Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Uniform mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

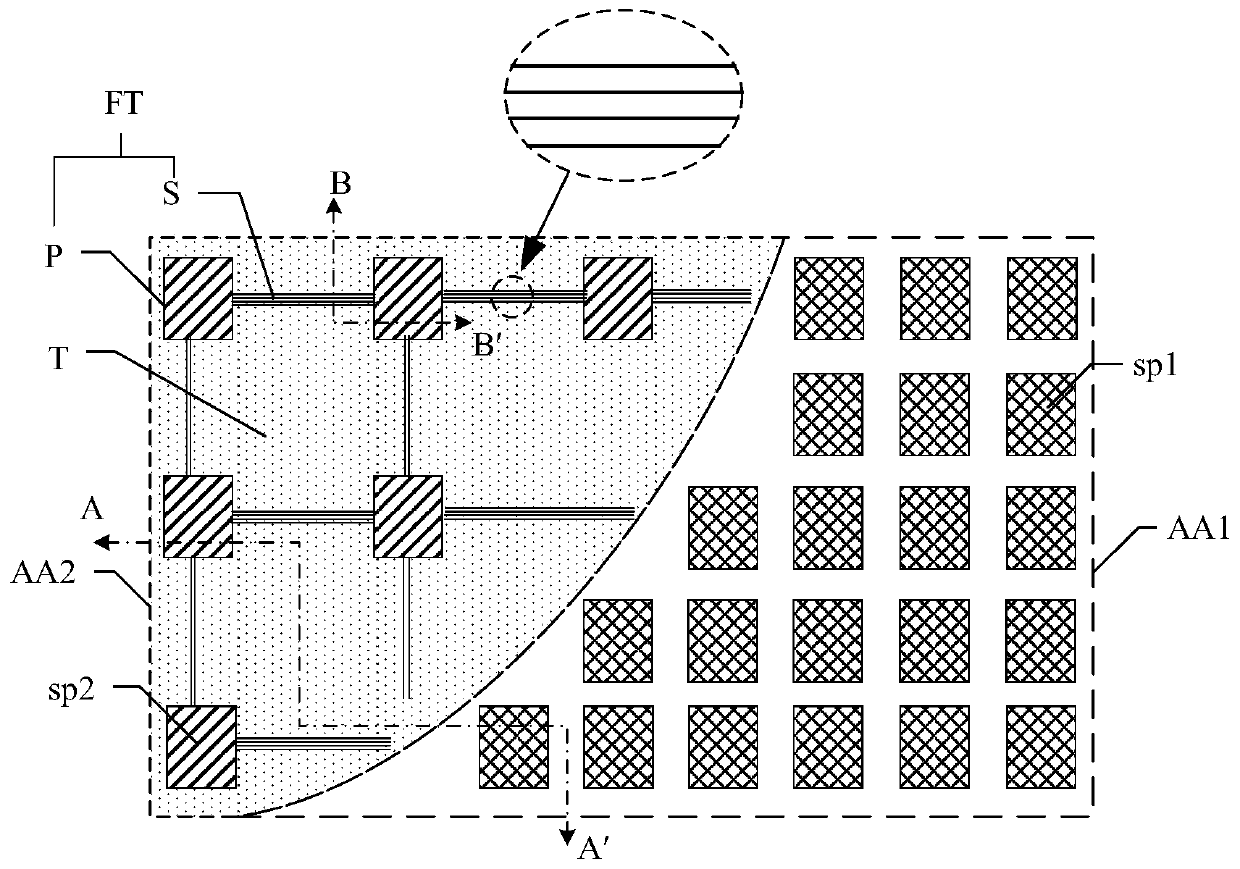

Display panel and display device

InactiveCN110618557AUniform film thicknessIncrease the amount of received lightNon-linear opticsPixel densityOptical Module

The invention provides a display panel and a display device. The display panel comprises a first display area, a virtual hole area and a polarization structure, wherein the pixel density of the virtual hole area is smaller than that of the first display area, the virtual hole area comprises a plurality of light transmission areas and a plurality of non-light transmission areas, and the non-light transmission areas comprise pixel areas and routing areas; and the polarization structure is positioned on one side of the display surface of the display panel and comprises a first polarization part and a second polarization part, the light transmittance of the first polarization part is larger than that of the second polarization part, each light transmission area comprises a first light transmission part, and each pixel area comprises a second light transmission part. According to the display panel, the transmittance of the light transmission areas can be increased, and the received light quantity of an optical module under a screen is increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

