

This invention relates to a method of producing the dispersion consolidating copper alloy material. It uses machinery alloyed to blend the metal oxidation powder and copper powder with a certain proportion, and then agglomerating them, then using water sealing heat extrusion to do cold plastic deformation processing to obtain the product.>The advantage of this invention is that it can make sure the quality of the copper alloy material, and the cost is low, the technique parameter is easy to control.

Owner:湘潭市电磁线厂有限公司

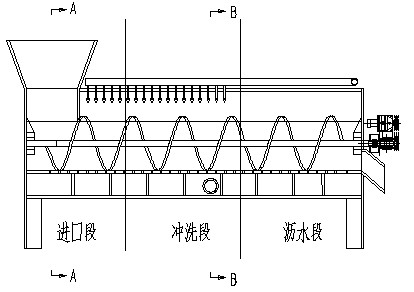

Melting and washing screening method for kitchen waste treatment system

ActiveCN102553893AAvoid re-consumptionGuaranteed sizeSolid waste disposalElectronic waste recyclingScreening methodPulp and paper industry

The invention discloses a melting and washing screening method for a kitchen waste treatment system, wherein the kitchen waste treatment system comprises a sorting machine, a high-temperature melting and washing screening machine, a grinding machine, a vibrating screen, a horizontal centrifuge, a pulping machine, a vertical centrifuge and a serous fluid pool, and an inlet of the sorting machine is provided with a feeding apparatus; the melting and washing screening method comprises the following steps of: feeding in a transporting way, cleaning in a sorting way, screening in a melting and washing way, refining in a grinding way, firstly centrifuging, pulping in a hydrating way, and discharging oil in a centrifuging way; the kitchen waste belongs to a ripe material, and is easy to melt in a hydrating way; the material is transported by a screw shaft arranged in the middle, and the screw shaft is reasonable to design, and is convenient, quick and direct to transport the material; three sections of structures with different functions are respectively arranged, i.e. the melting of organic matters, the cleaning of waste residue, and the recovering of moisture can be realized on the same assembly line, so that the cleaned waste residue is good in cleanliness, and good in organic matter use ratio; and the wool to be ground is completely soaked in high-temperature water, so that the organic matter is obvious in cleaning effect.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

Low-cost Q345R steel plate and production method thereof

The invention discloses a low-cost Q345R steel plate which comprises the following chemical components in percentage by weight: 0.16-0.18% of C, 0.2-0.3% of Si, 1.3-1.5% of Mn, at most 0.02% of P, at most 0.005% of S, 0.0015-0.003% of Ca, 0.017-0.027% of Als, and the balance of iron and impurities. The invention also discloses a production method of the low-cost Q345R steel plate. The low-cost Q345R steel plate can be produced by proper heating, controlled rolling and controlled cooling; and no expensive alloy elements, such as Nb, V, Ti and the like, are added to the steel plate, so the production cost is low.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

High-toughness mining chain steel and manufacturing method thereof

ActiveCN113322409AEasy to rollReasonable ingredientsFurnace typesForging press detailsTemperingWeather resistance

The invention discloses high-toughness mining chain steel and a manufacturing method thereof. The high-toughness mining chain steel comprises the following components in percentage by weight: 0.20-0.28% of C, 0.01-0.40% of Si, 0.50-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.30-2.00% of Cr, 0.50-2.00% of Ni, 0.10-0.80% of Mo, 0.01-0.30% of Cu, 0.01-0.05% of Al, 0.001-0.10% of Nb, 0.001-0.10% of V, less than or equal to 0.00018% of H, less than or equal to 0.0150% of N, less than or equal to 0.0020% of O and the balance of Fe and inevitable impurities. The manufacturing process comprises the working procedures of smelting, refining, vacuum treatment, casting, heating, forging or rolling, quenching and tempering heat treatment and the like. The chain steel has high strength and good impact toughness, ductility and percentage reduction of area, can resist stress corrosion cracking, has good weather resistance, wear resistance and fatigue resistance, and can be used for engineering machinery, ocean engineering and other occasions needing high-strength and high-toughness steel.

