Sulfur and dust removing method for boiler

A technology for desulfurization and dust removal and boilers, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. , good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] With the adoption of the present invention, the boiler waste gas and smoke enter the water film dedusting purification tower under the action of the induced draft fan, and the circulating pump pumps the spray water with pH=8-10 into the tower for multi-stage spraying to remove the dust in the waste gas and SO 2 , the waste gas after dust removal and desulfurization is discharged from the chimney at high altitude; the dust removal and desulfurization sewage flows into the sedimentation tank, the dust is settled in the sedimentation tank and is cleaned out of the tank by the dust remover, and the clean water flows into the clarification tank. After desulfurization, the pH value of the spray water drops, which needs to be quantified Add NaOH lye to the water (NaOH reagent is commercially available), so that the spray water always maintains pH=8~10, so as to ensure the desulfurization effect.

Embodiment 2

[0024] SO in boiler exhaust gas 2 and smoke and dust are eliminated according to the following steps:

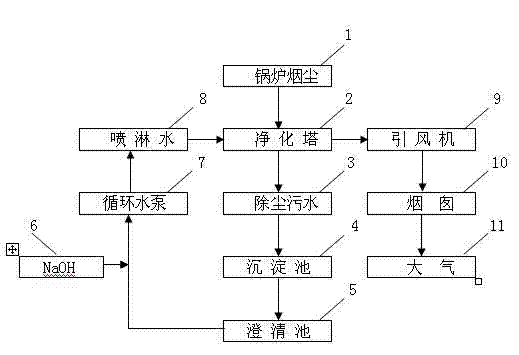

[0025] Boiler soot 1 enters the purification tower 2, and in the tower, it is sprayed in multiple stages by spraying water to remove dust and SO in the exhaust gas 2 The dedusting and desulfurization sewage 3 flows into the sedimentation tank 4. After the dust settles in the sedimentation tank, it is cleaned out of the tank by the dust remover, and the supernatant flows into the clarification tank 5. After desulfurization, the pH value of the spray water drops, and it is necessary to add lye to the water quantitatively. NaOH6 (NaOH reagent is commercially available) keeps the spray water at pH=8-12, and the circulating water pump 7 injects the spray water 8 into the purification tower. The chimney 10 discharges into the atmosphere 11 at high altitude. Appropriately increasing the pH value of the spray water is more conducive to improving the desulfurization effect. The dus...

Embodiment 3

[0027] Comparative test (same batch of raw materials)

[0028] (1) Conventional coal-fired boiler inertial dedusting method: Inertial dedusting method is a method of separating dust particles from the airflow by using the inertial force generated by the impact of dusty flue gas on the baffle or the change of direction of the airflow. The steps are: the boiler smoke enters the flue through the flue inlet under the action of the induced draft fan, the smoke impacts the smoke hood and changes direction, the inertial force separates the larger dust particles from the flue gas, and the dust-removed flue gas passes through the chimney vented to the atmosphere.

[0029] (2) Water film desulfurization and dedusting method of the present invention: method step sees embodiment 2:

[0030] Comparative test data

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com