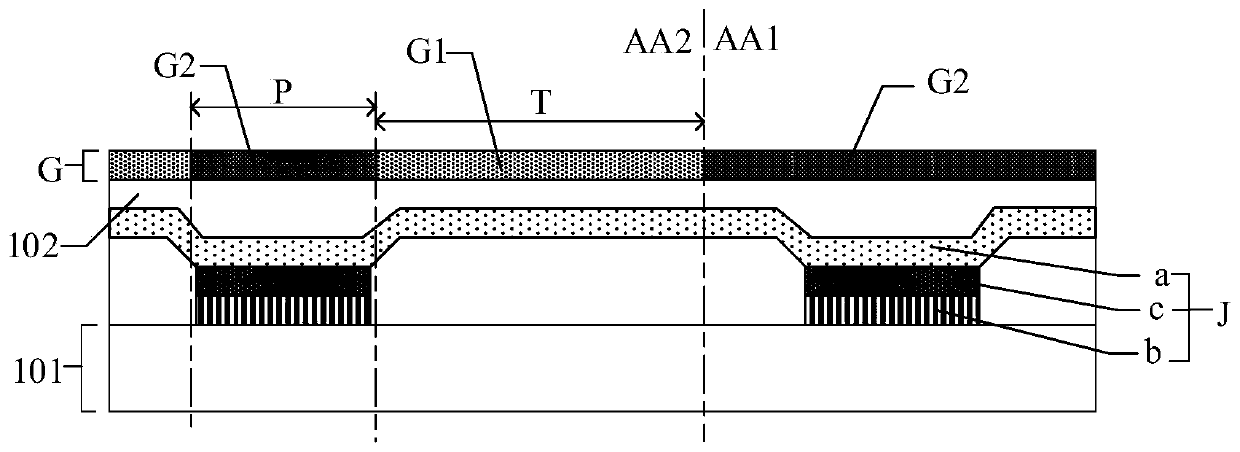

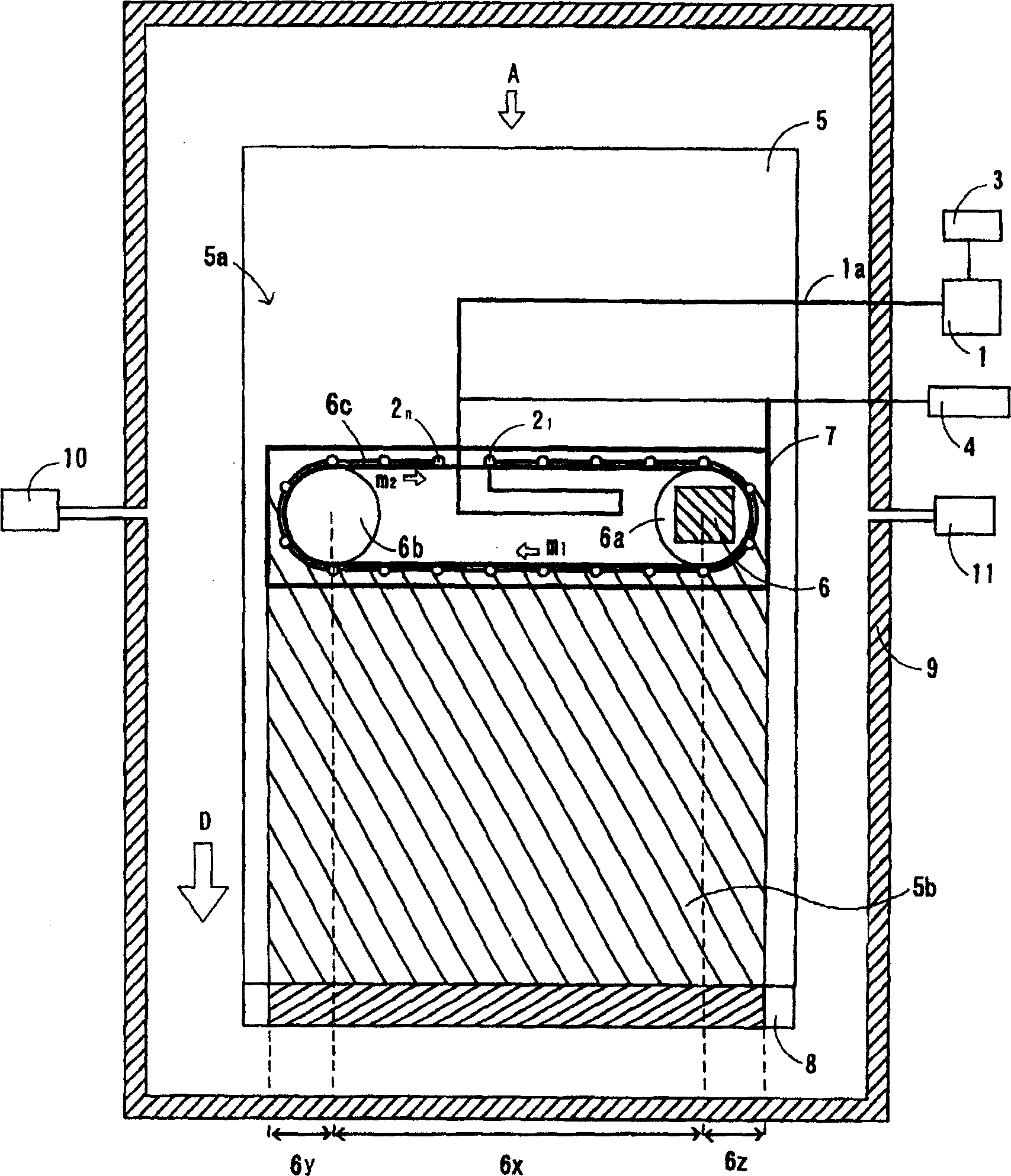

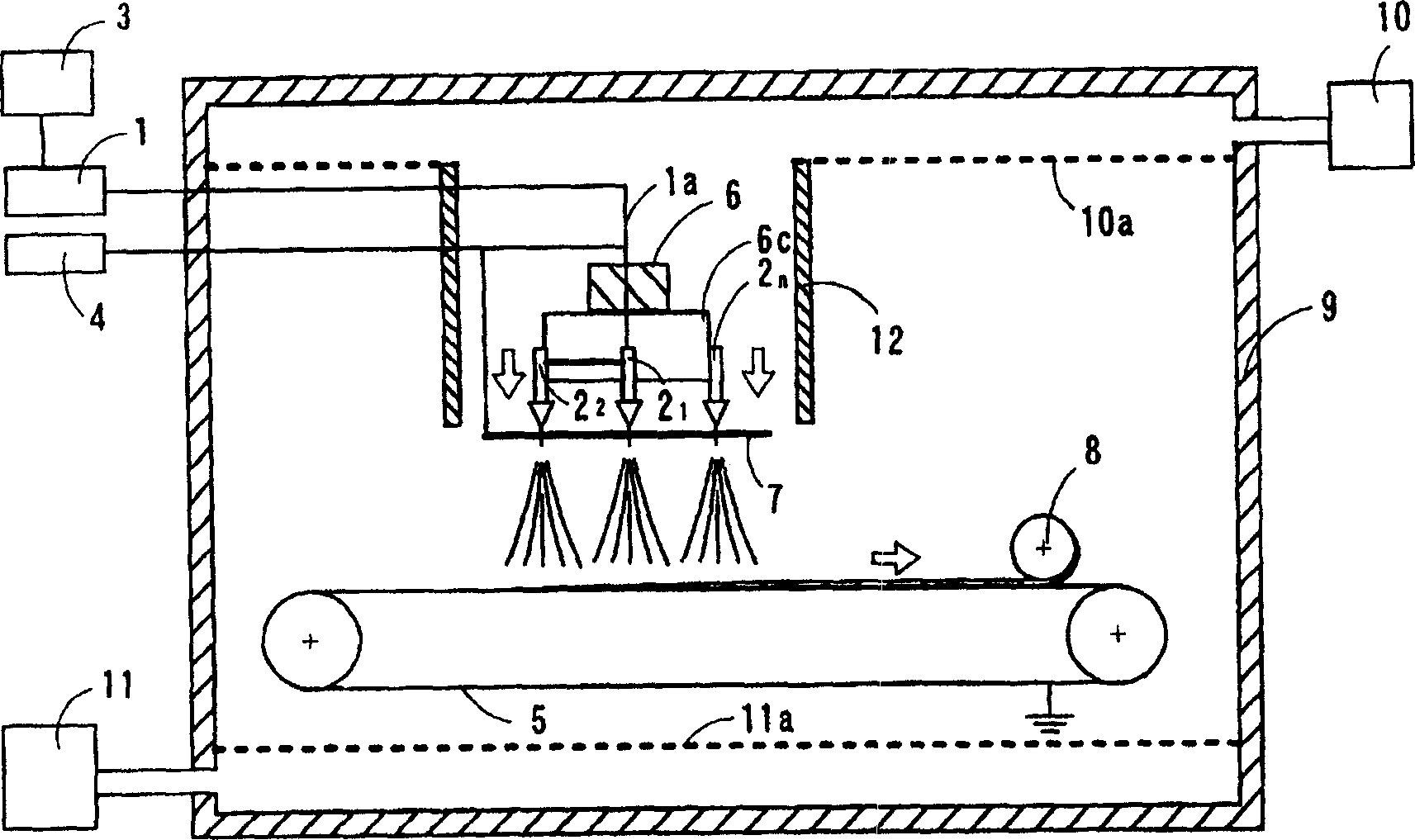

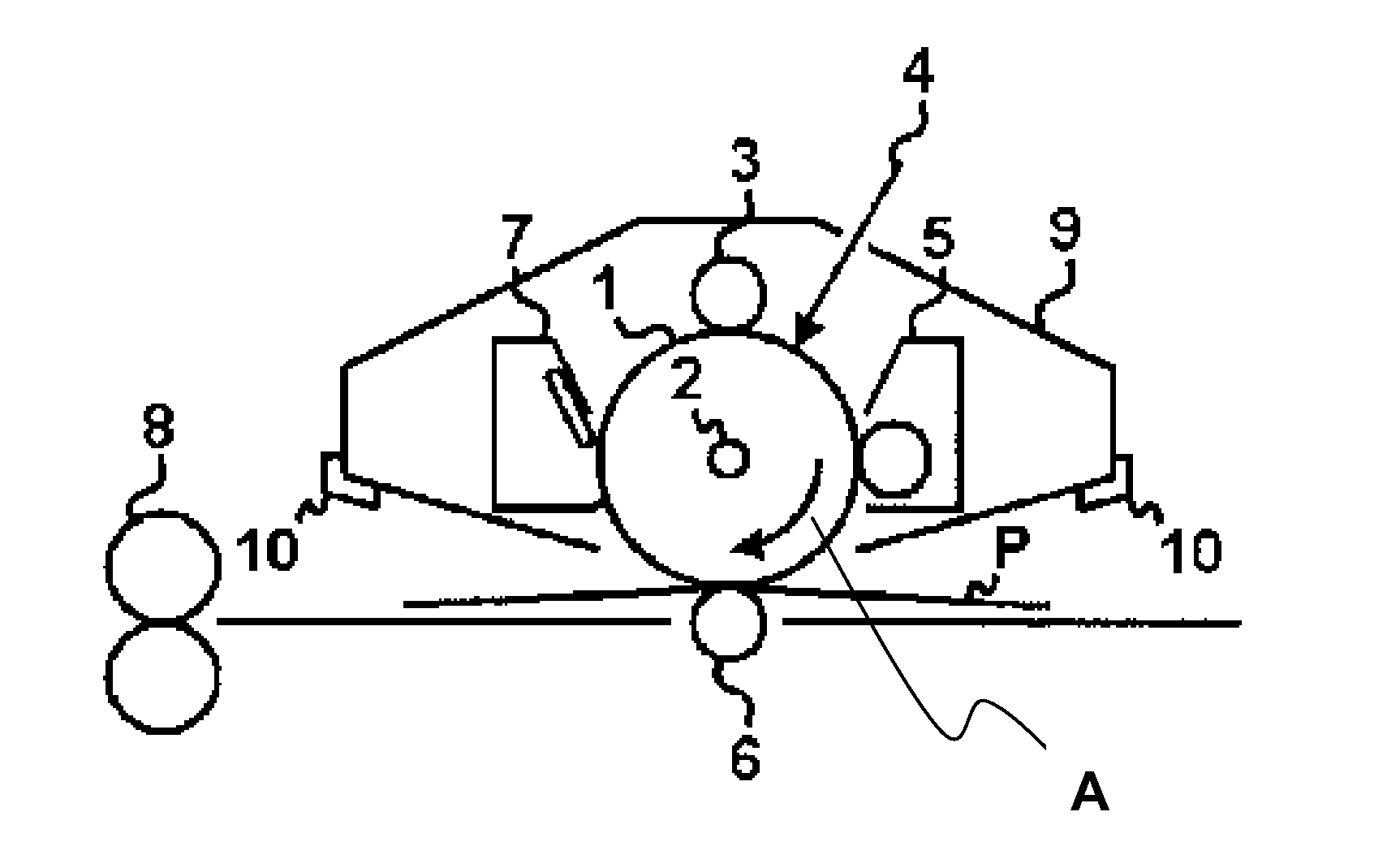

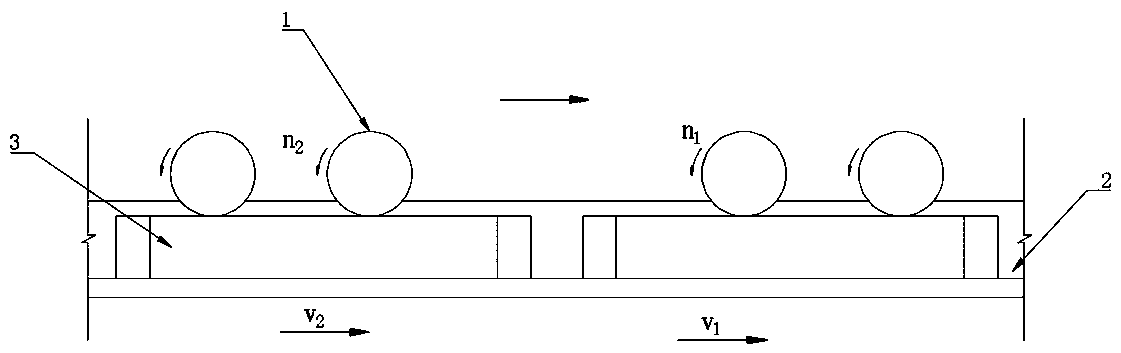

Method and apparatus of producing fibrous aggregate

InactiveCN1749450AUniform mechanical strengthUniform amount of fiberFelting apparatusDry spinning methodsLinear motionFiber

The present invention discloses a method for manufacturing a fiber aggregate, comprising: a supplying and jetting step of supplying the spinning stock solution from the spinning stock solution storage part to the spinning stock solution ejection part through a supply pipe, and spraying the spinning stock solution from the spinning stock solution ejection part ; Fiber gathering process, the above-mentioned spinning dope that is sprayed out acts on an electric field to make it stretch and fiberize, and the fibers obtained are directly gathered on the collection surface of the collector, and the above-mentioned collection surface is moved in a certain direction while forming A fiber aggregate; it is characterized in that: the above-mentioned spinning dope ejection part is carried on a support body that can move around a circular orbit between a pair of rotating shafts, and the direction of motion in the linear motion region of the above-mentioned circular orbit is the same as that of the above-mentioned The spinning dope is jetted from the spinning dope jetting section while the above-mentioned support body is looped at a constant speed in a state where the width direction of the collecting surface is aligned.

Owner:JAPAN VILENE CO LTD

Fuel cell leveling layer composition and preparation method thereof as well as gas diffusion layer

InactiveCN101540405AImprove utilization efficiencyImprove power generation efficiencyCell electrodesSolid electrolyte fuel cellsSolventChemistry

