Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1626results about "Level indicators by pressure measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

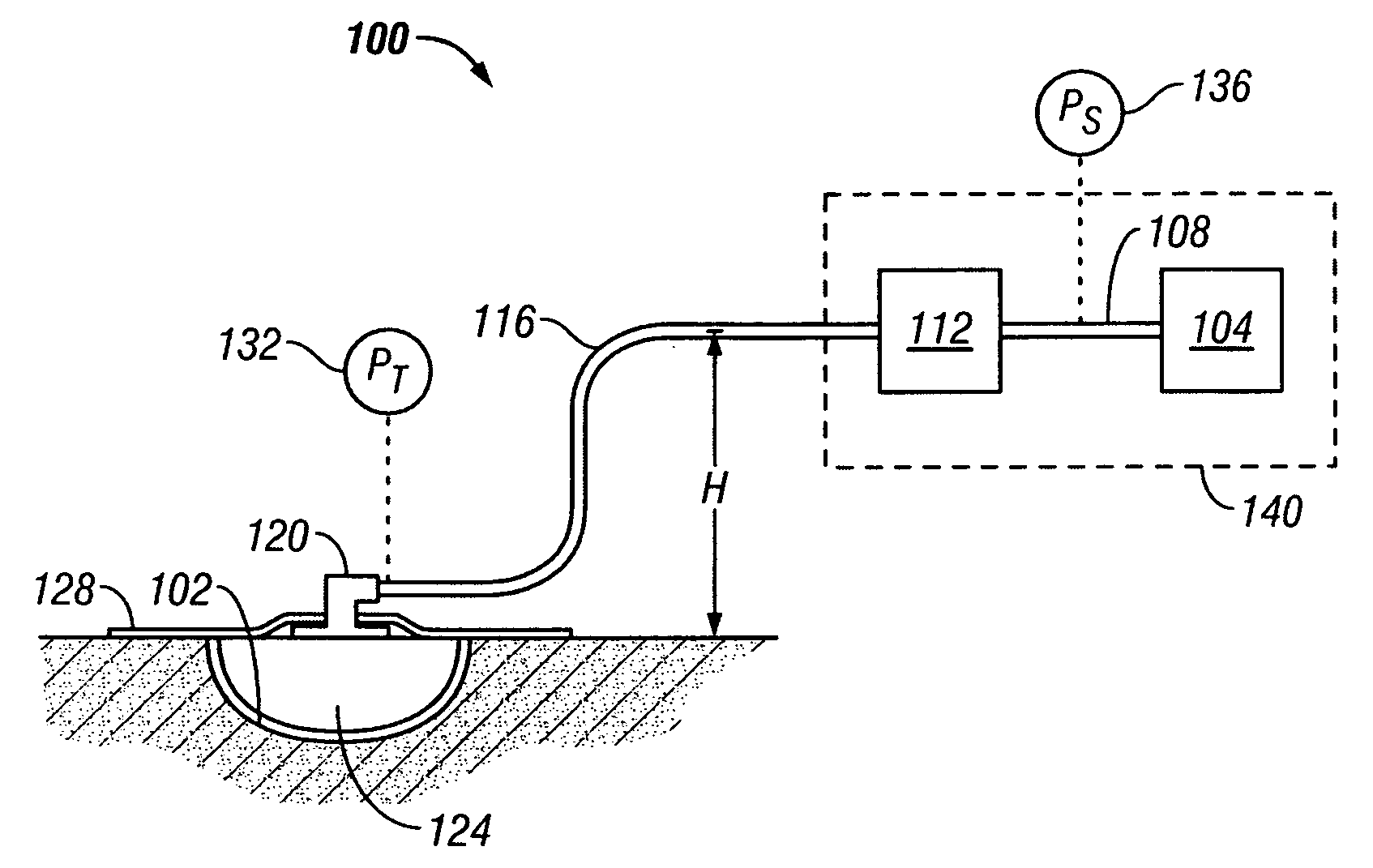

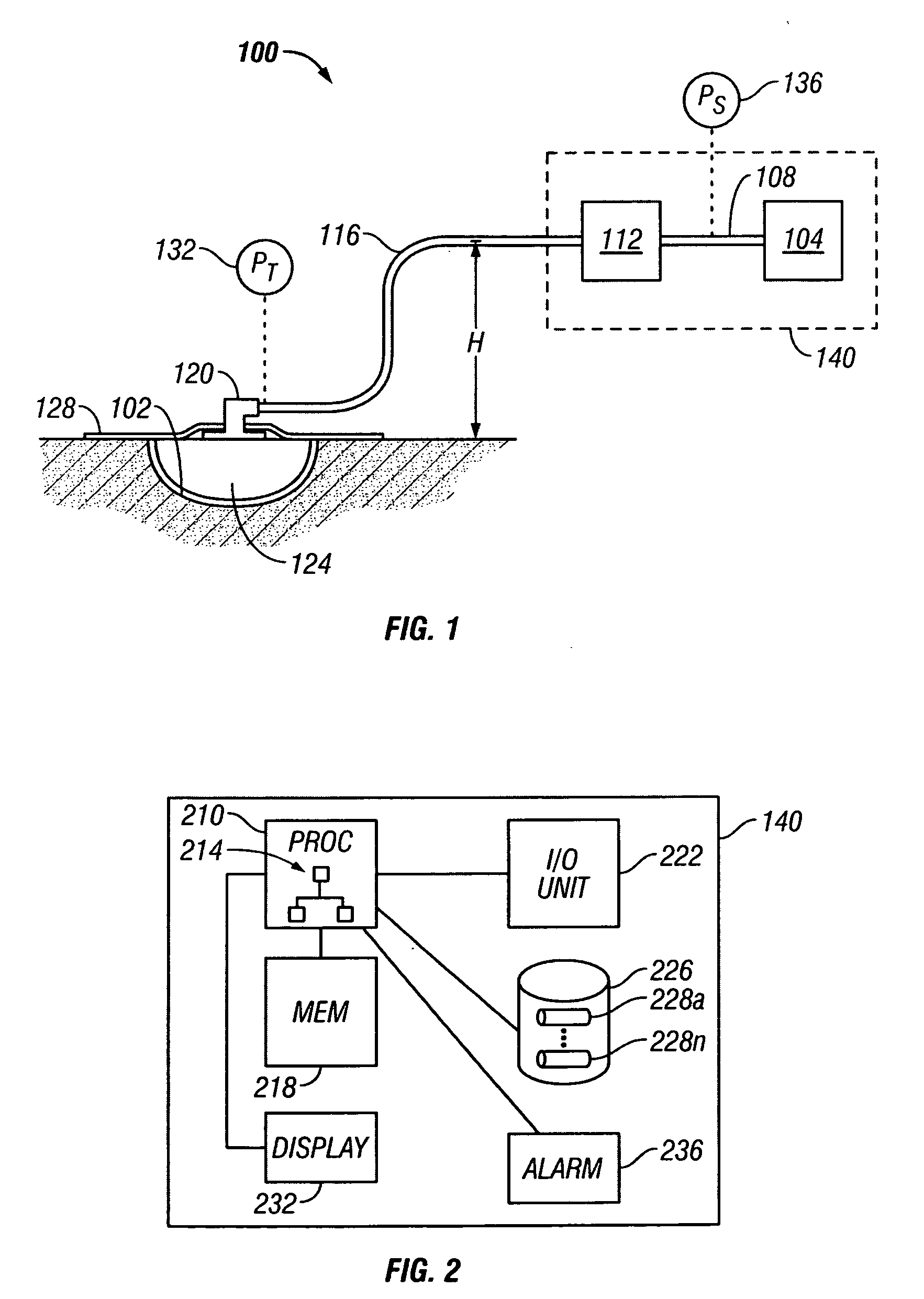

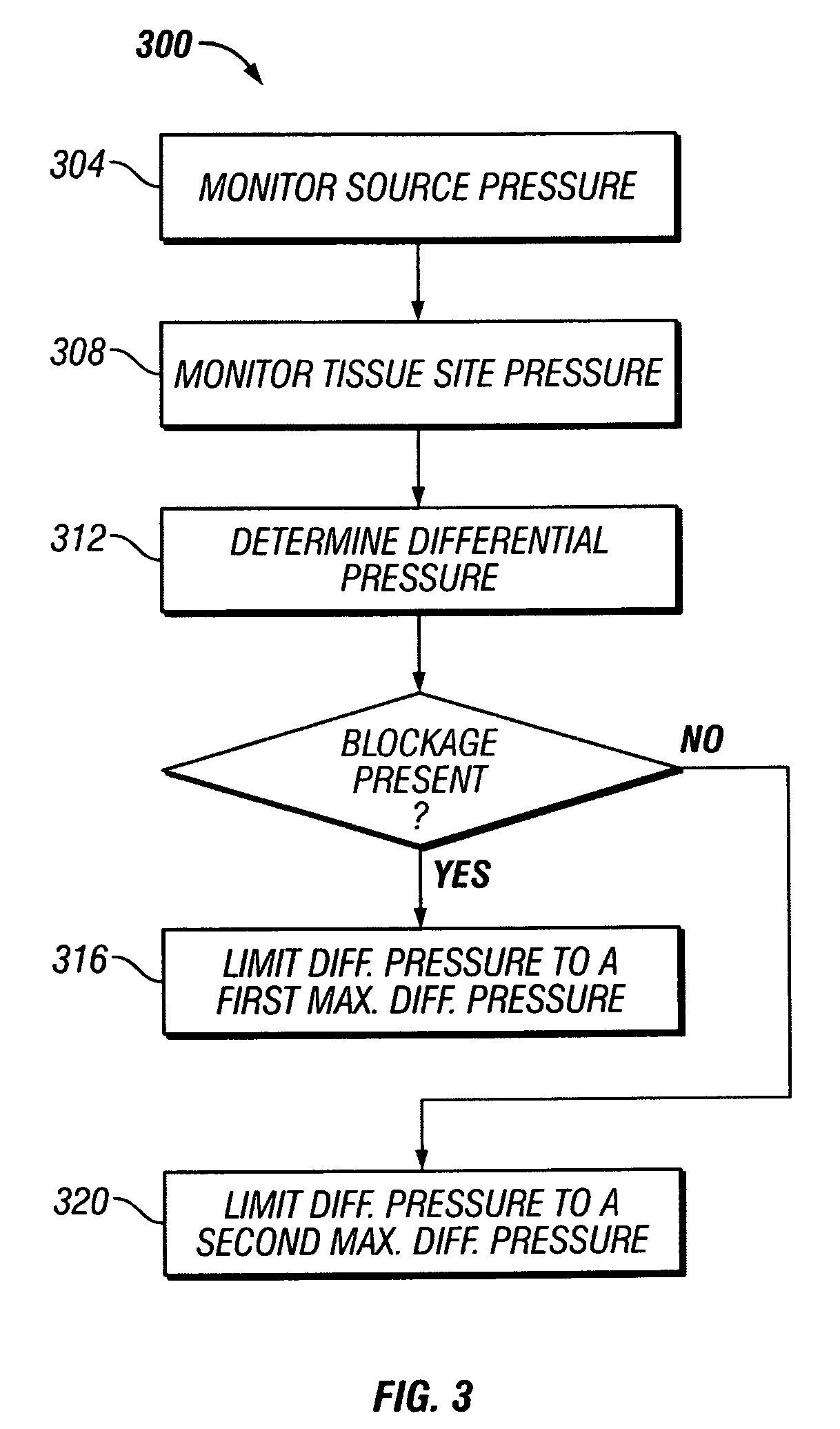

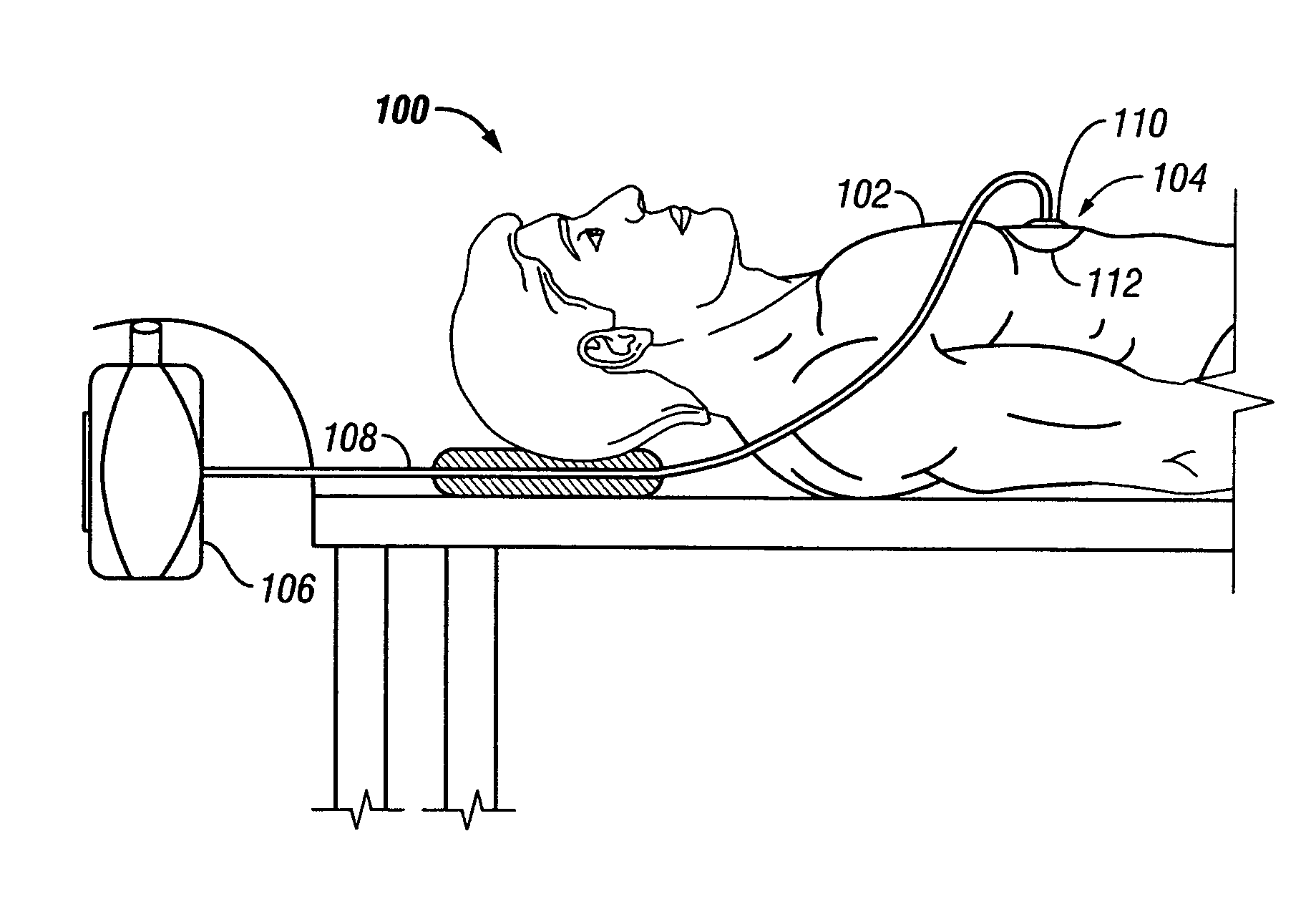

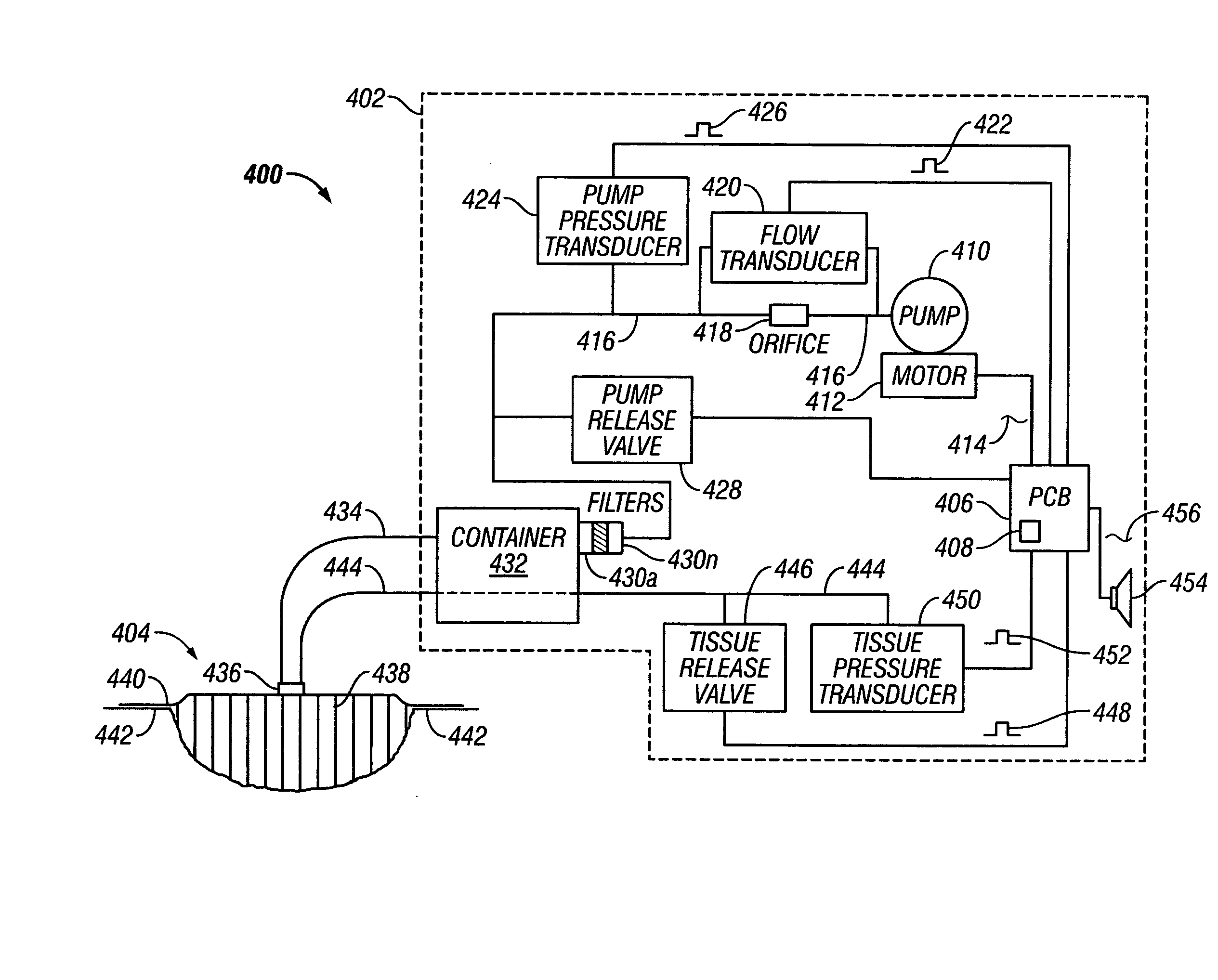

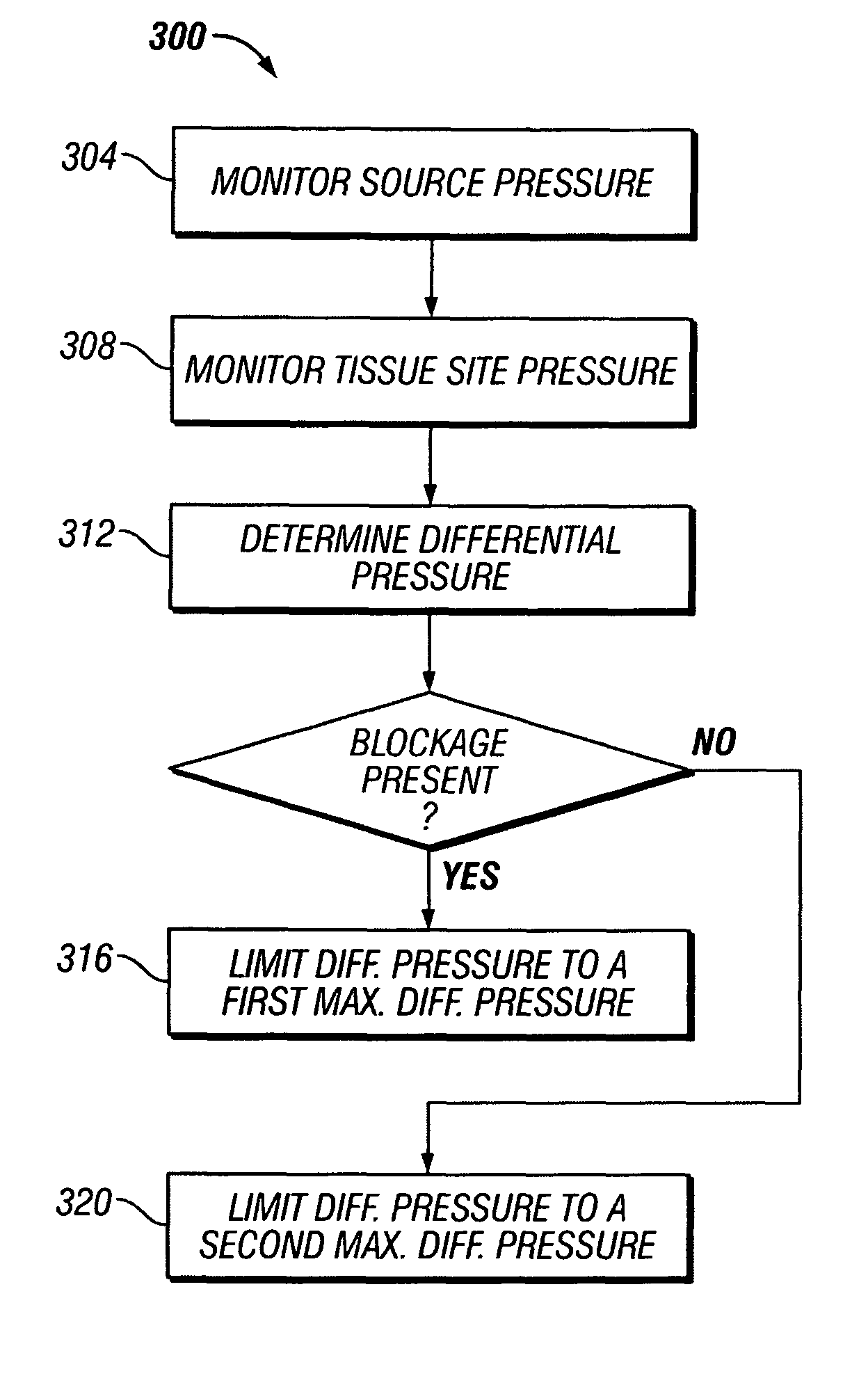

Reduced pressure treatment system having blockage clearing and dual-zone pressure protection capabilities

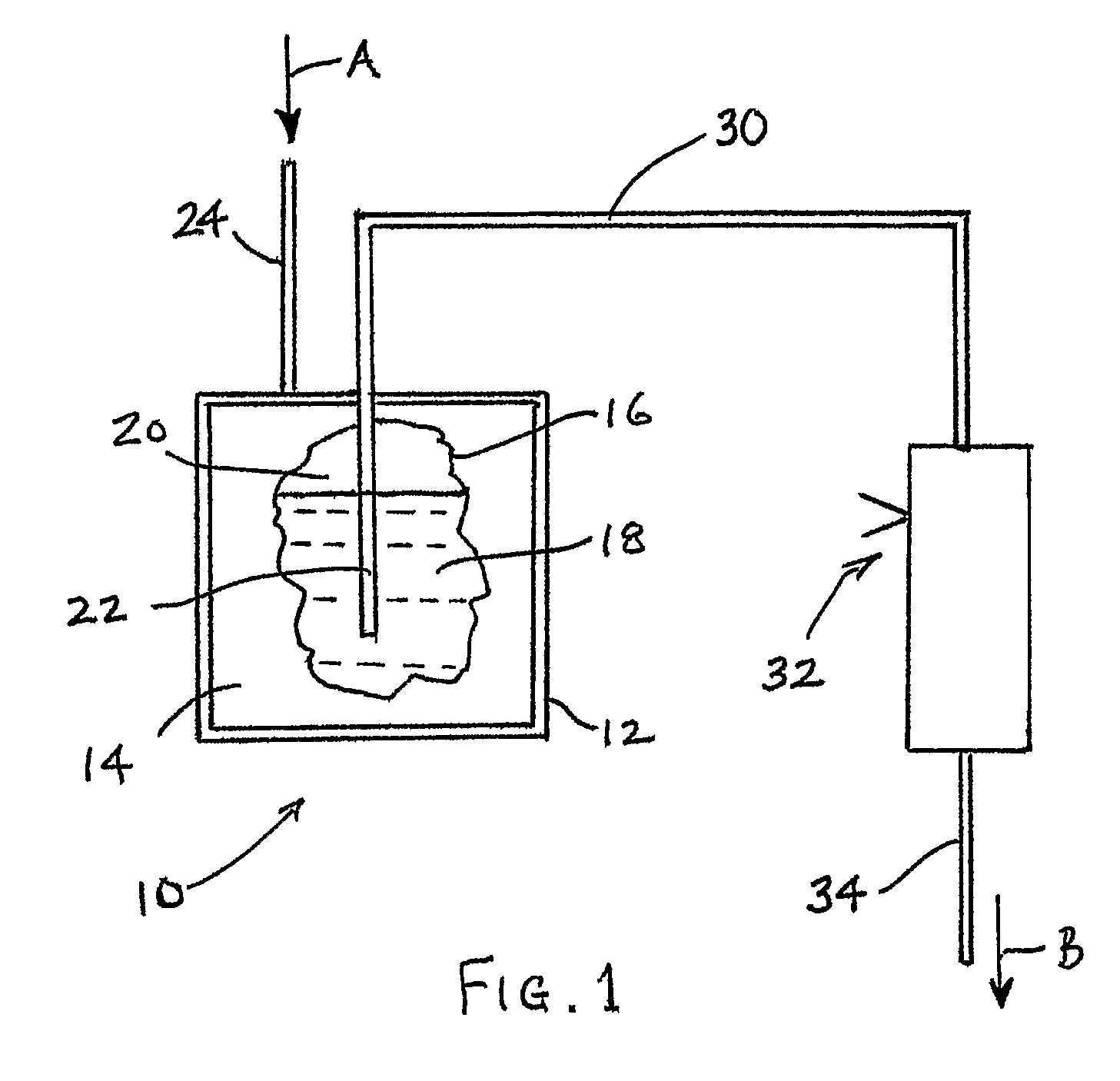

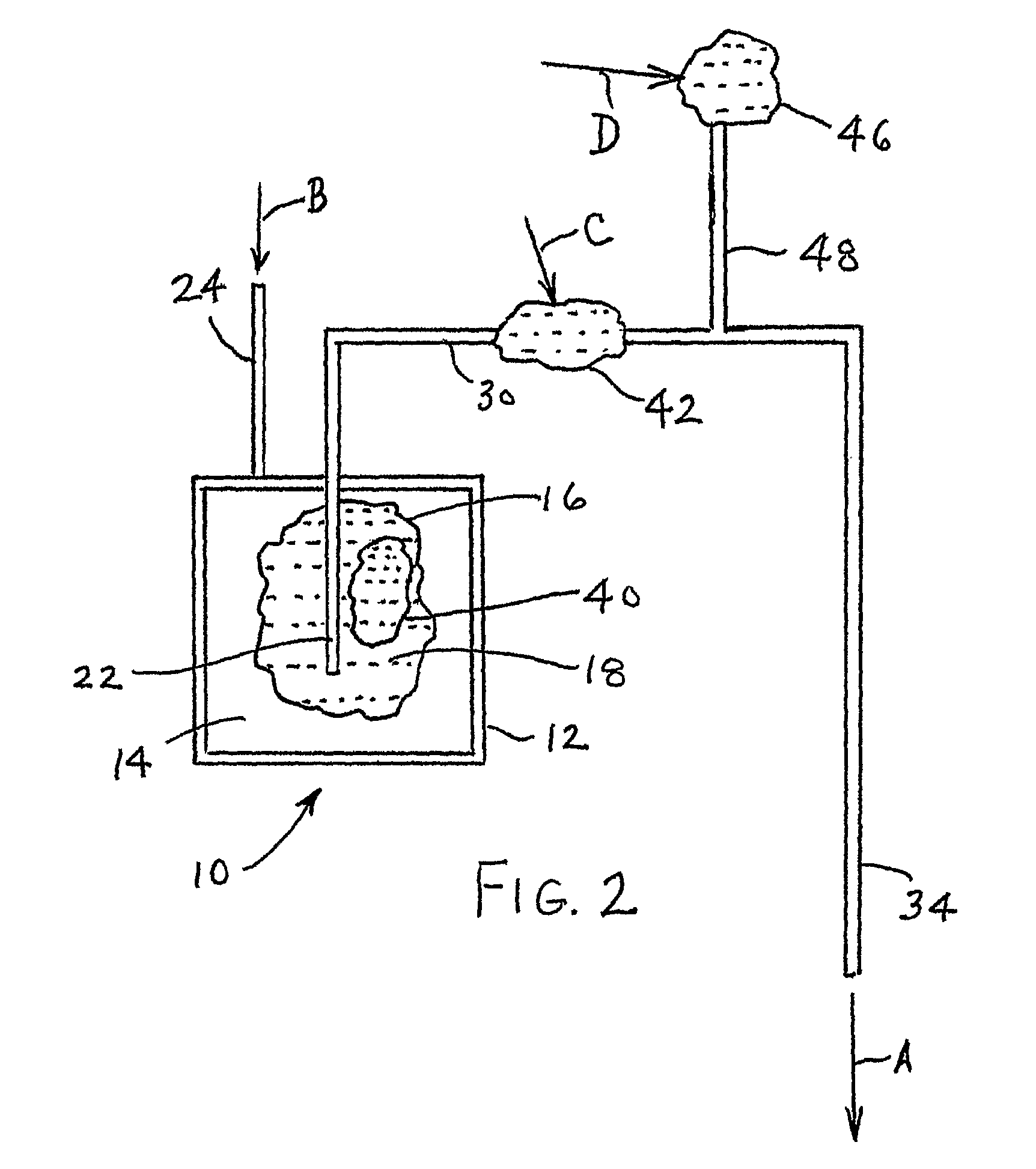

A method of treating a tissue site is provided. The method includes applying a reduced pressure to a tissue site with a reduced pressure source. A source pressure is monitored at the reduced pressure source, and a differential pressure is determined between the source pressure and the desired tissue site pressure. If a blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a first maximum differential pressure. If no blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a second maximum differential pressure.

