Scale-inhibition copper-based catalyst alloy and preparation method thereof

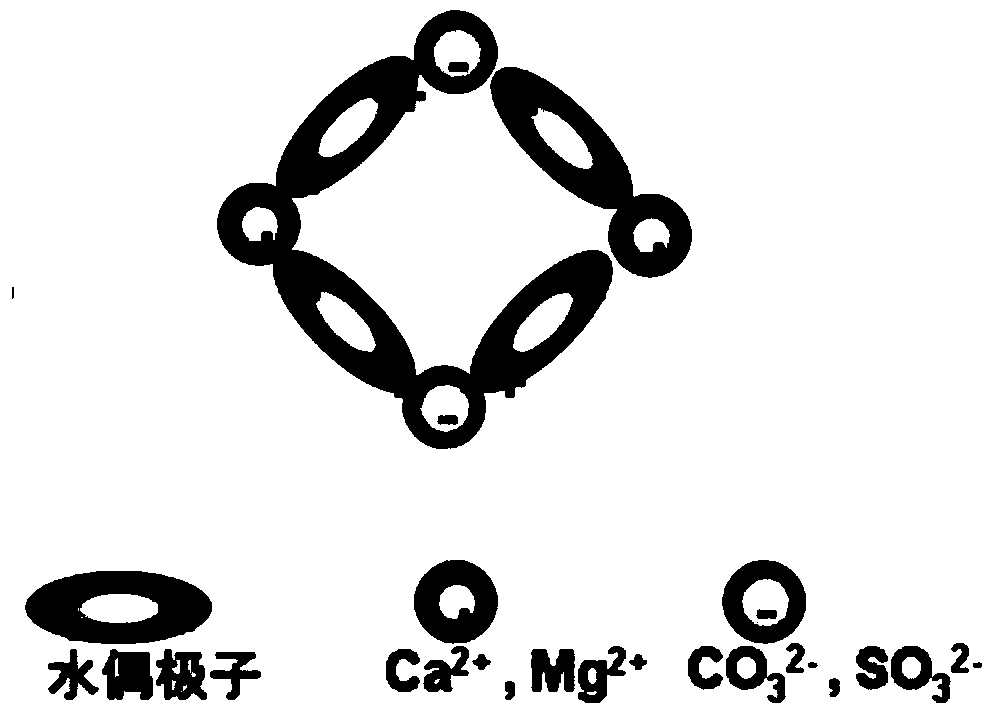

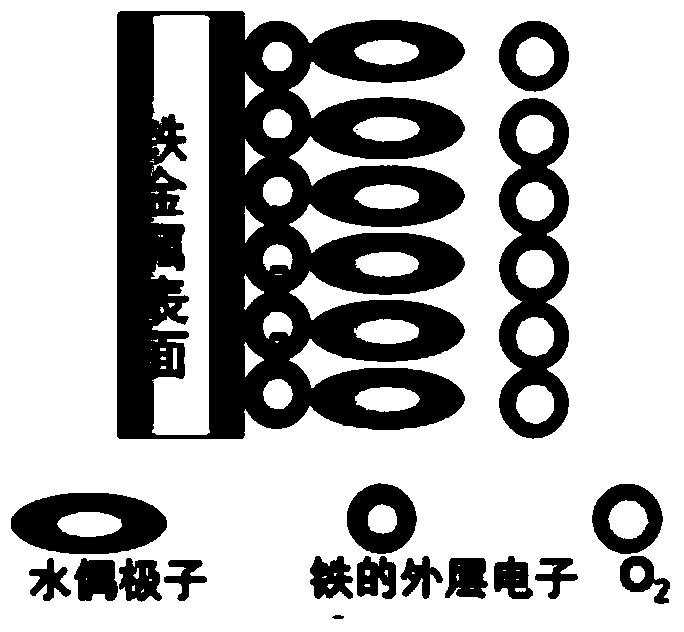

A technology of alloy and catalyst, which is applied in the field of copper-based catalyst alloy and its preparation, can solve the problems of reducing the scaling rate and the combination rate of anion and cation, and achieve the effect of decreasing the scaling index, increasing the solubility, and preventing the formation of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