The invention discloses a fuel cell leveling layer composition and a preparation method thereof as well as a gas diffusion layer. The leveling layer composition comprises a conducting carbon material, an organic pore creating material, a water retention agent, a solvent and a hydrophobing agent, and the mass ratio of the conducting carbon material, the organic pore creating material, the water retention agent and the hydrophobing agent is 1:0.1 to 0.5:0.5 to 10:0.01 to 1. The leveling layer composition can effectively reduce the poriness on the surface of carbon paper, increase the mechanical strength of the gas diffusion layer and reduce the constriction resistance between a leveling layer and a catalyst layer, and the gas diffusion layer containing the leveling layer composition has higher surface smoothness, good ventilation property and water transmissibility, and no fine cracks.

Owner:HANERGY TECH

Production method of three-dimensional porous composite bar

The invention discloses a production method of a three-dimensional porous composite bar. The method is characterized by comprising the following steps of: preparing a graphene oxide solution; adding calcium salt and phosphate into the graphene oxide aqueous solution to be uniformly stirred, thus obtaining a graphene oxide / hydroxyapatite precursor solution; and adding konjac glucomannan into the graphene oxide / hydroxyapatite precursor solution under stirring, stirring the solution for 10-120 minutes at 35-60 DEG C, standing, filling the obtained mixed solution into a dialysis bag, soaking the sealed dialysis bag into alkaline solidification liquid, soaking the dialysis bag for 5-15 days at 40-60 DEG C, soaking materials in the dialysis bag in deionized water, cleaning and drying the materials, freezing the materials at a super low temperature and performing vacuum freeze drying on the materials to obtain the three-dimensional porous composite bar. The mechanical property and porosity of the produced composite bar can meet the clinical use requirements of bone repair scaffold materials, and the composite bar can effectively promote bone tissues to quickly and spontaneously repair defects and has a good effect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

