Production method of HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar

A production method and anti-corrosion technology, applied in metal rolling and other directions, can solve problems such as difficulty in meeting high-performance construction requirements, large temperature fluctuations of the cooling bed on the rolling piece, and unstable performance of the steel bar, and reduce the number of castings. The effect of blank defects, significant grain refinement strengthening, and small composition fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

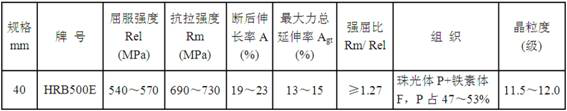

[0043] Example 1—Rolling Φ40mm HRB500E fine-grained high-strength anti-seismic anti-corrosion steel bar

[0044] S100: Molten iron (chemical composition C: 4.0~5.0wt%, Si: 0.30~0.55wt%, Mn: 0.30~0.60wt%, P: 0.080~0.120wt%, S≤0.045wt%, the rest is Fe or not Avoided impurities), steel scrap (chemical composition C: 0.12~0.20wt%, Si: 0.15~0.35wt%, Mn: 0.35~0.65wt%, P: 0.025~0.040wt%, S: 0.025~0.040wt%, the rest Fe and unavoidable impurities) and pig iron (chemical composition C: 3.0~3.5wt%, Si: 0.30~0.55wt%, Mn: 0.40~0.65wt%, P: 0.060~0.100wt%, S: 0.030~0.050 wt%, the rest is Fe and unavoidable impurities), according to 930~940kg / t respectively 钢 , 100~115kg / t 钢 , 30~40kg / t 钢 Put it into a 120-ton converter, carry out conventional top-bottom compound blowing, add lime, dolomite, and magnesite balls according to the conventional amount to make slag, control the carbon content at the end point to be 0.08-0.12wt%, and tap the steel at a temperature of 1620-1660°C; Add lime and r...

Embodiment 2

[0055] Example 2—Rolling Φ40mm HRB500E fine-grained high-strength anti-seismic and anti-corrosion steel bars

[0056] S100: same as embodiment 1.

[0057] S200: same as embodiment 1.

[0058] S300: same as embodiment 1, obtain molten steel with the following composition:

[0059] C:0.23wt%, Si:0.55wt%, Mn:1.38wt%, S:0.030wt%, P:0.020wt%, Cr:0.238wt%, Ni:0.090wt%, V: 0.107wt%, the rest are Fe and unavoidable impurities;

[0060] S400: same as embodiment 1.

[0061] S500: The S400 bloom is sent to the end-in and side-out heat-resistant slide rail push-steel double heat storage heating furnace through the conveying roller table at a hot charging temperature of 600-650°C for heating, in which blast furnace gas and air are preheated at the temperature ≥1000℃, the furnace chamber of the heating furnace adopts a micro-positive pressure operation of 10-15Pa, and the atmosphere in the furnace is a reducing atmosphere; the temperature of the soaking section of the heating furnace is...

Embodiment 3

[0067] Example 3—Rolling Φ40mm HRB500E fine-grained high-strength anti-seismic anti-corrosion steel bar

[0068] S100: same as embodiment 1.

[0069] S200: same as embodiment 1.

[0070] S300: same as embodiment 1, obtain molten steel with the following composition:

[0071] C:0.24wt%, Si:0.49wt%, Mn:1.40wt%, S:0.035wt%, P:0.025wt%, Cr:0.245wt%, Ni:0.100wt%, V: 0.112wt%, the rest are Fe and unavoidable impurities;

[0072] S400: same as embodiment 1.

[0073] S500: The S400 bloom is sent to the end-in and side-out heat-resistant slide rail push-steel double heat storage heating furnace through the conveying roller table at a hot charging temperature of 600-650°C for heating, in which blast furnace gas and air are preheated at the temperature ≥1000°C, the furnace chamber of the heating furnace adopts a micro-positive pressure operation of 10-15Pa, and the atmosphere in the furnace is a reducing atmosphere; the temperature of the soaking section of the heating furnace is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strong bend ratio | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com