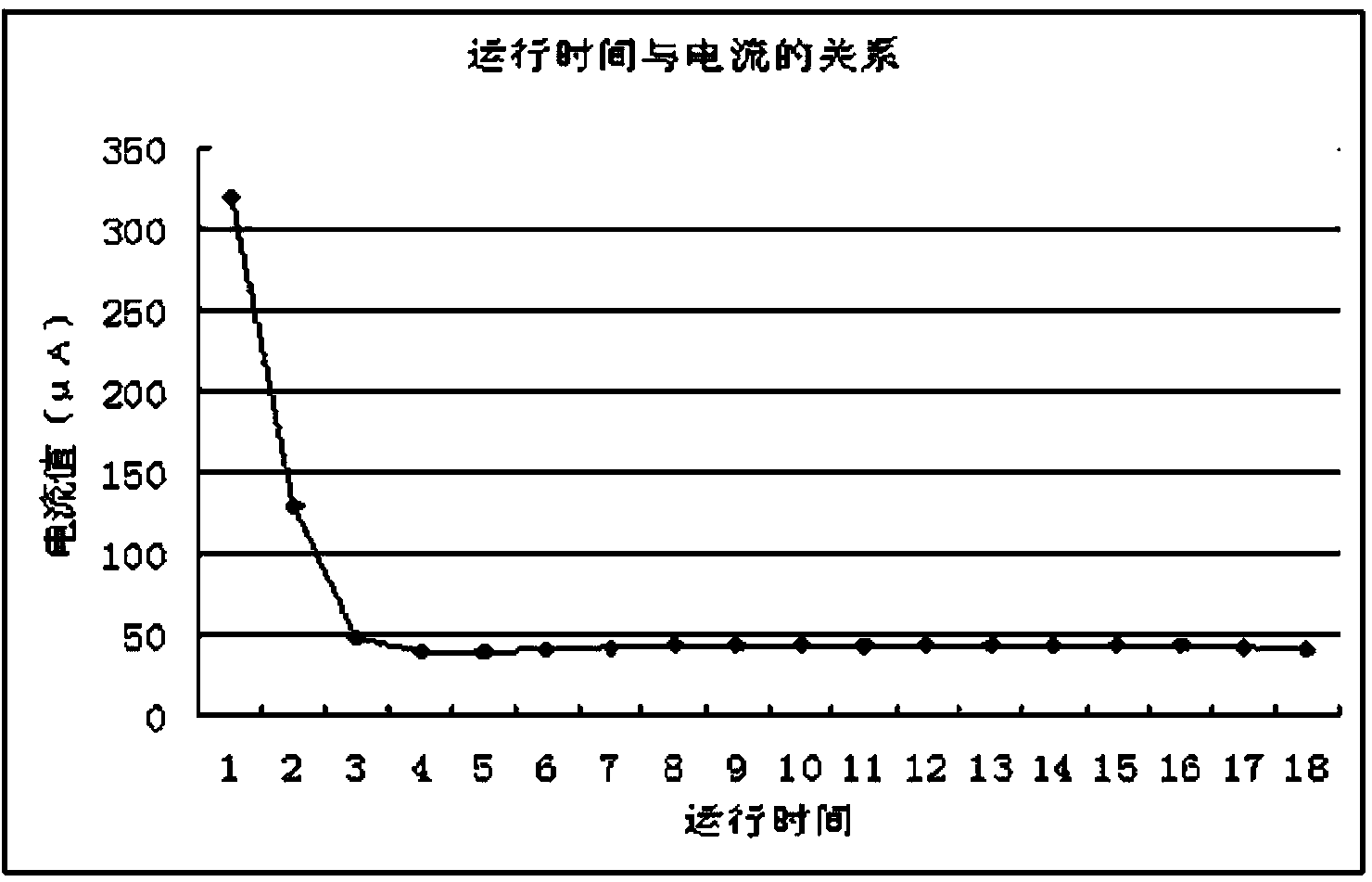

Examples

Embodiment 1

[0014] The weight percent of each component of the copper-based catalyst alloy used for scale inhibition is: Cu: 40%, Ni: 5%, Zn: 10%, Sn: 5%, Ag: 0.5%, Fe: 0.1, Sb : 0.01%, Mn: 0.05%, each component is compounded into a columnar crystal alloy that grows oriented along the S100 crystal axis.

[0015] The preparation method of the copper-based catalyst alloy used for scale inhibition is as follows: raw materials are prepared according to the weight percentages of the above-mentioned components, and the raw materials have a purity of more than 99.9% in lumps with a volume of 2 cm 3 , Spread 1cm thick charcoal in a clean induction furnace crucible, evenly spread half of the Cu material on the charcoal by weight, then evenly spread all the Ni blocks on the Cu material, and then spread 1cm thick charcoal, start Heat up the furnace to 1000°C. After all the metals are melted, quickly add all the Fe and Sb blocks, stir until the metals are completely melted, then quickly add all the M...

Embodiment 2

[0017] The weight percent of each component of the copper-based catalyst alloy for scale inhibition is: Cu: 50%, Ni: 10%, Zn: 20%, Sn: 15%, Ag: 10%, Fe: 5%, Sb: 1%, Mn: 2%, each component is synthesized into a columnar crystal alloy oriented along the S100 crystal axis through high temperature chemical reaction. The preparation method of this example is consistent with that described in Example 1.

Embodiment 3

[0019] The weight percent of each component of the copper-based catalyst alloy used for scale inhibition is: Cu: 55%, Ni: 18%, Zn: 30%, Sn: 18%, Ag: 12%, Fe: 6%, Sb: 1.5%, Mn: 0.8%, each component is synthesized into a columnar crystal alloy oriented along the S100 crystal axis through high temperature chemical reaction. The preparation method of this example is consistent with that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com