Owner:3M INNOVATIVE PROPERTIES CO

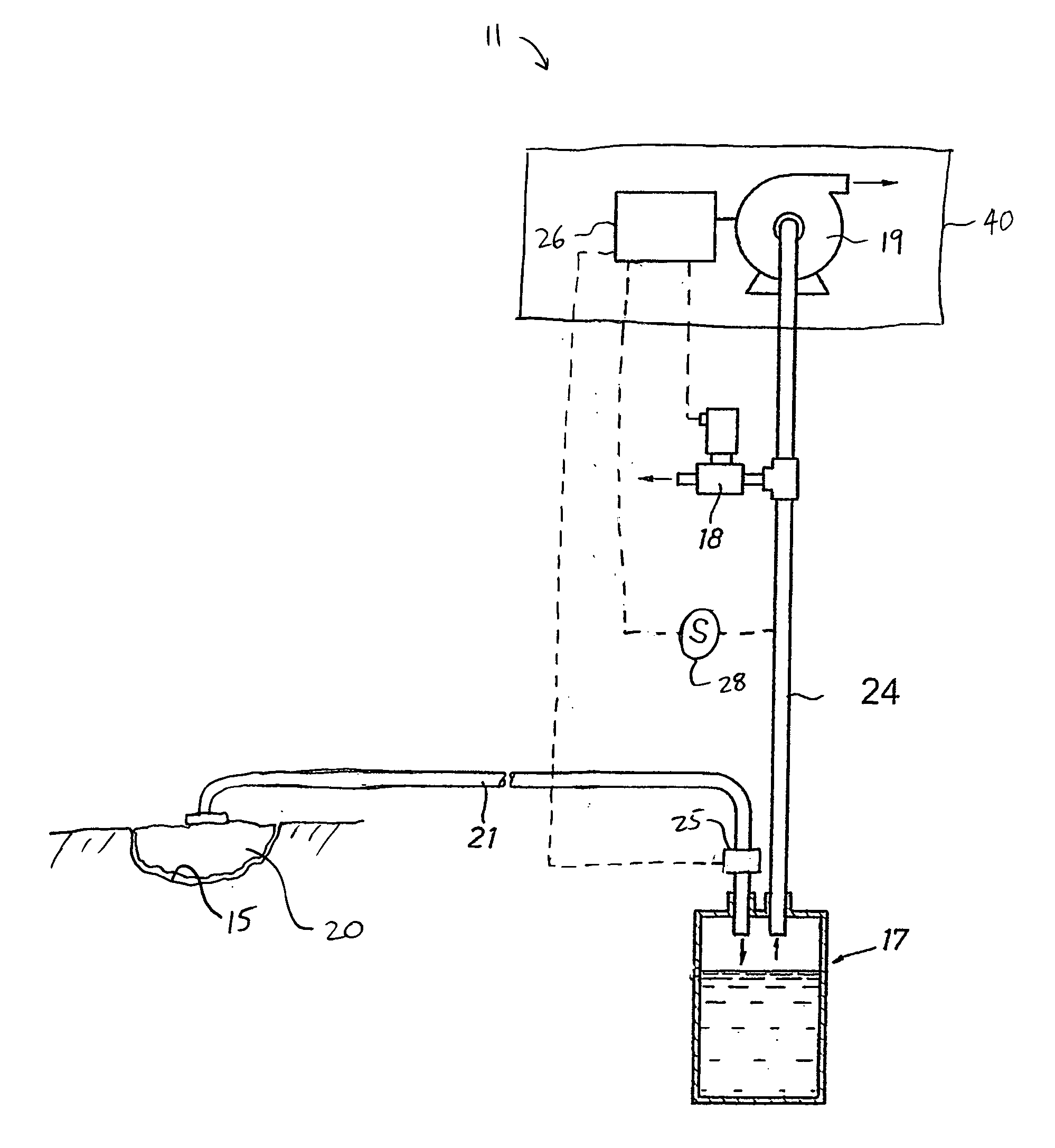

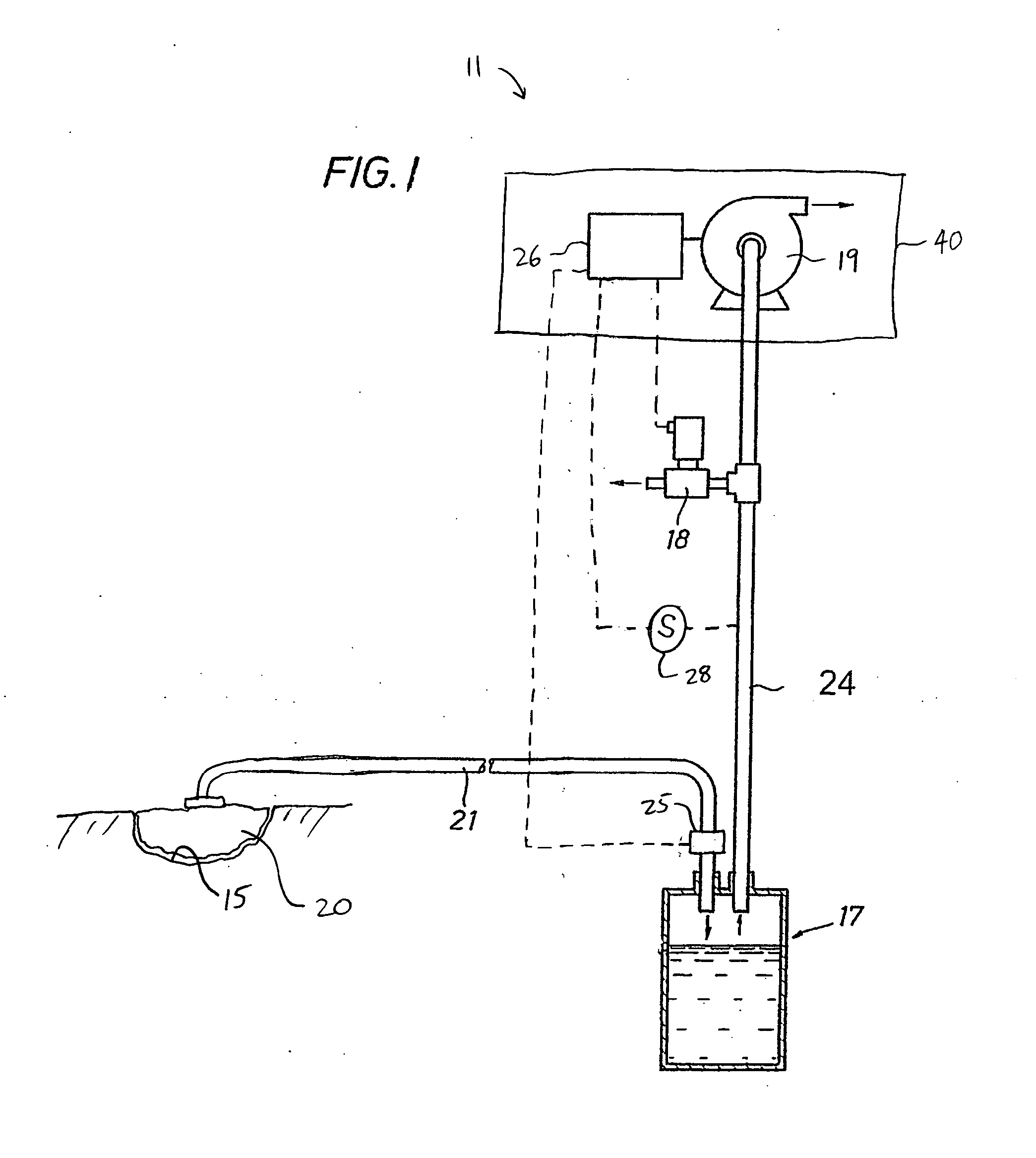

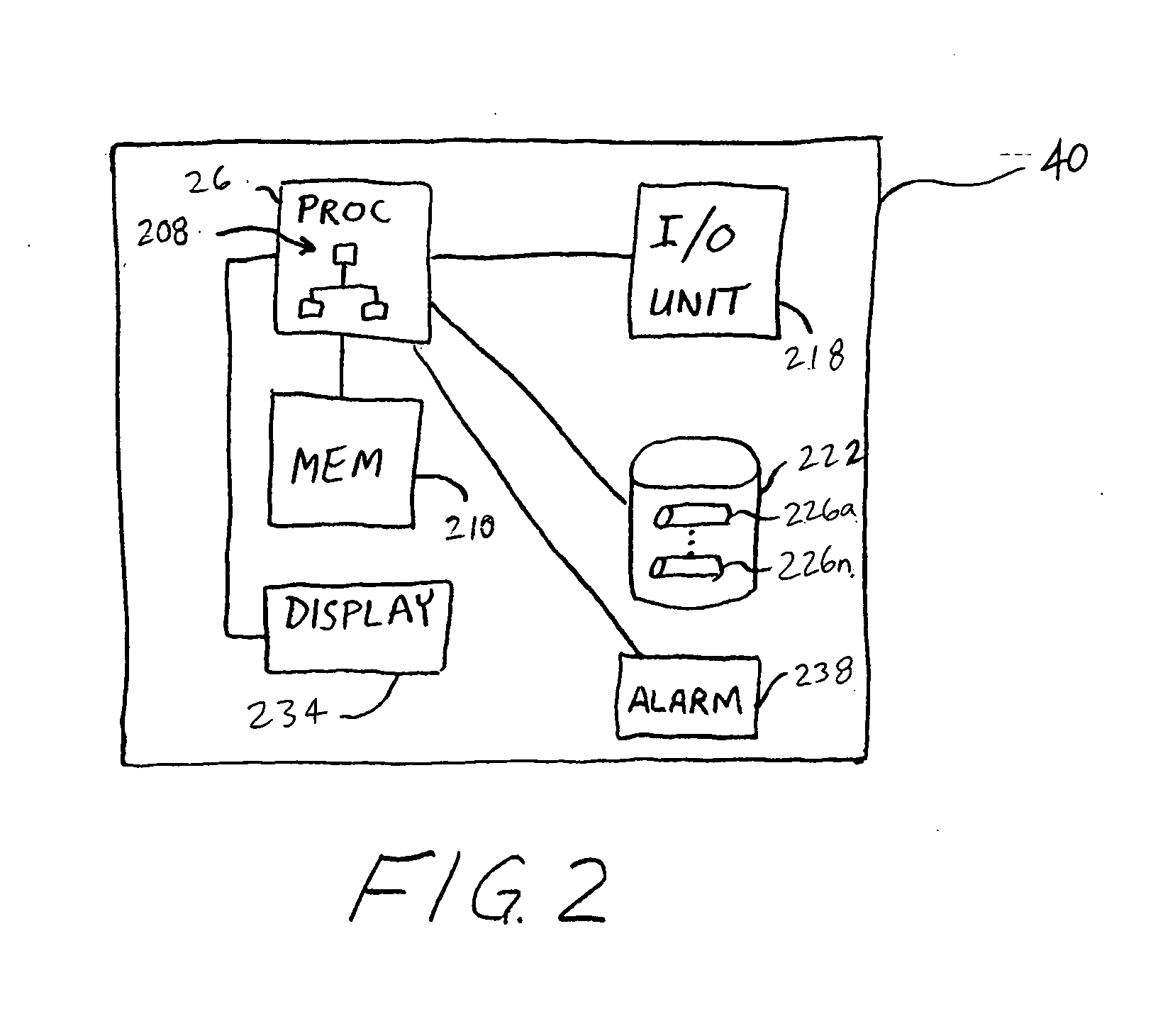

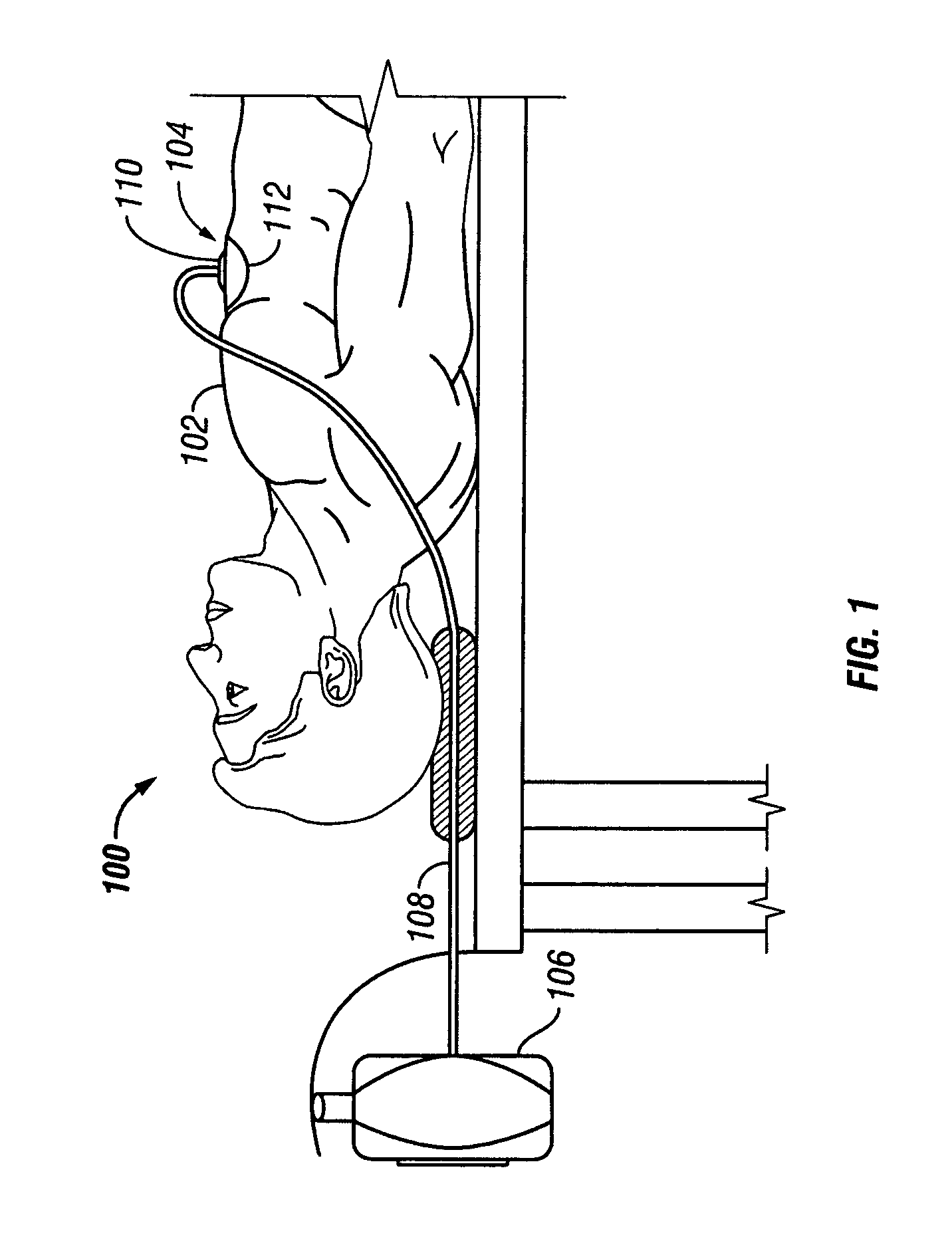

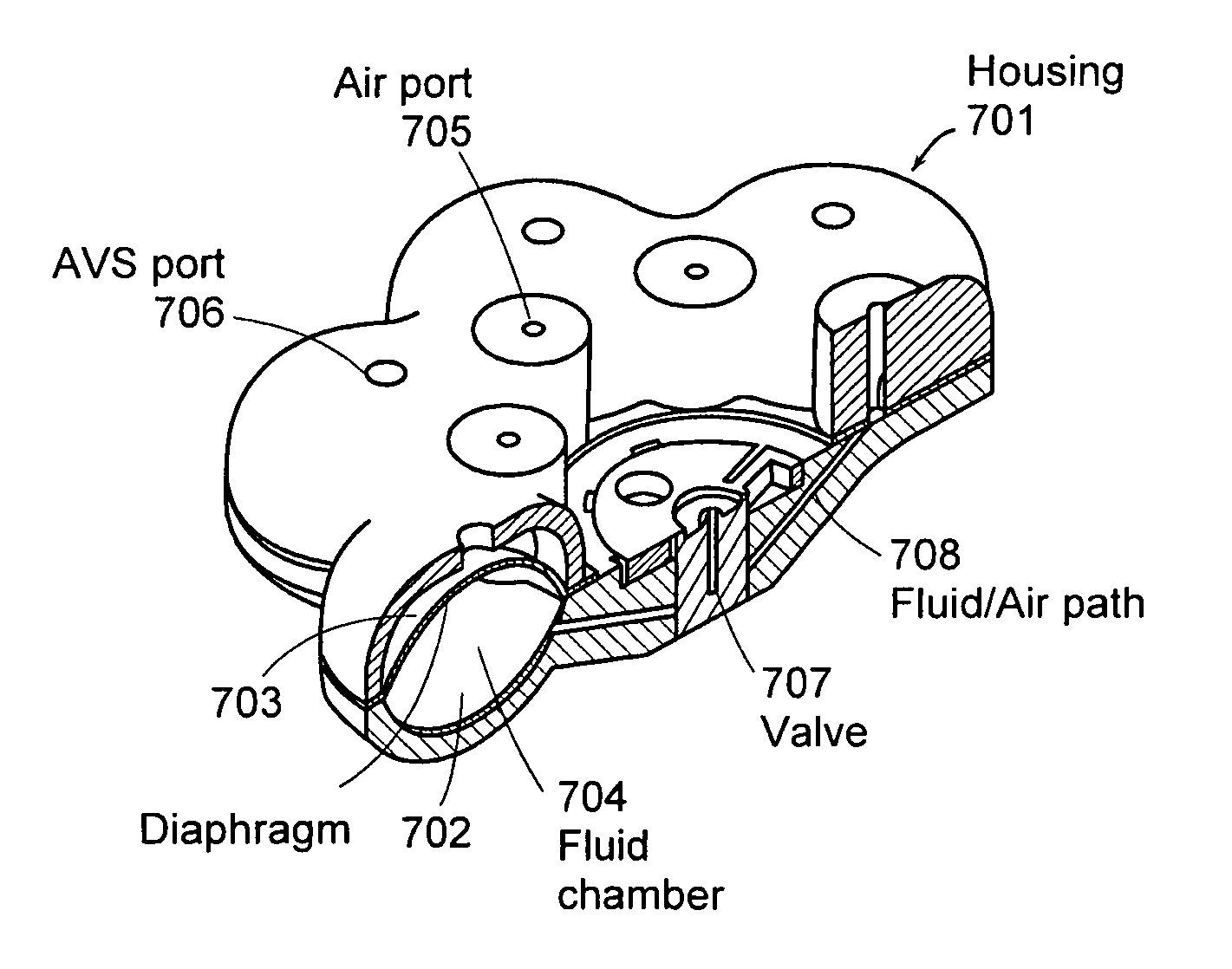

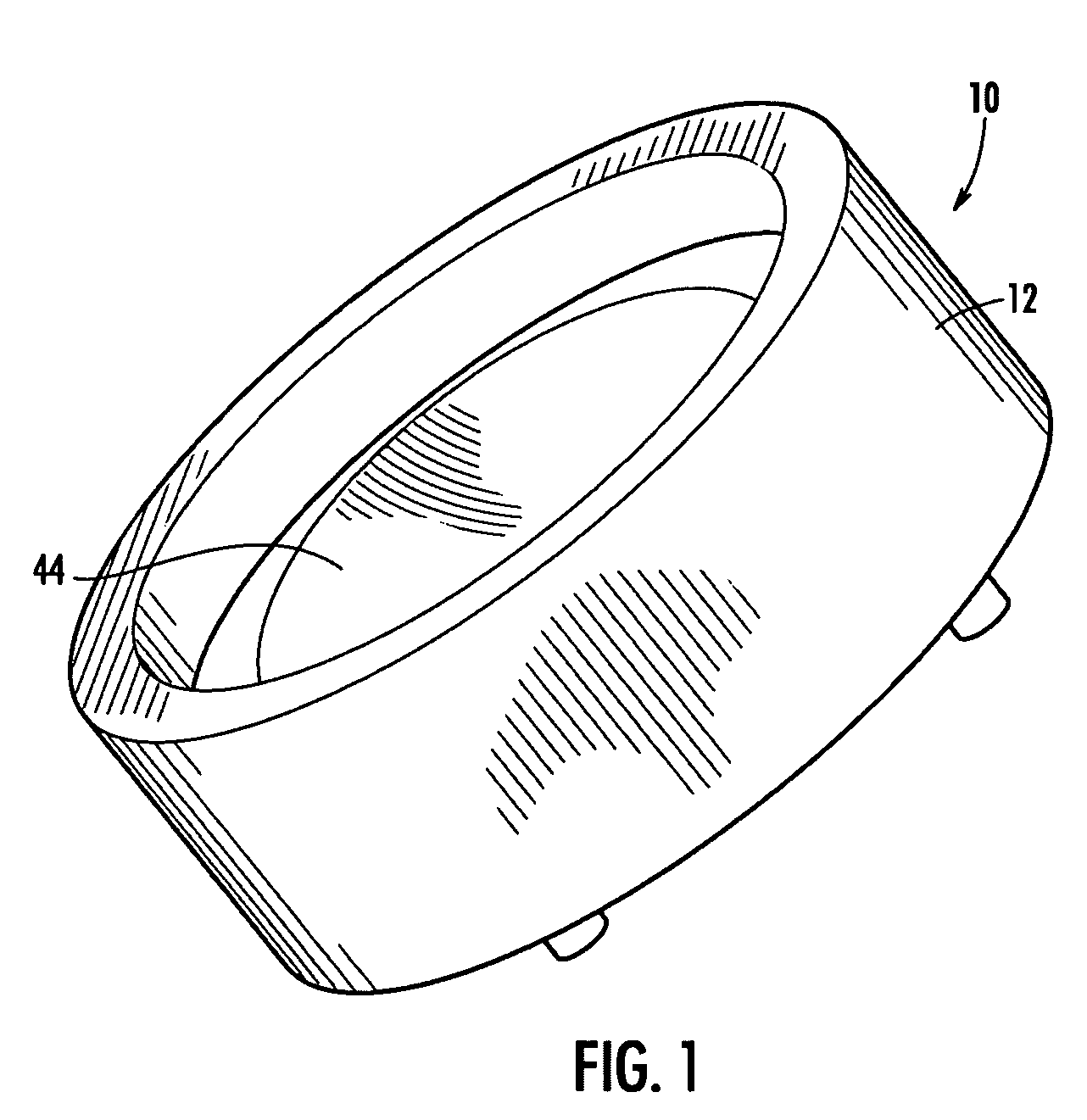

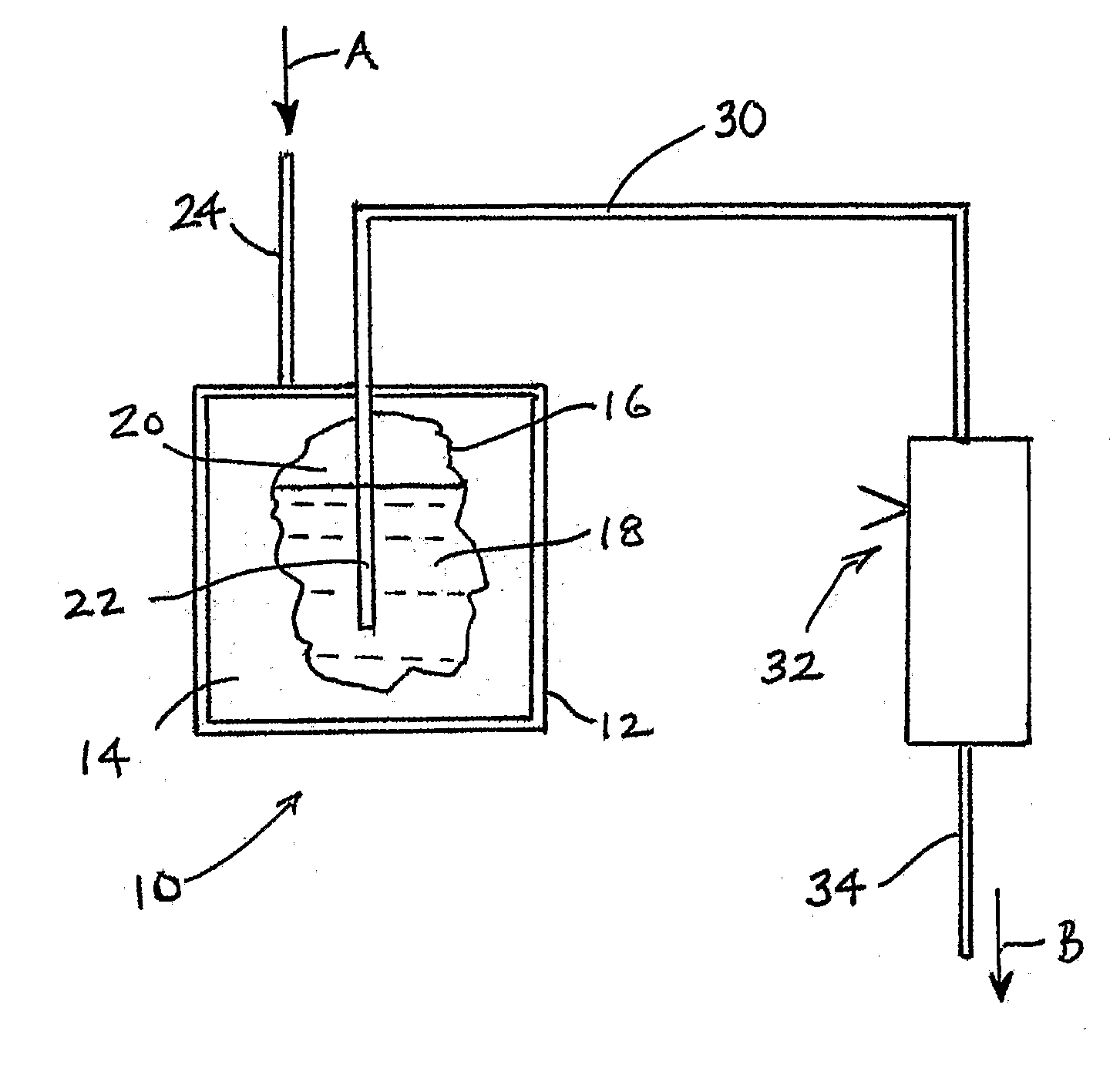

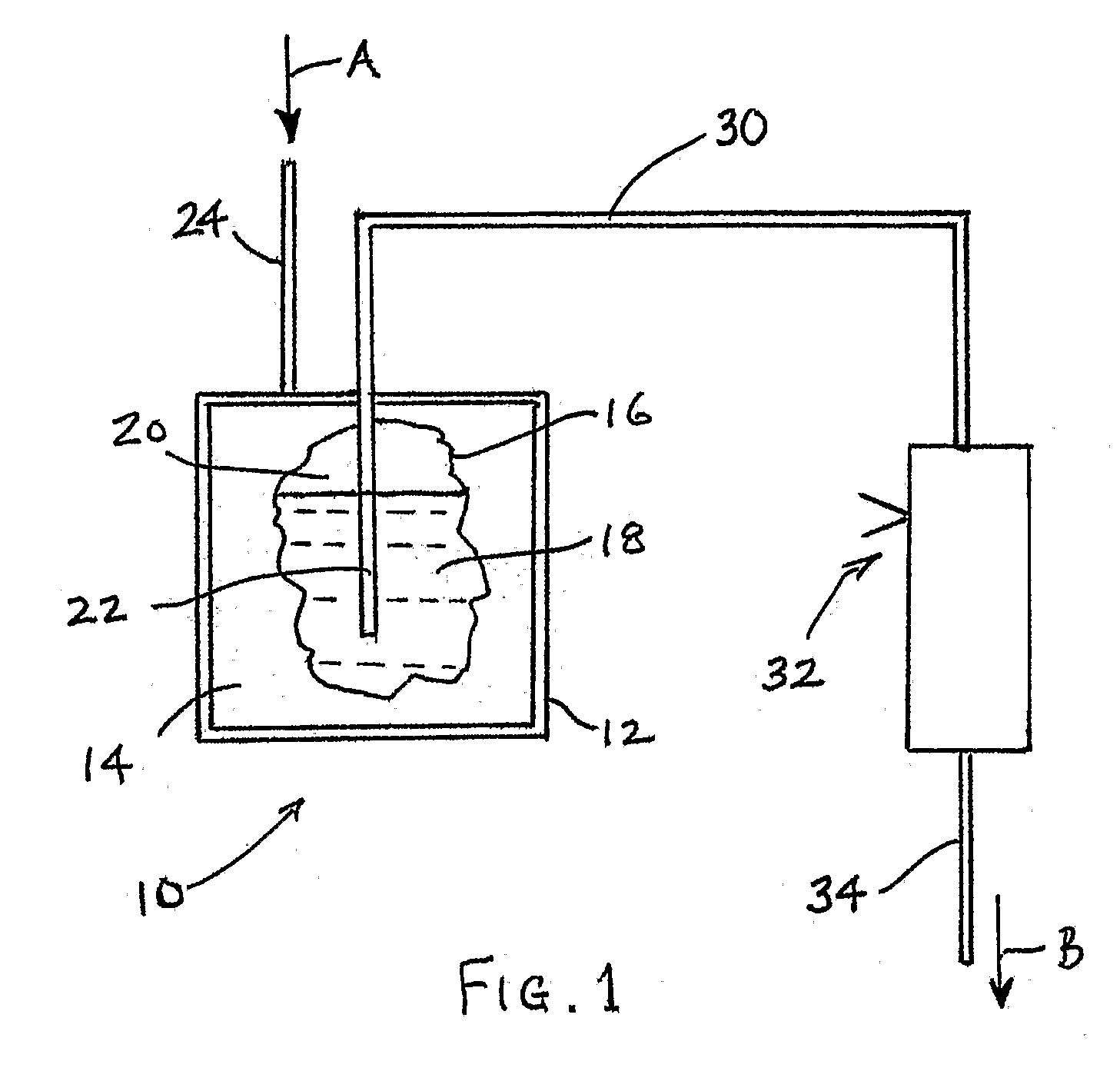

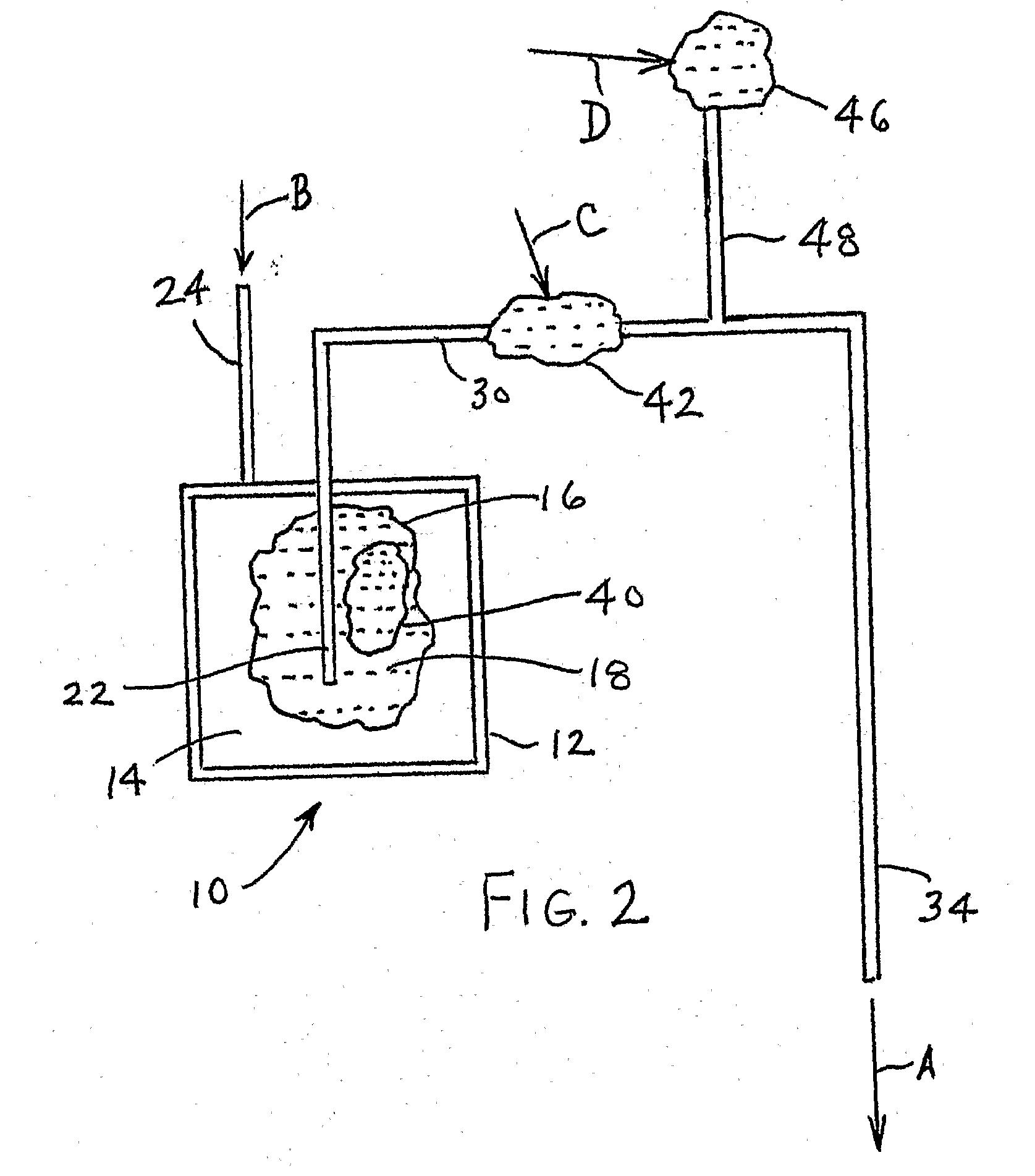

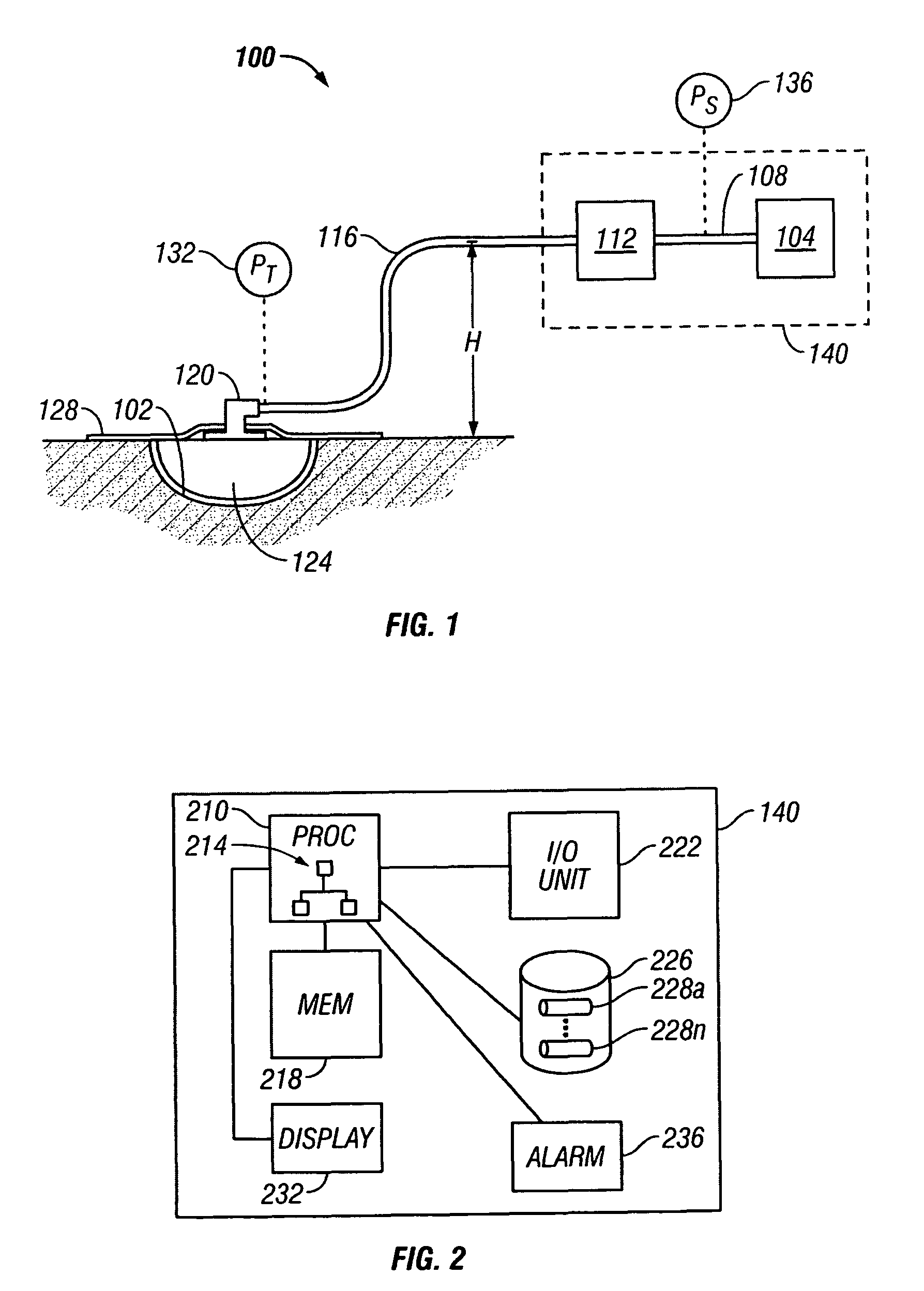

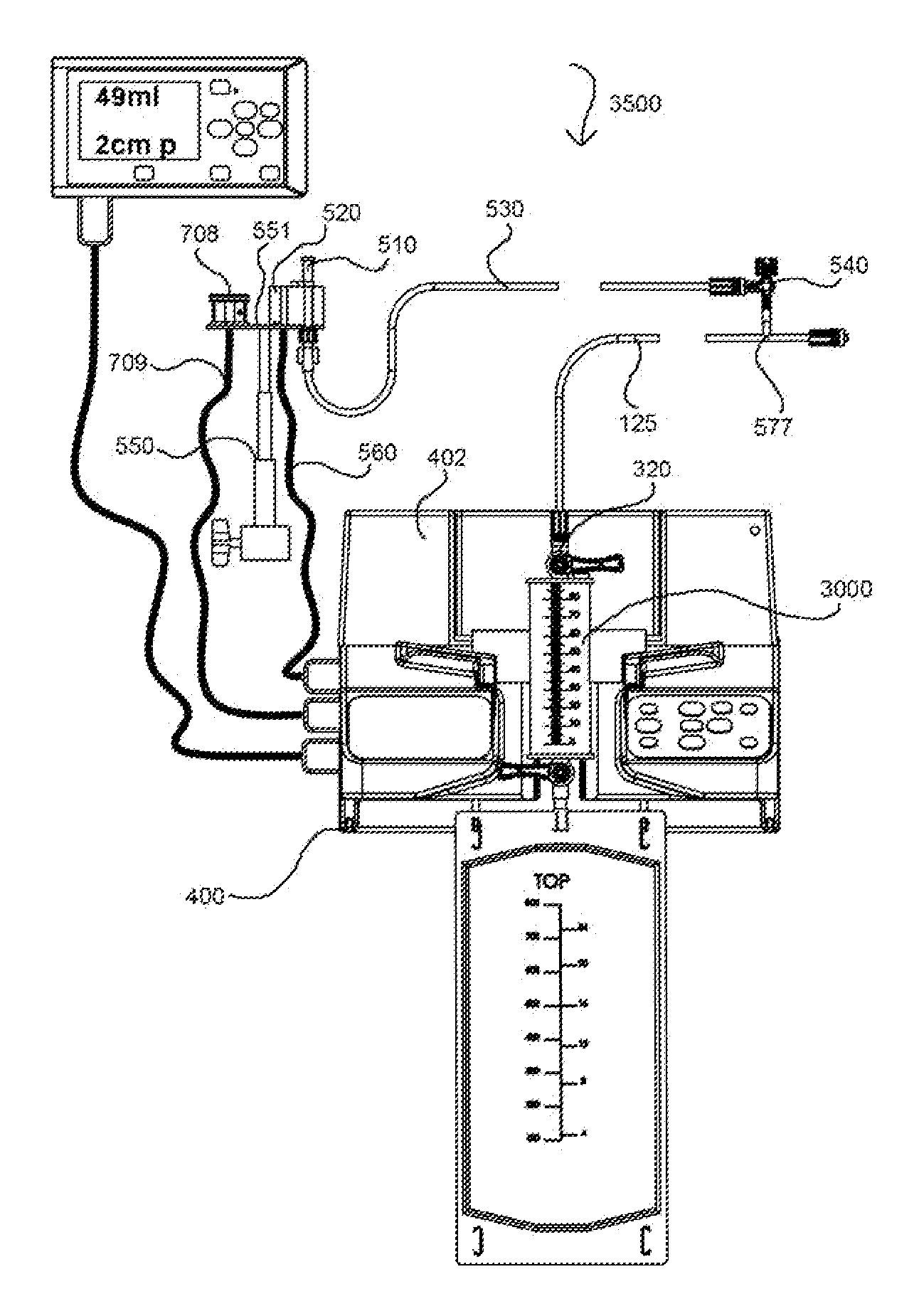

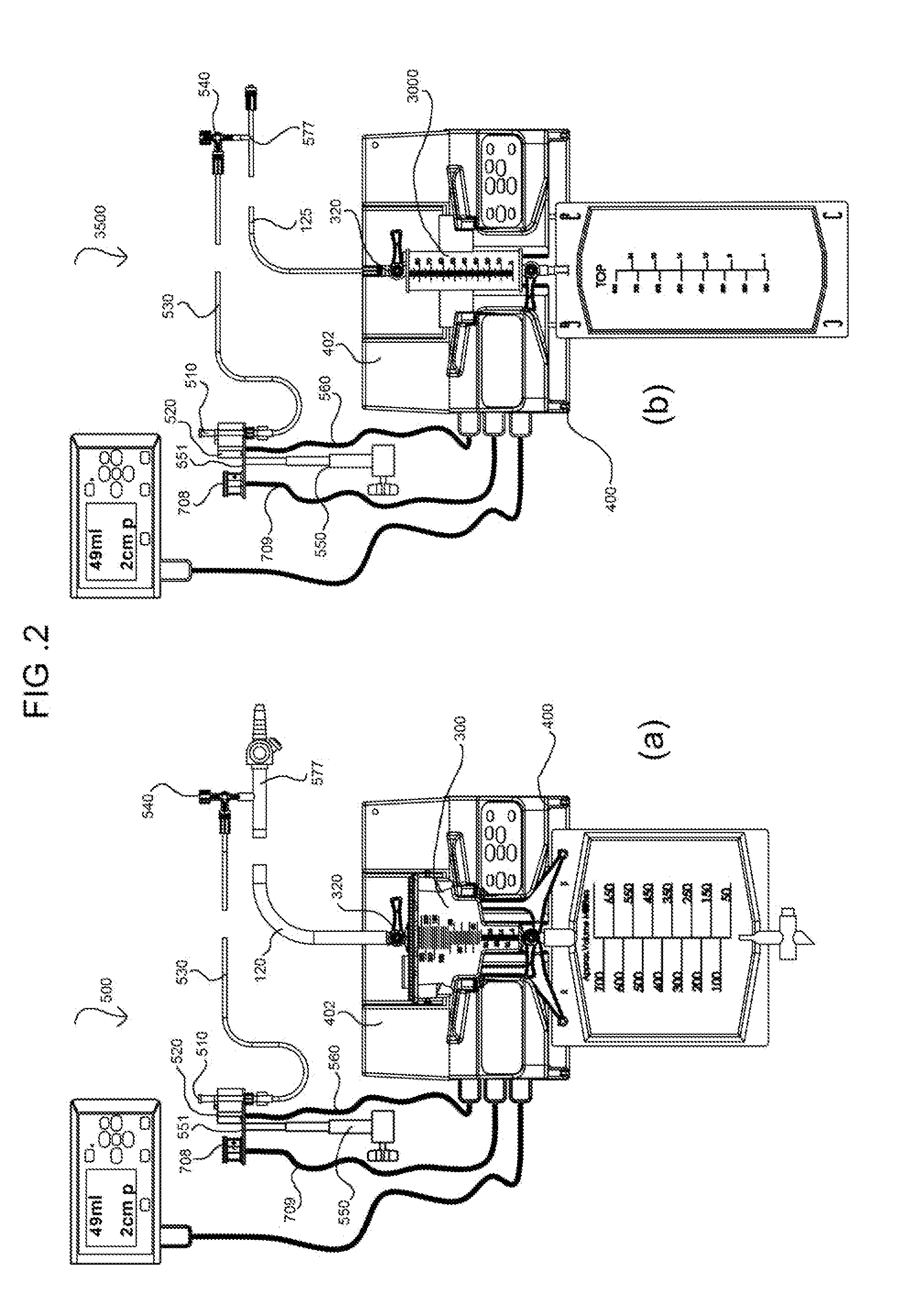

System and method for determining a fill status of a canister of fluid in a reduced pressure treatment system

ActiveUS20080071235A1Reduce pressureElectrotherapyTesting/calibration apparatusCatheterBiomedical engineering

A reduced pressure treatment system is provided that includes a canister that is fluidly connected to a tissue site and is configured to receive fluid drawn from the tissue site under the influence of a reduced pressure. A reduced pressure source provides the reduced pressure and is fluidly connected to the tissue site by a fluid communication path, which may include a source conduit, the canister, and a target conduit. A sensing device communicates with the source conduit and is configured to sense a pressure in the source conduit. A valve communicates with the source conduit and is configured to vent the reduced pressure. A processing unit communicates with the sensing device and the valve and is configured to open the valve for a selected amount of time, determine a decay of reduced pressure, and determine a fill status of the canister based on the decay of reduced pressure.

Owner:KCI LICENSING INC

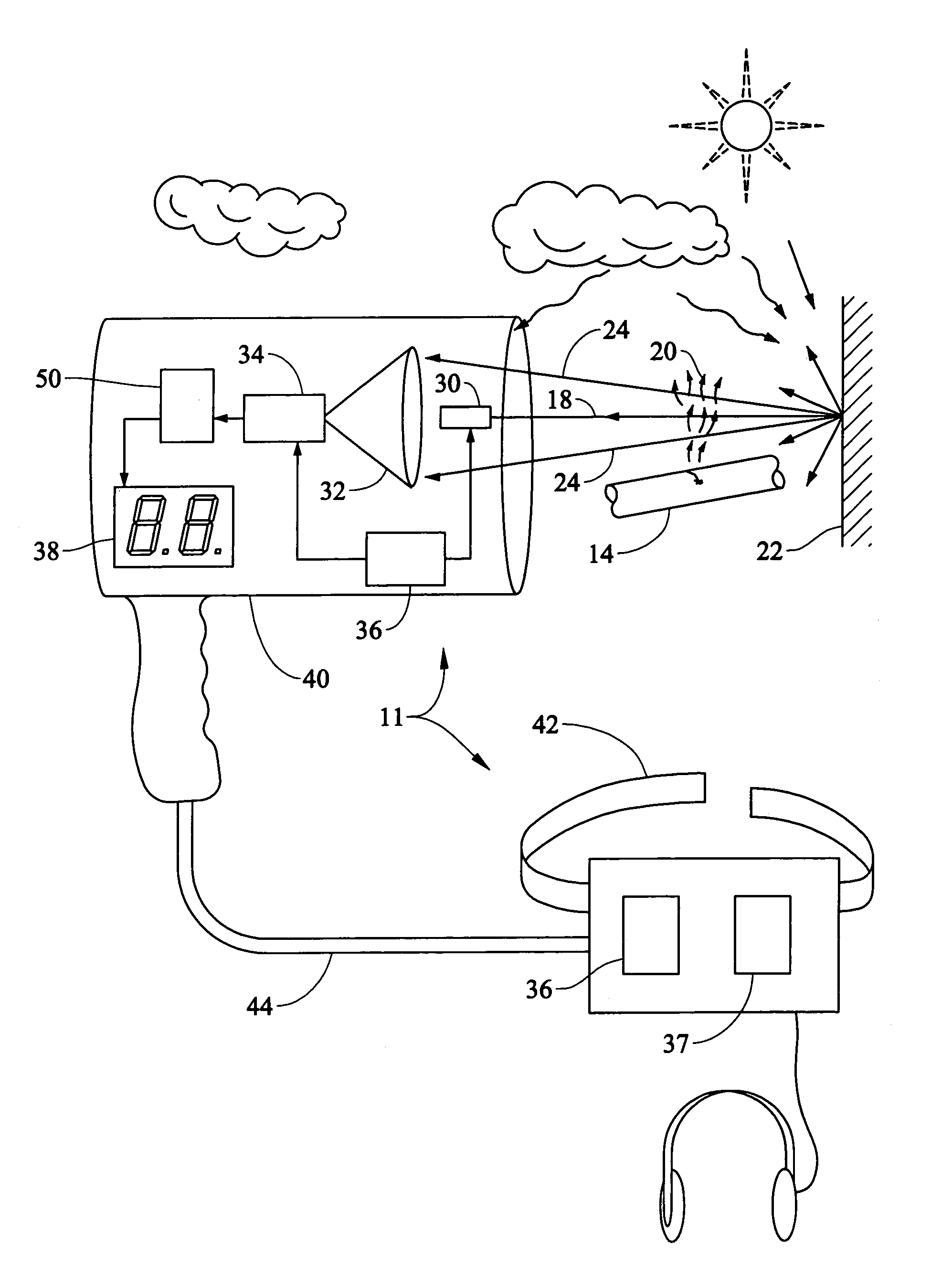

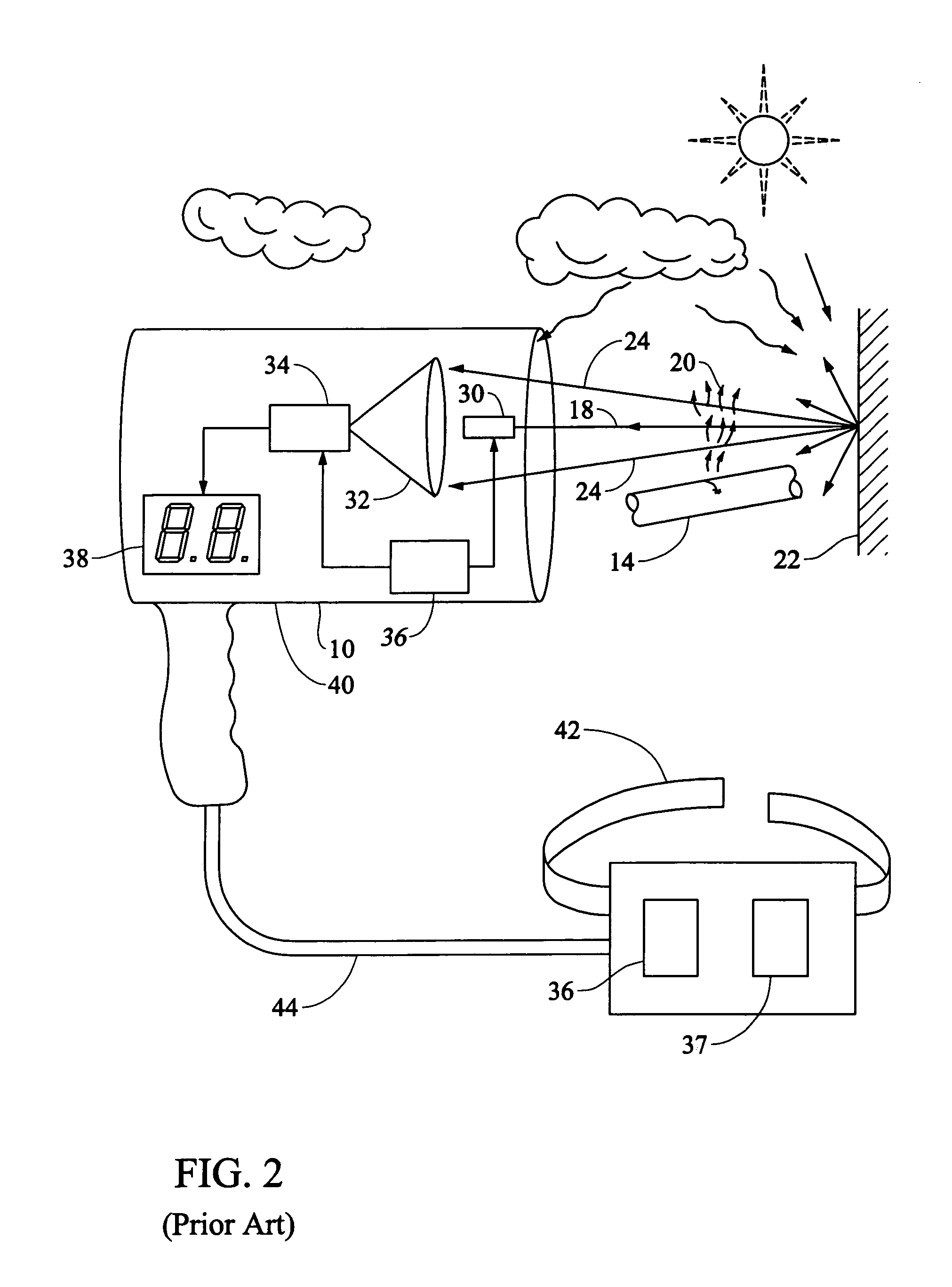

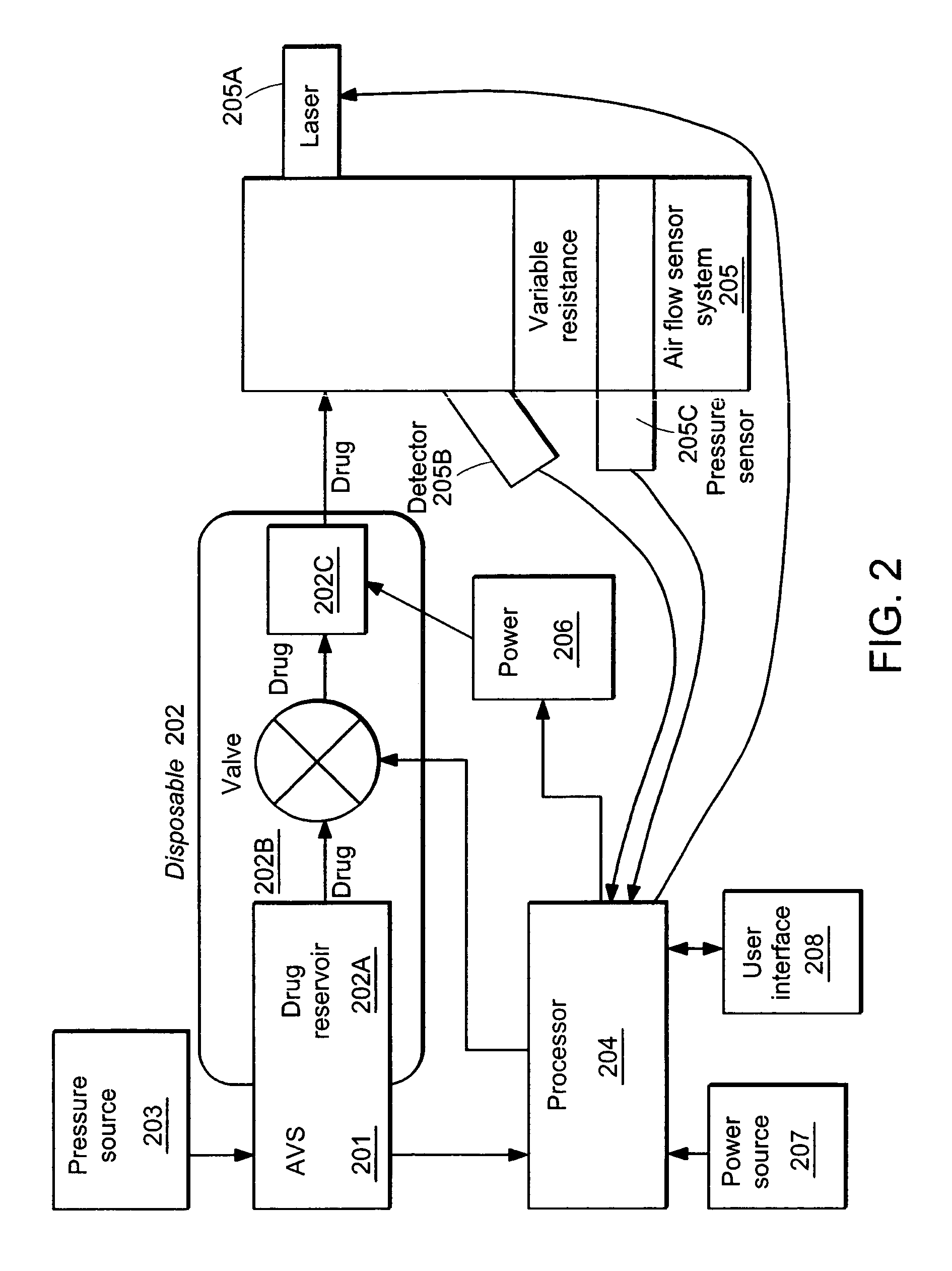

Method and apparatus for laser-based remote methane leak detection

ActiveUS7075653B1Promotes user comfortEasy to identifyDetection of fluid at leakage pointRadiation pyrometryMoving averageSpectroscopy