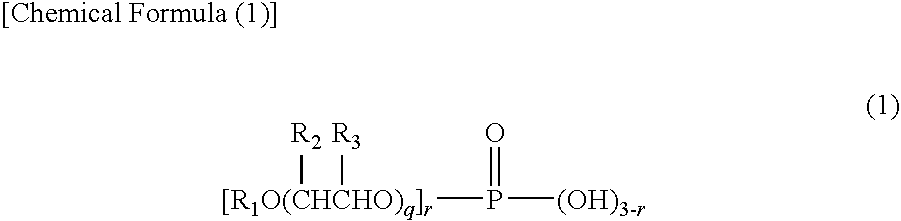

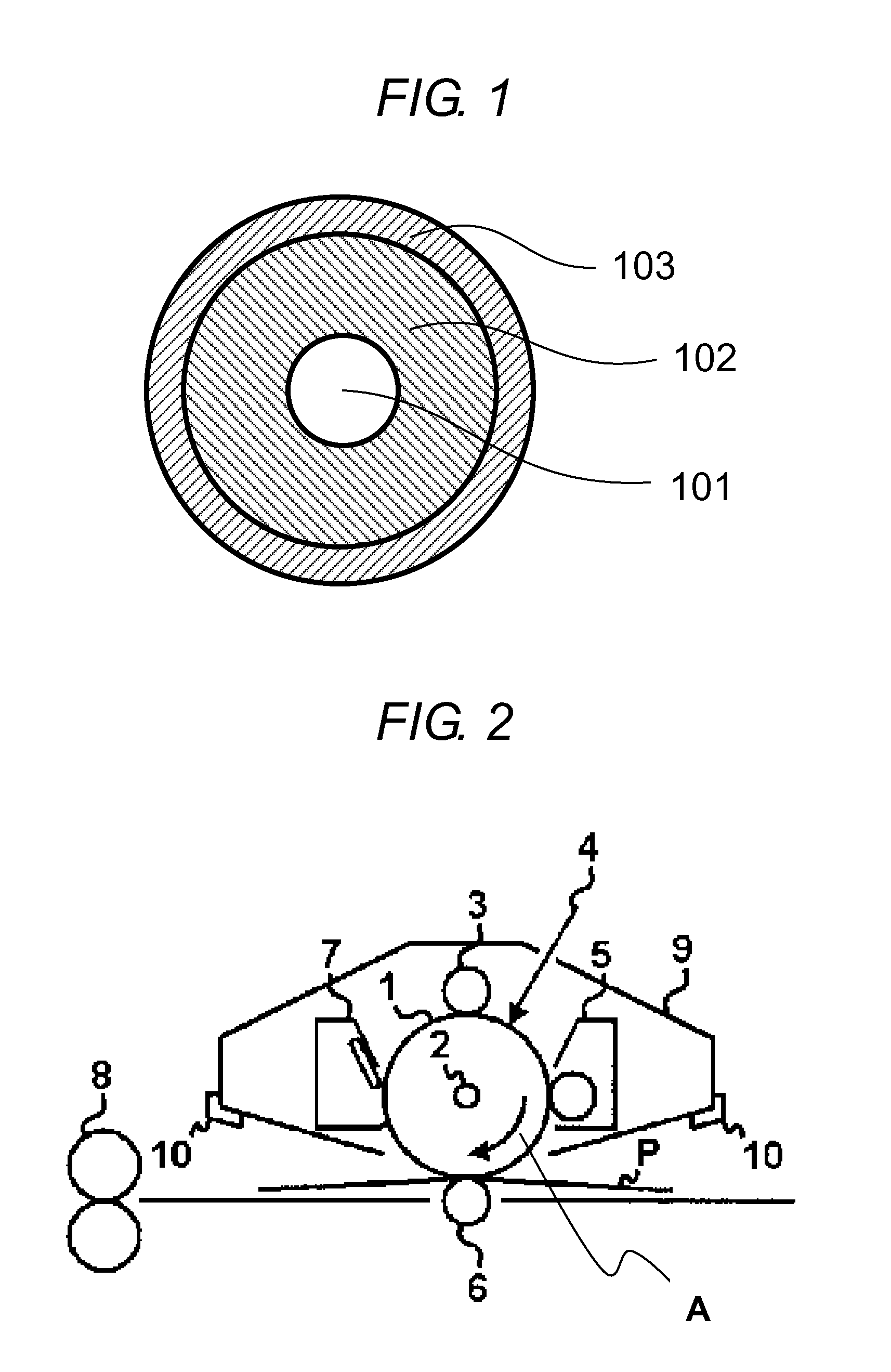

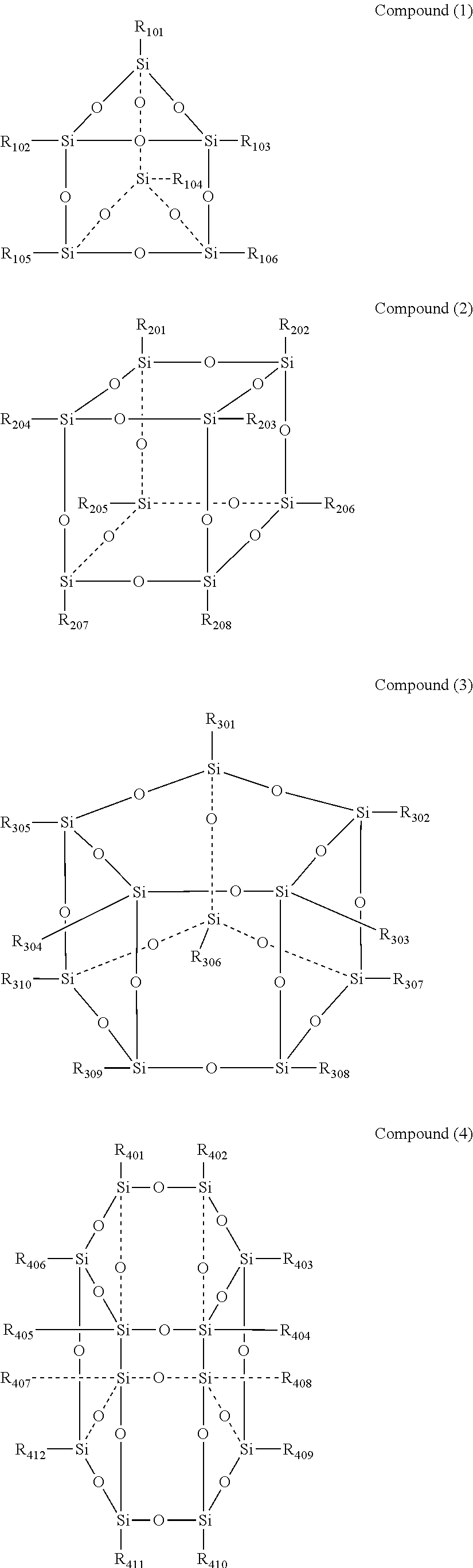

Charging member, process cartridge and electrophotographic apparatus

ActiveUS8092358B2Avoid excessive changesHigh quality imagingLiquid surface applicatorsShaft and bearingsSurface layerSilsesquioxane

The present invention provides a charging member which can maintain excellent wear resistance even though being used repeatedly. In the charging member having a surface layer, the surface layer is a surface layer constituted by at least one selected from silsesquioxanes having structures represented by a compound (1), a compound (2), a compound (3), a compound (4), a compound (5) and a compound (6), and a polysiloxane having a first unit represented by SiO0.5R1(OR2)(OR3), a second unit represented by SiO1.0R4(OR5) and a third unit represented by SiO1.5R6, wherein the silsesquioxane is contained in the polysiloxane.

Owner:CANON KK

Manufacturing method for cold drawn welded pipe used for hydraulic oil cylinders

InactiveCN104646449AReduce processing difficultyImprove deburring speedWelding jointMagnetic leakage

The invention relates to a manufacturing method for a cold drawn welded pipe used for hydraulic oil cylinders. The manufacturing method includes the steps of: longitudinal shearing, roll bending formation, high-frequency welding, weld joint treatment, sizing, online eddy current flow detection, stress relief annealing, pre-straightening treatment, pipe cutting, normalizing air cooling treatment, pinching, pickling treatment, phosphating treatment, saponification treatment, cold-drawing, induction furnace quenching treatment, box type furnace tempering treatment, straightening treatment, fine boring rolling, magnetic leakage flaw detection, and pipe cutting measurement. The product obtained by the method provided by the invention has the advantages of high yield strength, high tensile strength, precise size, smooth surface, fast machine shaping speed, high yield, and remarkably improved manufacturing precision. The cold drawn welded pipe has good surface smoothness and low roughness, the follow-up gold processing amount is reduced, the steel utilization is improved, the manufacturing cost is lowered, and energy saving and environmental protection are promoted.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