Owner:BAOSHAN IRON & STEEL CO LTD

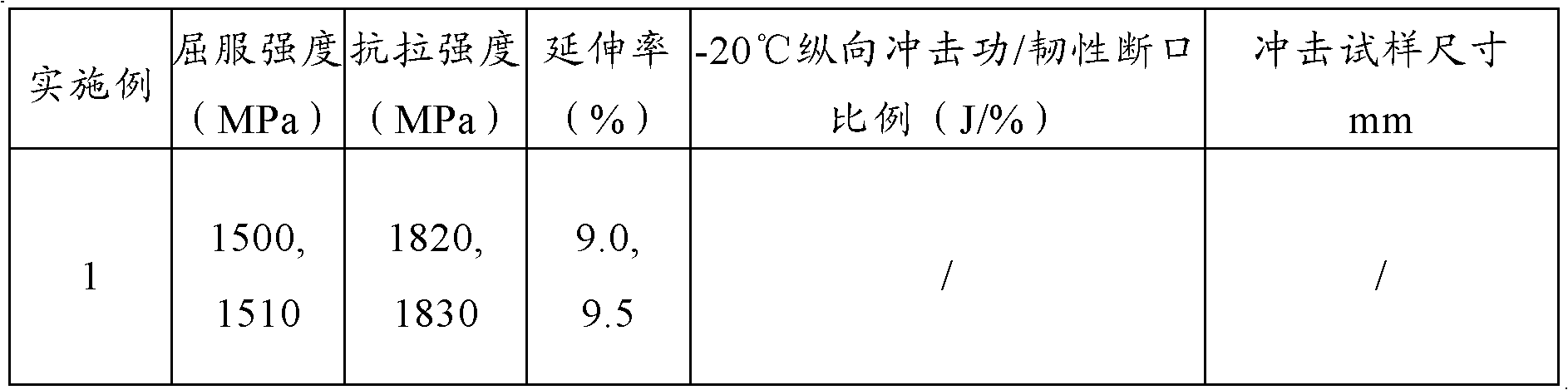

Ultrahigh-strength steel plate and production method thereof

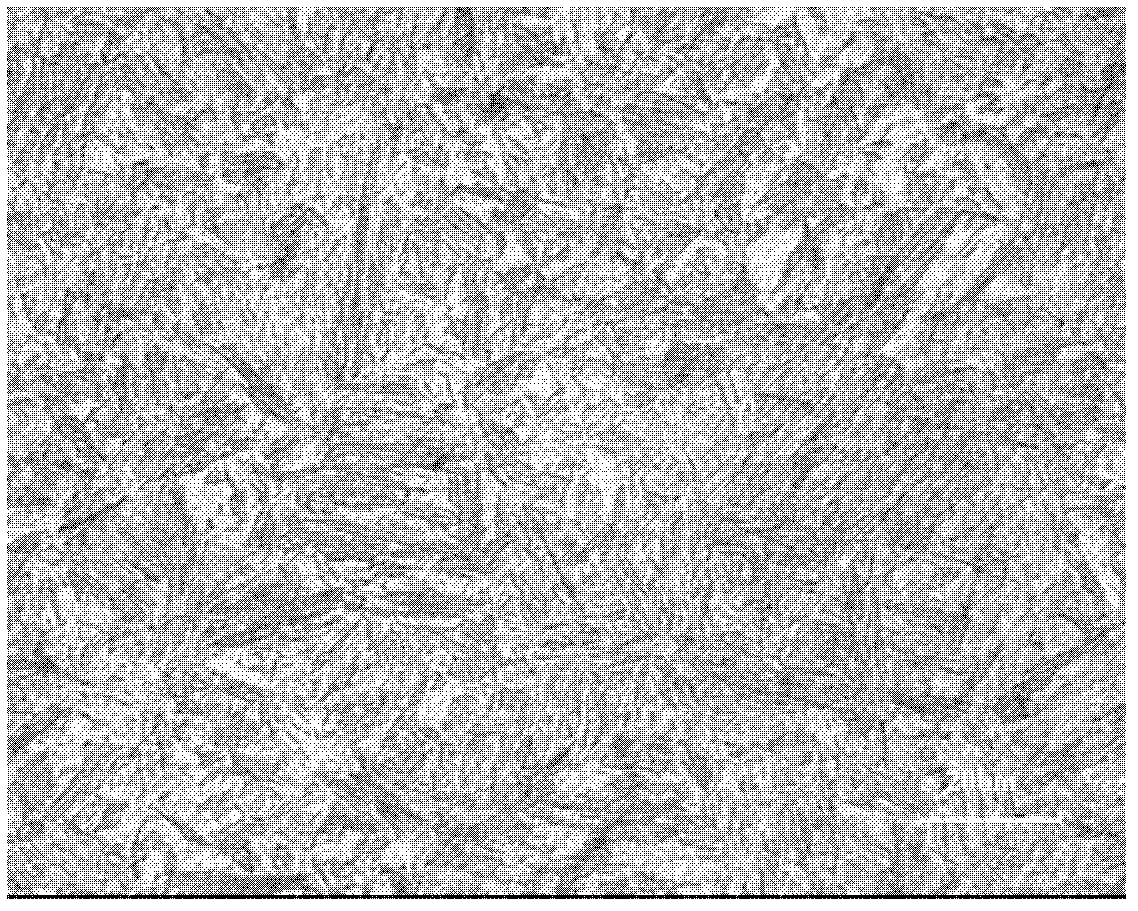

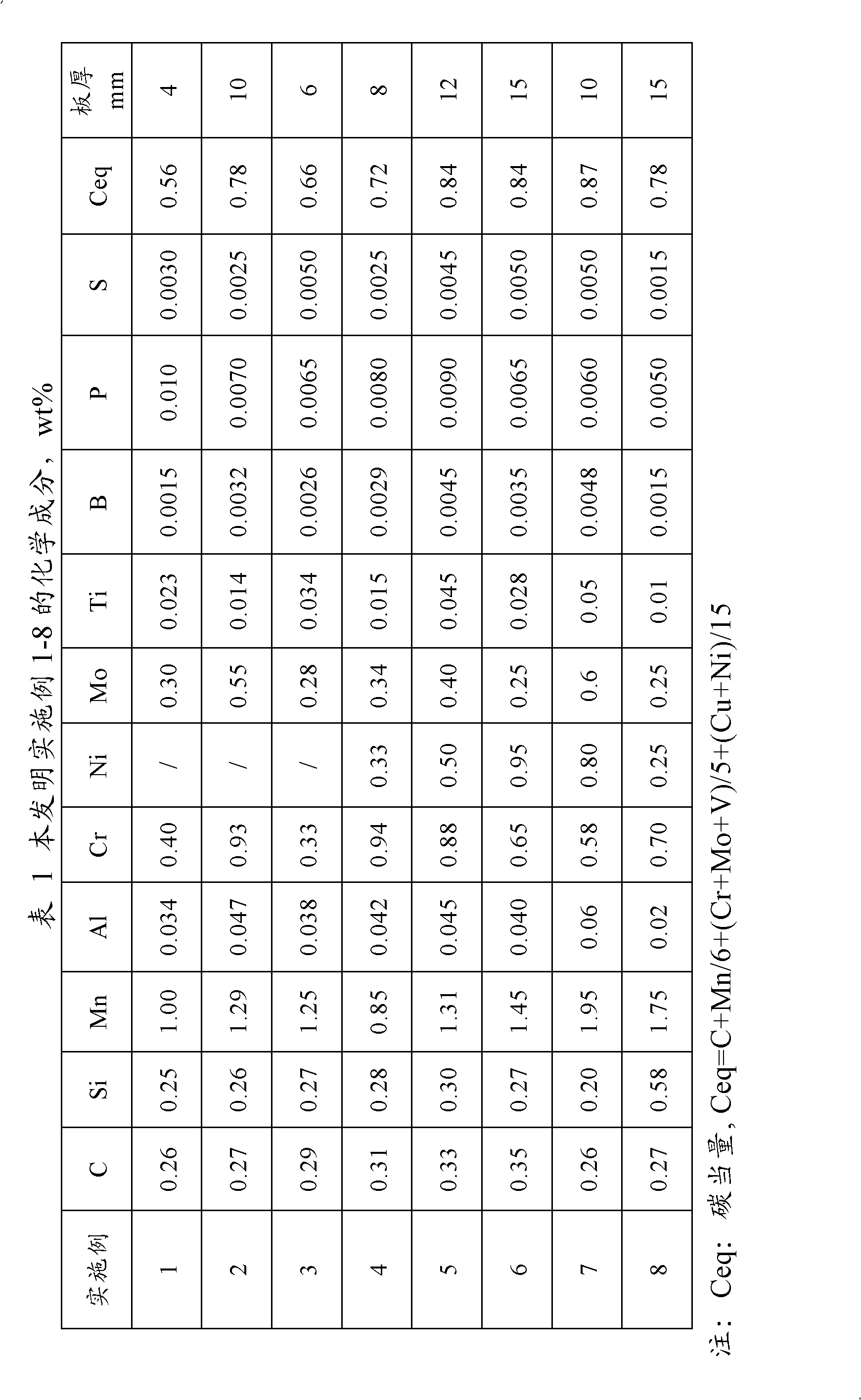

The invention relates to an ultrahigh-strength steel plate, which comprises, by weight percentage, 0.25-0.35% of C, 0.20-0.60% of Si, 0.8-2.0% of Mn, no more than 0.010% of P, no more than 0.005% of S, 0.02-0.06% of Al, 0.30-1.00% of Cr, 0.20-0.60% of Mo, 0.01-0.05% of Ti, 0.001-0.005% of B, no more than 1.0% of Ni, and the balance of Fe and unavoidable impurities. A production method of the ultrahigh-strength steel plate includes: smelting the components, obtaining a blank or ingot by casting; heating the bank or ingot to 1180-1250 DEG C prior to rolling, rolling in the first stage in a recrystallization area, performing multi-pass high reduction rolling with accumulative deformation not less than 80%; rolling in the second stage in a non-recrystallization area, finish rolling temperature being controlled at 870 to 930 DEG C); accelerating to cool the rolled steel plate to below 200 DEG C; and tempering at 200+ / -20 DEG C to obtain the steel plate 4-15mm thick. The yield strength of the steel plate is not less than 1400MPa, the tensile strength of the steel plate is not less than 1800MPa, and Charpy impact power Akv at -20 DEG C is not less than 20J.

