Method for recycling and purifying acid mist

A technology of acid mist and purification tower, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of excessive HCI content in mist, increase the cost of wastewater treatment, waste pickling solution, etc., and reduce the dosage , the effect is good, the effect of reducing the consumption of hydrochloric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Original recycling process:

[0019] The acid mist in the pickling device 1 is collected by the mist collector 2, the acid mist directly enters the purification tower 3, the acid mist passes through the purified waste gas, passes through the mist exhaust fan 4, and is discharged into the atmosphere through the chimney 5, and the waste water sprayed by the purification tower is discharged into the waste water treatment stand. Embodiment 1 has a simple process, poor purification effect, high consumption and substandard discharge.

Embodiment 2

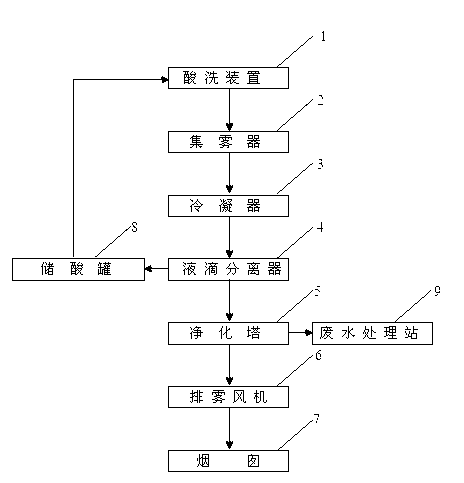

[0021] The acid mist in the pickling device 1 is collected by the mist collector 2; the collected acid mist enters the condenser 3, and most of the acid mist is condensed into liquid acid; then enters the droplet separator 4 for vapor-liquid separation; the separated acid mist The liquid enters the acid storage tank 8 for storage in order to reconfigure the acid liquid; after the droplets are separated, the remaining small part of the acid mist enters the purification tower 5, and the acid mist passes through the tower and undergoes a neutralization reaction with the alkaline spray water of pH > 10 Thus, it is washed, absorbed and purified, and the spray wastewater in the purification tower flows into the wastewater treatment station; the remaining exhaust gas is discharged through the chimney 7 at high altitude.

Embodiment 3

[0023] A method for recovering and purifying acid mist: Under the action of the mist exhaust fan 4, the acid mist in the pickling device 1 is collected by the mist collector 2; the collected acid mist enters the condenser 5 at a temperature of 15°C, and most The acid mist condenses into liquid acid; then enters the droplet separator 6 for vapor-liquid separation, and controls the droplet diameter to be 0.05mm for separation, and the separated acid solution enters the acid storage tank 7 for storage in order to reconfigure the acid solution; After the separation, the remaining small part of the acid mist enters the purification tower 3, and the acid mist is washed in the purification tower through neutralization reaction with the NaOH spray water of PH>10, and meets the national discharge standard through two washings, absorption and purification; The remaining exhaust gas is discharged to the atmosphere through the chimney 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com