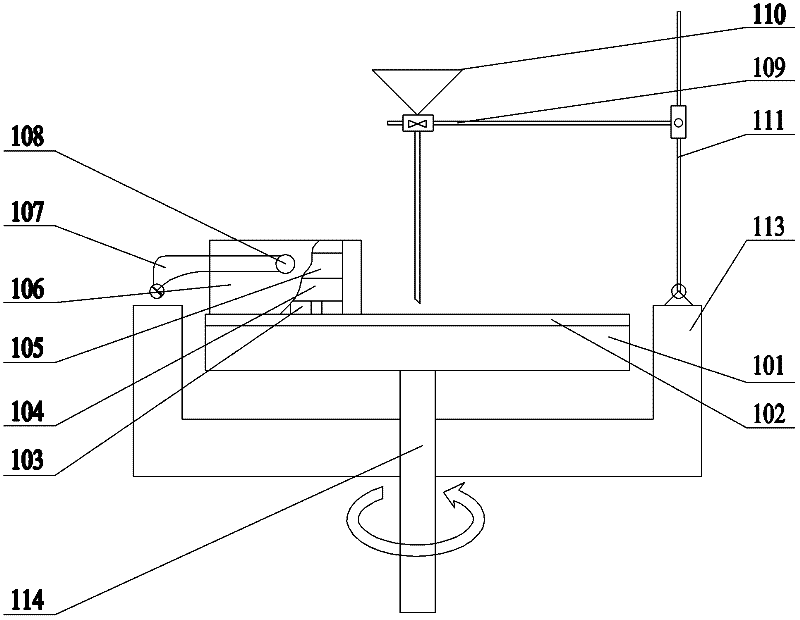

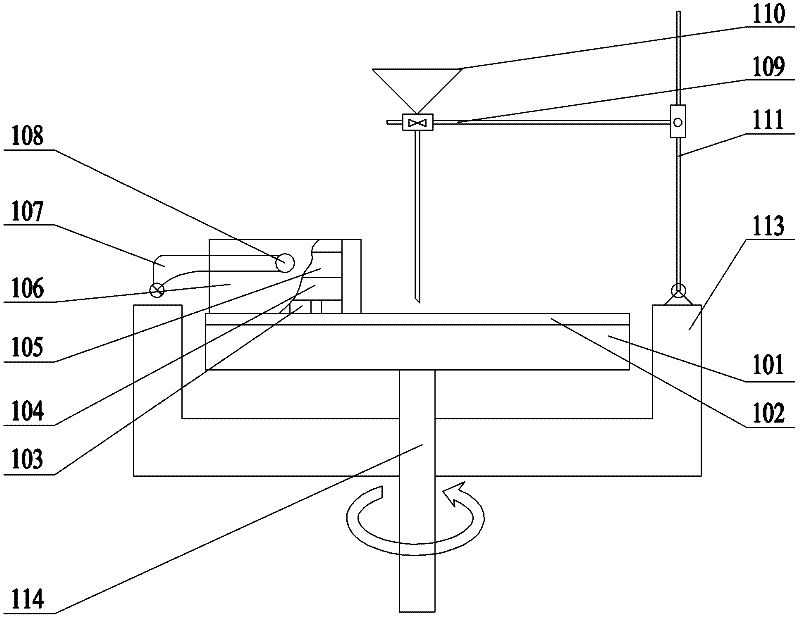

Sapphire substrate polishing device and process

The invention discloses a sapphire substrate polishing device and a polishing process. A rotating shaft is rotatably mounted on a frame, a polishing table is fixed to the top end of the rotating shaft, a crystal polishing pad is fixed to the upper surface of the polishing table, an abrasive feeding mechanism is arranged above the crystal polishing pad, a fixing ring is mounted on a mechanical armthrough a rubber wheel, a substrate fixing disk is arranged in the fixing ring, a pressing mechanism for pressing a sapphire substrate fixed by the substrate fixing disk towards the crystal polishingpad is arranged above the substrate fixing disk, the crystal polishing pad is formed by adhering crystal chips of the same thickness onto the upper surface of the polishing table through ultraviolet glue, and the gap between each two adjacent crystal chips ranges from 0.5mm to 2mm. After polishing, the planeness of the sapphire substrate is smaller than 5 micrometers, the surface roughness of thesapphire substrate is smaller than 0.3 nanometer, the surface of the substrate is not provided with complicated products, complicated post cleaning is omitted, cost is saved, and the rate of finishedproducts is increased.

Owner:保山鑫隆电子科技有限公司

Manufacturing method of cold drawn welded pipe for precision oil cylinder

The invention relates to a manufacturing method of a cold drawn welded pipe for a precision oil cylinder. The manufacturing method comprises the following steps: longitudinal shearing, rolling forming, high-frequency welding, tensioning, online eddy current inspection, stress relief annealing, normalizing air cooling treatment, pre-straightening treatment, pipe cutting, pinching, acid washing treatment, phosphating treatment, saponification treatment, cold drawing, induction furnace quenching treatment, tempering treatment in a box type furnace, straightening treatment, honing, magnetic leakage inspection and pipe cutting measurement. A product obtained by the method has the advantages of high yield strength, high tensile strength, precise size, smooth surface, high processing and forming speed, high yield, obviously improved manufacturing precision, good surface smoothness of the cold drawn welded pipe, low roughness, reduced subsequent gold processing, improved utilization rate of steel, reduced manufacturing cost and capability of promoting energy conservation and environmental protection.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

Crosslinkable rubber composition and cross-linked rubber

ActiveUS8153712B2Small compression setUniform mechanical strengthGroup 4/14 element organic compoundsLayered productsCross-linkPolymer science

A crosslinkable rubber composition comprising 0.2 to 10 parts by weight of an aromatic secondary amine-based anti-aging agent and 0.5 to 20 parts by weight of a polyamine-based crosslinking agent with respect to 100 parts by weight of a nitrile rubber including an α,β-ethylenically unsaturated nitrile unit and an α,β-ethylenically unsaturated dicarboxylic acid monoester unit, and with iodine value of 120 or less. The present invention can provide a crosslinkable rubber composition, providable of a cross-linked rubber excellent in a variety of properties such as mechanical strength and small in compression set, and a cross-linked rubber obtained by cross-linking the rubber composition.

Owner:ZEON CORP

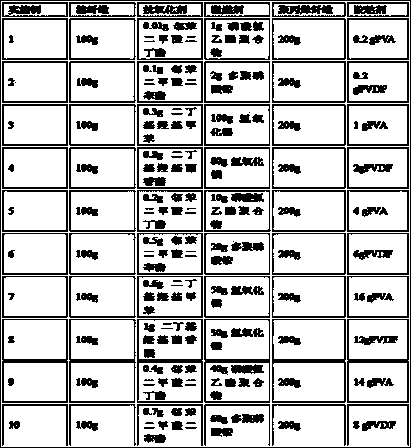

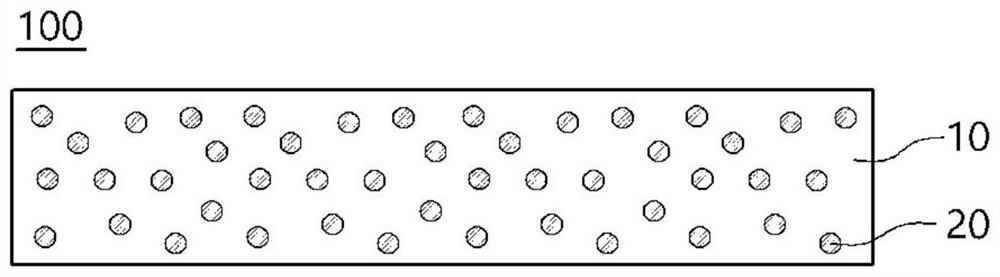

Manufacturing method for lithium ion battery diaphragm

InactiveCN103700800ARegular arrangement of fiber chainsUniform mechanical strengthSynthetic resin layered productsElectrical equipmentHot pressLithium electrode

The invention relates to a lithium ion battery diaphragm and a preparation method of the lithium ion battery diaphragm. The lithium ion battery diaphragm provided by the invention is divided into three layers, wherein a core layer is a cotton fiber film layer; an upper layer and a lower layer are polypropylene fiber film layers; the core layer of the diaphragm is a film formed by pulping cotton fibers and then performing a wet manufacturing technology on the pulped cotton fibers by using an antioxidant, a fire retardant and the like; each surface layer is a film formed by performing hydrophilic modification on polypropylene fibers and then performing the wet manufacturing technology on the modified polypropylene fibers by using an adhesive; the cotton fiber film is used as the core layer, and the polypropylene fiber films are used as the upper surface layer and the lower surface layer, so that the lithium ion battery diaphragm is prepared by hot pressing by two hot pressing rollers under the condition of 110-150 DEG C. The porosity of the lithium ion battery diaphragm is 40-80 percent, and the aperture is 0.01-0.2 microns; the tensile strength of the lithium ion battery diaphragm in both the longitudinal direction and the transverse direction is basically the same, which is 120-300Mpa; the puncture strength is higher than 20kg.mm<-1>; under 90 DEG C, the shrinkage rate is less than 1 percent; the lithium ion battery diaphragm is 20-60 microns thick. The lithium ion battery diaphragm is uniform in porosity distribution, high in mechanical strength, low in shrinkage rate, high in thermal stability and high in hydrophilicity / liquid retaining performance and is easy to prepare, pollution-free and suitable for industrial production.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