Owner:BAOSHAN IRON & STEEL CO LTD

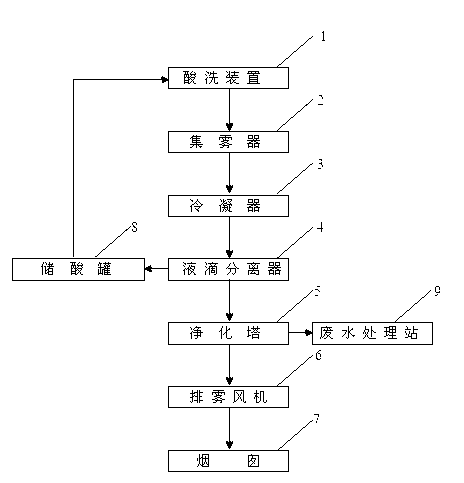

Method for recycling and purifying acid mist

InactiveCN102989291AAcid mist is fully purifiedReduce consumptionDispersed particle separationVapor condensationEmission standardAtmosphere

The invention discloses a method for recycling and purifying acid mist. According to the method, the acid mist in a pickler is collected by a mist collector under the action of a mist exhaust fan; the acid mist enters a condenser, and most acid mist is condensed into liquid acid; the liquid acid further enters a liquid drop separator so as to be subjected to gas-liquid separation; the separated acid liquid enters an acid storage tank to be stored up and laid up for being prepared into acid liquid; a small part of acid mist enters a purifying tower; the acid mist has neutral reaction in the purifying tower through alkali (NaoH) spray water (the pH value is 10 to 16) so as to be washed, absorbed and purified; and the residual waste gas is discharged to the atmosphere through a chimney. By recycling the acid mist HC1, the condensed acid liquid is recycled, the hydrochloric acid consumption is reduced by 12%, the burden of the purifying tower is alleviated, the feeding quantity of the NaOH is reduced by 80%, the acid mist is sufficiently purified, and the waste gas discharged to the atmosphere meets the exhaust standards of China.