A method and apparatus for remote laser-based detection of gas at levels exceeding natural background levels preferably utilizing wavelength modulated tunable diode laser absorption spectroscopy. In a preferred embodiment, background gas and noise are estimated using statistical moving average and variance calculations. Gas concentration length measurements resulting from the spectroscopy are preferably compared in real-time or near-real-time to the sum of the background and noise estimates and an alarm limit to detect gas presence of concern. Gas levels exceeding this detection threshold are preferably indicated by a prolonged output tone with a pitch indicative of the magnitude of the gas measurement, and gas levels below the detection threshold are preferably indicated by silence.

Owner:HEATH CONSULTANTS

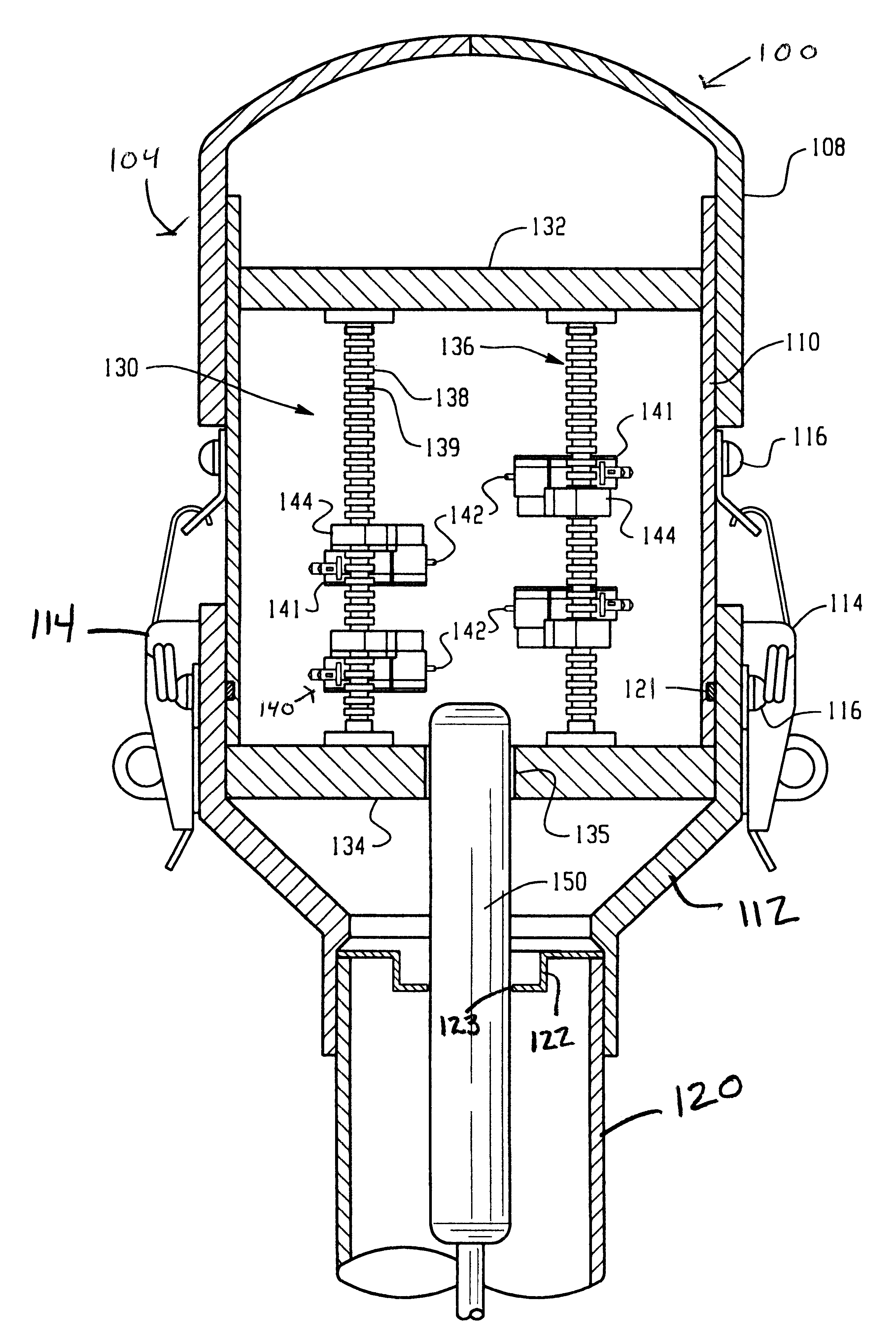

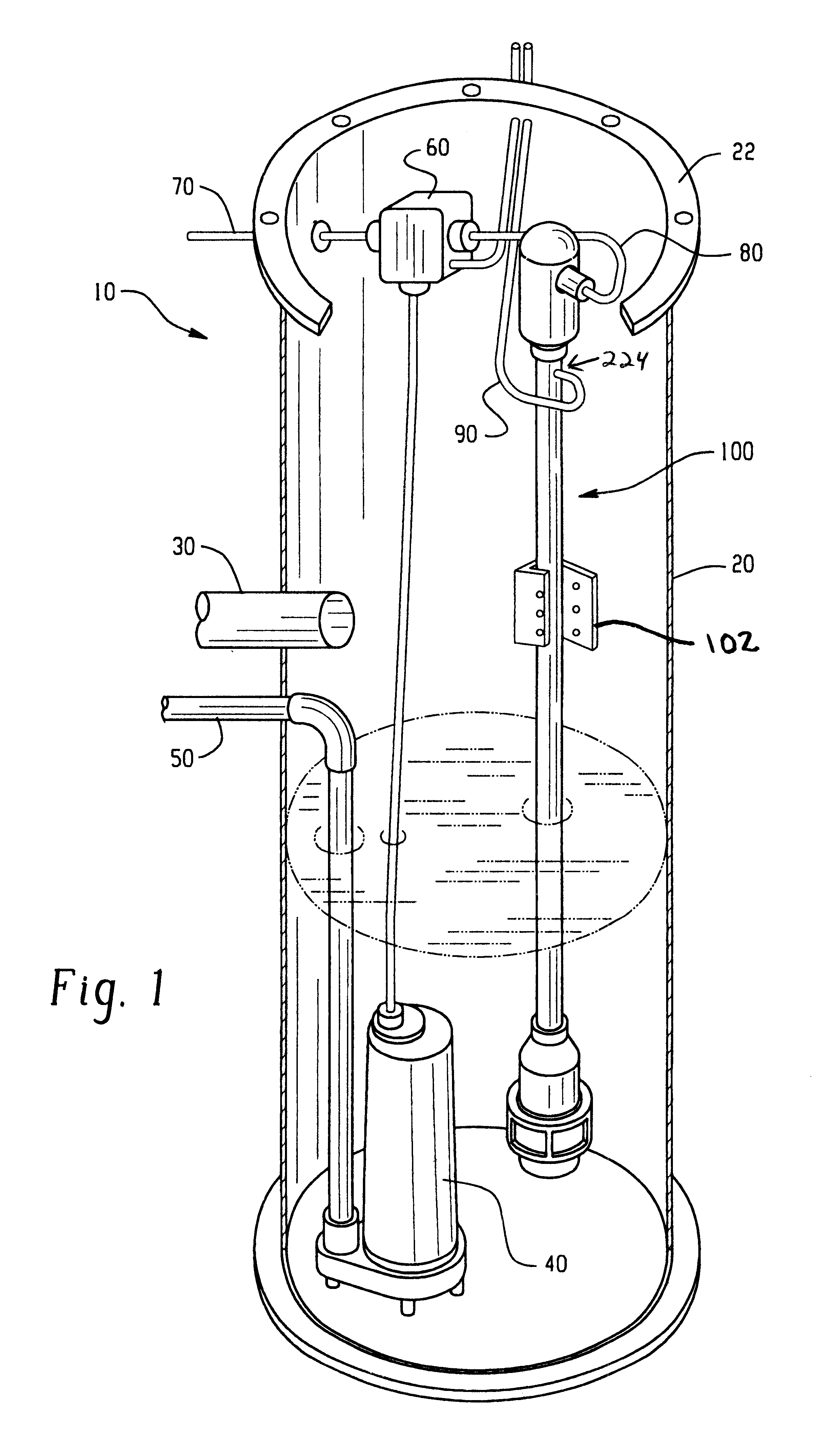

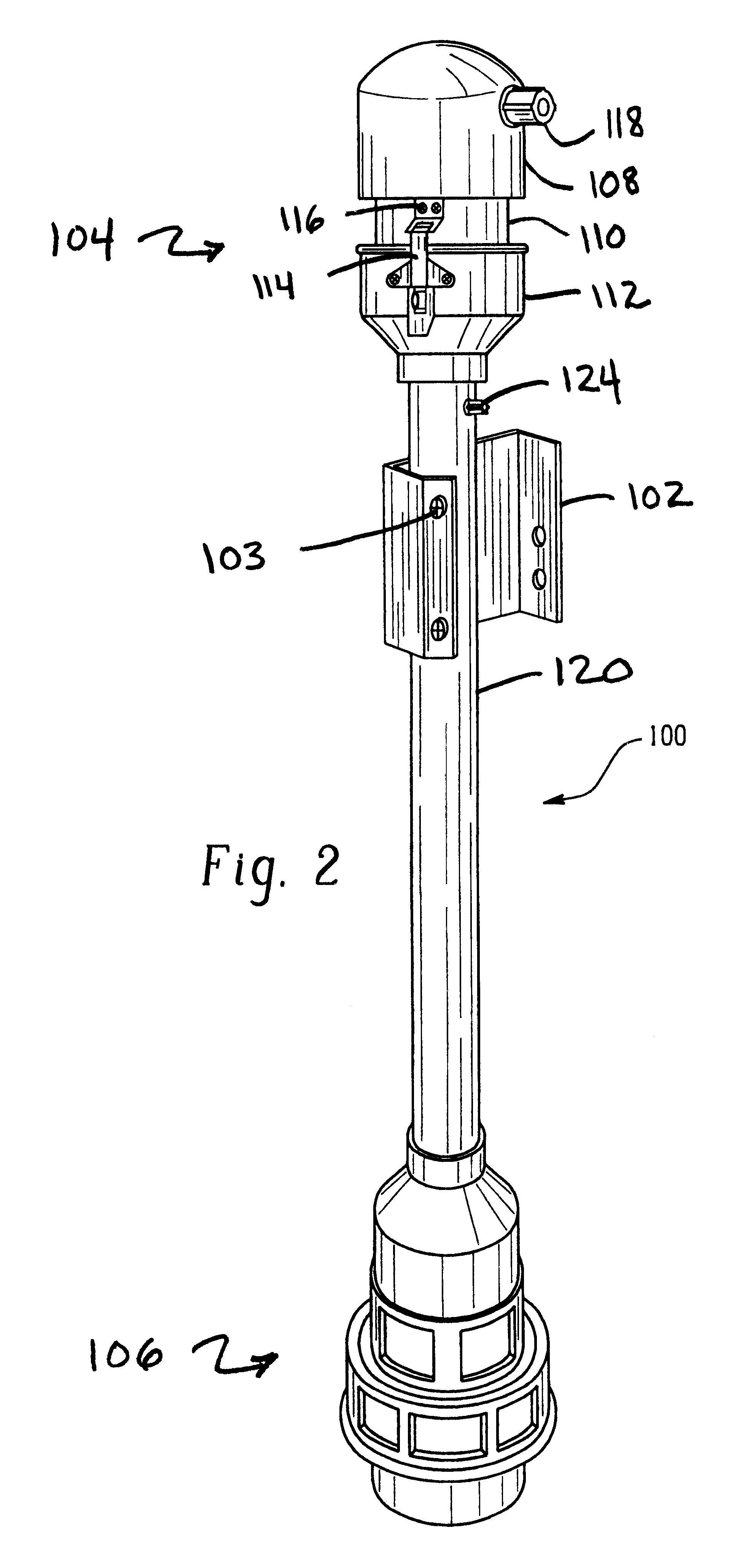

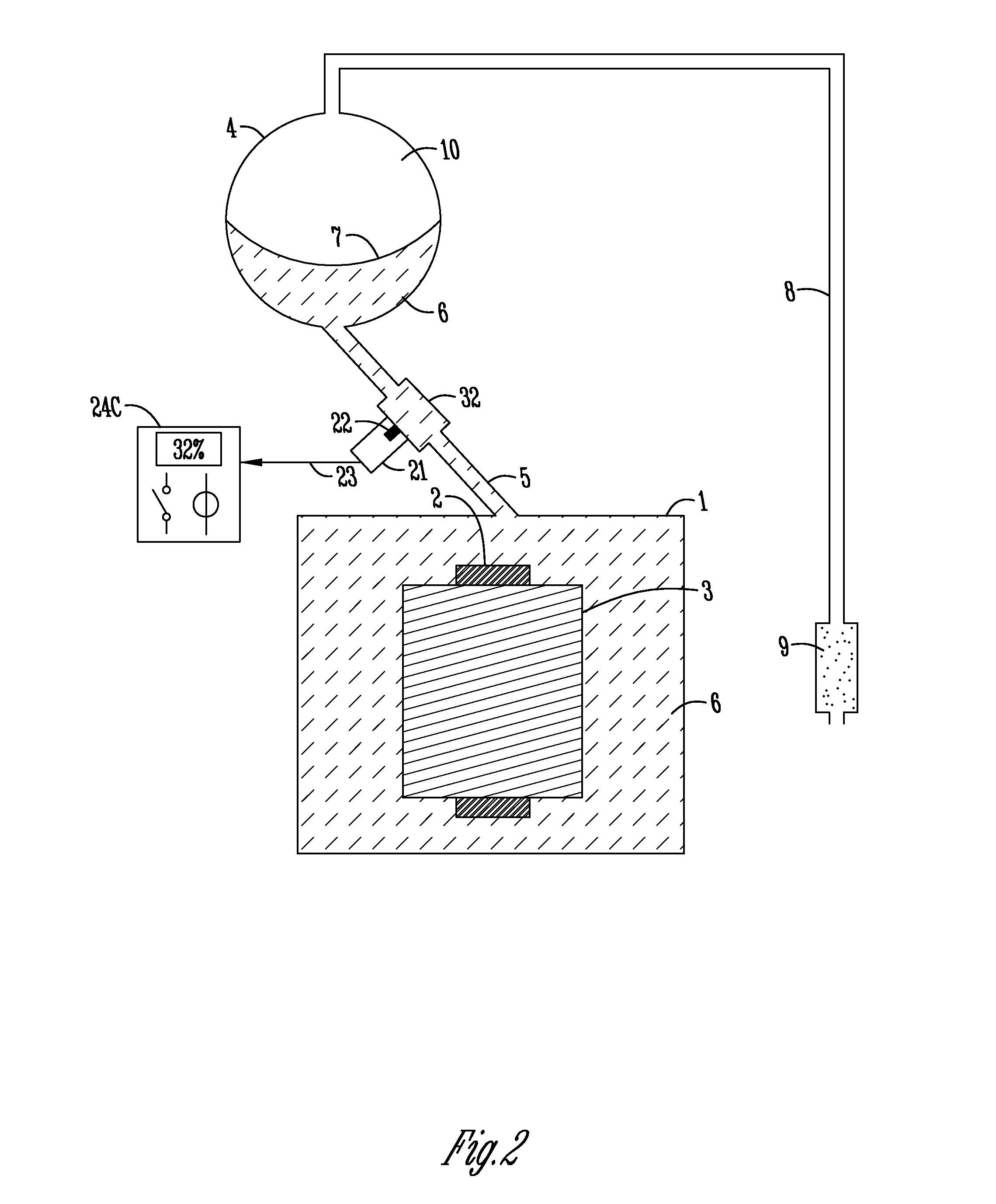

Fluid level sensing and control system

InactiveUS6595051B1Easy to captureReduce system costFluid pressure measurement by electric/magnetic elementsElectric switchesControl systemTransducer

An improved pressure activated control apparatus is provided for sensing fluid pressure and triggering one or more switches in response to the fluid pressure, as desired. The apparatus is designed to be placed within a fluid of a reservoir. The apparatus includes a first resilient member, such as a pliable rolling diaphragm or bellofram, having an outer surface exposed to the fluid and responsive to the fluid pressure. The pressure activated control apparatus includes a second resilient member, such as a spring with a chosen spring constant, k, that provides a biasing force against the diaphragm that is opposite the fluid pressure. A transducer is operative to monitor changes in pressure of gases within the apparatus causes by movement of the diaphragm. A controller is responsive to the transducer and selectable fluid level thresholds to activate pumps and / or valves for adjusting the level of the fluid in the reservoir.

