One-step forging and molding method of steering knuckle of heavy-duty car

A heavy-duty vehicle and forging forming technology, which is applied to vehicle parts, railway car body parts, transportation and packaging, etc. It can solve the problems of large one-time investment in equipment, large tonnage of forging machine tools, and many connection auxiliary facilities, etc., to achieve high production efficiency , less forging equipment and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

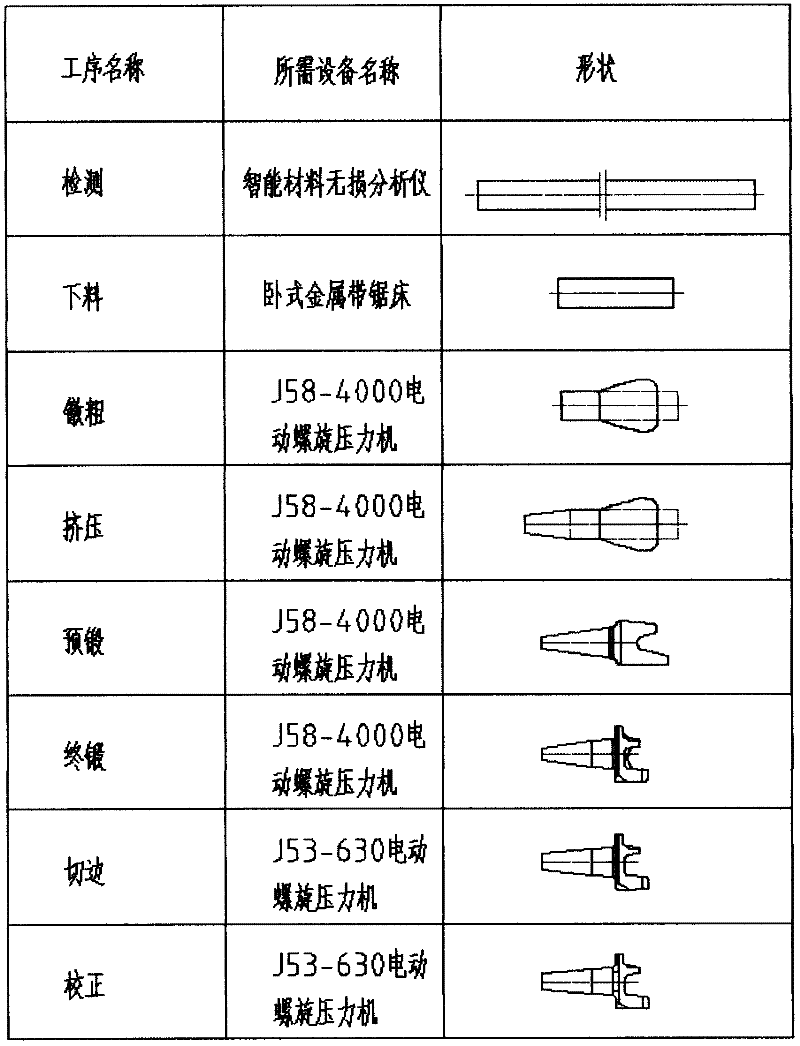

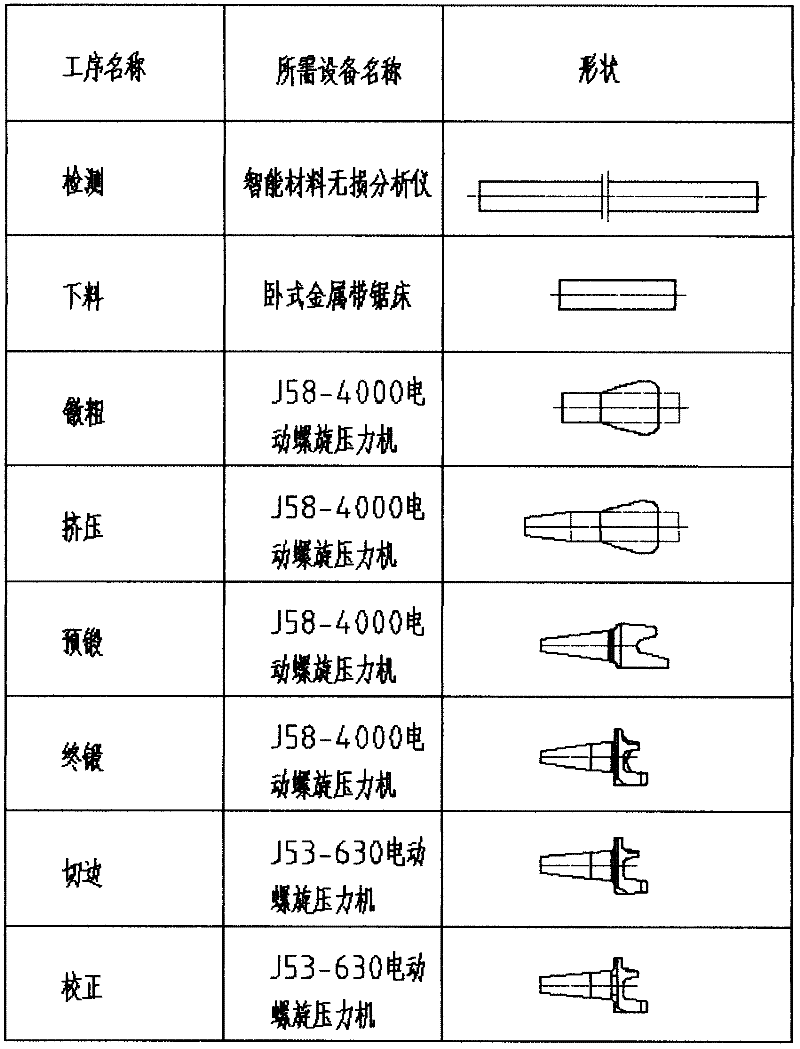

[0021] ■Inspection: Put the bar on the conveyor belt, let the bar pass through the end of the feeding belt in turn, install the XH91-ZWCF-II intelligent material hardness non-destructive sorting instrument, and the non-destructive sorting instrument mixes the material through the PLC preset value , heat treatment hardness, carbon content, surface hardening degree, heat treatment state, cracks, etc. are directly analyzed and sorted, and the number of bars is recorded. Qualified bars are sent to the blanking process, waiting for blanking.

[0022] ■Blanking: cut the qualified bar after inspection into the specified size and put it into the tiltable box, and transport it to the heating process.

[0023] ■Heating: The material lifting device sends the bars in the tiltable box into the step-type intermediate frequency heating furnace in turn, and the step-type intermediate frequency heating furnace pushes the materials out of the furnace body according to the production rhythm of f...

Embodiment 2

