Garnet ferrite with high temperature stability and preparation method thereof

A technology of garnet and ferrite, which is applied in the field of microwave magnetic material preparation, can solve the problems of less material reports, and achieve the effects of optimizing microstructure and performance, improving temperature stability, and low ferromagnetic resonance linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

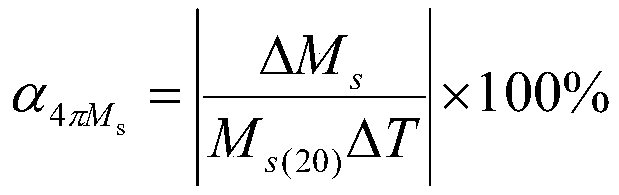

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of garnet ferrite with high temperature stability, comprising the following steps:

[0027] Step 1. Weighing: Y 2 o 3 、Gd 2 o 3 , Fe 2 o 3 、Al 2 o 3 , Mn 3 o 4 , CaCO 3 , ZrO 2 , V 2 o 5 As raw material, according to the structural formula Y 2.7-x Ca 0.3-z Gd x al y Fe 4.68-y-z Zr 0.3 mn 0.02 V z o 12 (wherein x=0.4, y=1.2, z=0.05) ratio, take raw material;

[0028] Step 2, a ball mill: put the raw material weighed in step 1 into a steel ball mill tank, use deionized water as a solvent, and perform ball milling according to the mass ratio of material: water: zirconium balls = 1:1.5:4, and the ball mill speed is 241 revolution / min, ball milling time 6h;

[0029] Step 3, pre-burning: take out the slurry obtained after the first ball milling in step 2, dry it in an oven, put it into a box furnace, and pre-fire it for 2 hours in an air atmosphere at a temperature of 1100°C;

[0030] Step 4, secondary ball milling: crush the calci...

Embodiment 2

[0035] A preparation method of garnet ferrite with high temperature stability, comprising the following steps:

[0036] Step 1. Weighing: Y 2 o 3 、Gd 2 o 3 , Fe 2 o 3 、Al 2 o 3 , Mn 3 o 4 , CaCO 3 , ZrO 2 , V 2 o 5 As raw material, according to the structural formula Y 2.7-x Ca 0.3-z Gd x al y Fe 4.68-y-z Zr 0.3 mn 0.02 V z o 12 (wherein x=0.2, y=1.2, z=0.1) ratio, take raw material;

[0037] Step 2, a ball mill: put the raw material weighed in step 1 into a steel ball mill tank, use deionized water as a solvent, and perform ball milling according to the mass ratio of material: water: zirconium balls = 1:1.5:4, and the ball mill speed is 241 revolutions per minute, ball milling time 4h;

[0038] Step 3, pre-burning: take out the slurry obtained after the first ball milling in step 2, dry it in an oven, put it into a box furnace, and pre-fire it for 2 hours in an air atmosphere at a temperature of 1100°C;

[0039] Step 4, secondary ball milling: crush th...

Embodiment 3

[0044] A preparation method of garnet ferrite with high temperature stability, comprising the following steps:

[0045] Step 1. Weighing: Y 2 o 3 、Gd 2 o 3 , Fe 2 o 3 、Al 2 o 3 , Mn 3 o 4 , CaCO 3 , ZrO 2 , V 2 o 5 As raw material, according to the structural formula Y 2.7-x Ca 0.3-z Gd x al y Fe 4.68-y-z Zr 0.3 mn 0.02 V z o 12 (wherein x=0.6, y=1.0, z=0.2), the raw material is weighed;

[0046] Step 2, a ball mill: put the raw material weighed in step 1 into a steel ball mill tank, use deionized water as a solvent, and perform ball milling according to the mass ratio of material: water: zirconium balls = 1:1.5:4, and the ball mill speed is 241 revolution / min, ball milling time 6h;

[0047] Step 3, pre-burning: take out the slurry obtained after the first ball milling in step 2, dry it in an oven, put it into a box furnace, and pre-fire it in an air atmosphere at a temperature of 1100°C for 3 hours;

[0048] Step 4, secondary ball milling: crush the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com