Owner:SJE RHOMBUS

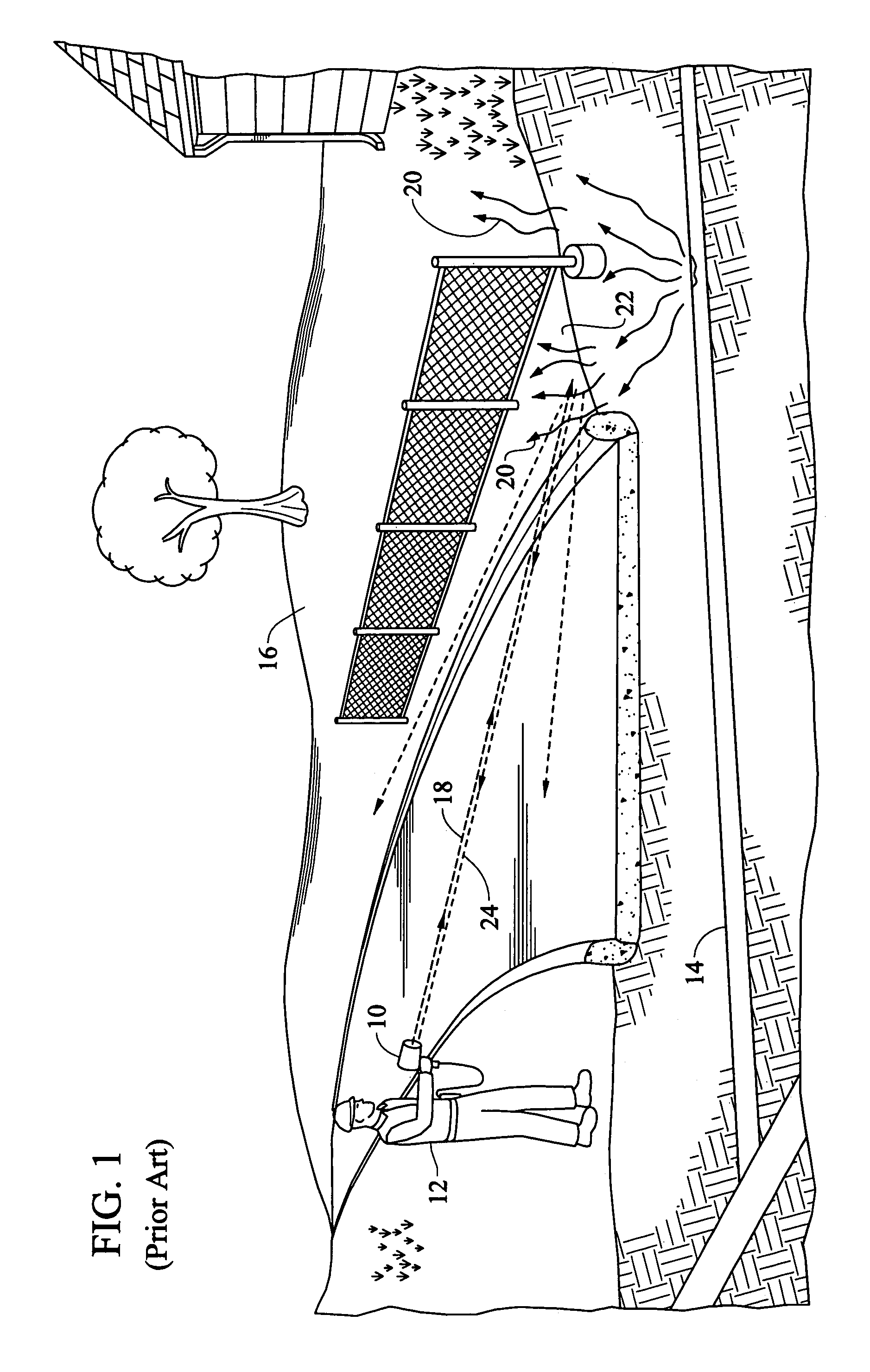

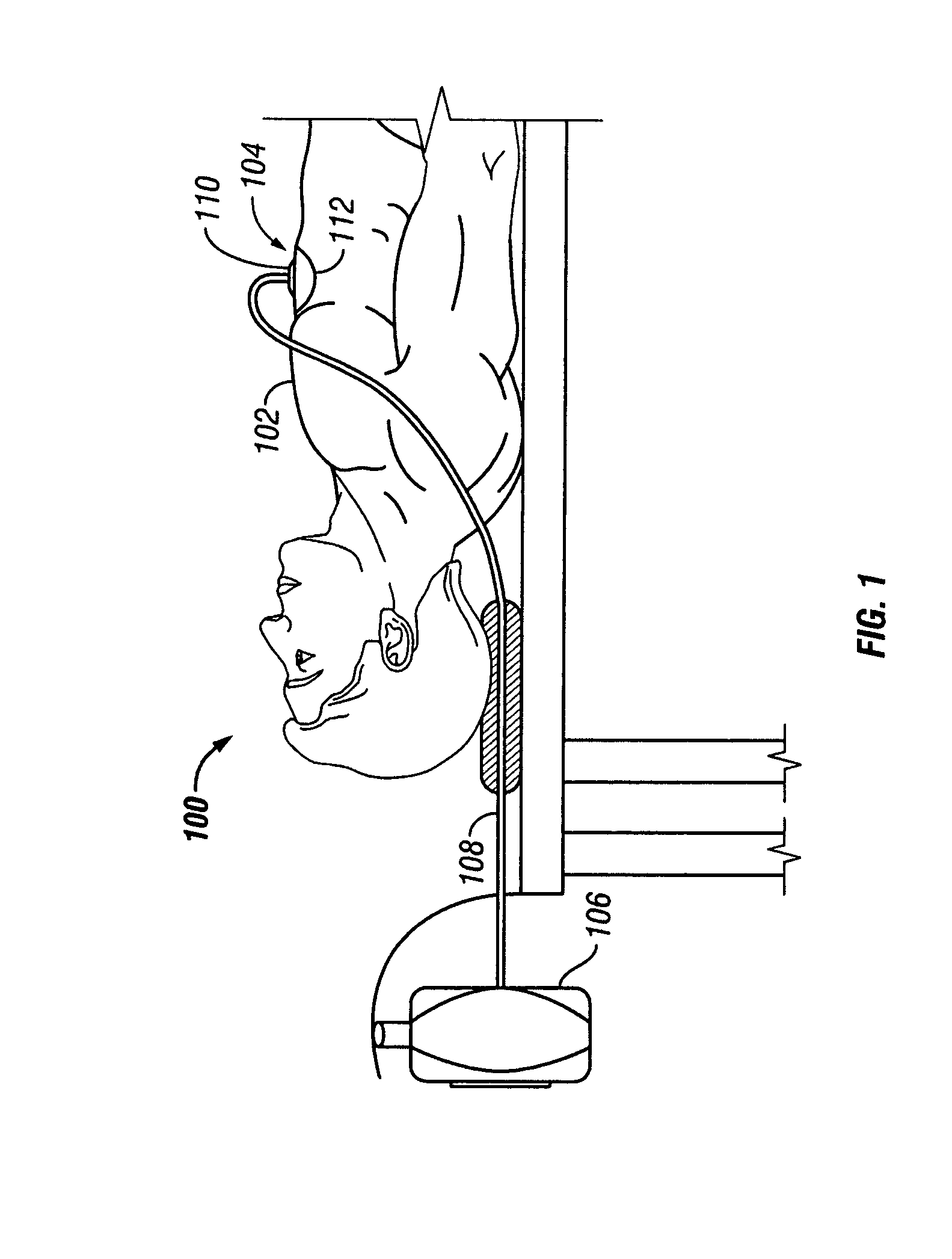

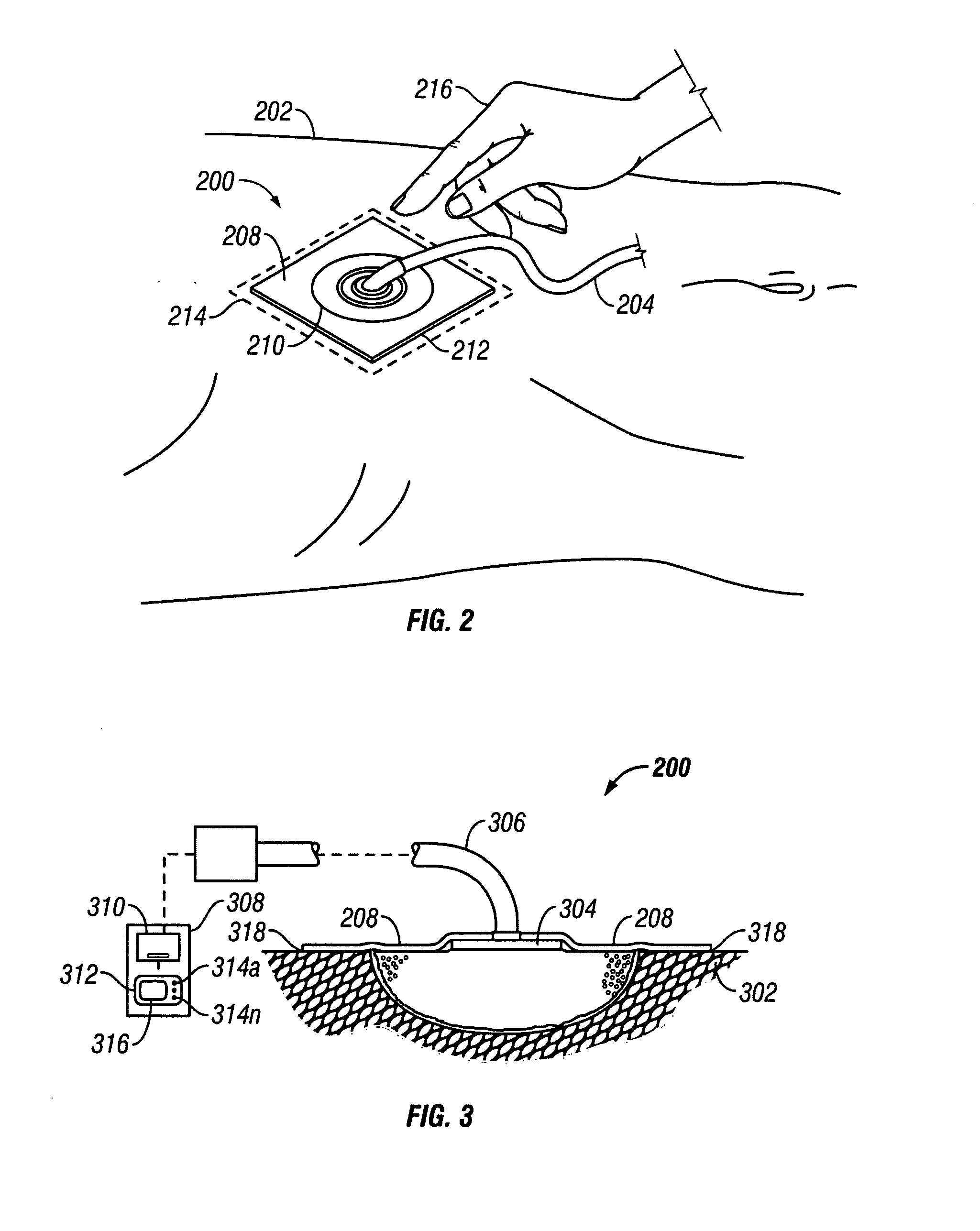

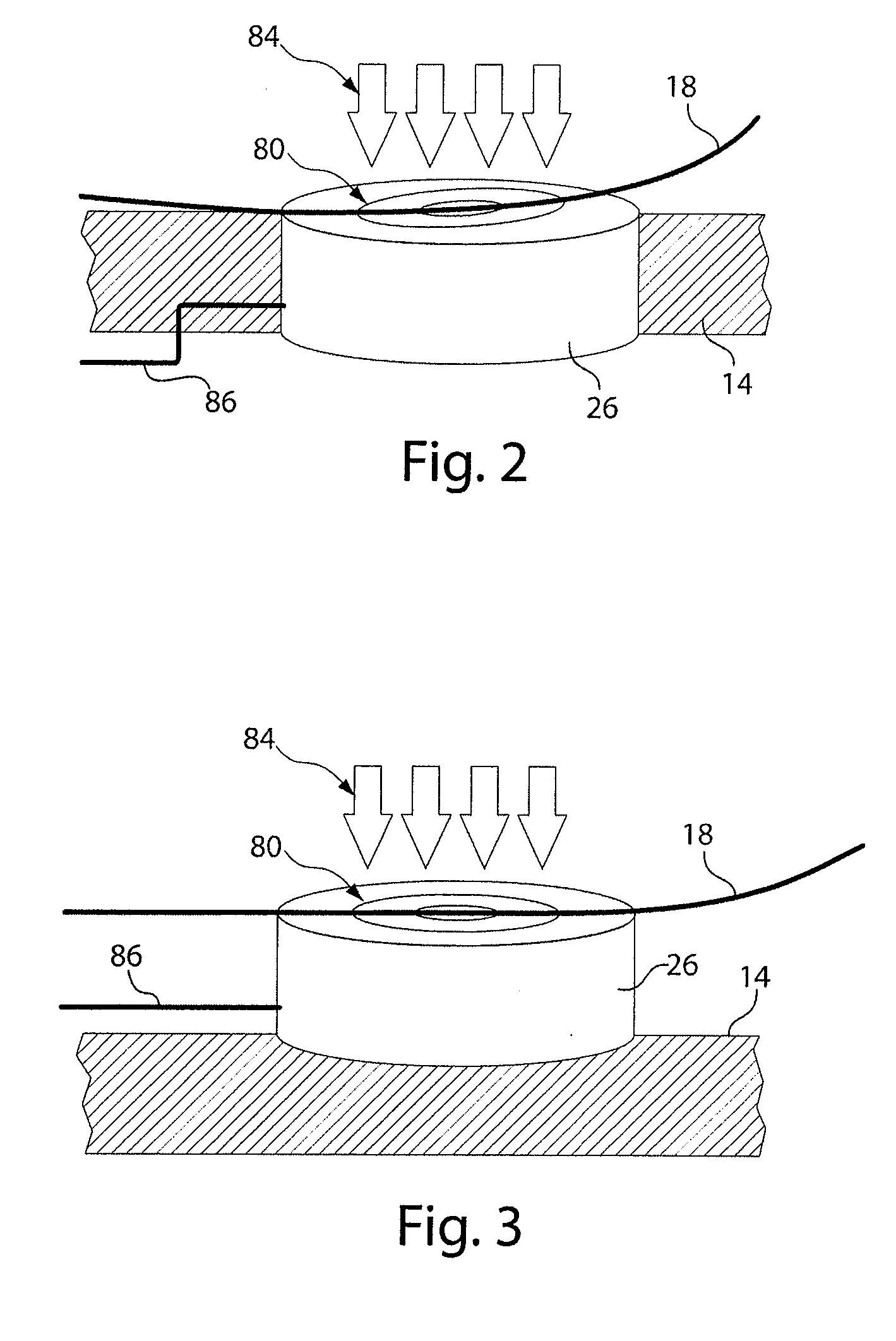

System and method for locating fluid leaks at a drape of a reduced pressure delivery system

A system and method for performing tissue therapy may include applying a reduced pressure to a tissue site of a patient. A fluid parameter associated with applying a reduced pressureto the tissue site may be sensed. An audible fluid leak location sound may be generated in response to sensing the fluid parameter. The audible fluid leak location sound may be altered in response to sensing that the fluid parameter changes. By altering the audible fluid leak location sound in response to sensing a change of the fluid parameter, a clinician may detect location of a fluid leak at the drape by applying force to the drape. The force applied to the drape may be a clinician pressing a finger onto an edge of the drape.

Owner:SOLVENTUM INTPROP CO

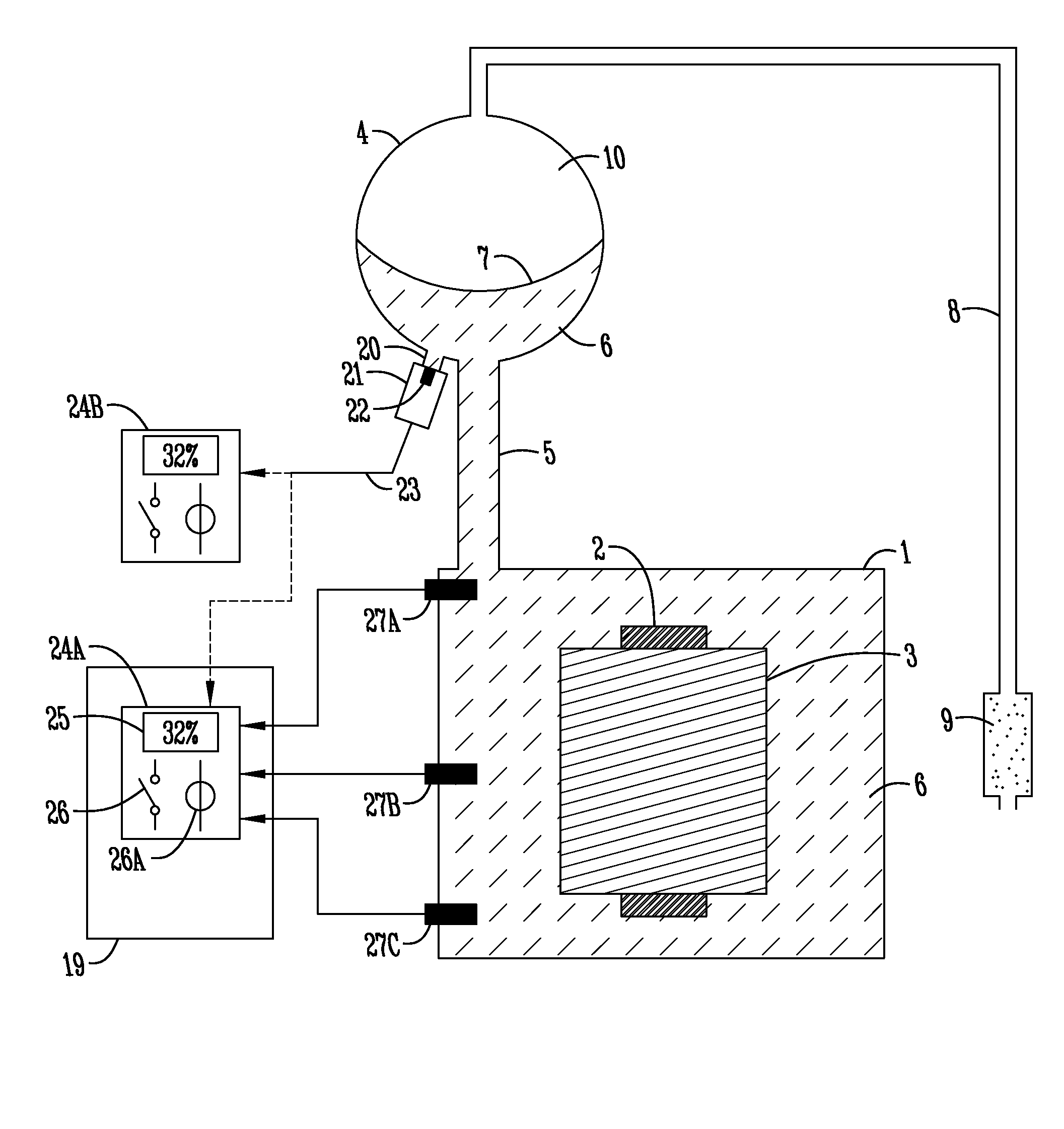

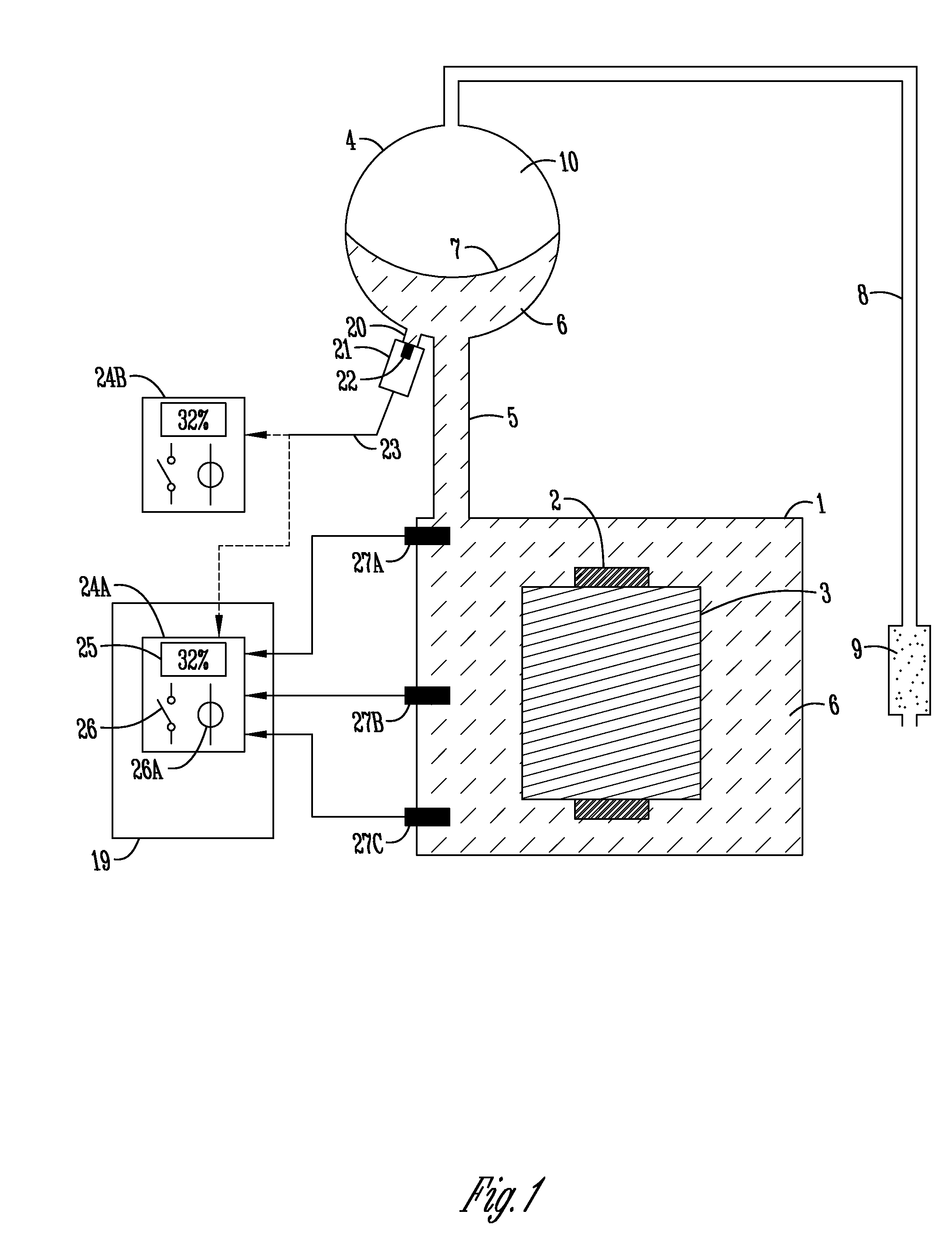

System for monitoring oil level and detecting leaks in power transformers, reactors, current and potential transformers, high voltage bushings and the like

ActiveUS20110156918A1Without usingAvoid more failuresDrawing from basic elementsAlarmsEngineeringHigh pressure

System for monitoring oil level and detecting leaks in power transformers, reactors, current and potential transformers, high voltage bushings and the like, notably for a system that through the use of sensors and other electronic components measures and monitors transformers and similar equipment in real time, filled with insulating oil, with greater precision and without need for floats or mobile mechanical parts, while presenting countless facilities in the sense of making level monitoring more reliable and safer, highlighting the level error calculations, oil leak detection alarm, excess oil detection alarm during the equipment filling process and calculation of tendencies of evolution for levels among other facilities.

Owner:SANTOS EDUARDO PEDROSA

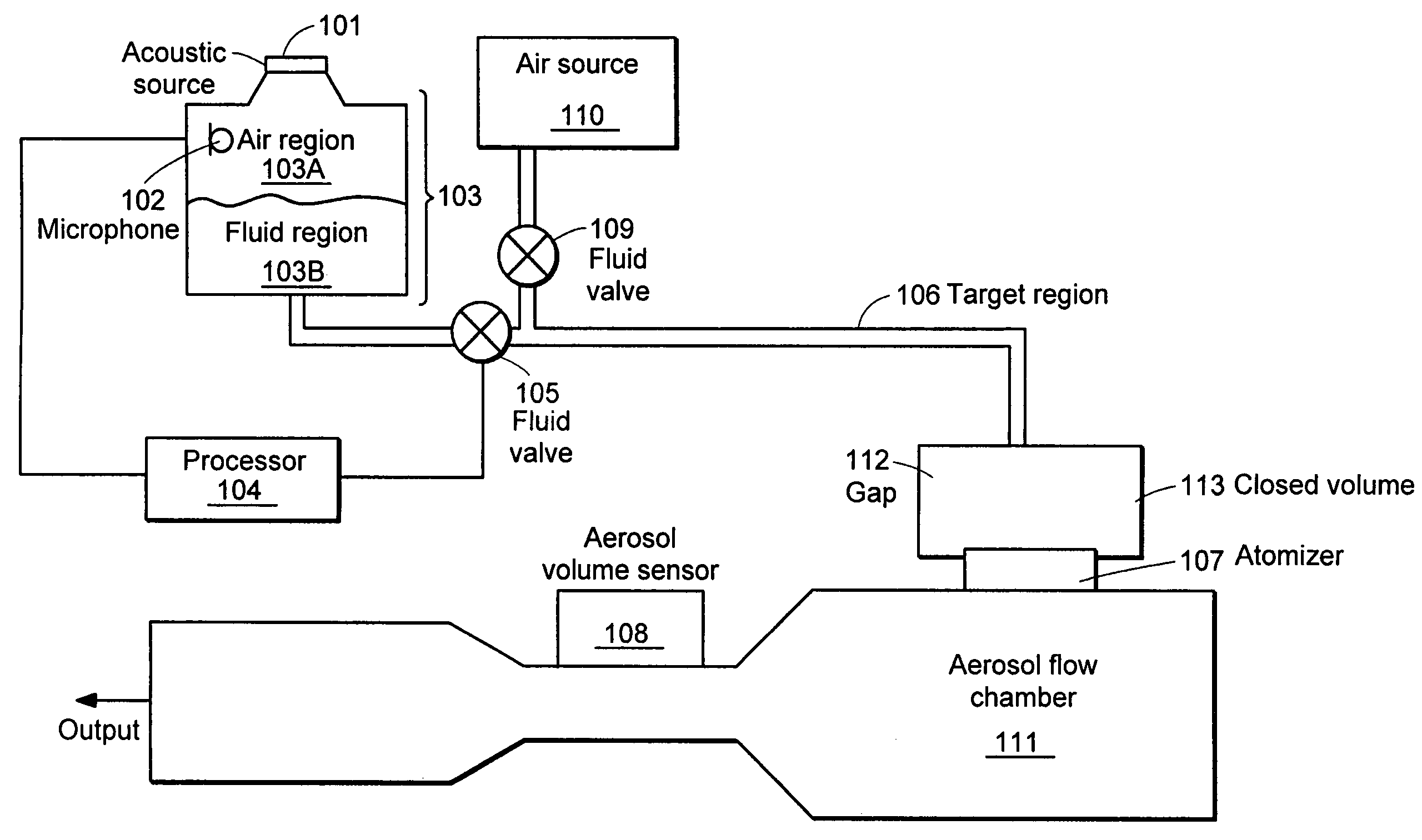

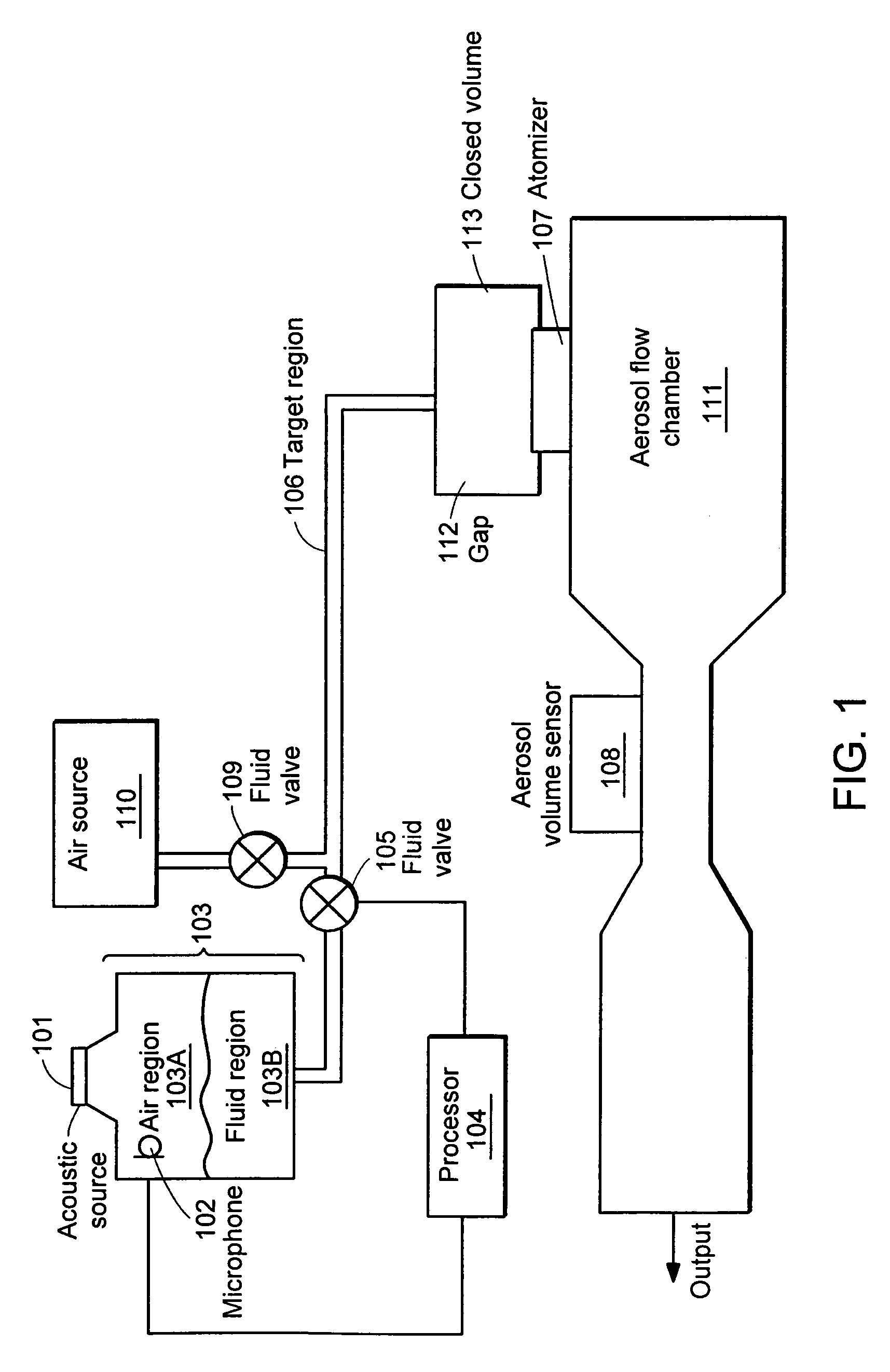

System and method for improved volume measurement

InactiveUS7066029B2Material analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidVolume measurementsEngineering

An apparatus comprises a variable acoustic source and a microphone, both acoustically coupled to a volume having a fluid region and an air region. The apparatus also can include a processor to determine a volume of the air region based on signals received from the microphone and the variable acoustic source. A fluid valve is coupled to the processor, and is configured to allow an amount of fluid to exit the fluid region associated with the volume of the air region. An atomizer, coupled to the fluid region, is configured to aerosolize at least a portion of the fluid.

Owner:DEKA PROD LLP

System and method for locating fluid leaks at a drape of a reduced pressure delivery system

A system and method for performing tissue therapy may include applying a reduced pressure to a tissue site of a patient. A fluid parameter associated with applying a reduced pressureto the tissue site may be sensed. An audible fluid leak location sound may be generated in response to sensing the fluid parameter. The audible fluid leak location sound may be altered in response to sensing that the fluid parameter changes. By altering the audible fluid leak location sound in response to sensing a change of the fluid parameter, a clinician may detect location of a fluid leak at the drape by applying force to the drape. The force applied to the drape may be a clinician pressing a finger onto an edge of the drape.

Owner:KCI LICENSING INC

System and method for aerosol delivery

An apparatus comprises a variable acoustic source and a microphone, both acoustically coupled to a volume having a fluid region and an air region. The apparatus also can include a processor to determine a volume of the air region based on signals received from the microphone and the variable acoustic source. A fluid valve is coupled to the processor, and is configured to allow an amount of fluid to exit the fluid region associated with the volume of the air region. An atomizer, coupled to the fluid region, is configured to aerosolize at least a portion of the fluid.