Owner:TIANJIN YIBO STEEL MAKING

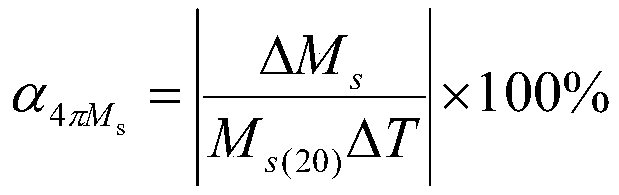

Garnet ferrite with high temperature stability and preparation method thereof

ActiveCN109867518AImprove temperature stabilityGuaranteed low ferromagnetic resonance linewidthInorganic material magnetismInductances/transformers/magnets manufactureMicrowaveMetallurgy

The invention discloses garnet ferrite with high temperature stability and a preparation method thereof, and belongs to the technical field of preparation of microwave magnetic materials. The structural formula of the garnet ferrite is Y<2.7-x>Ca<0.3-z>Gd<x>Al<y>Fe<4.68-y-z>Zr<0.3>Mn<0.02>V<z>O<12>, wherein x is greater than or equal to 0.2 and less than or equal to 0.8, y is greater than or equalto 0.6 and less than or equal to 1.4, and z is greater than or equal to 0.05 and less than or equal to 0.20. According to the garnet ferrite with high temperature stability, Gd<3+>, Al<3+> and V<5+>are simultaneously introduced for substitution, and a Bi2O3 additive is doped, so that alpha<4[phi]Ms> of the obtained garnet ferrite material in a temperature range from -55 DEG C to +85 DEG C is ina range of 0.360-0.475% / DEG C, the temperature of 4[pi]Ms at normal temperature is in a range of 300-500 Gs, and the Curie temperature T<c> is in a range of 110-165 DEG C. in addition, a low ferromagnetic resonance linewidth of the material can be ensured while temperature stability of the material is greatly improved

Owner:江西尚朋电子科技有限公司

High-tenacity steel and steel plate adaptive to high heat input welding and production method thereof

ActiveCN101724779AReduce contentLow carbon equivalentTemperature control deviceMetal rolling arrangementsUltimate tensile strengthContinuous casting

The invention provides a high-tenacity steel and a steel plate adaptive to high heat input welding and a production method thereof. The high-tenacity steel and steel plate comprise the following compositions by weight percent: 0.045-0.075% of C, 0.20-0.40% of Si, 1.20-1.60% of Mn, 0.015-0.025% of Nb, 0.02-0.06% of Al, 0.006-0.020% of Ti, 0.020-0.060% of N, P is no more than 0.015%, S is no more than 0.003% and the balance Fe and inevitable impurities. The invention also provides a production method for the steel plate, including smelting, continuous casting, heating, rolling and cooling. The invention adopts low C-moderate Mn-low Si-micro Nb and Ti-no B series of steel grade, and improves the strength, low-temperature tenacity and weldability of the steel plate by strengthening the control of thermo-mechanical rolling and post-rolling accelerated cooling technology.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate with 115 MPa grade yield strength and manufacturing method thereof

InactiveCN102618800AGrain refinementImprove low temperature impact toughnessChemical compositionUltimate tensile strength

The invention discloses a steel plate with the 115 MPa grade yield strength. The steel plate comprises the following chemical compositions in percentage by weight: 0.14-0.17wt% of C, 0.10-0.30wt% of Si, 0.80-1.20wt% of Mn, less than or equal to 0.015wt% of P, less than or equal to 0.003wt% of S, 0.30-0.50wt% of Cr, 0.40-0.70wt% of Mo, 1.1-2.2wt% of Ni, 0.01-0.06wt% of Nb, 0.04-0.06wt% of V, 0.003-0.02wt% of Ti, 0.03-0.07wt% of Al, 0.0006-0.0020wt% of B, the rest of Fe and other inevitable impurities. The steel plate with the 115 MPa grade yield strength also meets the following conditions: C+Mn / 2 is greater than or equal to 0.23Ni+0.32Mo+0.49Si+0.17Cr-153.21B and is less than or equal to 0.49Ni+0.64Mo+0.76Si+0.53Cr-132.61B, and Qm is greater than or equal to 2.77 and is less than or equal 4.92. The steel plate has the advantages that the yield strength is greater than or equal to 1150MPa, the tensile strength is greater than or equal to 1200MPa, the charpy impact energy (Akv) (minuse 40 DEG C) is greater than or equal to 60 J, and the carbon equivalent (CEV) is less than or equal to 0.60%, and the steel plate has excellent welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Ecological board production process

InactiveCN104029272AImprove wear resistanceImprove scratch resistanceWood veneer joiningDomestic articlesWear resistantCarbonization

The invention discloses an ecological board production process. The process includes 1, soaking tripolycyanamide paper into glue, placing the tripolycyanamide paper onto an engineered wood to send into a press for pressing; 2, performing base material curing treatment; 3, determining the thickness of the base material; 4, coating the glue and arranging the boards; 5, performing cold pressing treatment; 6, repairing; 7, performing ash scraping and twice sanding; 8, adhering the engineered wood with the tripolycyanamide paper on two faces of the base material in the middle, placing the engineered wood into a multi-layer press with stainless steel coated edges horizontally, controlling steel plates of the multi-layer press to close through a control switch of the multi-layer press, adjusting the temperature till 100 DEG C, adjusting the pressure of the multi-layer press til 15 Pa for 10 minutes, and an ecological board is obtained. The ecological board production process has the advantages that the defects of the prior art are overcome, process is designed reasonably, the produced ecological board is environment-friendly and wear-resistant, has fine scrape resistance, contamination resistance and flame resistance, is free of carbonization and can be produced in large scale, and production efficiency is improved.