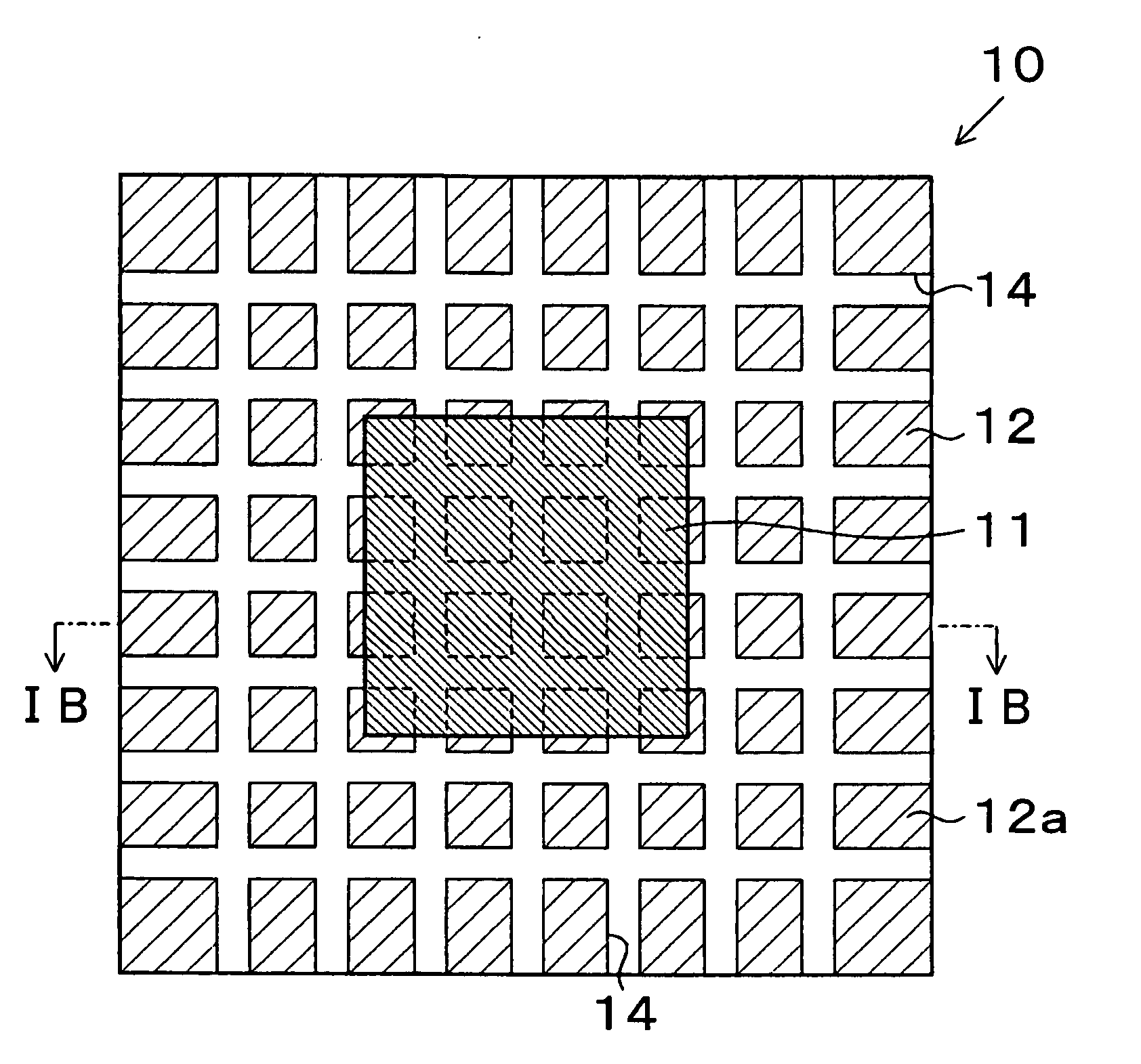

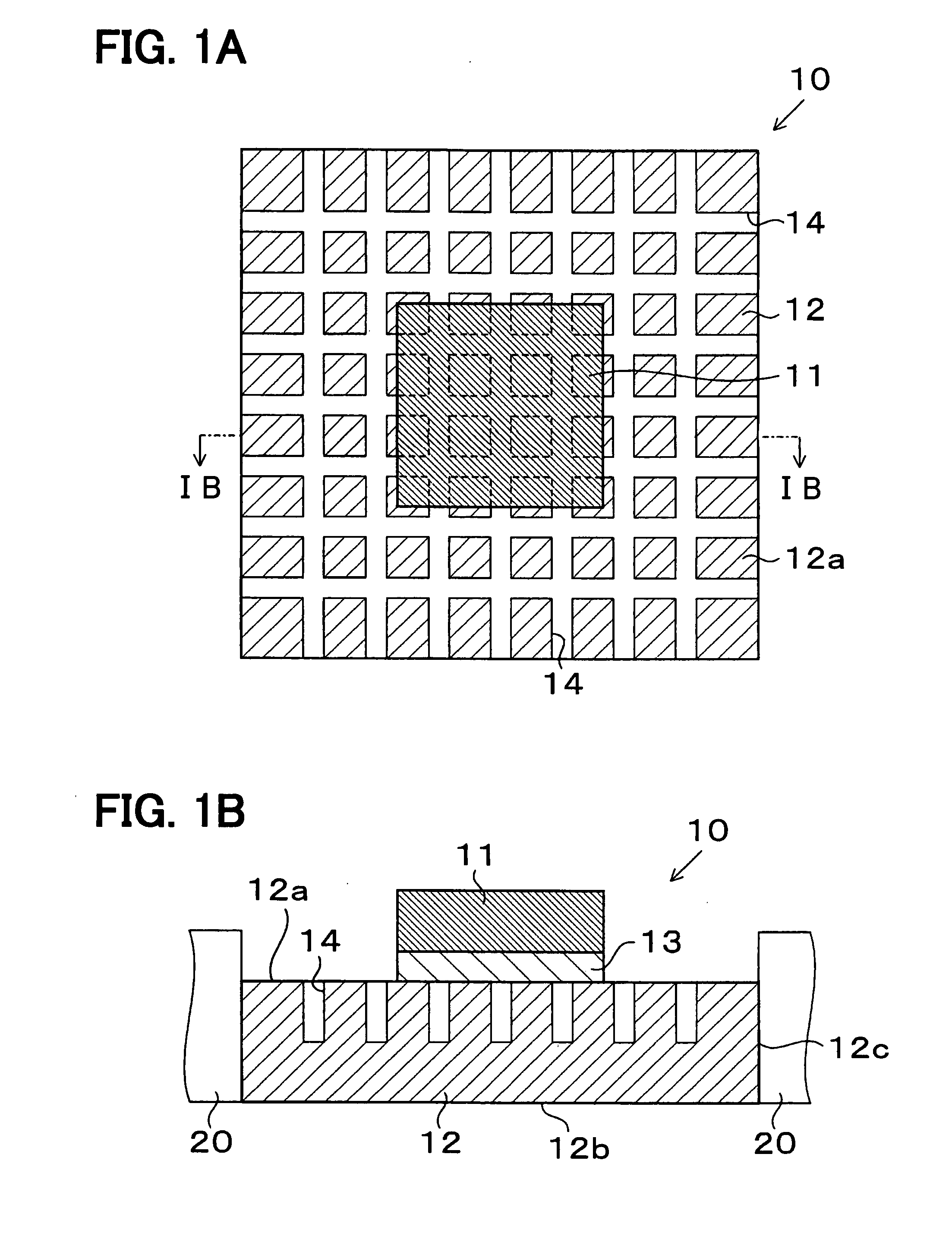

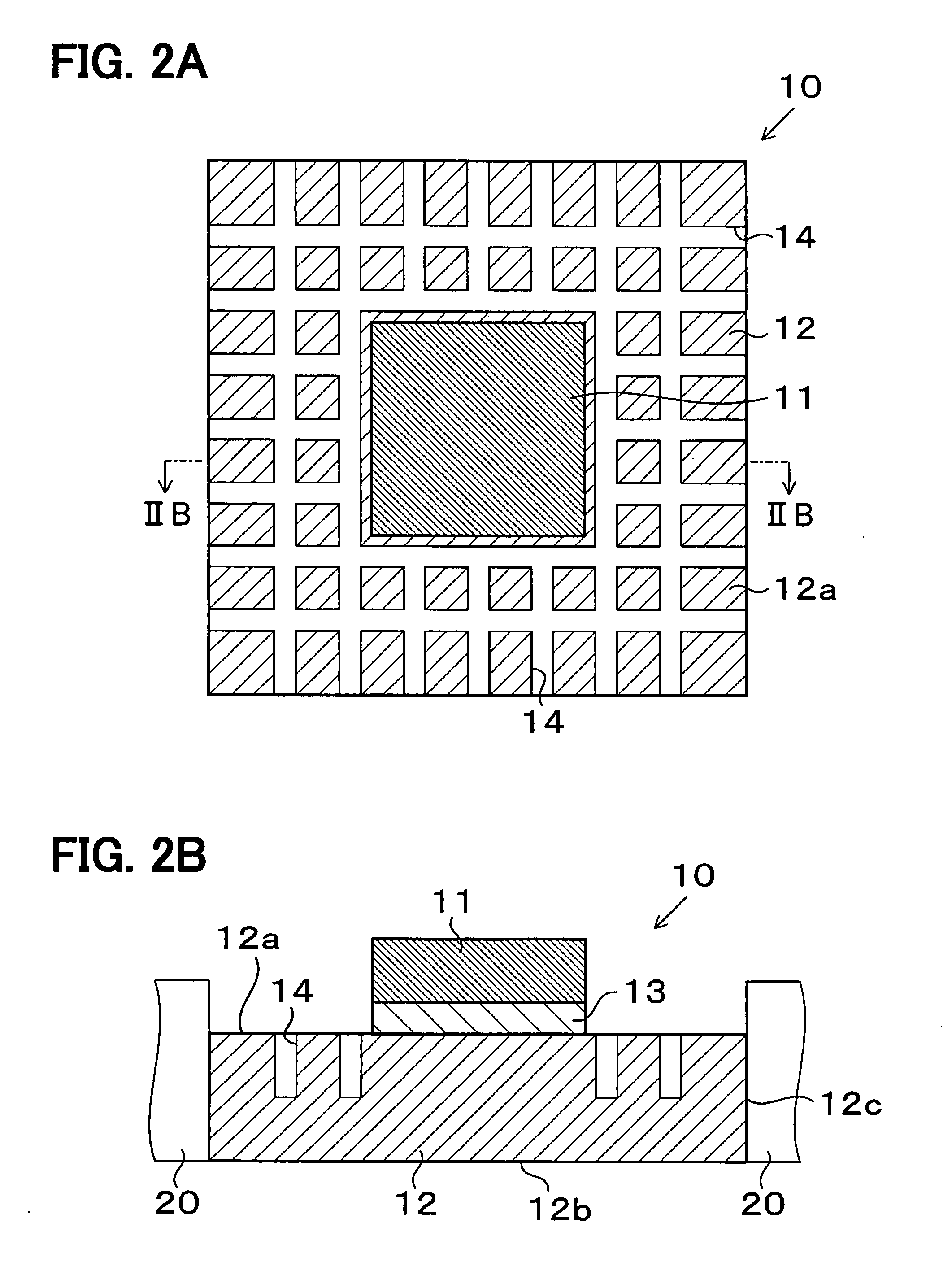

Ultrasonic sensor having vibrator mounted on substrate

InactiveUS20070204697A1Reduce stiffnessImprove directivityMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementMobile vehicleUltrasonic sensor

An ultrasonic sensor composed of a substrate and a piezoelectric vibrator mounted on the substrate is advantageously used as a sensor for detecting a distance to an object located in front of an automotive vehicle. Ultrasonic waves transmitted from the sensor are reflected by the object, and the reflected waves are received by the sensor. Based on the reflected waves, the distance from the vehicle to the object is calculated. To reduce rigidity and thereby to lower a resonant frequency of the substrate to a desirable level, grooves are formed in the substrate. A thickness of the substrate is not reduced to maintain its mechanical strength against an impact force. A resonant frequency which is desirable to realize a sufficiently high directivity and sensitivity is obtained in this manner without enlarging a size of the ultrasonic sensor.

Owner:DENSO CORP

Ultrasonic sensor having vibrator mounted on substrate

InactiveUS7622849B2Reduce stiffnessImprove directivityPiezoelectric/electrostriction/magnetostriction machinesSound producing devicesMobile vehicleUltrasonic sensor

Owner:DENSO CORP

Charging member, process cartridge and electrophotographic apparatus

ActiveUS20110182617A1Excellent durabilityUniform mechanical strengthLiquid surface applicatorsShaft and bearingsChemistrySurface layer

The present invention provides a charging member which can maintain excellent wear resistance even though being used repeatedly. In the charging member having a surface layer, the surface layer is a surface layer constituted by at least one selected from silsesquioxanes having structures represented by a compound (1), a compound (2), a compound (3), a compound (4), a compound (5) and a compound (6), and a polysiloxane having a first unit represented by SiO0.5R1(OR2)(OR3), a second unit represented by SiO1.0R4(OR5) and a third unit represented by SiO1.5R6, wherein the silsesquioxane is contained in the polysiloxane.