Owner:DEKA PROD LLP

Apparatuses and methods for managing liquid volume in a container

An apparatus and method for managing a liquid volume in a container includes a detector for detecting liquid volume changes in the container during a first preset period, a first determiner for determining whether the changes are lower than the first preset threshold value, and a presenter for presenting the first prompt information in case the changes are lower than the preset threshold value.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

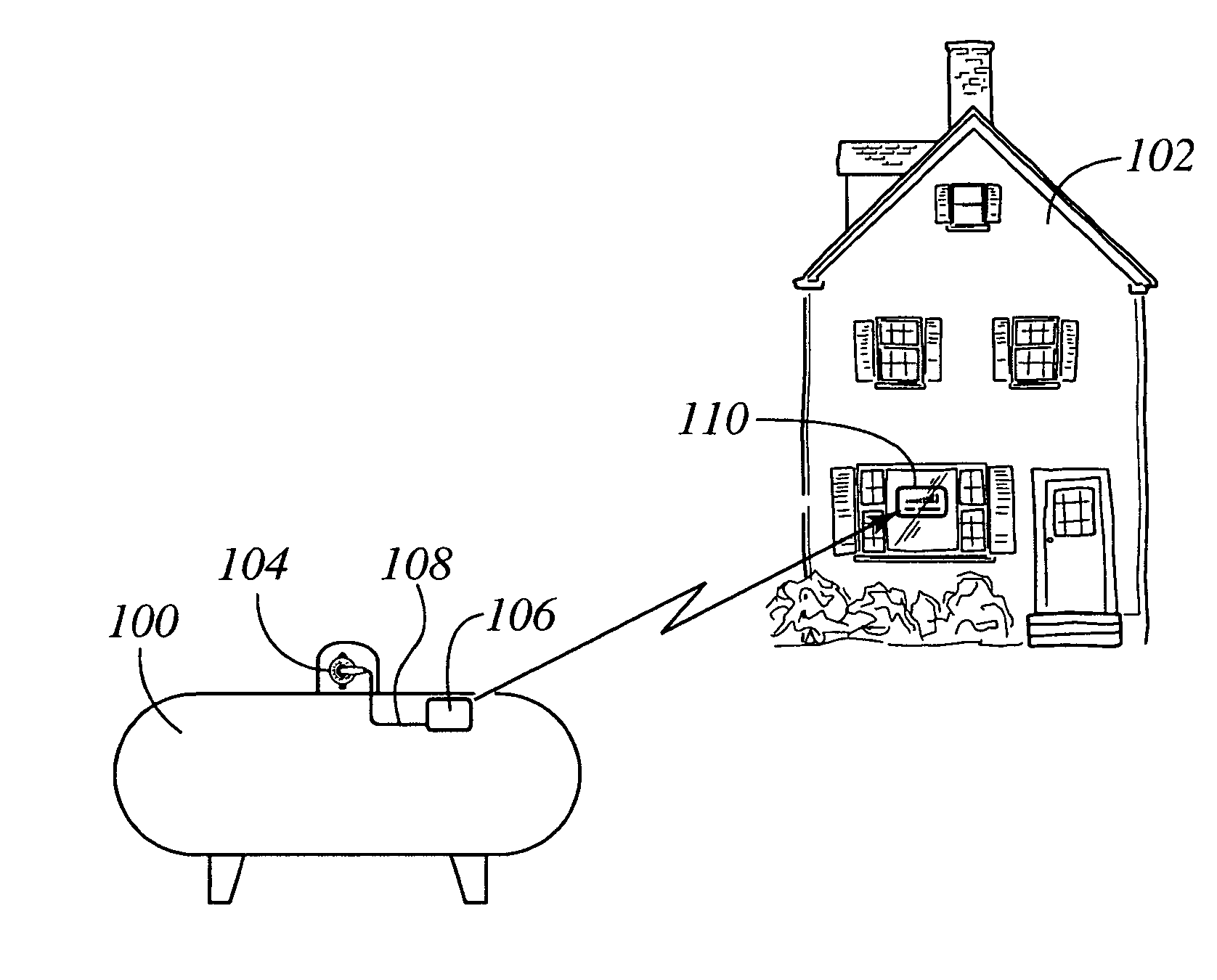

Will call wireless tank level monitoring system

ActiveUS7441569B2Lower requirementEasy to operateValve arrangementsLiquid fillingPower applicationElectrical battery

A wireless tank level monitoring system is provided. The system includes a transmitter that is located in close proximity to the storage tank. The transmitter is coupled to a remote-ready tank level gauge, which provides a ratio-metric voltage output proportional to the liquid volume inside the tank. The transmitter periodically monitors the output from the level gauge and transmits the information to a base station located remotely from the storage tank. The base station displays the tank level numerically in percent full, graphically with a bar chart, or both. A conspicuous visual indication is provided by the base station when the tank level drops below a predetermined set point. In battery powered applications, the base station also reads and provides a visual indication of a low battery condition for both the transmitter and base station.

Owner:INVENSYS SYST INC

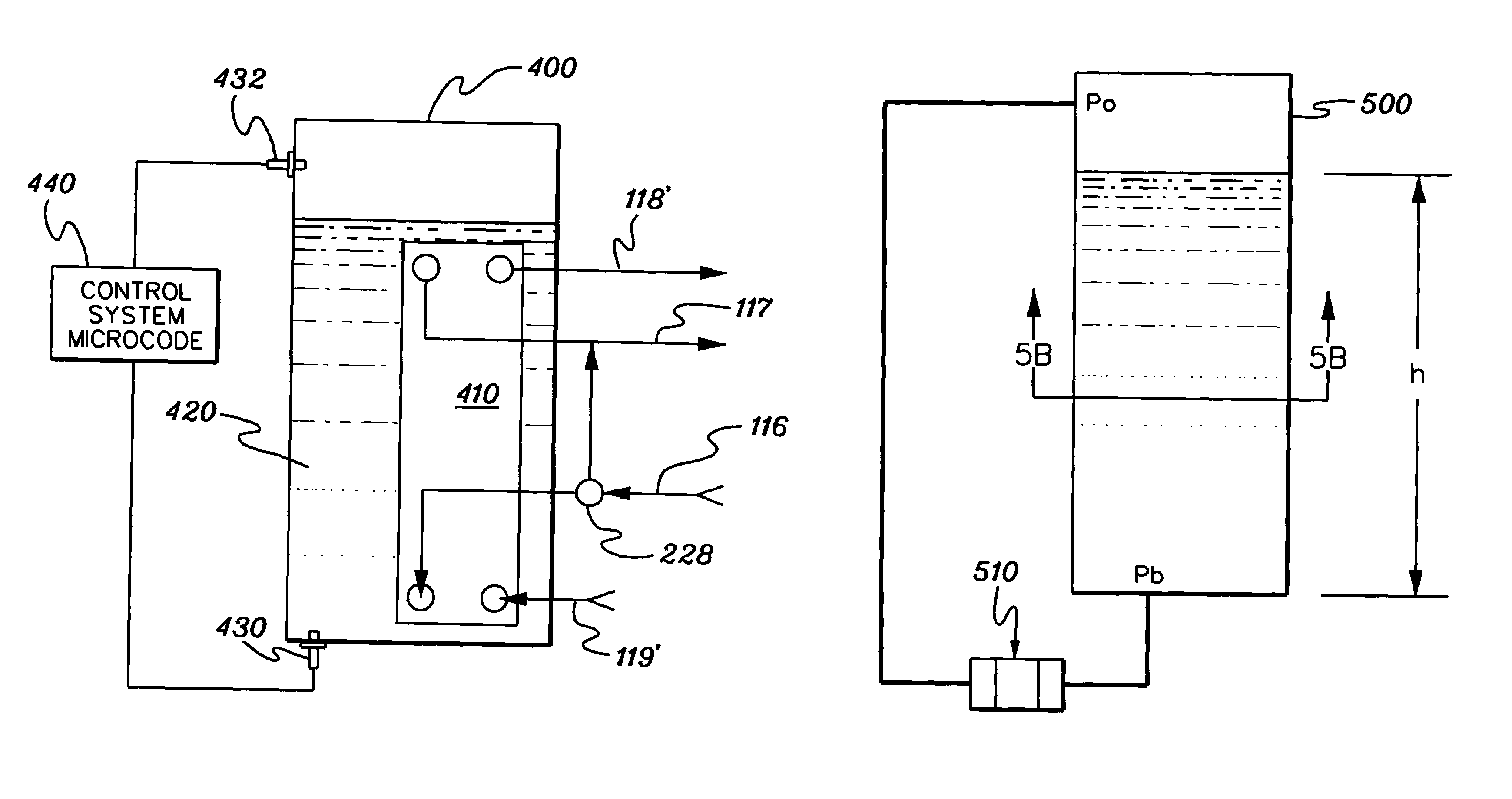

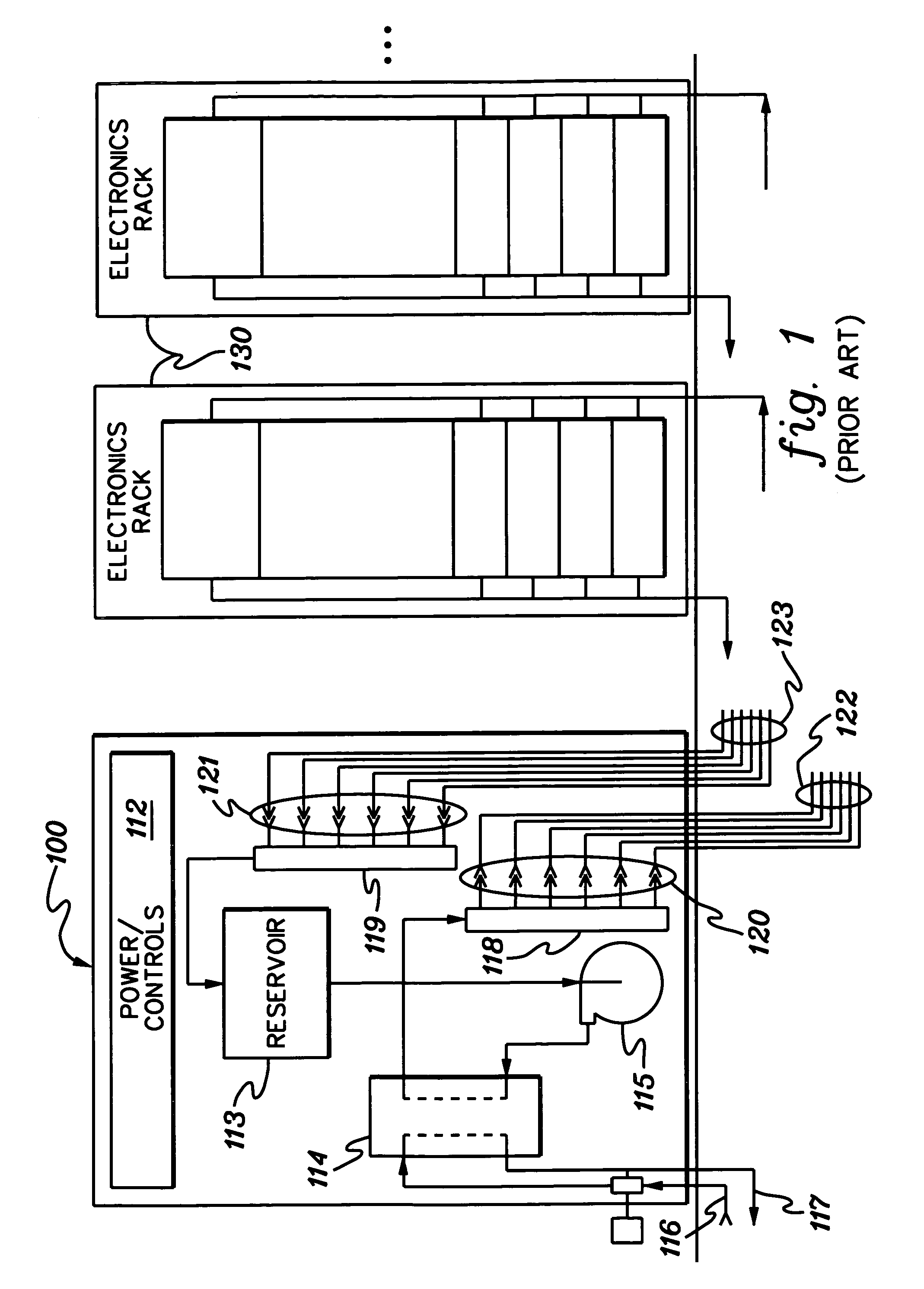

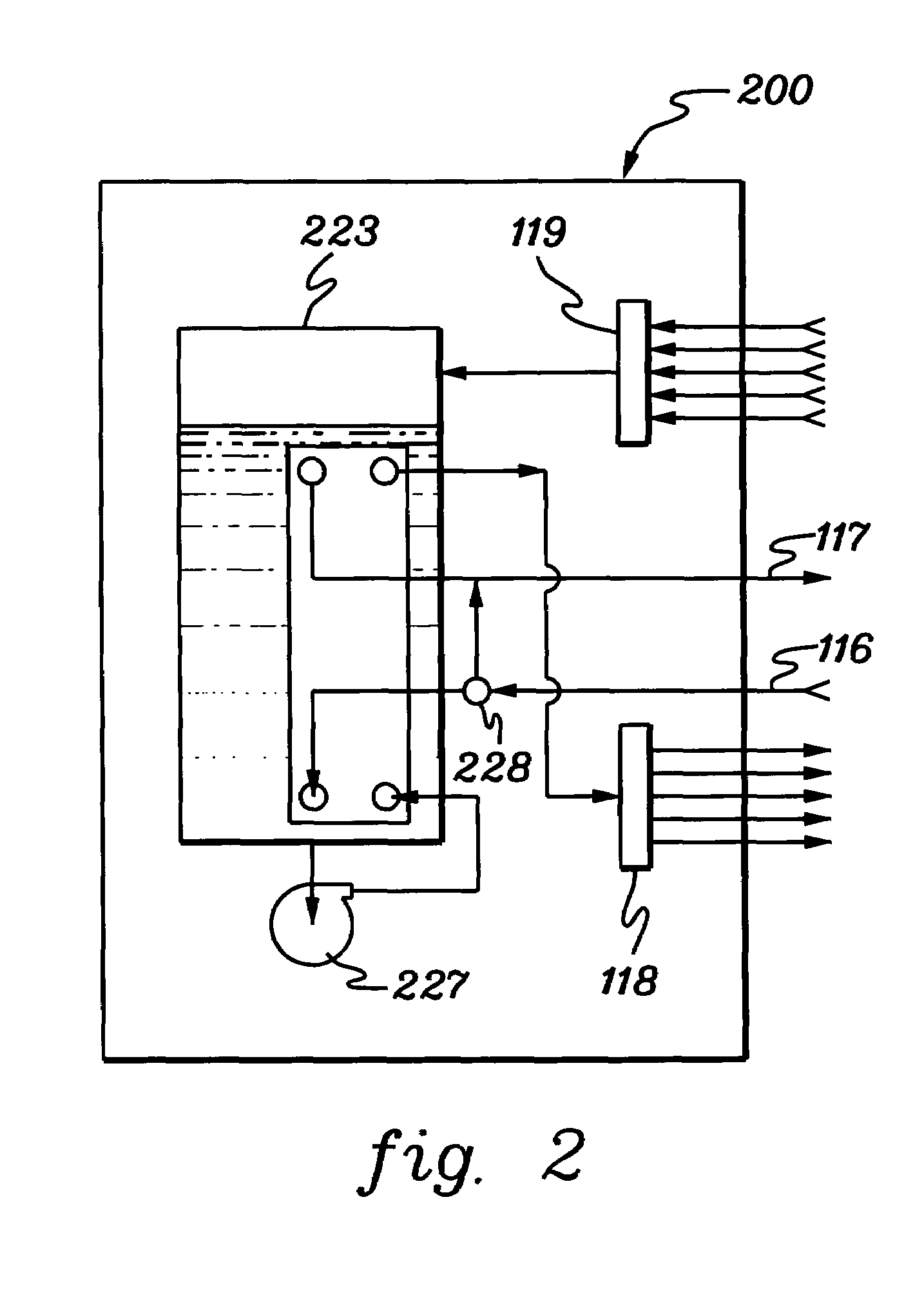

Method, system and program product for monitoring rate of volume change of coolant within a cooling system

InactiveUS7000467B2Detection of fluid at leakage pointDigital data processing detailsExpansion tankSystems design

Method, system and program product are provided for monitoring coolant within a cooling system designed to provide system coolant to one or more electronics subsystems. The monitoring technique includes employing at least one pressure transducer to obtain multiple pressure measurements related to an amount of coolant within an expansion tank of the cooling system, and determining a rate of volume change of coolant within the expansion tank employing the multiple pressure measurements. Successive pressure measurements can be taken at a known time interval to determine the rate of volume change of coolant within the expansion tank. An automatic determination can also be made on the immediacy of action to be taken for service of the cooling system based on the rate of volume change of coolant within the expansion tank.

Owner:IBM CORP

Method for detecting a liquid level in a container in a circuit and a dialysis machine for actuating the method

InactiveUS6952963B2High precisionSimple and economical equipmentContainer/cavity capacity measurementSuction devicesProduct gasEngineering

A container of a dialysis machine has a determined shape and a known volume occupied in part by a volume of a mass of blood; a remaining part is occupied by a volume of a mass of gas. A disturbance is induced in a combined mass of the liquid and the gas in the container and an entity of the disturbance is measured. Measurements of pressure in the container before and after the disturbance are taken, the volume of gas is calculated using a function correlated to a gas law, and the volume and level of the liquid in the container are derived after the volume occupied by the gas is calculated.

Owner:GAMBRO DASCO SPA

Pressure sensor

InactiveUS7409863B2Fluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsLight beamOptical transmitter

A pressure sensor includes an optical transmitter transmitting a dispersive light toward two optical receivers, all carried in a housing. Pressure changes on the housing cause the light beam to be deflected with the amount of deflection measured by the difference in light received by each of the two receivers. A processor operable with the receivers provides a pressure measurement responsive to the light beam deflection.

Owner:SENSATA TECHNOLOGIES INC

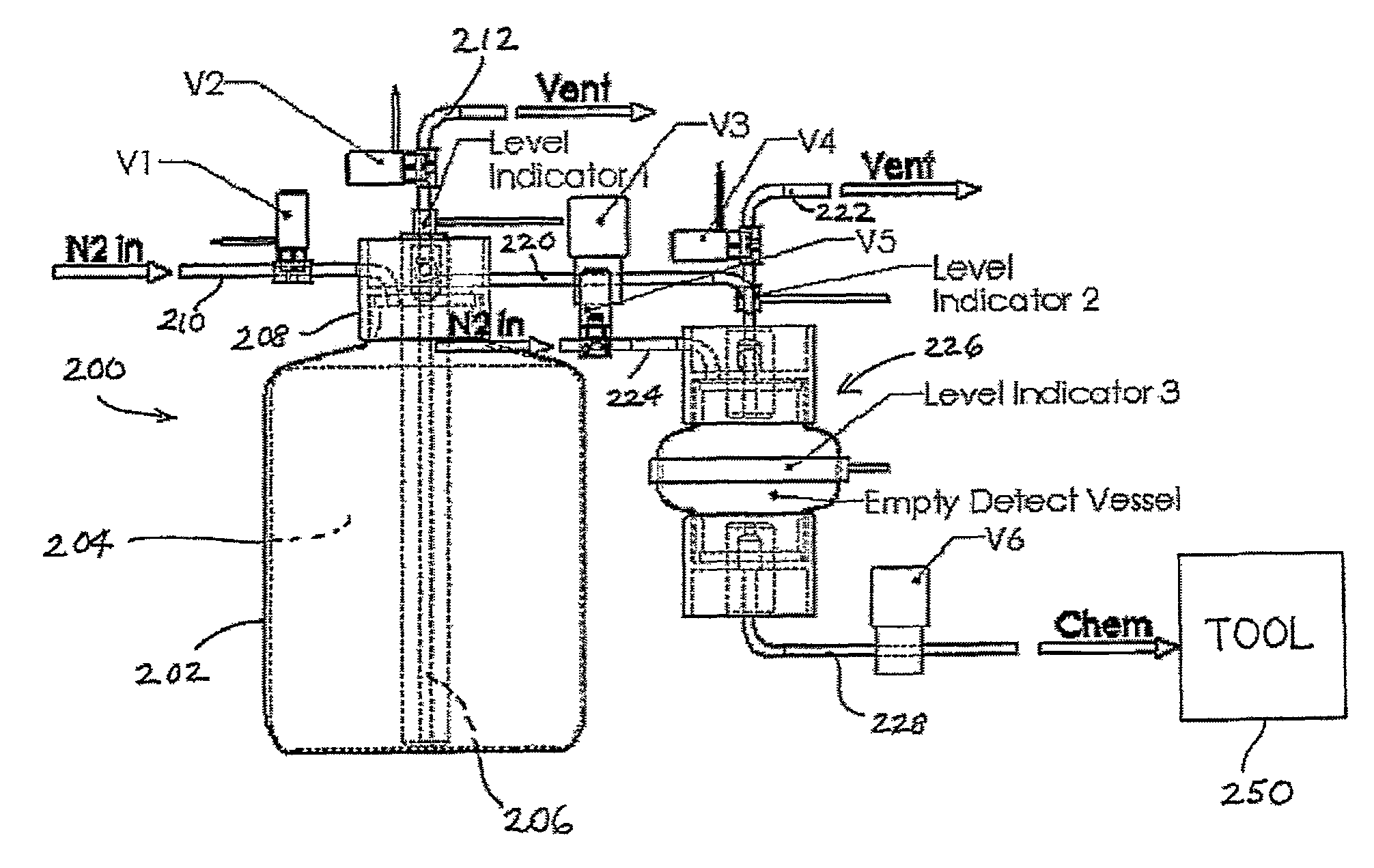

Liner-based liquid storage and dispensing systems with empty detection capability

Fluid supply systems for storage and dispensing of chemical reagents and compositions, e.g., high purity liquid reagents and chemical mechanical polishing compositions used to manufacture microelectronic device products, having capability for detection of an empty or near-empty condition when the contained liquid is at or approaching depletion during dispensing operation. Fluid delivery systems employing empty detect arrangements are described, including pressure transducer monitoring of dispensed material intermediate the supply package and a servo-hydraulic dispense pump, or monitoring of dispenser chamber replenishment times in a dispenser being replenished on a cyclic schedule to flow material from the dispenser to a downstream tool utilizing the dispensed material.

Owner:ADVANCED TECH MATERIALS INC

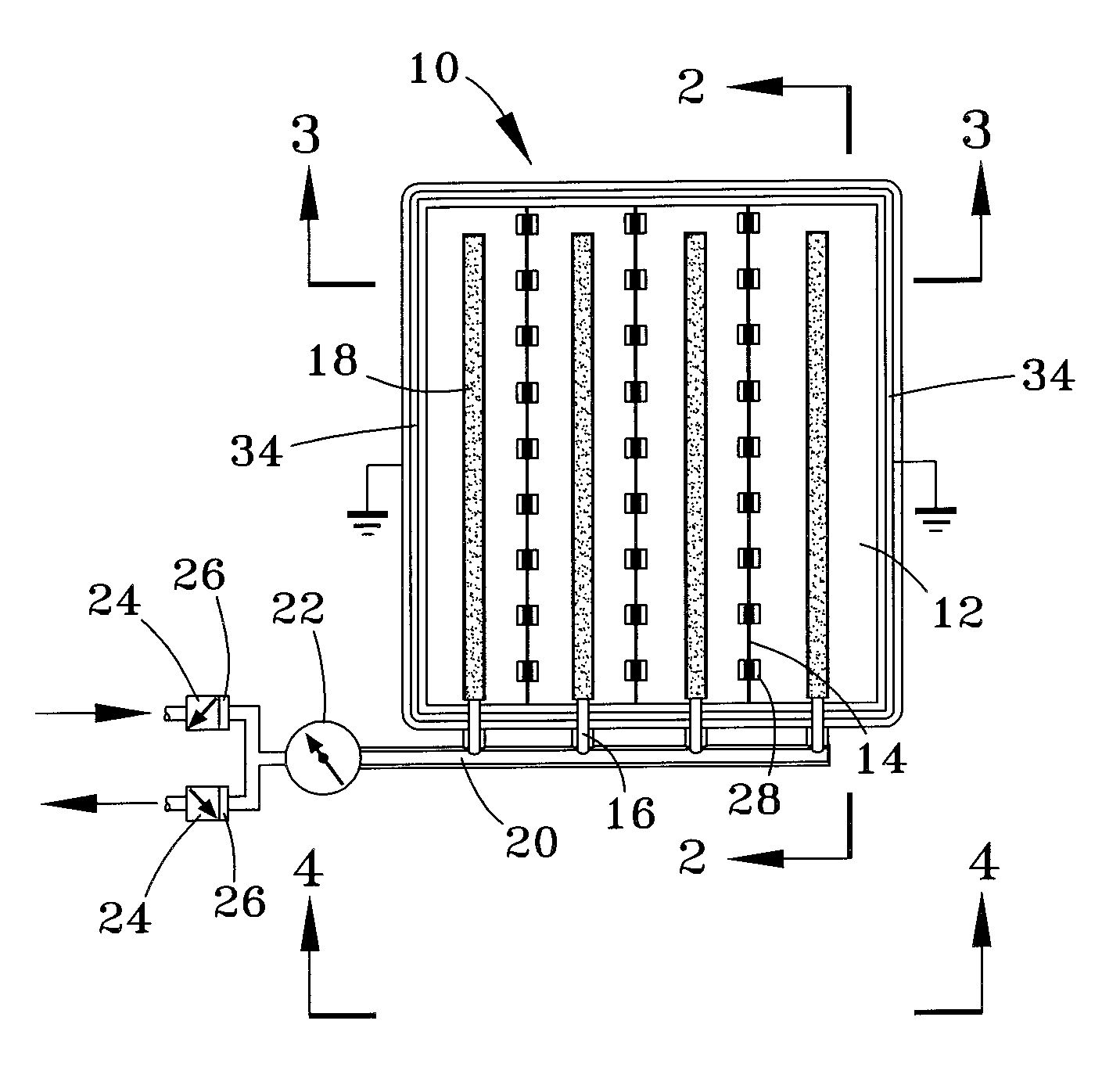

Weight measurements of liquids in flexible containers

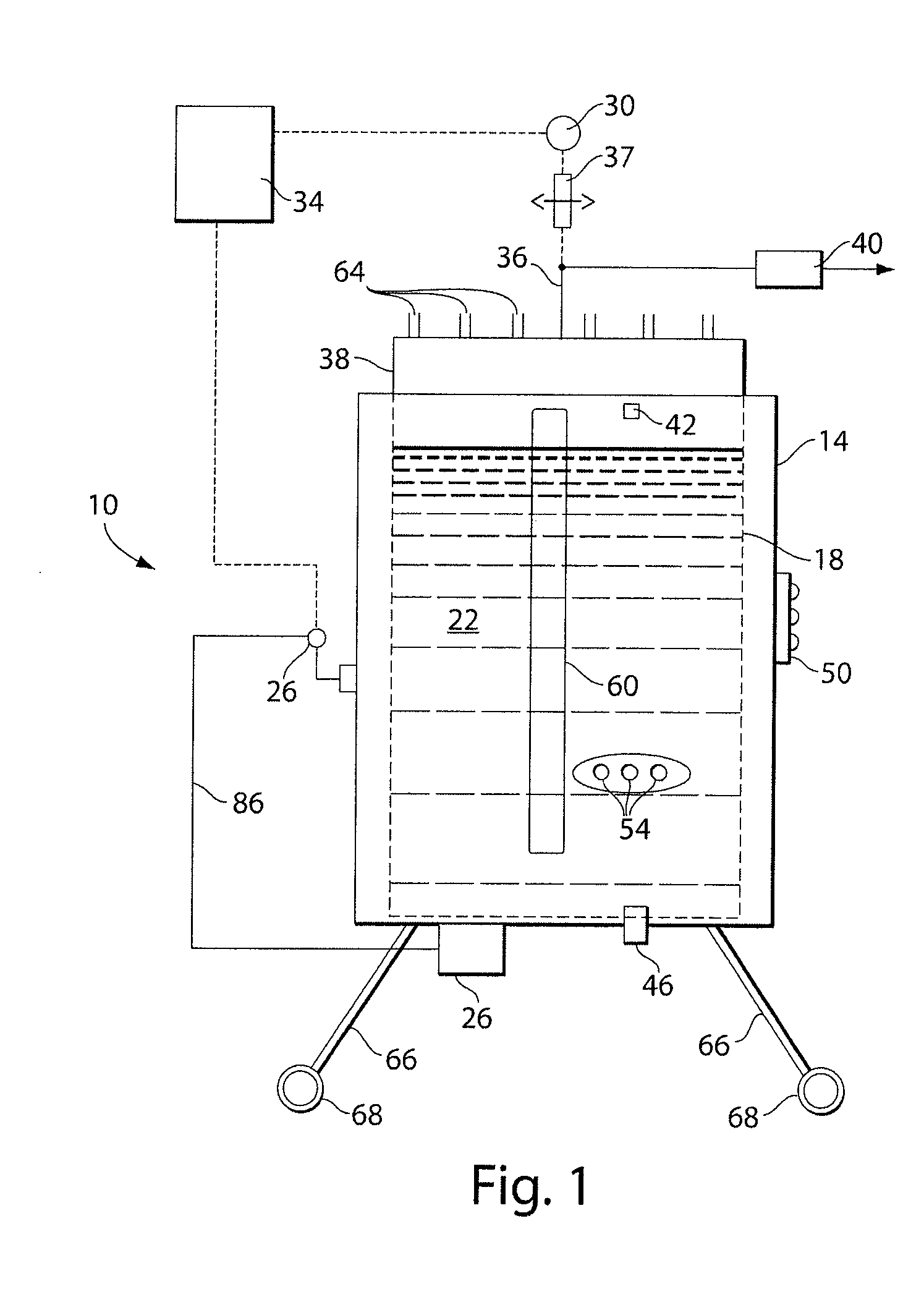

InactiveUS20080213874A1Bioreactor/fermenter combinationsBiological substance pretreatmentsControl systemContinuous flow

Articles and methods for measuring weight of a liquid in a disposable bag bioreactor are presented. In certain embodiments, bioreactor systems described herein include a supported container (e.g., a flexible bag in a reusable housing) for containing a liquid, and at least two pressure indicating sensors operatively associated with the container. A first pressure indicating sensor can be placed near the bottom of the container to measure the total downward force within the container, including the liquid head in the container and the gas pressure above the liquid. The second pressure indicating sensor can be placed near the top of the container to measure only the pressure at the top of or above the liquid. Signals from the pressure indicating sensors can be directed to a control system that receives the signals and calculates a difference between the signals. This difference can be used to determine a volume or a weight of the liquid in the container. Advantageously, real-time weight measurements can be obtained while the system is in operation and continuous flow processes can be monitored. Moreover, in some embodiments, the pressure indicating sensors are isolated from contact with any fluid (e.g., liquid) in the container and, therefore, do not require cleaning after processing of each batch of reactants. Contamination of the process fluid by contact with the pressure indicating sensors can also be avoided.

Owner:XCELLEREX INC

Reduced pressure treatment system having blockage clearing and dual-zone pressure protection capabilities

A method of treating a tissue site is provided. The method includes applying a reduced pressure to a tissue site with a reduced pressure source. A source pressure is monitored at the reduced pressure source, and a differential pressure is determined between the source pressure and the desired tissue site pressure. If a blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a first maximum differential pressure. If no blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a second maximum differential pressure.

Owner:3M INNOVATIVE PROPERTIES CO

Liner-based liquid storage and dispensing systems with empty detection capability

Fluid supply systems for storage and dispensing of chemical reagents and compositions, e.g., high purity liquid reagents and chemical mechanical polishing compositions used to manufacture microelectronic device products, having capability for detection of an empty or near-empty condition when the contained liquid is at or approaching depletion during dispensing operation. Fluid delivery systems employing empty detect arrangements are described, including pressure transducer monitoring of dispensed material intermediate the supply package and a servo-hydraulic dispense pump, or monitoring of dispenser chamber replenishment times in a dispenser being replenished on a cyclic schedule to flow material from the dispenser to a downstream tool utilizing the dispensed material.

Owner:ADVANCED TECH MATERIALS INC

Hydrogen storage tank and method of using

A hydrogen storage tank for containing solid-state hydrogen storage media, and method for determining the hydrogen fill level in the tank. The tank has at least one compartment for storing the storage media, passages for transporting hydrogen gas to and from the compartment, and a heat distribution system for establishing a substantially uniform temperature in the storage media. A look-up table is generated for the tank that relates hydrogen pressure changes in the tank versus hydrogen fill levels in the tank as a function of temperature. The tank is filled to full capacity by adsorbing hydrogen on the storage media. Thereafter, hydrogen is released from the storage media for a time period during which there is a substantially constant demand on the tank, the change in pressure of the released hydrogen gas is measured, and the look-up table is applied to determine the hydrogen fill level in the tank.