Owner:ANHUI DONGPING WOOD GRP

Production method of low-cost and high-strength steel plate

The invention discloses a low-cost and high-strength steel plate. A material of the steel plate includes the following chemical components by weight: 0.08-0.10% of C, 0.3-0.5% of Si, 1.5-1.8% of Mn, no more than 0.015% of P, no more than 0.007% of S, 0.2-0.4% of Cr, 0.04-0.06% of Nb, 0.04-0.07% of V, 0.008-0.02% of Ti, 0.0010-0.0025% of Ca, 0.015-0.03% of Als and the balance of iron and impurities. The invention also discloses a production method of the low-cost and high-strength steel plate. The method comprises the steps of continuous casting heating, rolling, cooling and heat treatment. The steel plate provided by the invention has yield strength and impact toughness met the requirements and eliminates expensive alloy like Mo; and a TMCP and tempering process are employed for production to realize simple process and low cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Oil-water separation process of pulpifying centrifugal treatment system

ActiveCN102583855AEasy to separateIncrease digestion rateEnergy based wastewater treatmentMultistage water/sewage treatmentOil and greaseWear resistant

The invention discloses an oil-water separation process of a pulpifying centrifugal treatment system. The pulpifying centrifugal treatment system comprises a pulp beater, a sand settling device, a horizontal centrifuge, a heater, a vertical centrifuge and a pulp tank. The oil-water separation process comprises the steps as follows: a preparation step, a primary heating step, a primary centrifugation step, a secondary heating step, a secondary centrifugation step and a hydration and pulp-beating step. Hydrated beaten pulp continuously and mutually collides with wear-resistant material in the equipment at a high speed and is ground into thickened pulp material, so that the digestion rate of a back-section anaerobic fermentation system and the biogas yield are increased; a secondary centrifugation step is added, so that the design flow of the oil-water separation process is reasonable, the next step vertical centrifugation effect is facilitated, and the outlet oil concentration and the operation efficiency are increased; a good centrifugal oil outlet effect is achieved, and the water content of obtained thick oil and the oil content of wastewater material are low; and the back-section anaerobic fermentation efficiency is improved, oil-water separation of the material is conducted more thoroughly and re-consumption of energy is avoided.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

Low-yield-ratio thick Q345R steel plate for pressure vessels and production method thereof

ActiveCN104120339AImprove surface qualityImprove mechanical propertiesChemical compositionSheet steel

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-strength steel sheet with yield strength of 1100MPa and manufacturing method thereof

A high-strength steel sheet with yield strength of 1100MPa and a manufacturing method thereof. The high-strength steel sheet comprises, based on the weight percentage, 0.15-0.25% of C, 0.10-0.50% of Si, 0.60-1.20% of Mn, no more than 0.013% of P, no more than 0.003% of S, 0.20-0.55% of Cr, 0.20-0.70% of Mo, 0.60-2% of Ni, 0-0.07% of Nb, 0-0.07% of V, 0.0006-0.0025% of B, 0.01-0.08% of Al, 0.003-0.06% of Ti, no more than 0.00018% of H, no more than 0.0040% of N, no more than 0.0030% of O, and the balance of Fe and inevitable impurities; and the carbon equivalent CEQ is no more than 0.60%. A quenching and a tempering heat treatment are employed to obtain a tempered martensite tissue. The steel provided by the present invention has yield strength no less than 1100MPa, tensile strength no less than 1250MPa, Charpy ballistic work Akv (-40 DEG C) no less than 50J, and good strength and toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

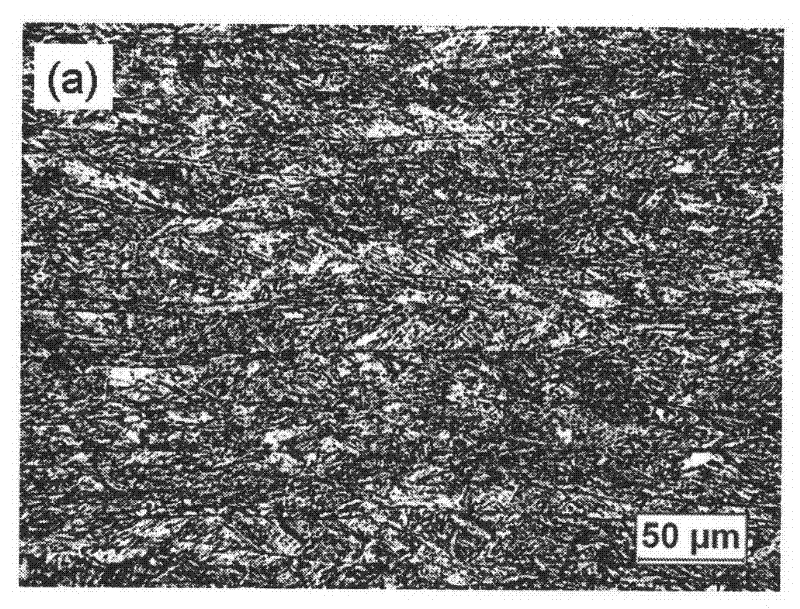

Low-carbon bainite thick steel plate with high strength and toughness and manufacturing method thereof