Owner:CANON KK

Infinite-arbitrary-length bamboo chip integrated material and manufacturing method thereof

PendingCN109808257AIncrease profitIncrease market shareCane mechanical workingLaminationButt jointEngineering

The invention discloses an infinite-arbitrary-length bamboo chip integrated material. The infinite-arbitrary-length bamboo chip integrated material is formed by a plurality of lengthened bamboo chipswhich are glued and overlaid; each lengthened bamboo chip is formed by a plurality of bamboo chip units which sequentially and continuously mesh and are connected in a butt joint mode; sharp teeth andgrooves are formed in the two ends in the length direction of the bamboo chip units, wherein the sharp tooth of each bamboo chip unit and the groove of the corresponding bamboo sheet unit are matchedto form a meshing butt-joint part, and the meshing butt-joint parts of the adjacent lengthened bamboo chips are arranged in a staggered mode; and the thickness of the bamboo chip units is 4-12 mm, and the width of the bamboo chip units is 15-50 mm. The invention further provides a manufacturing method of the bamboo chip integrated material. The manufacturing method comprises the steps of preparation of the bamboo chip units, meshing butt-joint, hot-pressing gluing and the like. The infinite-arbitrary-length bamboo chip integrated material and the manufacturing method thereof have the advantages that connectors are small, the mechanical strength is uniform, and the infinite-arbitrary-length bamboo chip integrated material is suitable for structures such as van truck bottom plates.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

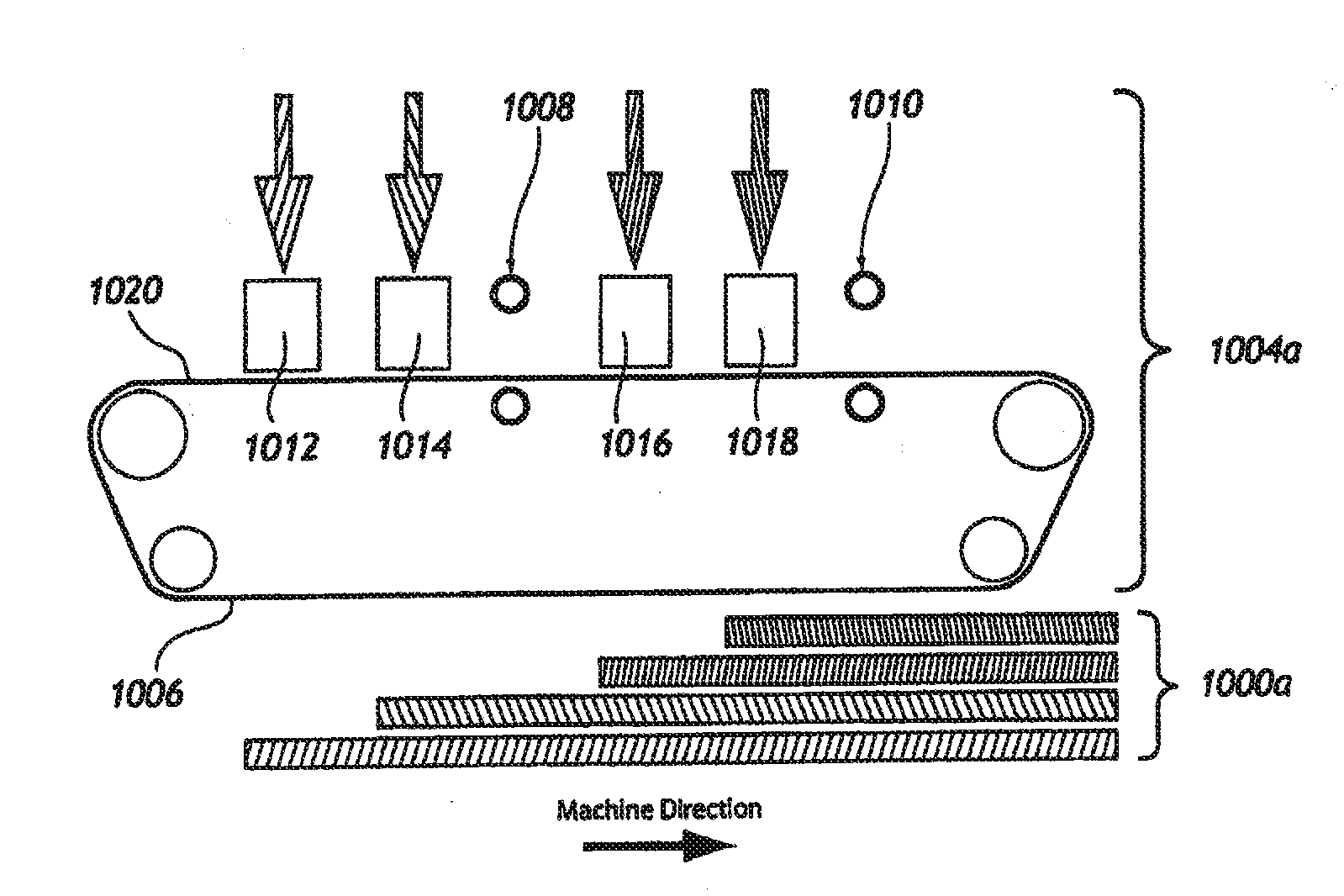

Unitized composites utilizing melted synthetic fibers to achieve rough or abrasive attributes and decorative effects