Owner:INDIANA UNIV RES & TECH CORP

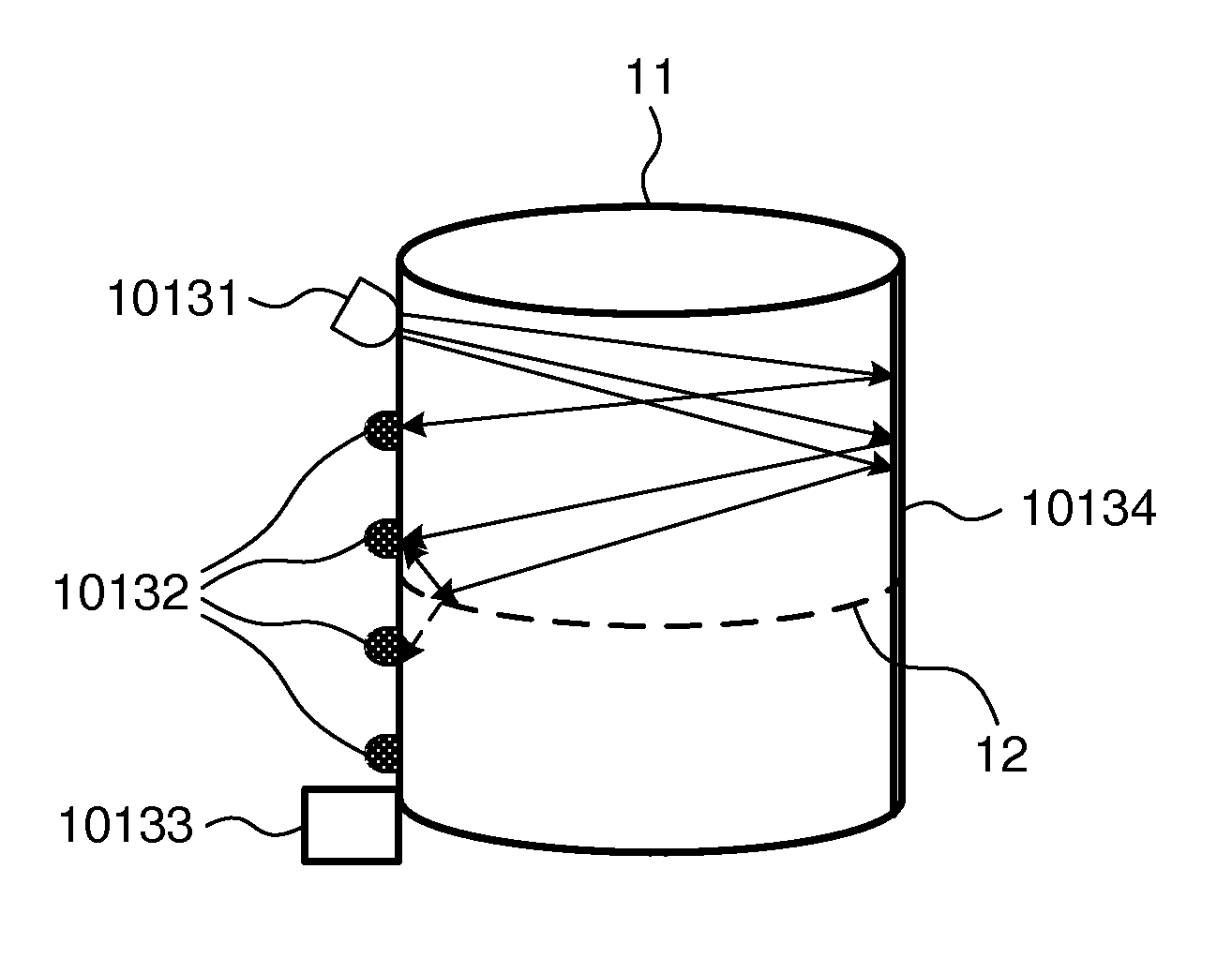

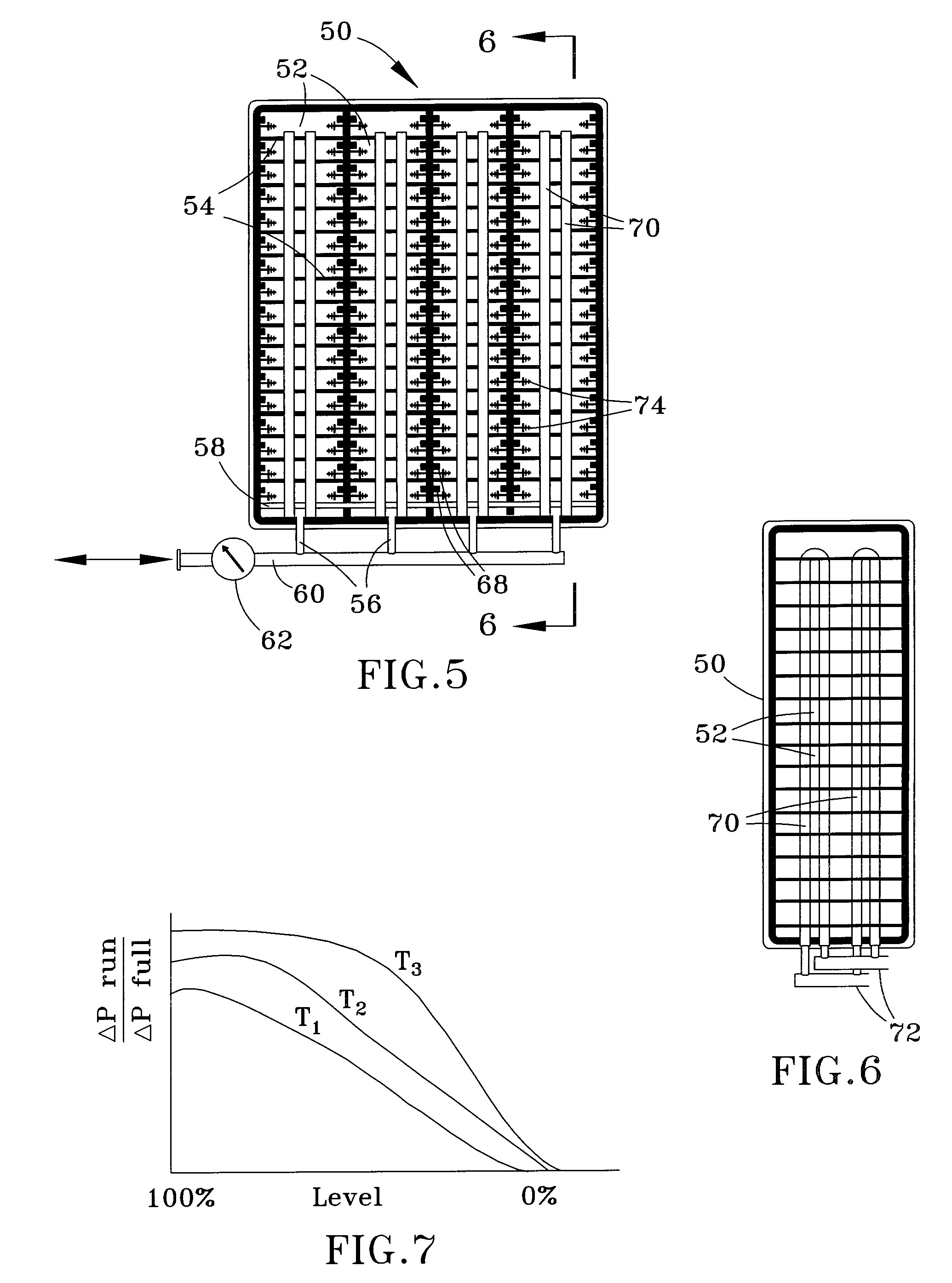

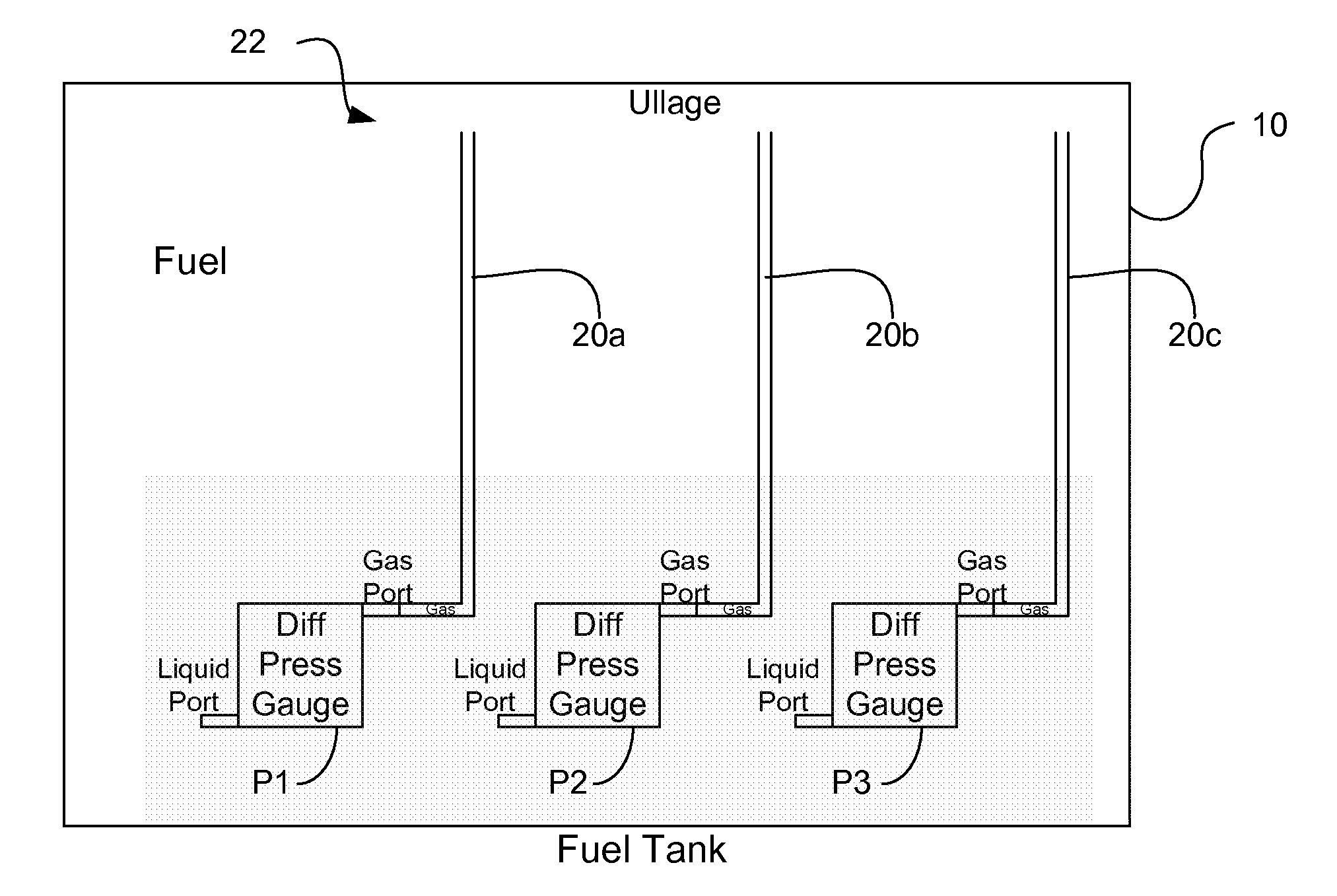

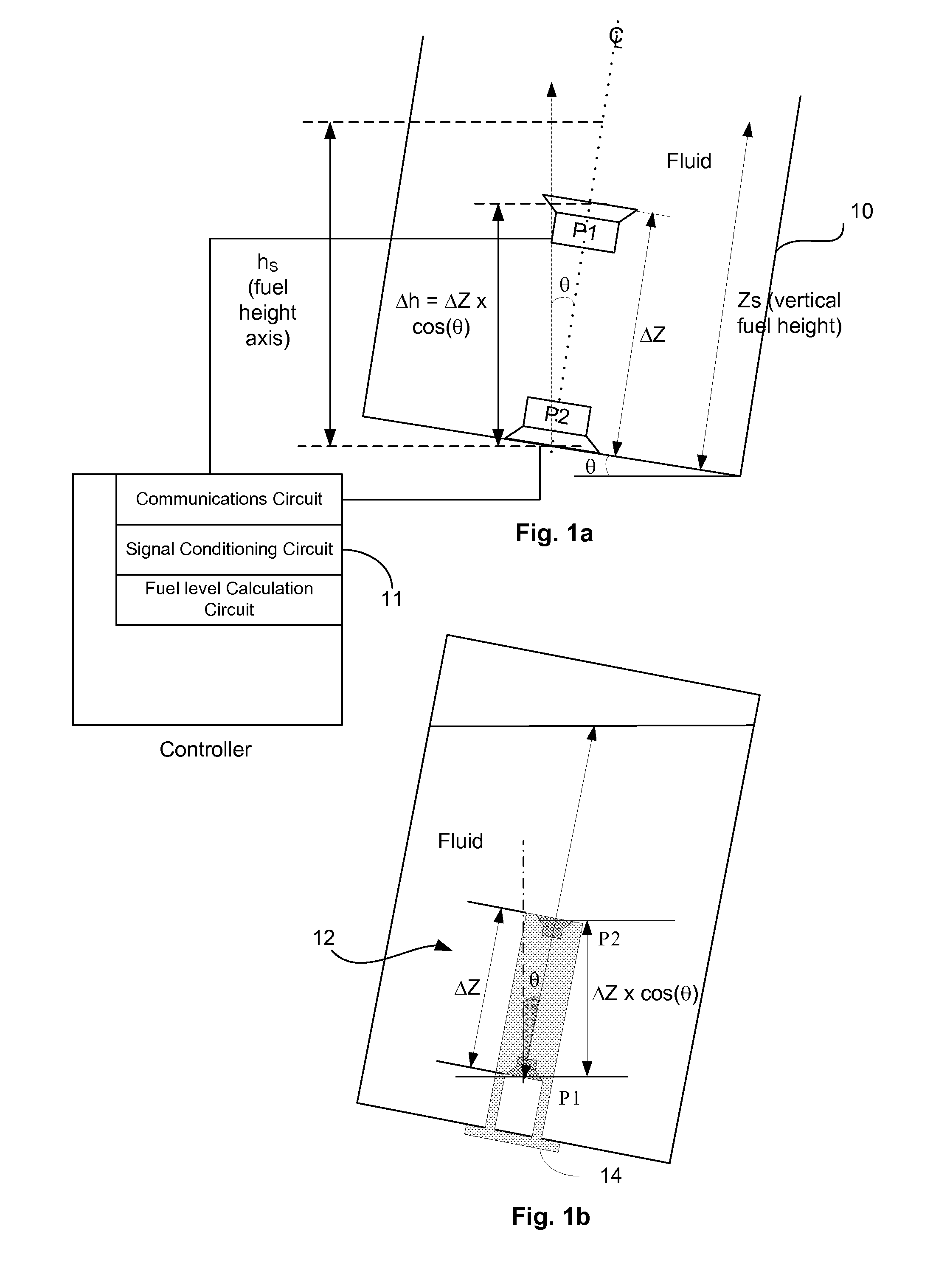

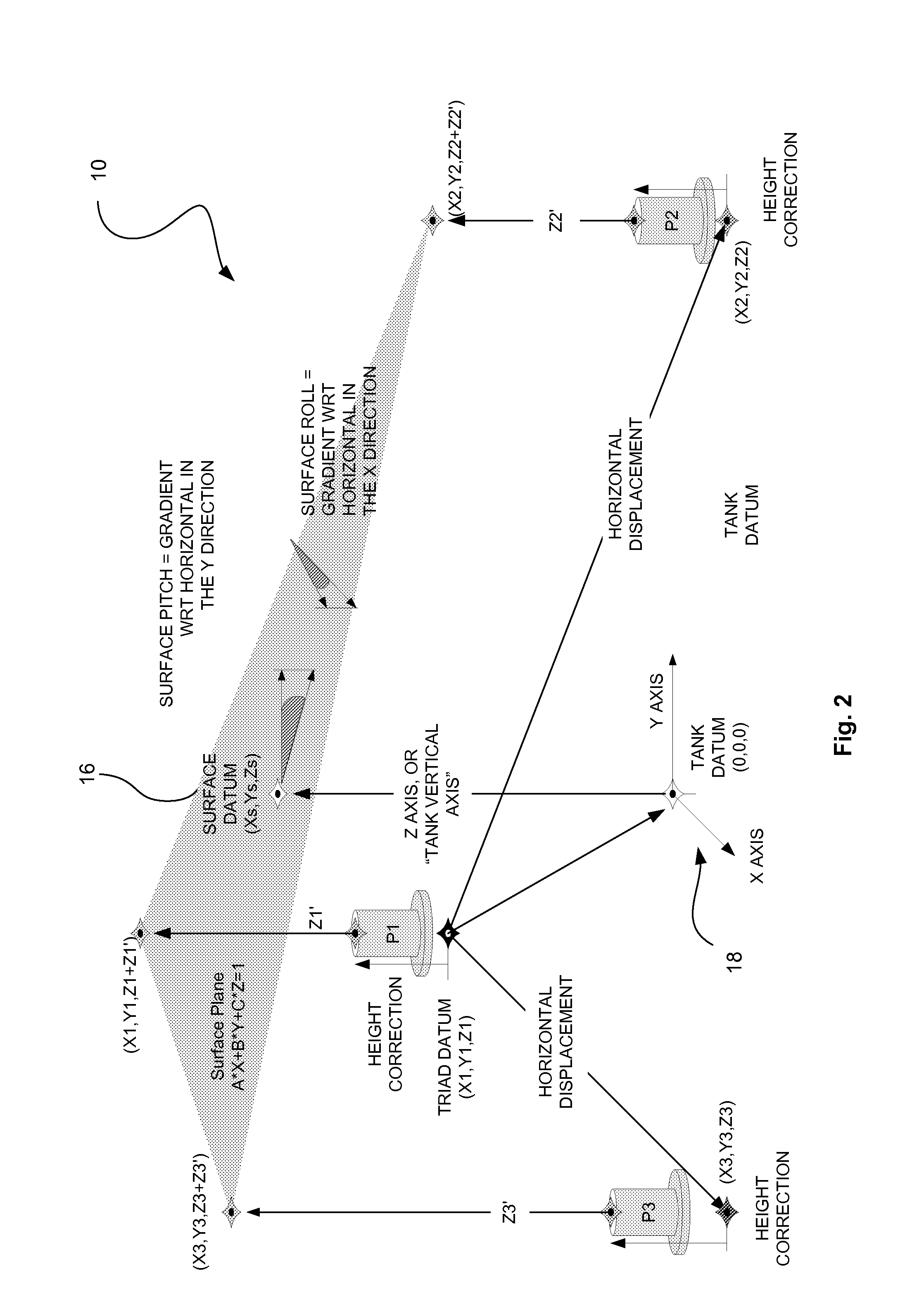

Aircraft fluid gauging techniques using pressure measurements and optical sensors

InactiveUS20150100253A1Flow propertiesFluid pressure measurement by mechanical elementsLevel measurementEngineering

A fluid level measurement system includes a first pressure sensor disposed inside a fluid tank at a first elevation relative to a height axis of the fluid tank, and a second pressure sensor disposed inside the fluid tank at a second elevation relative to the height axis of the fluid tank, the second elevation different from the first elevation. The first pressure sensor and the second pressure sensor are configured to provide a signal indicative of a sensed pressure, and fluid height is calculated from the difference in sensed pressure between the first and second pressure sensors relative to the sensed pressure of either the first or the second pressure sensor.

Owner:PARKER HANNIFIN CORP

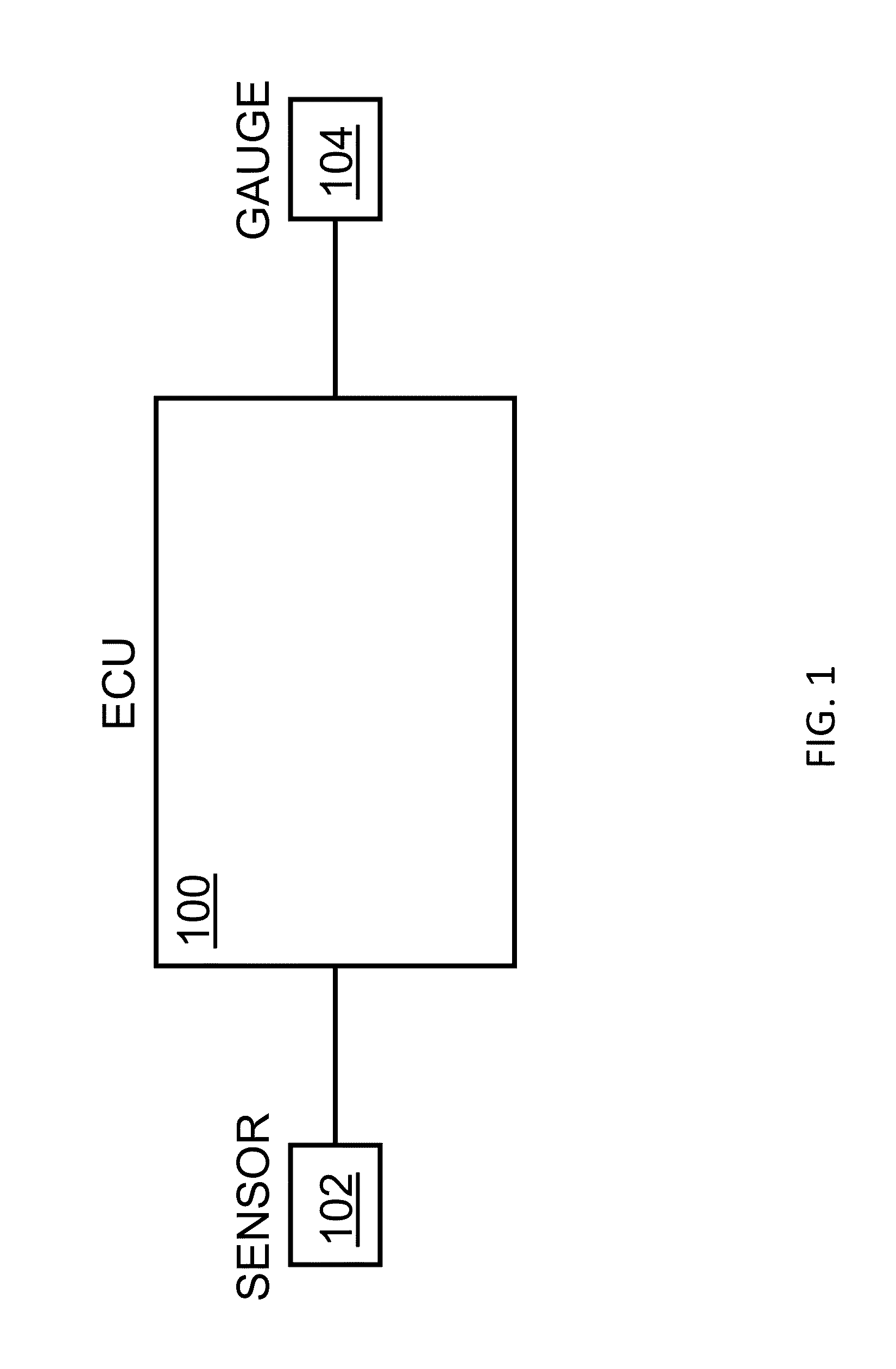

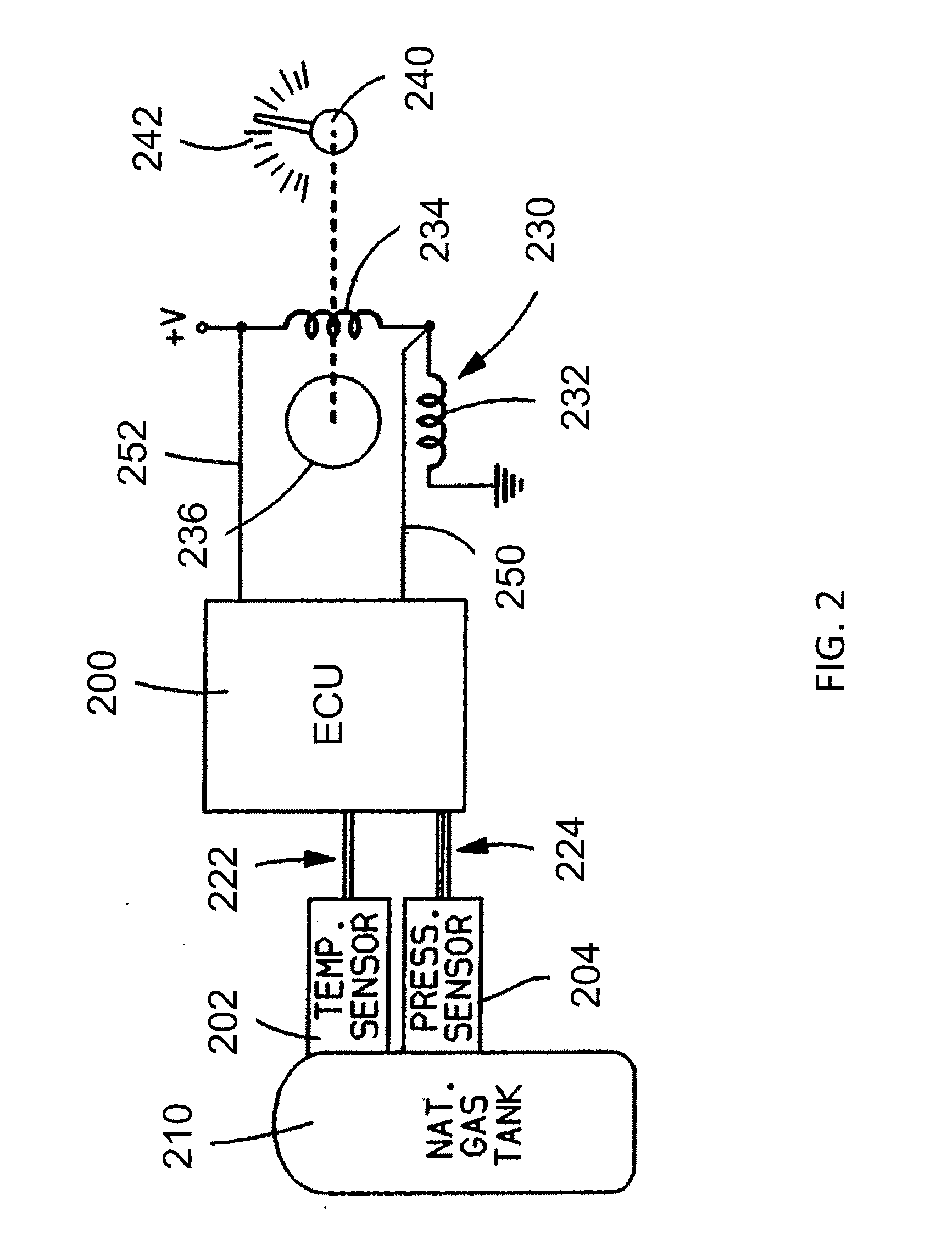

Systems and methods for monitoring and controlling fuel systems

Systems and methods may be provided for monitoring a fuel level of a vehicle. The fuel may be a gaseous fuel, such as natural gas. An electronic control unit may be able to receive a signal from one or more sensors. The electronic control unit may provide a command to drive a fuel gauge to display the fuel level. The electronic control unit may determine the gauge command based on the received signal and a filling compensation scheme. The electronic control unit may be initialized through a user interface. A filling compensation scheme may be selected during initialization. The electronic control unit may be capable of communicating various sensors, gauges, devices, controls and / or other ECUs of varying specifications.

Owner:AGILITY FUEL SYST LLC

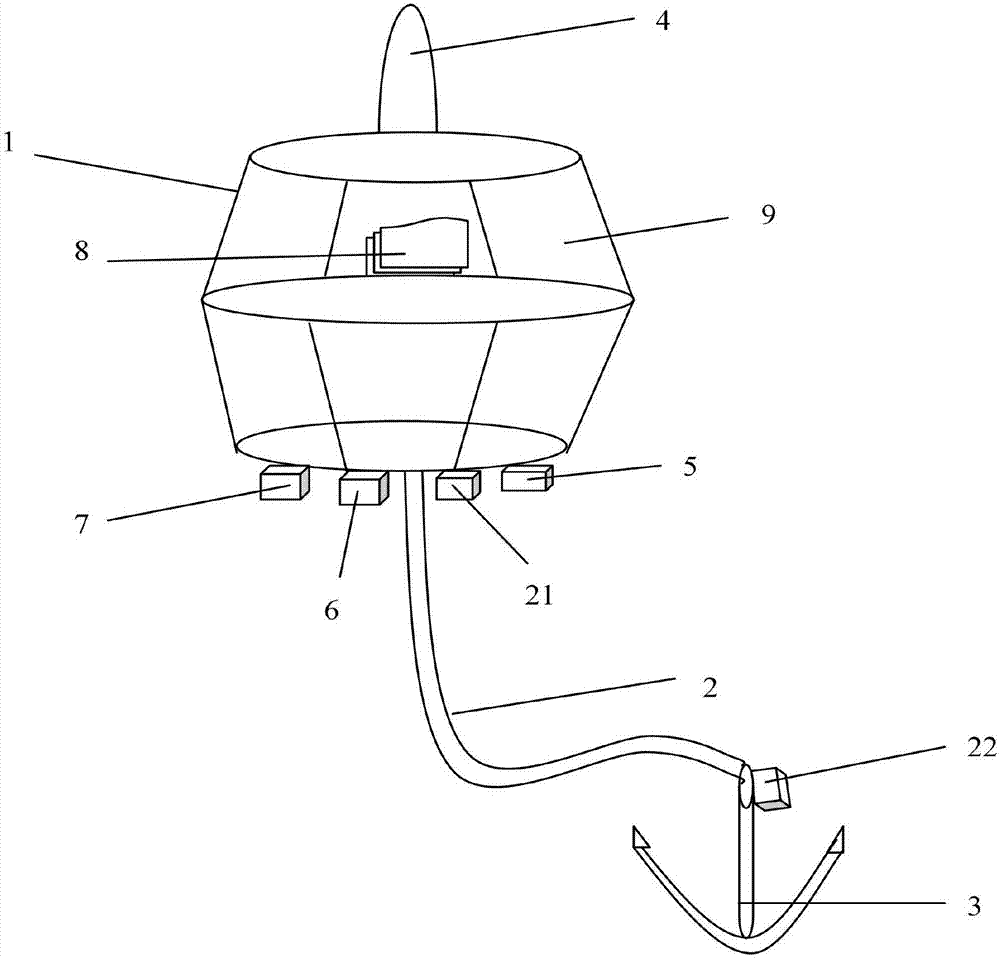

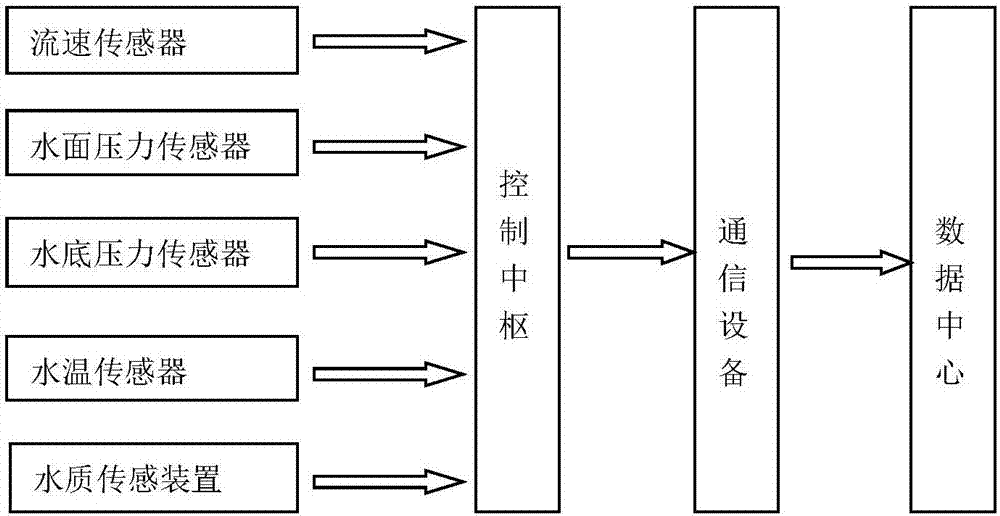

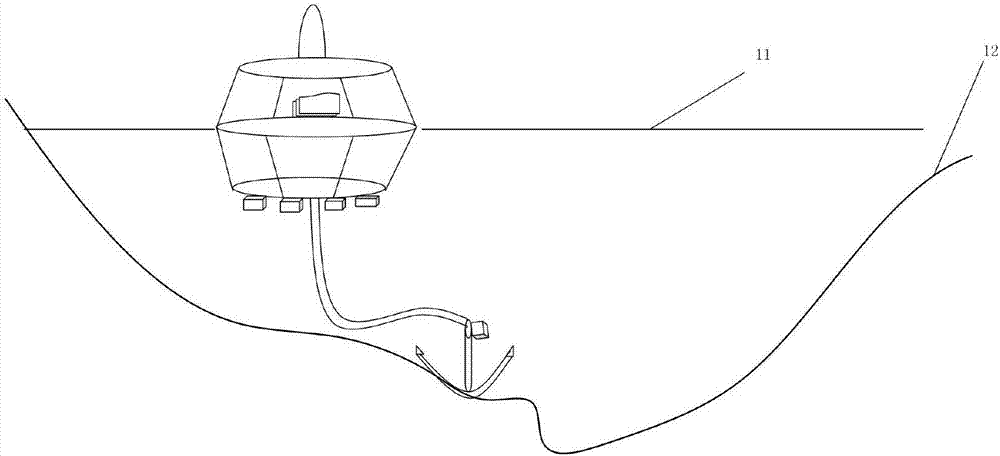

Float type automatic monitoring system of rivers and lakes of depopulated zone

PendingCN107576314AValid deliveryRealize online monitoringVolume/mass flow measurementTesting waterWater qualityEngineering

The invention relates to float type automatic monitoring equipment of rivers and lakes of a depopulated zone. The equipment comprises a floating ball, a multifunctional mooring cable and an underwaterdevice, wherein the floating ball, the multifunctional mooring cable and the underwater device are connected in sequence; communication equipment is arranged at the top of the floating ball, and a flow speed sensor, a water temperature sensor and a water quality sensing device are arranged at the bottom of the floating ball, so that signals can be effectively transmitted and online monitoring ofwater quality, water flow speeds and water temperature of water bodies of the lakes; the outer part of the floating ball is composed of a solar cell panel and self-powered and low-power-consumption operation can be realized; a water surface pressure sensor and a water bottom pressure sensor are arranged so that relative water levels of the lakes are measured through pressure difference and the influences, caused by environment factors including atmospheric pressure changes and the like, on the measurement of the water levels are overcome.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION +1