ActiveCN102162061AReduce contentLow costTemperature control deviceMetal rolling arrangementsSheet steelUltimate tensile strength

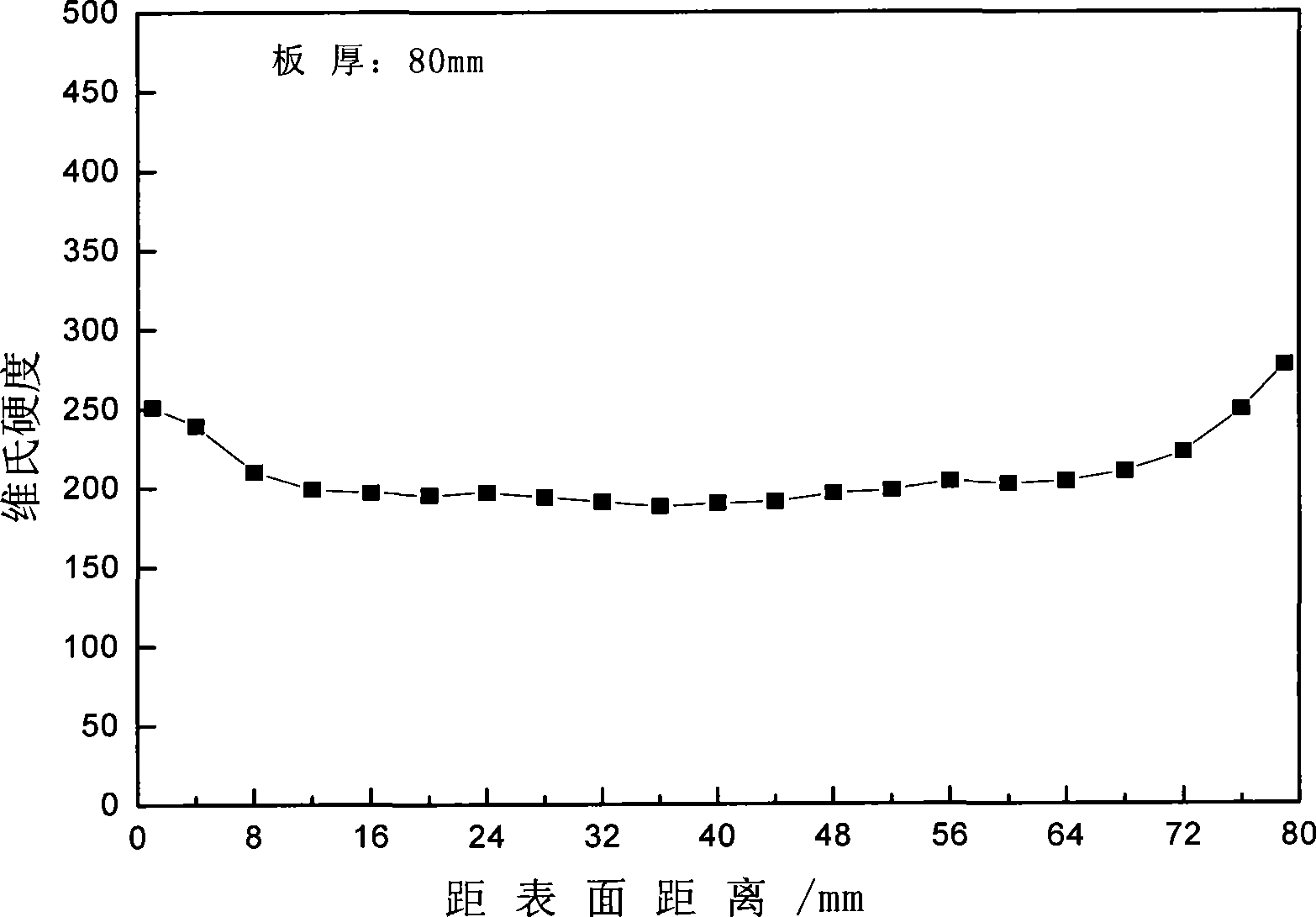

The invention relates to a low-carbon bainite thick steel plate with high strength and toughness and a manufacturing method thereof. The steel plate comprises the following components in percentage by mass: 0.02 to 0.09 percent of C, 0.35 to 0.60 percent of Si, 1.50 to 1.85 percent of Mn, 0.15 to 0.30 percent of Mo, 0.04 to 0.07 percent of Nb, 0.04 to 0.07 percent of V, 0.0010 to 0.0020 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, less than or equal to 0.0030 percent of Zr, Mo in an amount which is more than or equal to 0.55-0.181Mn-1.51C and less than or equal to 8.7-3.69 Mn-29.18C, and the balance of Fe and inevitable impurities. The steel plate does not need quenching and heat treatment, so the manufacturing process is simplified, and the manufacturing cost of steel is reduced. The yield strength of the steel plate with low welding crack sensitivity is more than 690MPa, the tensile strength is more than 770MPa, the Charpy impact power Akv (-20 DEG C) is more than or equal to 180J, and the thickness of the plate can reach 80 millimeters. The welding crack sensitivity index Pcm is less than or equal to 0.20 percent, and the steel plate has excellent welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Low alloy and high strength Q420C medium steel plate and production method thereof