[0032] ●Inspection: Put the bar on the conveyor belt, let the bar pass through the end of the feeding belt in turn, install the XH91-ZWCF-II intelligent material hardness non-destructive sorting instrument, the non-destructive sorting instrument mixes the material through the value preset by PLC , heat treatment hardness, carbon content, surface hardening degree, heat treatment state, cracks, etc. are directly analyzed and sorted, and the number of bars is recorded. Qualified bars are sent to the blanking process, waiting for blanking.

[0033] ●Blanking: cut the qualified bar after inspection into the specified size and put it into the tiltable box, and transport it to the heating process.

[0034] ●Heating: The material lifting device sends the bars in the tiltable box into the step-type intermediate frequency heating furnace in sequence, and the step-type intermediate frequency heating furnace pushes the material out of the furnace body according to the production rhythm of...

Embodiment 3

[0043] ◆Inspection: Put the bar on the conveyor belt, let the bar pass through the end of the feeding belt in turn, install the XH91-ZWCF-II intelligent material hardness non-destructive sorting instrument, the non-destructive sorting instrument mixes the material through the preset value of PLC , heat treatment hardness, carbon content, surface hardening degree, heat treatment state, cracks, etc. are directly analyzed and sorted, and the number of bars is recorded. Qualified bars are sent to the blanking process, waiting for blanking.

[0044] ◆Blanking: cut the qualified bars into the specified size and put them in the tiltable box, and transport them to the heating process.

[0045] ◆Heating: The material lifting device sends the bars in the tilting box into the step-type intermediate frequency heating furnace in sequence. According to the temperature of the discharge, the discharge device will divide the material into qualified and unqualified according to the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com