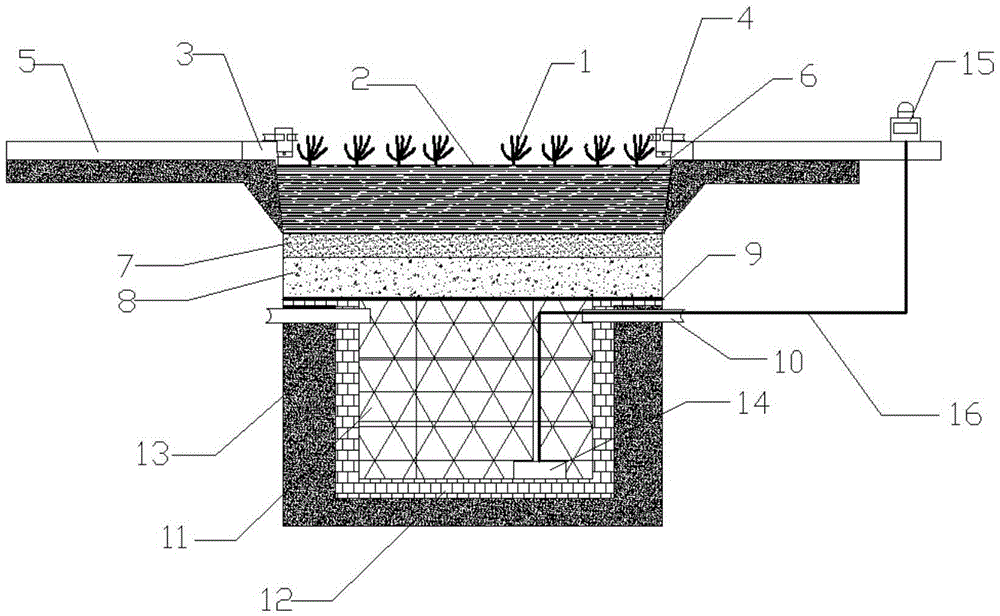

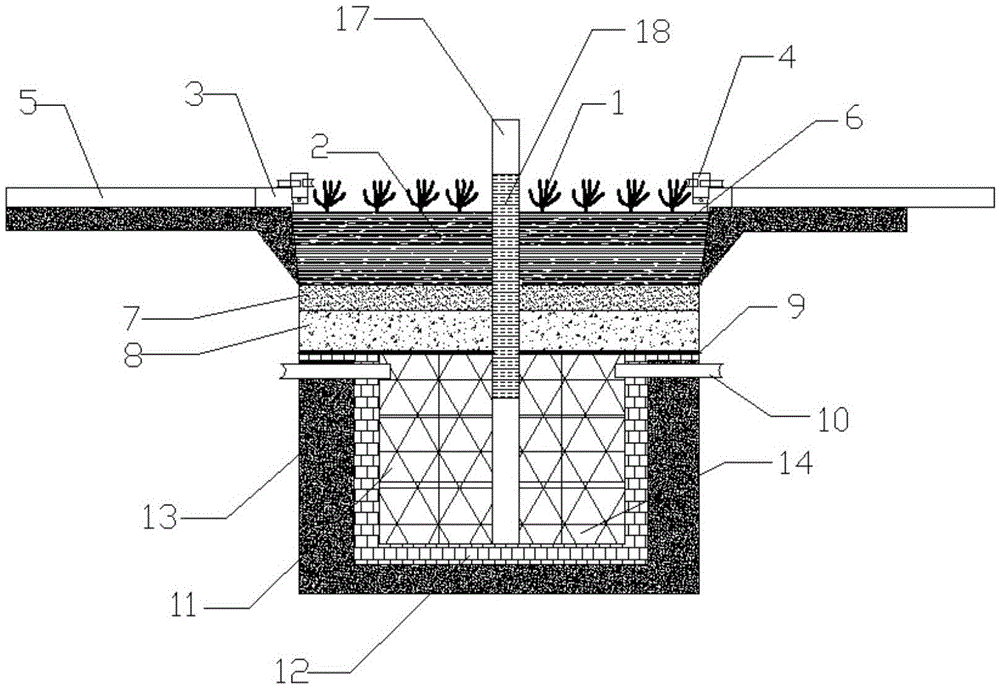

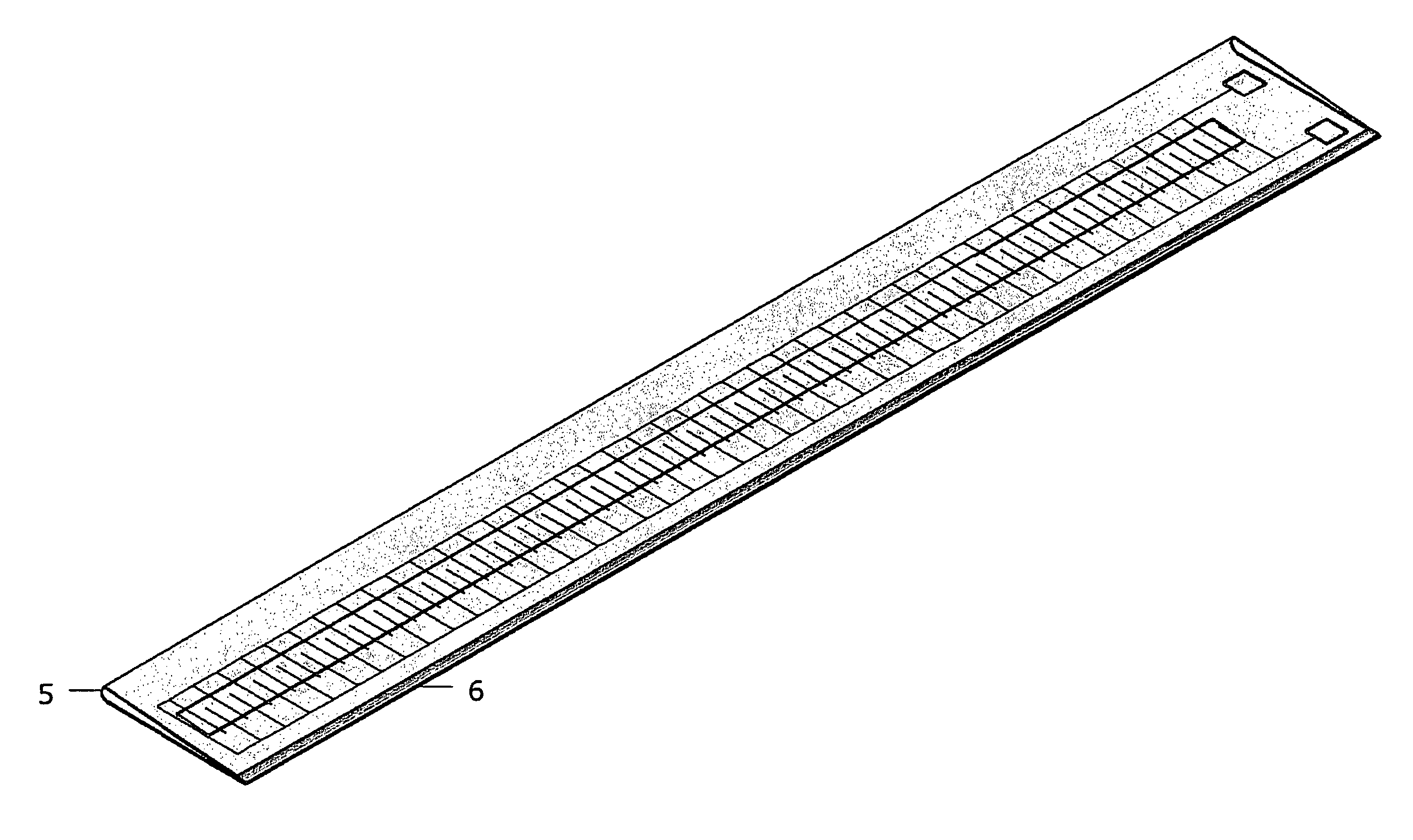

Source rainwater purification and storage system based on low impact development and installation method

ActiveCN105544343AEasy constructionShort construction periodSewerage structuresPaving gutters/kerbsEcological environmentEngineering

The invention discloses a source rainwater purification and storage system based on low impact development. The source rainwater purification and storage system comprises a permeable pavement road and a concave herbaceous field. The permeable pavement road and the concave herbaceous field are connected, the bottom of the concave herbaceous field is provided with a bioretention layer, the bioretention layer comprises a biological layer, a sand layer and a gravel layer that are distributed in order, the bottom of the gravel layer is provided with a rainwater collection tank, the joint between the gravel layer and the rainwater collection tank is externally provided with a geotechnical cloth, the rainwater collection tank is composed of several rainwater collection modules, the upper parts of the tank wall on two sides of the rainwater collection tank are respectively provided with an overflow pipe, the rainwater collection tank is equipped with a water level monitoring device, by adopting a module mutual splicing method, the construction becomes convenient and the construction period is short, the collected rainwater can provide water needed for growth of green plants on the ground for a long time, natural rainwater is effectively utilized to reduce the consumption of the tap water employed by people to irrigate plants. At the same time, retention rainwater is stored to reduce surface runoff, thus being conducive to construction of sponge cities and protection of the ecological environment.

Owner:HUAZHONG UNIV OF SCI & TECH

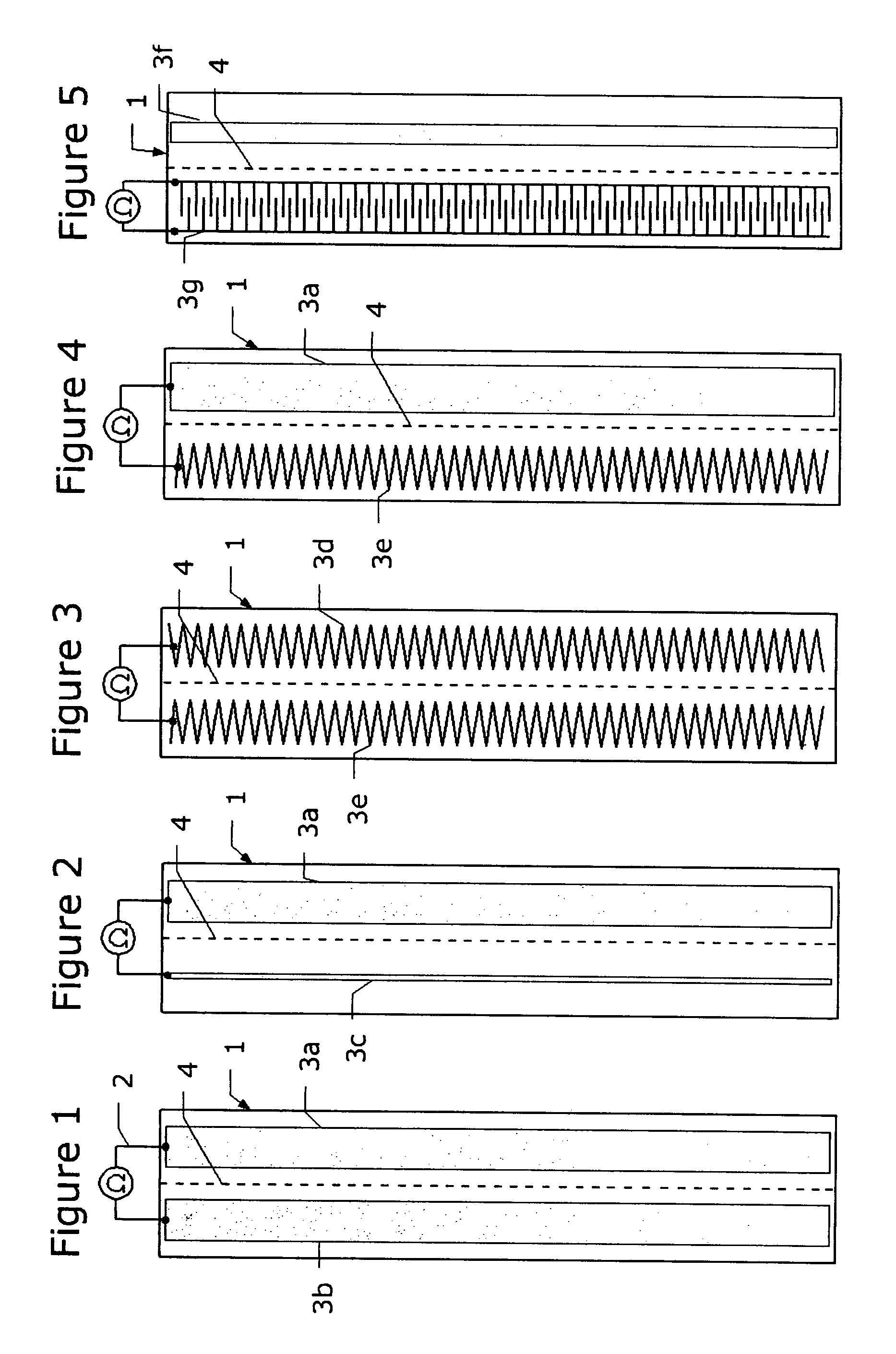

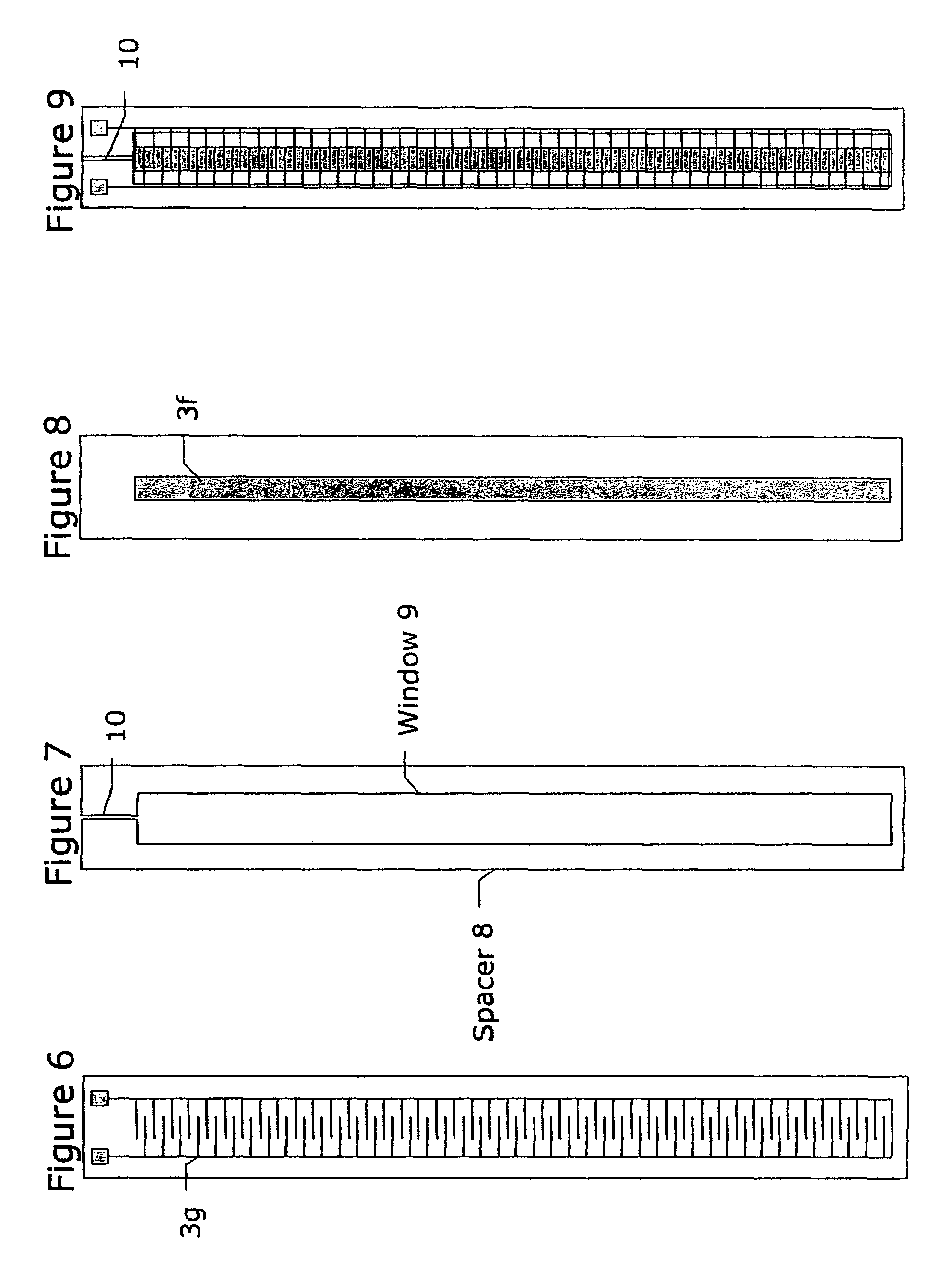

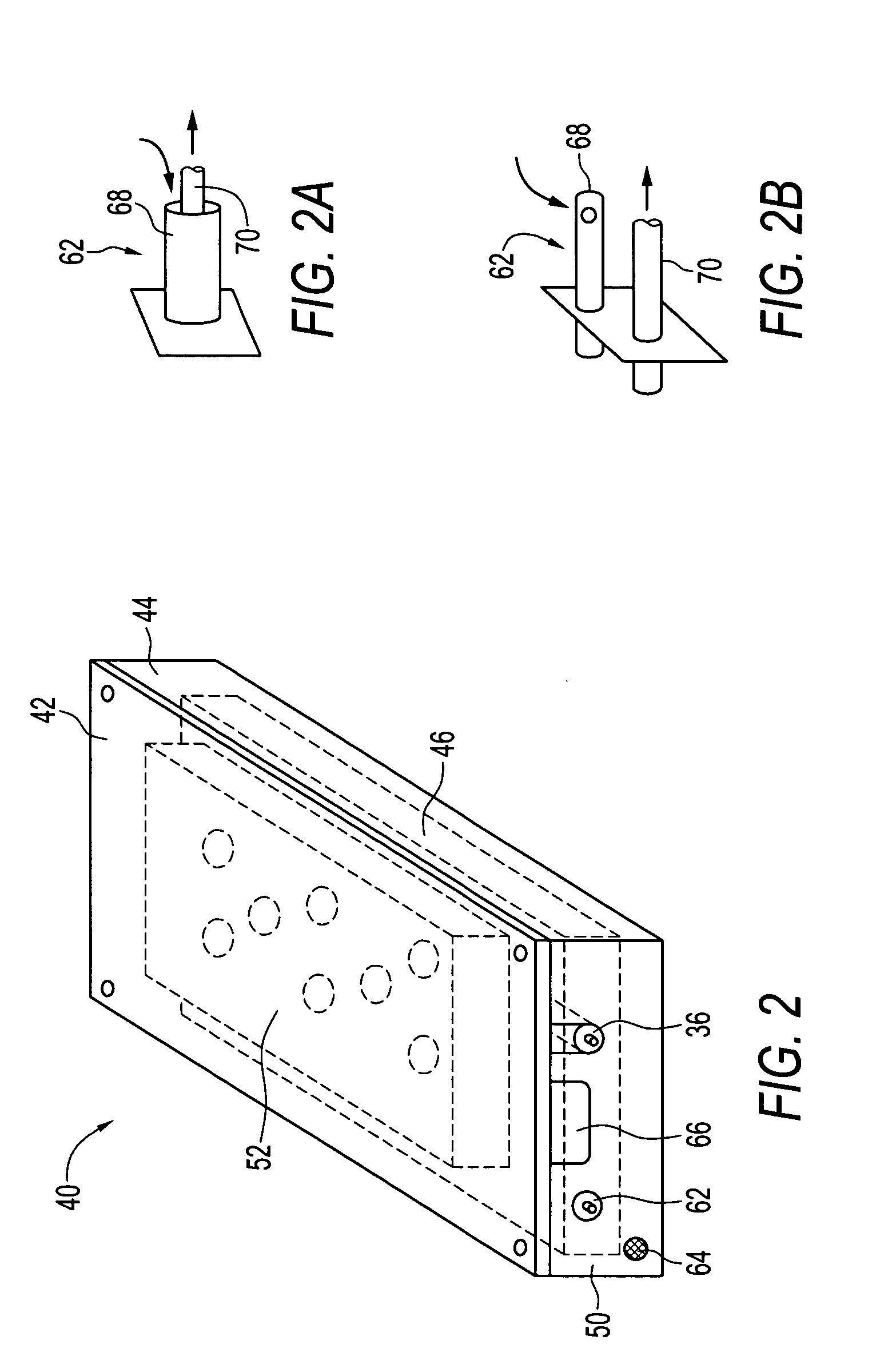

Low manufacturing cost printed ink liquid level sensors

ActiveUS7661307B1Reduce manufacturing costAccurately indicatedMachines/enginesLubrication indication devicesAdhesiveFuel tank

First and second elongated flexible insulated substrates have patterns of resistive liquid level sensor sections along the substrate lengths, each pattern comprising printable resistive ink of the same resistivity (ohms-squared), wherein the patterns can be simultaneously printed upon each substrate to save manufacturing costs. The substrates can be separated by an elongated spacer that couples longitudinal edges of the facing substrates together with an appropriate adhesive. Alternatively, the facing substrates can be folded along a central fold line to form a first longitudinal edge and adhesively joined along a second longitudinal edge opposite the first longitudinal edge. The flexibility of the substrates enables the low manufacturing cost liquid level sensors to be positioned in for example in a highly irregularly shaped vehicle fuel tank. Also, sections of varying lengths to be cut from the rolls on demand by users to form customized lengths of liquid level sensors for numerous applications.

Owner:MILONE CHRISTOPHER J

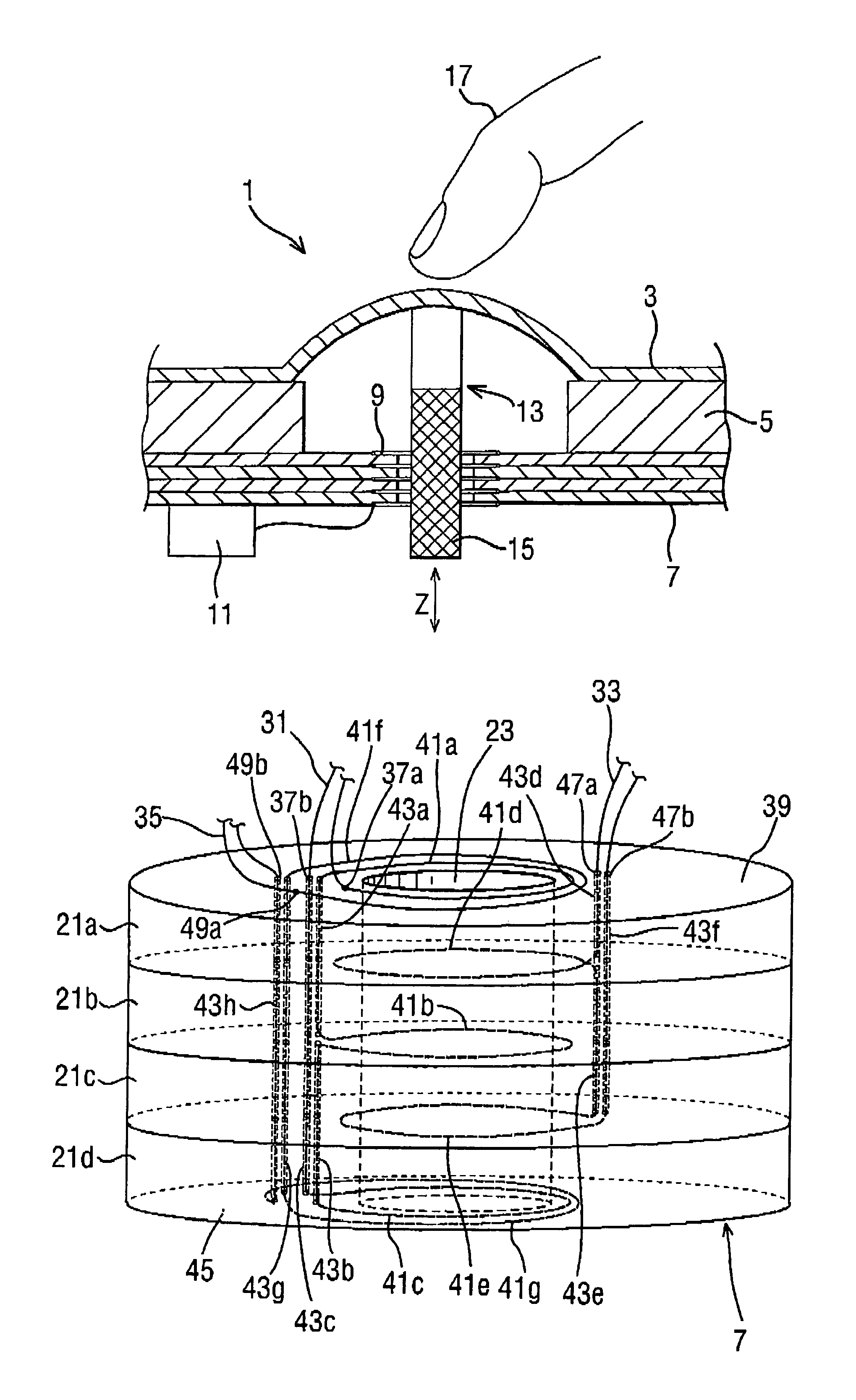

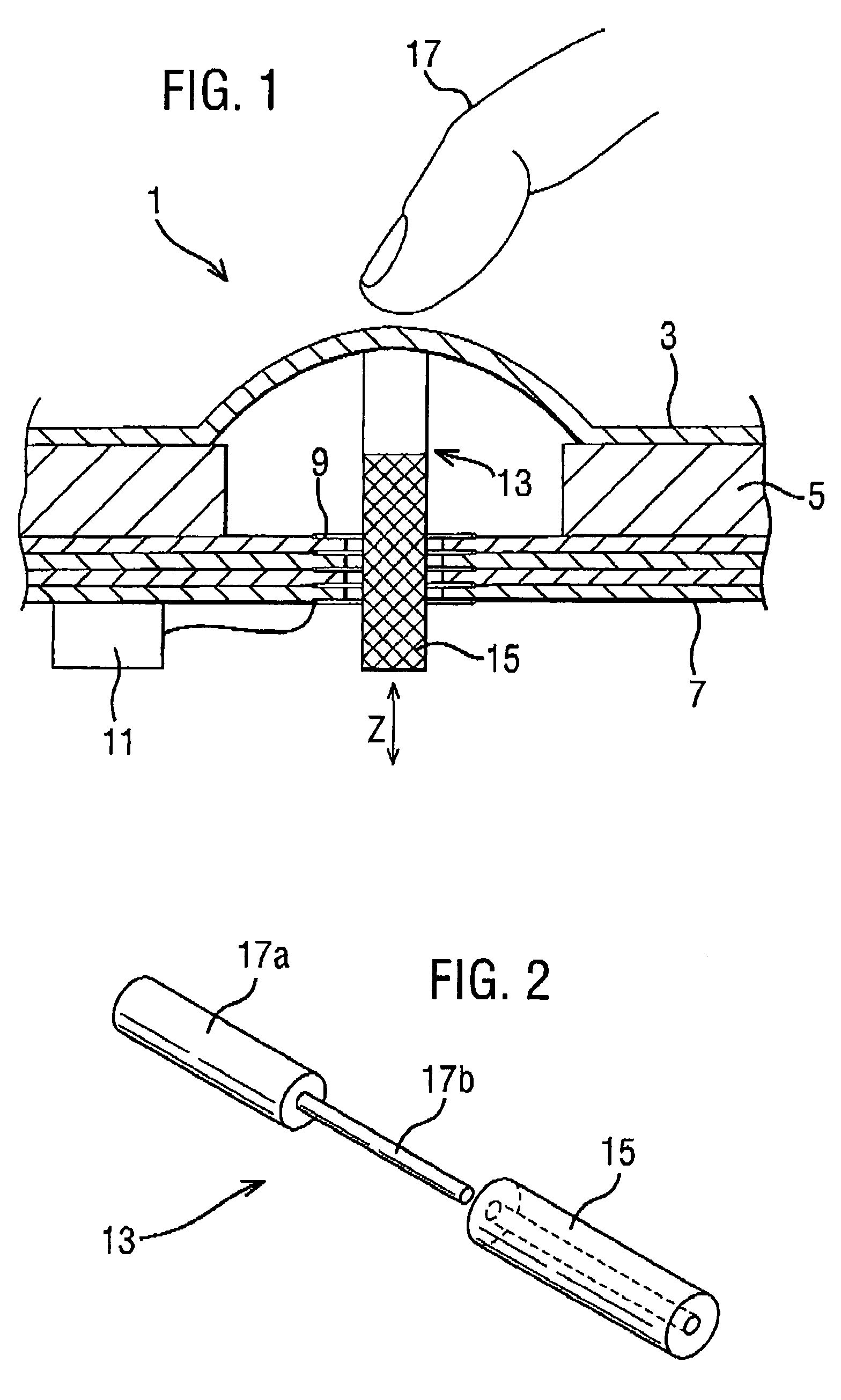

Sensing apparatus and method

There is described a position sensor comprising at least one planar substrate having formed thereon a magnetic field generator which comprises conductive tracks formed on at least two planes defined by the at least one planar substrate. An intermediate coupling element is operable to move relative to the at least one planar substrate along a measurement direction transverse to the planar substrate, the detector detects the position of the intermediate coupling element in a magnetic field generated by the magnetic field generator. The position sensor has particular application in man-machine interfaces such as push buttons and rotary switches.

Owner:TT ELECTRONICS TECH

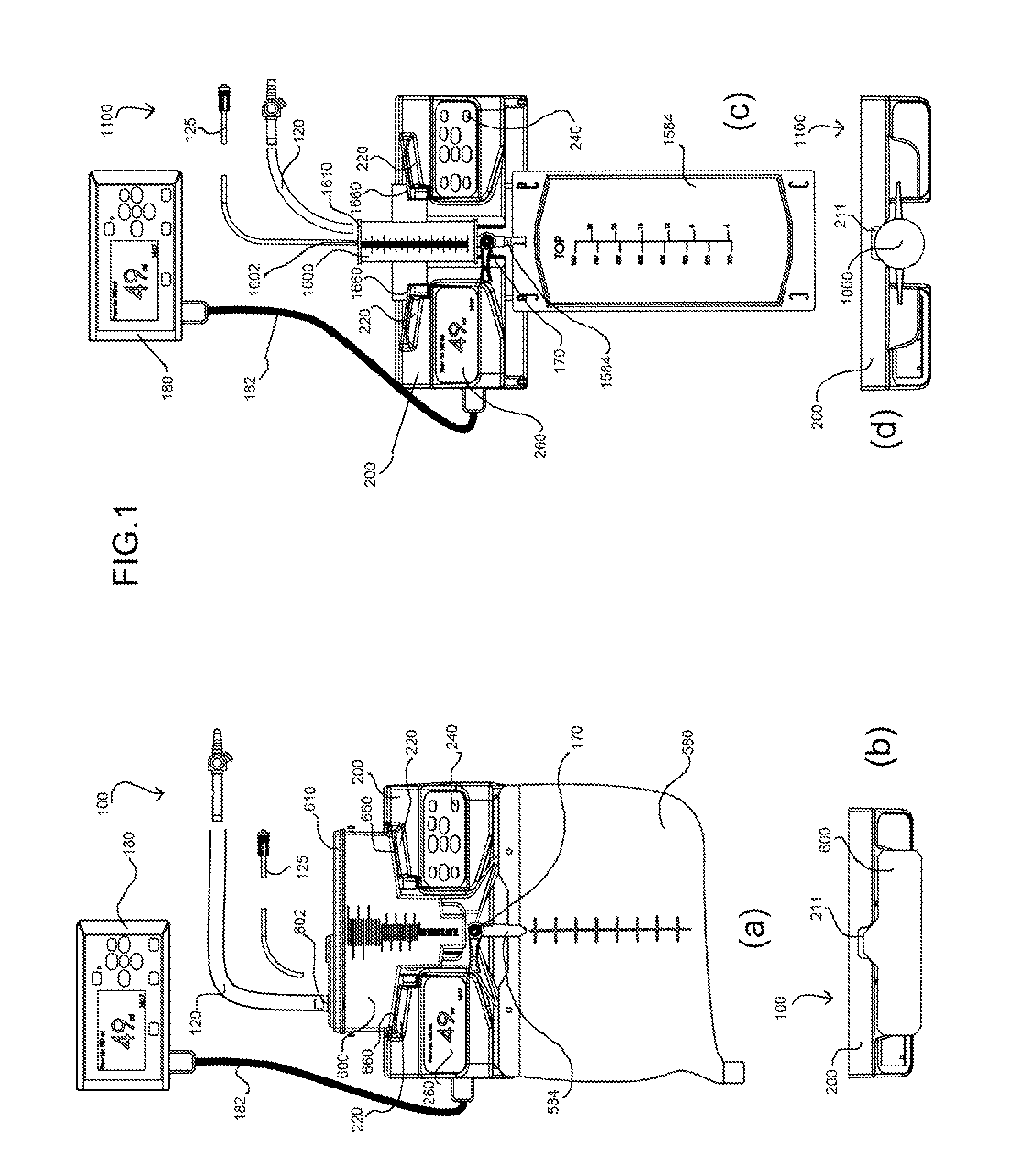

Apparatus and method for bedside collection of body fluids and automatic volume level monitoring

ActiveUS20120078137A1Novel featuresPrevent drainageVaccination/ovulation diagnosticsCatheterEngineeringBody fluid

A bedside apparatus and method designed to collect and monitor liquids output from a catheterized patient including an electronic unit and one of a plurality of defined disposable collecting and measuring rigid vessels that may differ in shape and size. Each defined vessel has at least one inlet to connect to a catheter outputting liquid from a patient in order to collect the liquid in the defined vessel. The defined vessel has at least one outlet valve to control draining of liquid from the vessel. An electronic unit has a configuration to receive the defined vessel and to securely mount and hold the defined vessel in a fixed relationship. The electronic unit further has a liquid level sensing device located in juxtaposition to the defined vessel to sense the level of liquid contained in the vessel.