The invention discloses a low alloy and high strength Q420C medium steel plate. The low alloy and high strength Q420C medium steel plate comprises the following chemical components by weight percent: 0.16-0.18% of C, 0.35-0.45% of Si, 1.45-1.55% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 0.015-0.03% of Als, and the balance of iron and impurities. The invention also discloses a production method for the low alloy and high strength Q420C medium steel plate. The production method is simple, and has a short production cycle and low production cost; and the strength of the steel plate is moderate, the yield strength is 430-460MPa, and the tensile strength is 540-590MPa.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

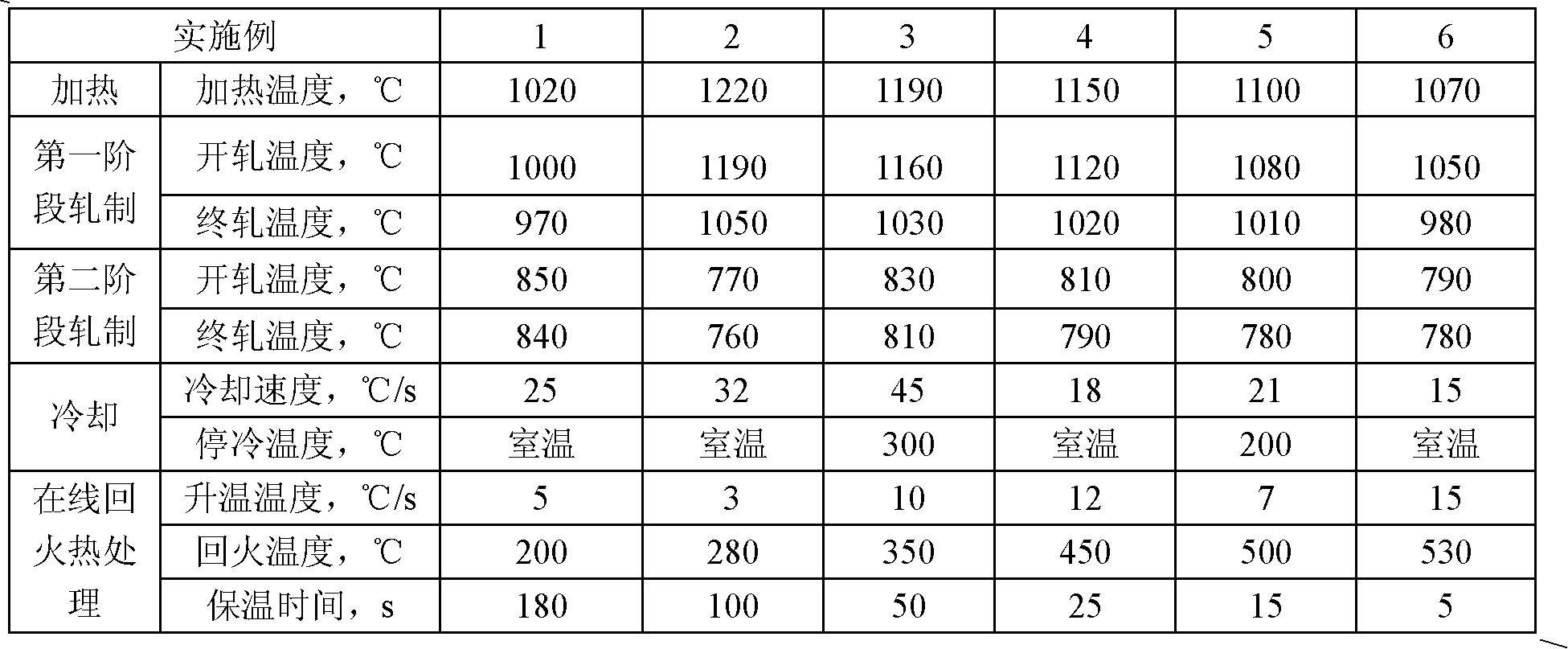

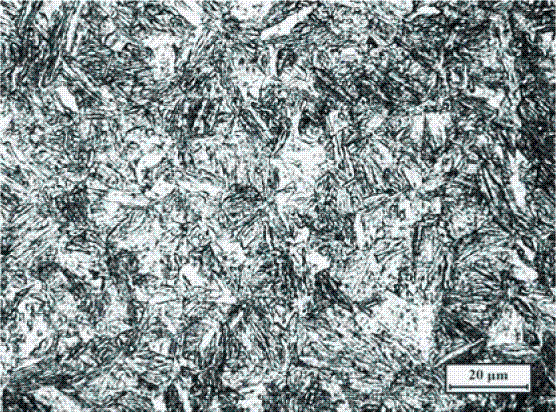

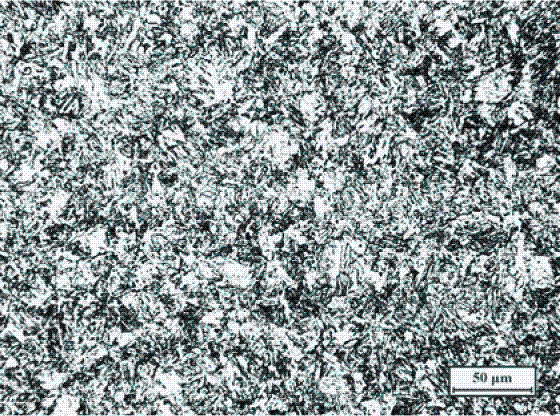

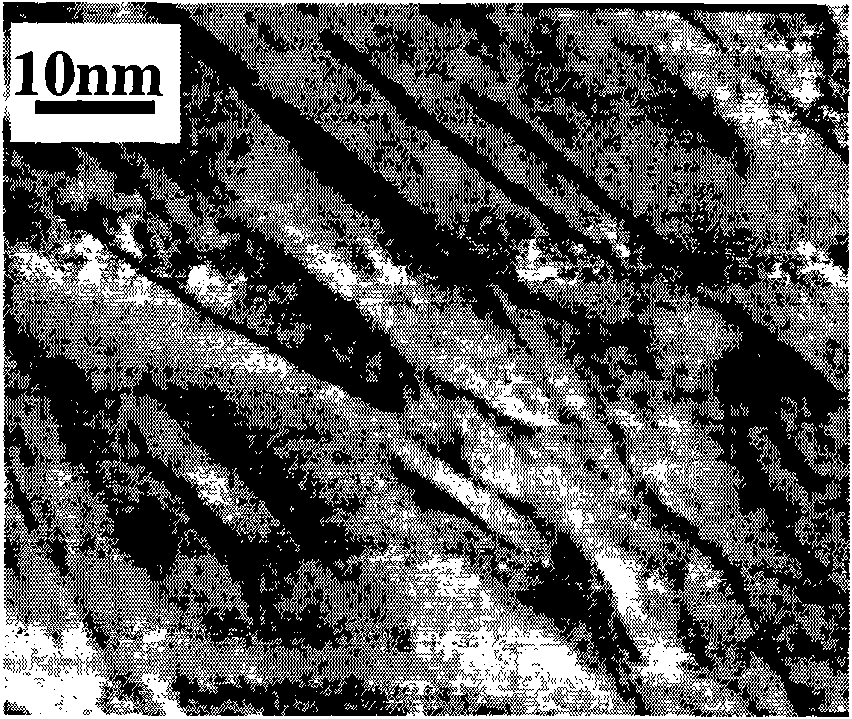

Ultra-high strength hot rolling wire rod of 2200 Mpa level and manufacture method thereof

ActiveCN101586208ALow content of alloying elementsSave resourcesTemperature control deviceWork treatment devicesWire rodChemical composition

The invention provides an ultra-high strength hot rolling wire rod of 2200 Mpa level and a manufacture method thereof. The ultra-high strength hot rolling wire rod of 2200 Mpa level comprises the following chemical components by weight percentage: 0.40 to 0.60 percent of C, 2.5 to 4.0 percent of Si, 3.0 to 5.0 percent of Mn, 0.40 to 0.60 percent of Mo, and the balance of Fe and unavoidable impurities. The invention adopts Mn-Si-Mo line components, and obtains the hot rolling wire rod taking a nanometer scale martensite structure as the characteristic through purification smelting, forging, rough rolling, finish rolling and the silking technology with the width of a martensite slab of about 5 to 15 nm. The ultra-high strength hot rolling wire rod has the steel yield strength no less than 1900 Mpa, the tensile strength no less than 2200 Mpa, the yield ratio no less than 0.85 percent, the elongation no less than 8.0 percent and the reduction of area no less than 40 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

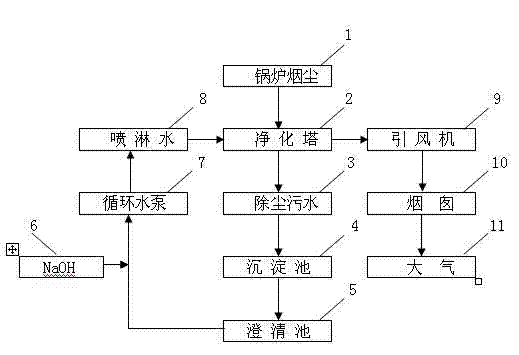

Sulfur and dust removing method for boiler

InactiveCN103041685AImprove desulfurization effectReasonable design processUsing liquid separation agentSulfurDual effect

The invention discloses a sulfur and dust removing method for a boiler. The method comprises the following steps: introducing industrial boiler exhaust gas into a sulfur and dust removing purifying tower under the action of an induced draft fan; injecting spray water having the pH ranging from 8 to 12 to the tower by a circulating water pump for multiple-stage spraying so that dust and SO2 in the exhaust gas are removed, and discharging the exhaust gas without dust and sulfur to high altitude by a chimney; flowing sulfur and dust removal sewage into a settling pond; settling the dust in the settling pond and then clearing away the dust out of the pond by a dust remover, while flowing the clear water into a clarification tank; and because the pH value of the spray water is reduced after sulfur removal, quantitatively adding NaOH alkali liquor to water so that the spray water is capable of keeping the pH between 8-12 all the time, thereby guaranteeing the sulfur removal effect. The method provided by the invention is reasonable in process flow, reliable and excellent in effect, has dual effects of dust removal and sulfur removal, and has wide application prospect in industrial enterprises.

Owner:TIANJIN YIBO STEEL MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com