Owner:BIOMETRIX

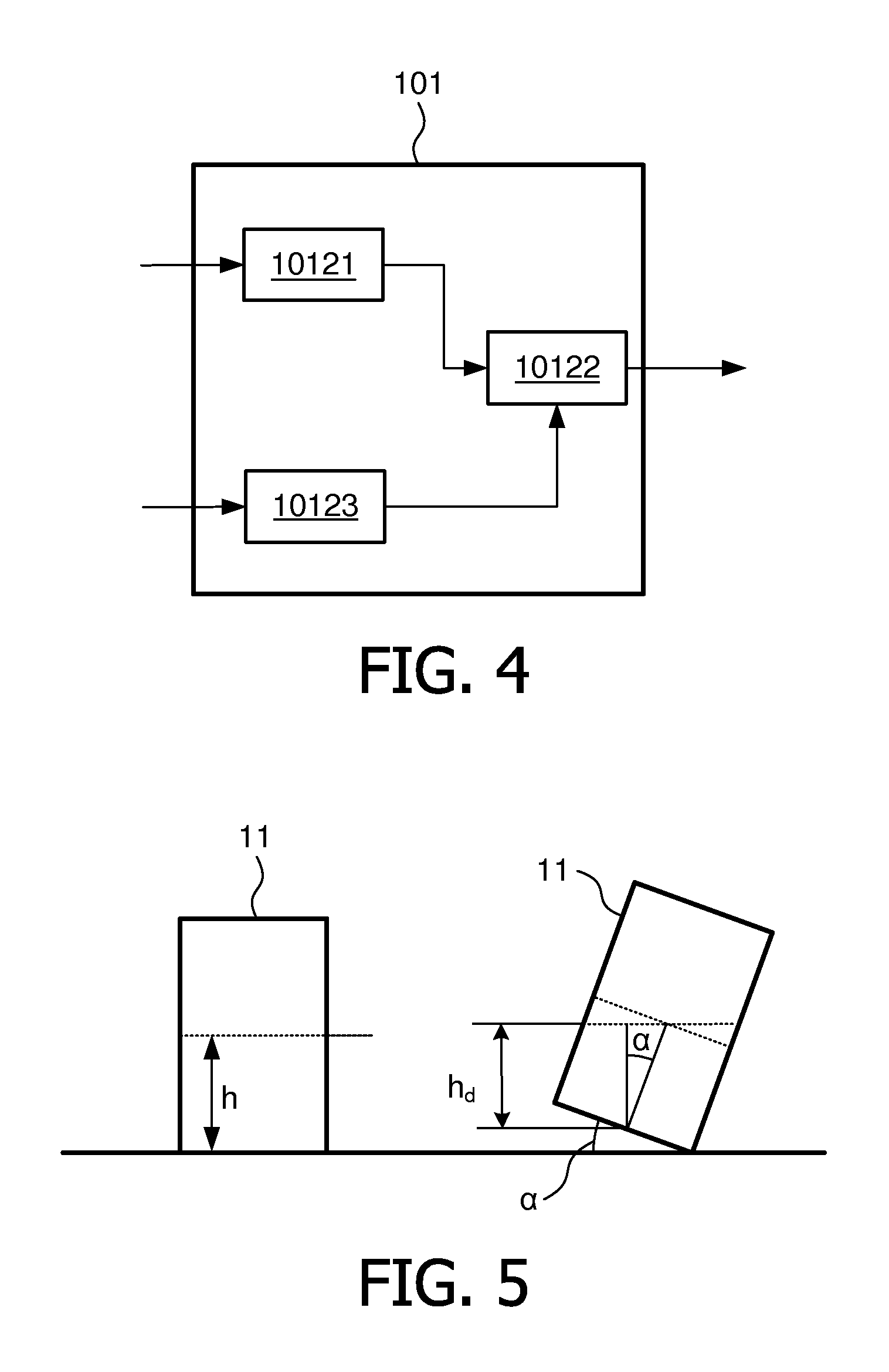

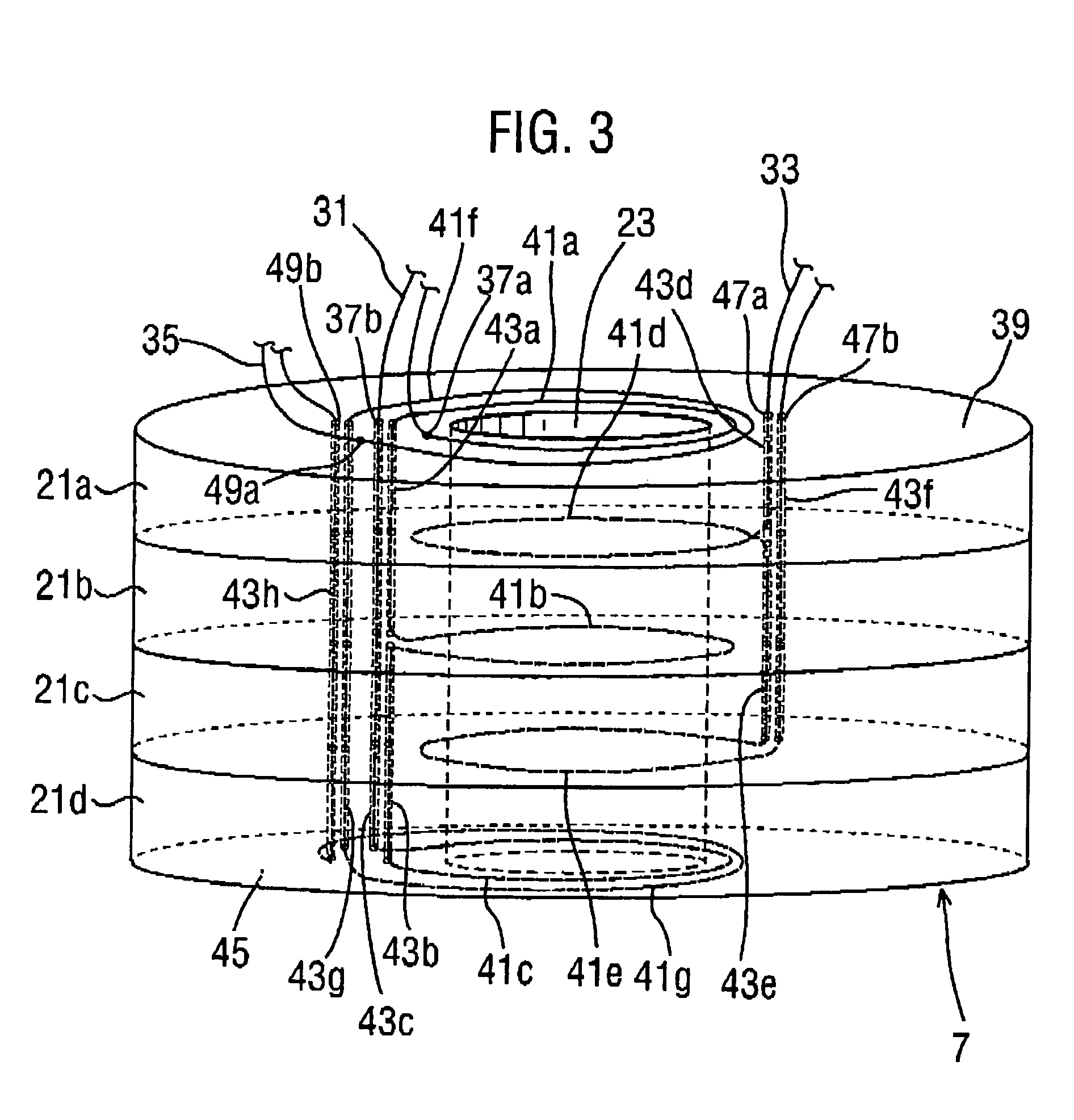

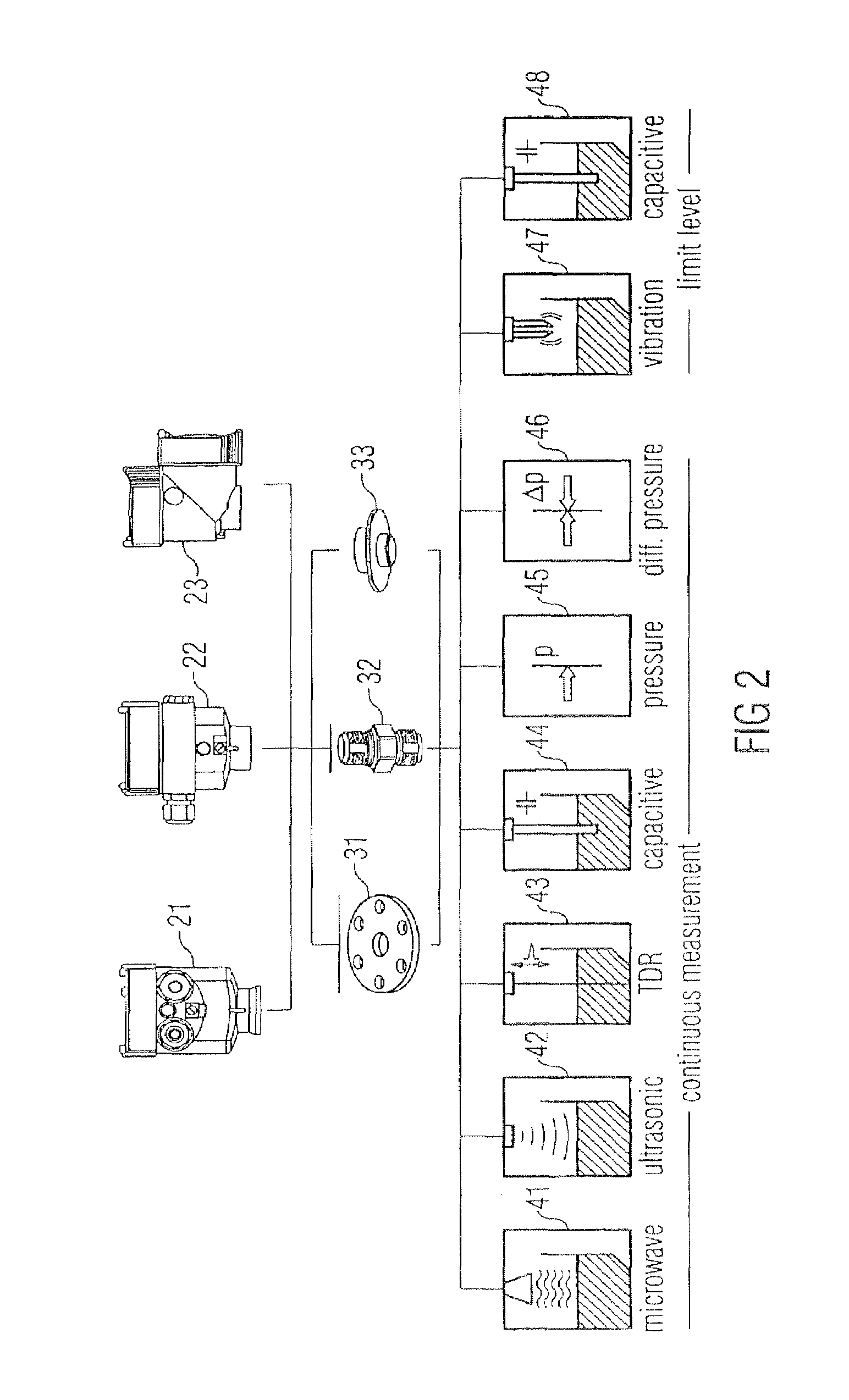

System for Manufacturing a Modularly Structured Apparatus for Determining a Physical Process Quantity, and Standardized Components

InactiveUS20100000316A1Cost of manufactureLow costResistance/reactance/impedenceSimultaneous indication of multiple variablesElectricityModularity

A system for providing different versions of a modularly structured apparatus for determining a physical process quantity, wherein at least two devices to be generated from the system are based on different measuring principles, including a number sensor units (41-48), each sensor unit being designed for detecting a determined physical measuring quantity and for converting said measuring quantity into an electrical measuring signal, wherein at least two of the sensor units are distinguished from each other by their underlying measuring principles; at least one evaluation unit (10), adapted to connect to the sensor units, for evaluating and generating a process quantity signal representing the physical process quantity from the measuring signal of a sensor unit; at least one output unit (13) for outputting the process quantity signal; at least one voltage supply unit (16); and at least one housing unit (22-24) configured to accommodate at least the evaluation unit.

Owner:VEGA GRIESHABER GMBH & CO

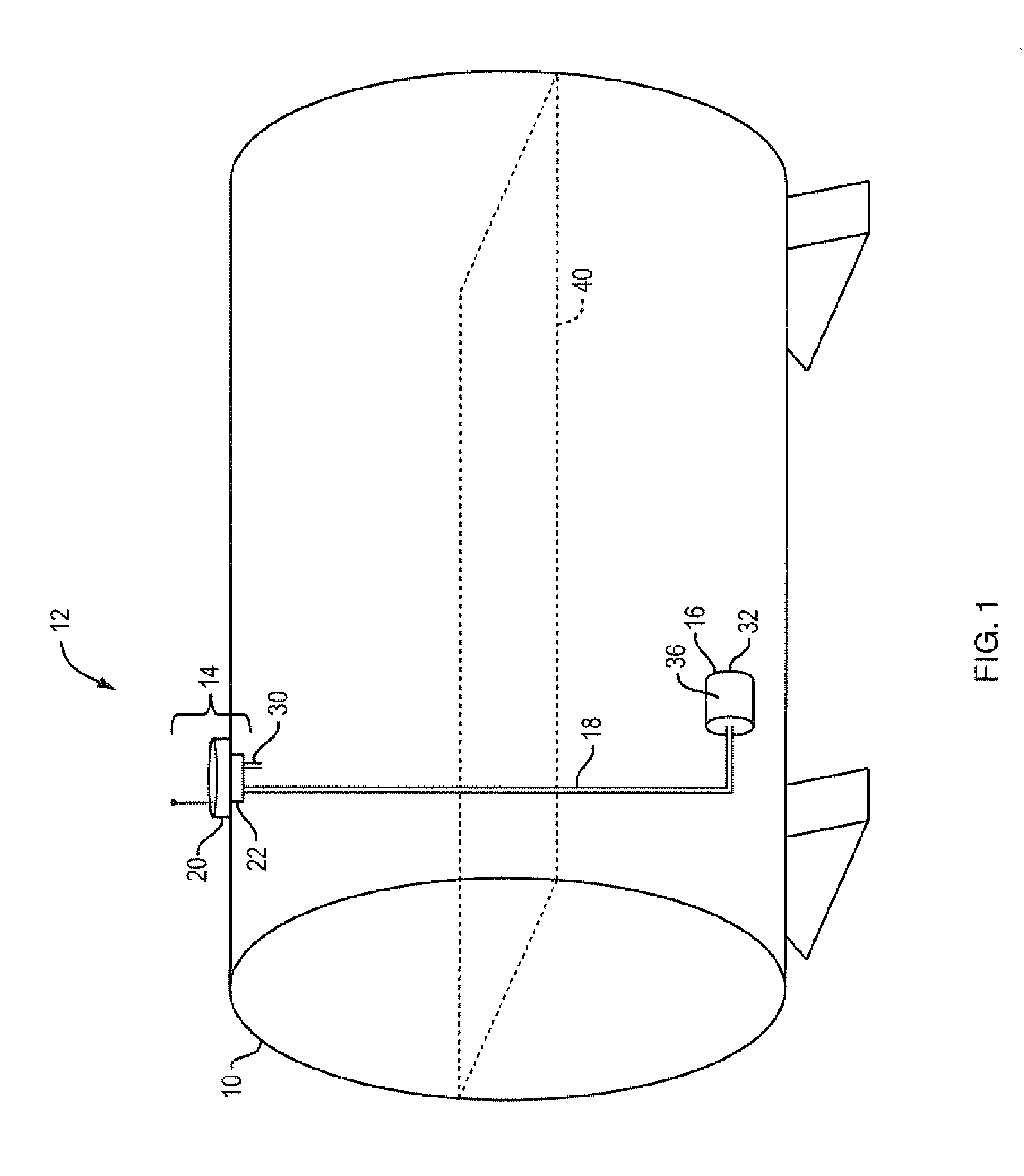

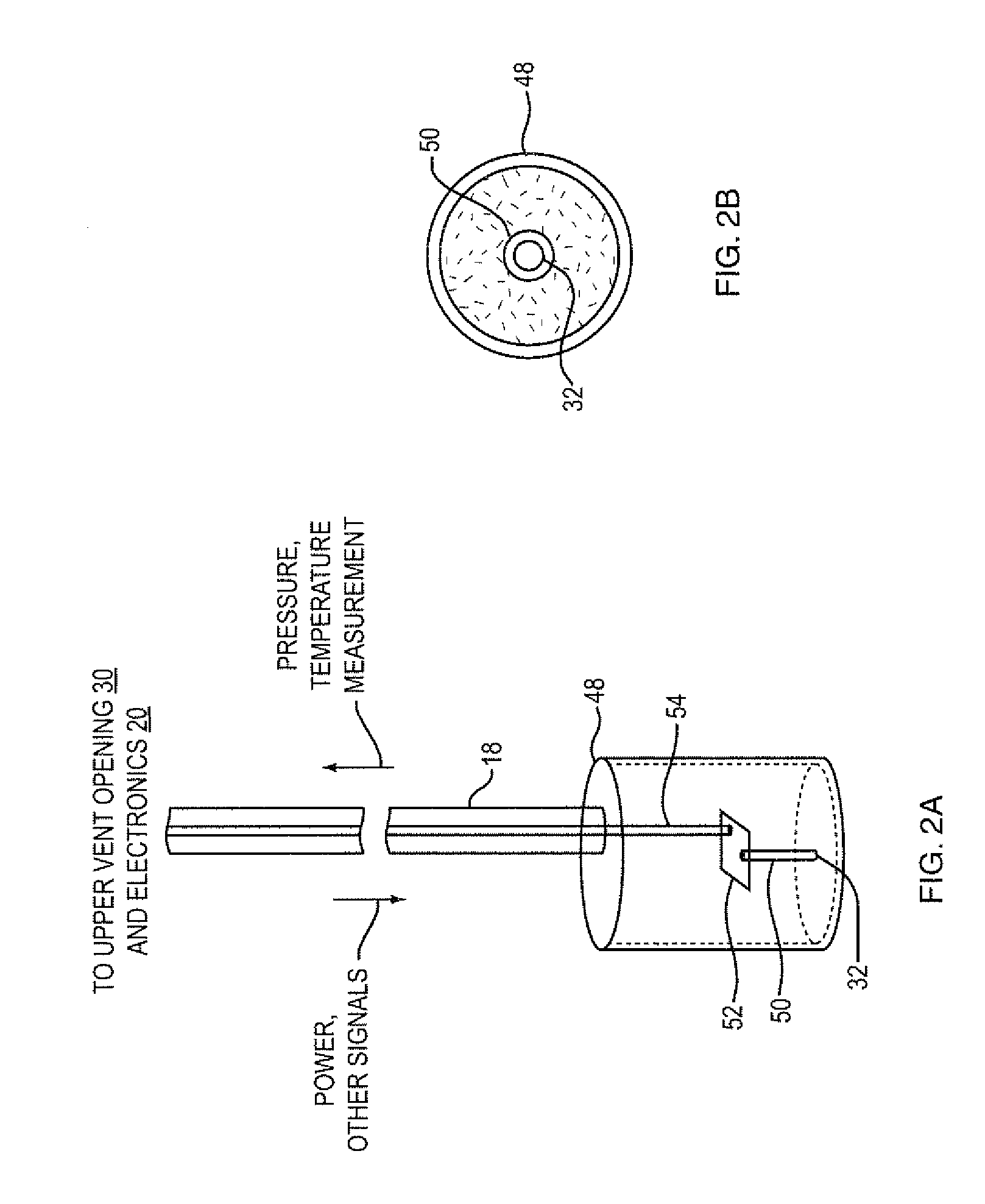

Remote level gauge adapted for liquid fuel tank

InactiveUS20110000295A1Conserve battery lifeAvoid excessive changesMachines/enginesLubrication indication devicesRadiotransmitterWireless data

An apparatus for sensing a fluid level that, in one embodiment, is adapted to fit the threads of a fill pipe or vent cap in a storage tank. A first (or upper) part of the assembly is secured in an upper portion of the tank (such as is provided at a threaded vent opening) and includes components to permit sensing pressure at a first location. A second (lower) portion of the assembly sensing pressure at a second location is disposed in a weighted casing. The second portion is coupled to the first portion through a cable that carries a section of tubing. Circuitry disposed in the second portion receives a pressure indication from the upper portion through the tubing, and detects a fluid pressure at both the upper and lower portion of the tank. The difference between the two pressures is indicative of fluid level. This level is then sent back up to the electronics assembly in the first (upper) portion. The electronics assembly can contain a microprocessor and a radio transmitter, such as a cellular or other wireless data network transmitter, to report the fluid level to a remote station such as operated by a fuel supplier. In more particular aspects, the reports of fluid levels can be delayed until periods of significantly less change in fluid level or an indication that use of the tank as stopped, to save battery life.

Owner:KRITLOW MARK +1

Fuel gauge for fuel cartridges

ActiveUS20050115312A1Reactant parameters controlContainer/cavity capacity measurementCapacitanceElectrical resistance and conductance

Fuel gauges for fuel supplies for fuel cells are disclosed. Each fuel gauge has a property that is readable by an electrical circuit. These properties are related to the remaining fuel in the fuel supplies. These properties include, but are not limited to, electrical capacitance, magnetic, semi-conducting resistance, bi-metal resistance, and oscillating magnetic field. These fuel gauges are functional at any fuel supply orientation.

Owner:INTELLIGENT ENERGY LTD

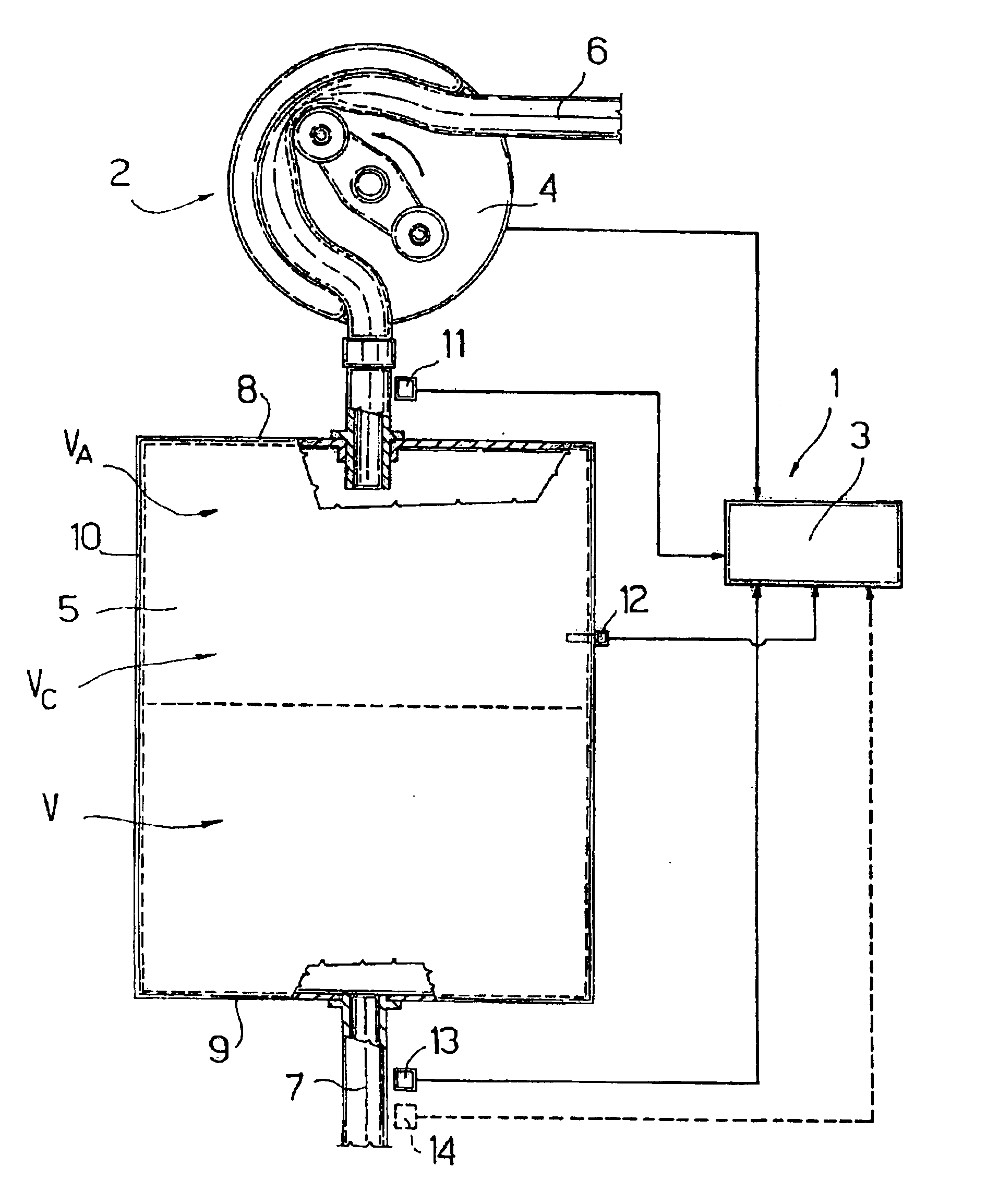

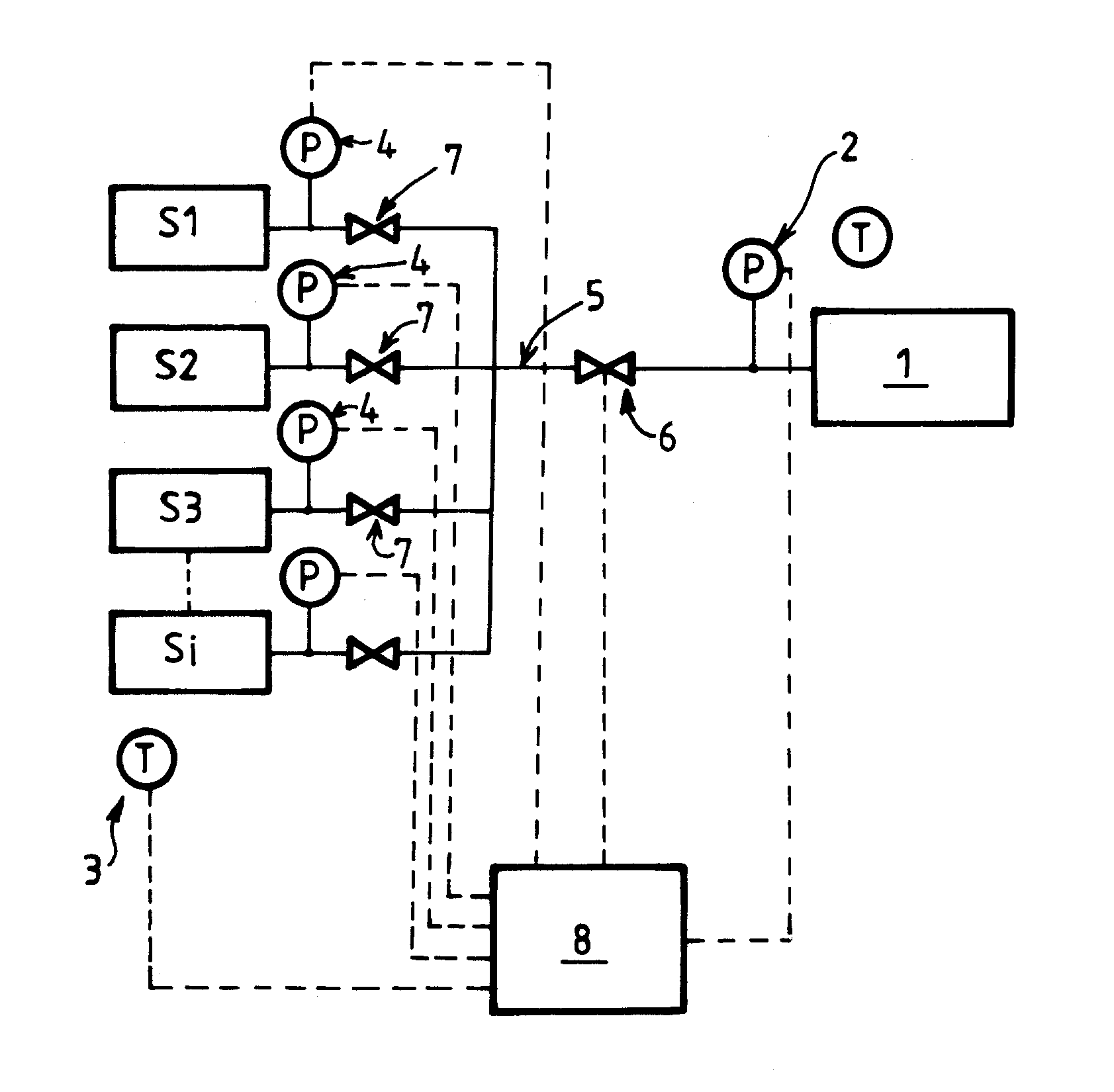

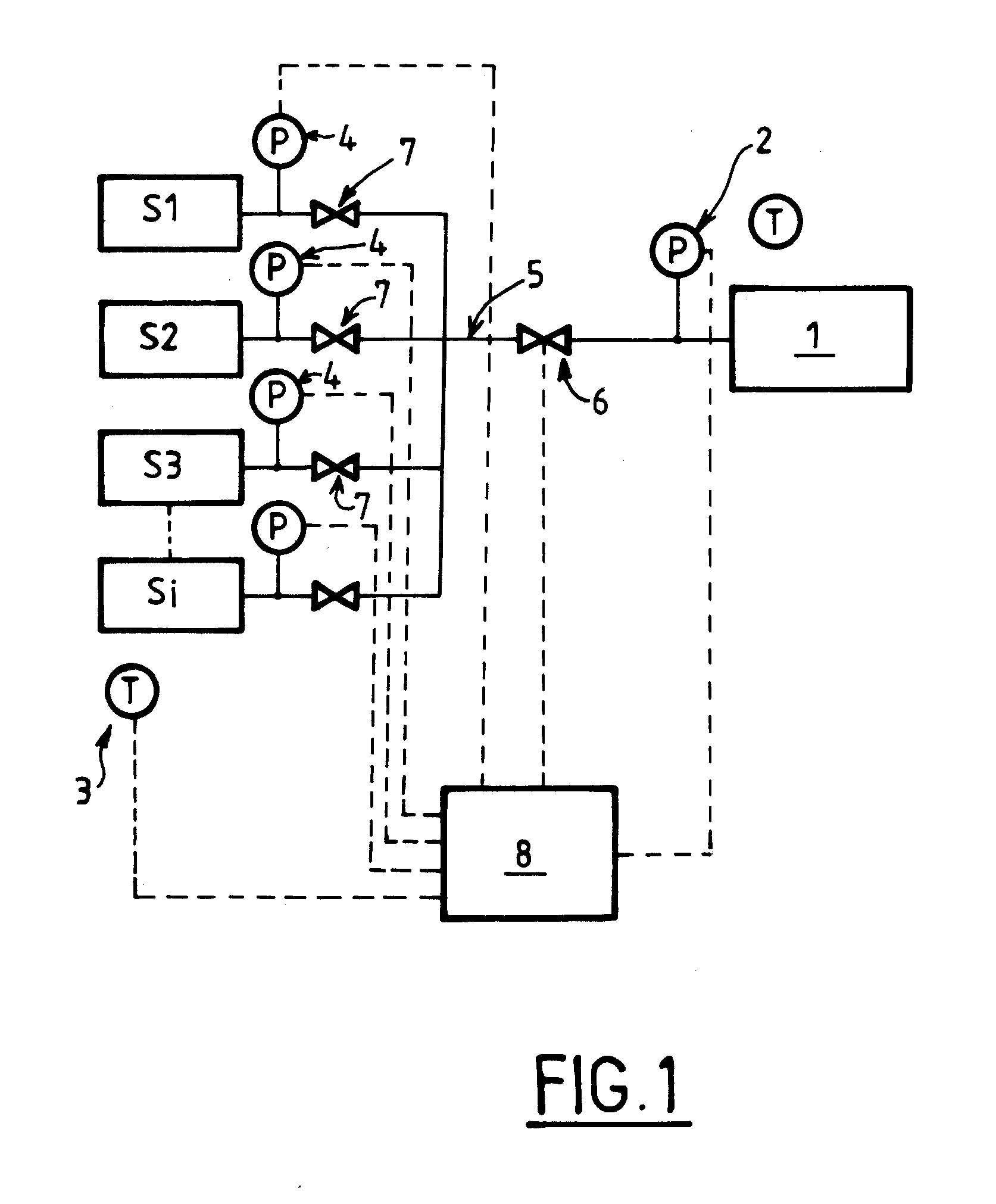

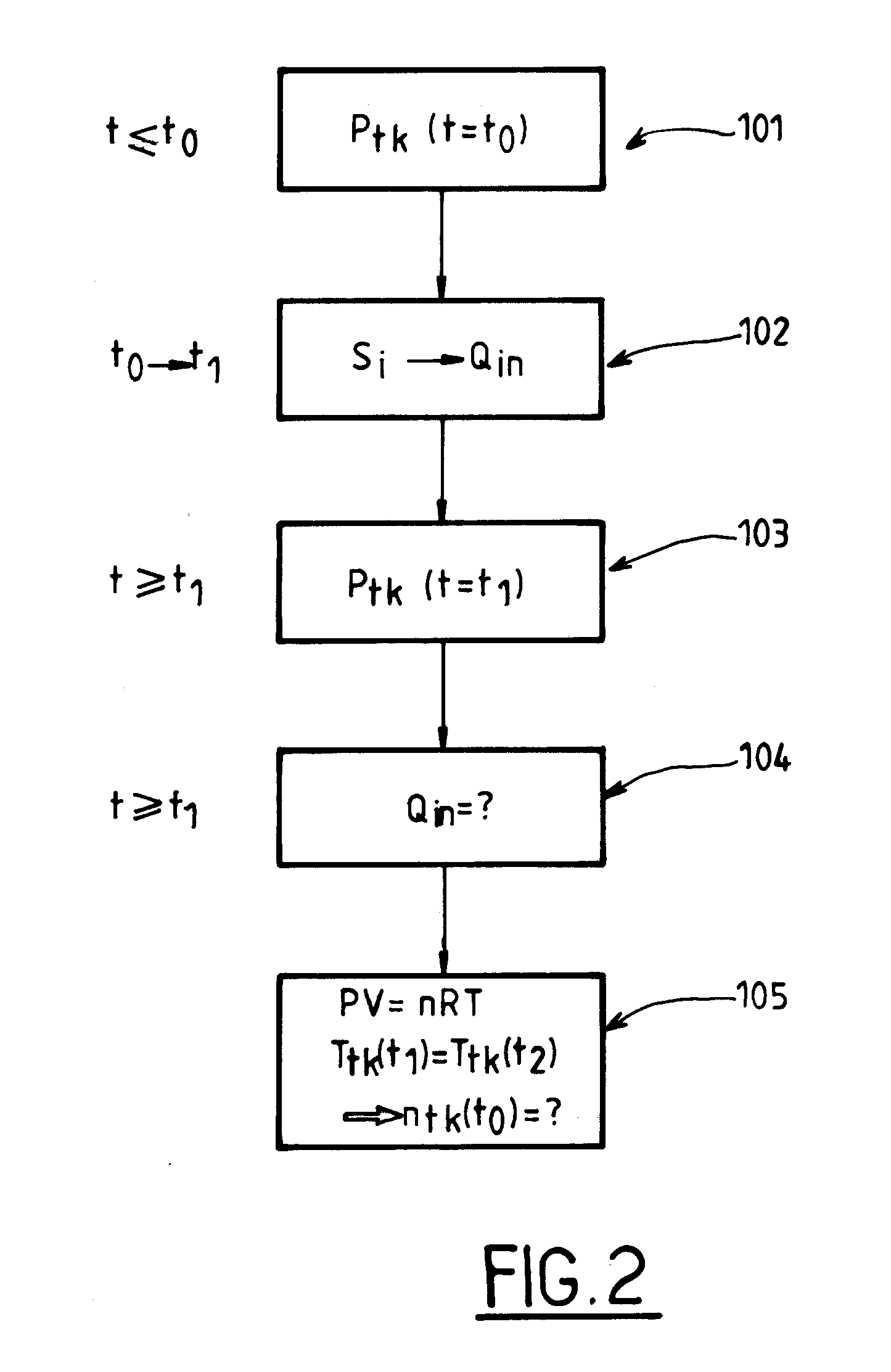

Method of Estimating the Volume of a Pressurized Gas Container

InactiveUS20110022337A1Testing/calibration apparatusInflated body pressure measurementStream flowVan der Waals equation

Method of estimating the volume (Vtk) of a tank (1), comprising:a first step of determining the quantity (ntk(ti)) of gas contained in the tank (1) at a first time (t=t1); thena step of transferring a checking stream of gas from a source (S1, S2, S3, . . . , Si) into the tank (1), the checking stream flowing over a discrete period (t2−t1);a step of determining the quantity (Q=ntk(t2)−ntk(t1)) of gas transferred from the source (S1, S2, S3, . . . Si) into the tank (1) during flow of the checking stream of gas; anda step of calculating the volume (Vtk) of the tank (1) by applying the law of conservation of enthalpy (H) of the gas, considering that the transfer of the checking stream of gas is adiabatic (Ttk(t1)=Ttk(t2) and Tsi(t1)=Tsi(t2)), expressing the enthalpy of the gas in the tank as a function only of the temperature Ttk(ti) of the gas and the pressure Ptk(ti) of the gas (Htk=function of (Ttk(ti); Ptk(ti)), using the perfect gas law or a Van der Waals equation of state expressing the volume of the tank Vtk(ti) (in cubic metres) only as a function of the known or previously estimated variables.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com