InactiveUS8440123B2Large absorbencyShort fiber airlaidMechanical working/deformationFilament/thread formingMaterials scienceSynthetic fiber

A manufacturing process for making short fiber low denier unitized composite fabrics with abrasive features includes steps of depositing an assembly comprising one or more layers of fibrous material and optionally one or more layers of non-fibrous material, at least one of the outer layers containing a multicompartment synthetic fiber, and activating at least one component of the multicomponent fiber to impart an abrasive attribute to the outer surface.

Owner:MARKETING TECH SERVICE

Microwave curing process of bonded NdFeB magnet

InactiveCN102982995AImprove curing efficiencyIncrease productionMaintainance of heating chambersFurnace typesHigh energyUltimate tensile strength

The invention discloses a microwave curing process of a bonded NdFeB magnet, aiming at solving the problems of low efficiency and high energy consumption of the traditional electrothermal curing process. The microwave curing process comprises the following steps of: (1) putting a green body of the bonded NdFeB magnet on a ceramic substrate, and putting the ceramic substrate into a microwave kiln; (2) starting an exhaust system of the microwave kiln, heating to 135-145 DEG C at a heating speed of 15 DEG C / min-20 DEG C / min, and maintaining the temperature for 10-15min; and (3) powering off the exhaust system after the temperature preservation is ended, and taking the bonded NdFeB magnet out. The microwave curing process disclosed by the invention is short in curing time, low in energy consumption, small in curing deformation rate, uniform in product quality and greatly improved in curing strength and yield of the bonded NdFeB magnets.

Owner:湖南航天有限责任公司

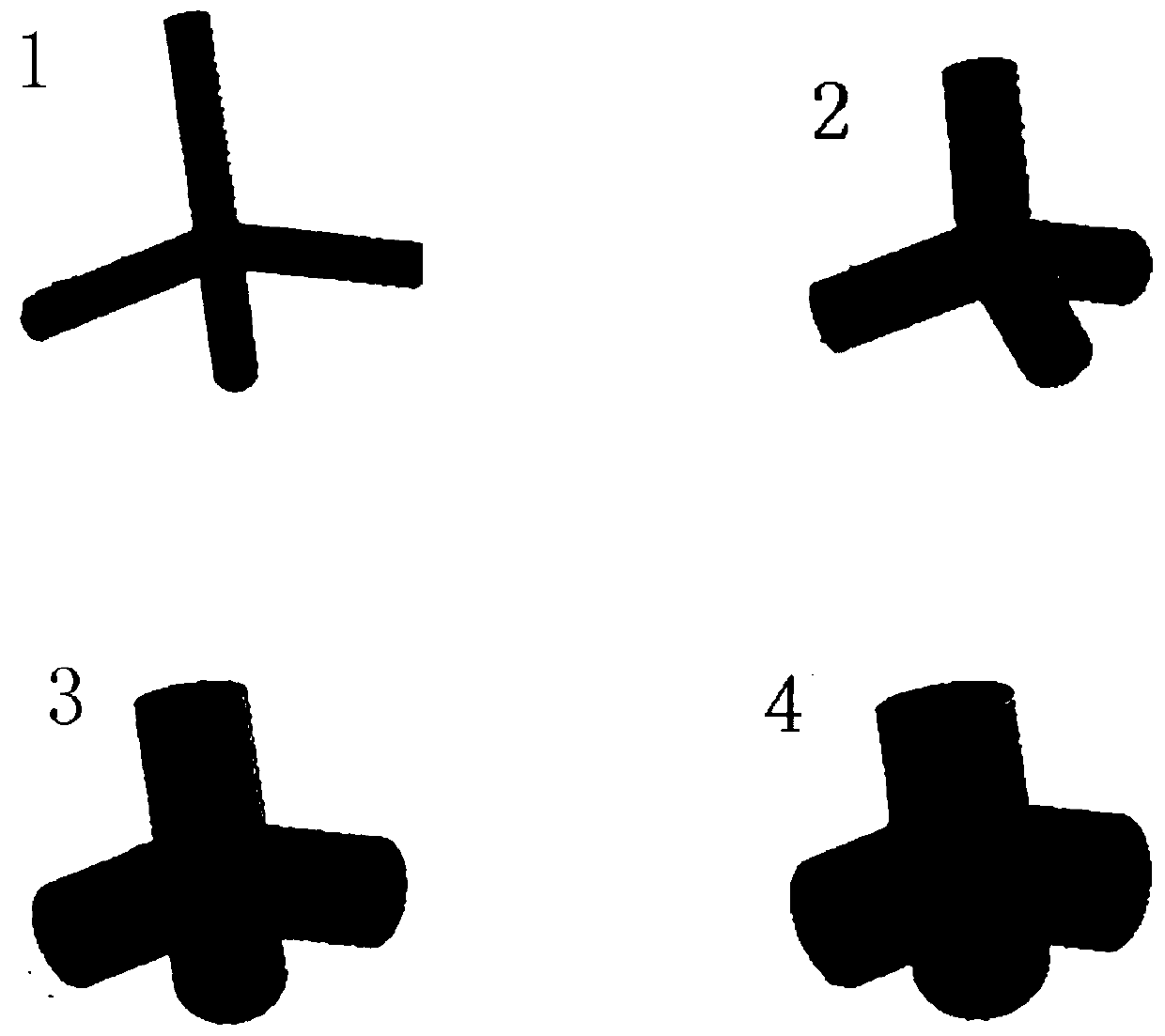

Radial classification porous titanium alloy part and 3D printing preparing method thereof

ActiveCN111390173AAchieve weight lossHigh mechanical strengthAdditive manufacturing apparatusTitanium alloyPorous titanium

The invention belongs to the field of 3D printing material design and preparing and particularly relates to a radial classification porous titanium alloy part and a 3D printing preparing method thereof. The porous titanium alloy part has the beneficial effects of being high in porosity, high in strength, small in mass and the like. The porous titanium alloy part comprises multiple basic units which are tightly arranged. The basic units include unit cells A, unit cells B, unit cells C and unit cells D. The unit cells A serve as the innermost layer of the porous titanium alloy part, and the minimum density and the maximum equivalent hole diameter of the porous titanium alloy part are formed; the unit cells B and the unit cells C serve as the sub inner layers of the porous titanium alloy partin sequence, the middle-grade hole diameter of the porous titanium alloy part is formed, and the unit cells B and the unit cells C serve as the multi-scale smooth transition of the material density of the porous titanium alloy part; the unit cells D serve as the outermost layer, and the minimum hole diameter and the maximum density of the porous titanium alloy part are formed; and therefore a structure where the porous titanium porosity and the equivalent hole diameter are in classification gradual change is formed in the porous titanium alloy part.

Owner:UNIV OF SCI & TECH BEIJING +1

Silica-containing conjugated diene based rubber composition and formed article

A silica-containing conjugated diene based rubber composition which is prepared by co-coagulating an aqueous dispersion or a solution of a conjugated diene based rubber (a) having a glass transition temperature of -120 to 0 DEG C and an aqueous dispersion of silica, so as to form a conjugated diene based rubber-silica mixture (A) containing 30 wt % or more of a component insoluble in toluene, and then compounding the above mixture with a conjugated diene based rubber (b) having a glass transition temperature being different from that of the above conjugated diene based rubber (a) by an absolute value of 3 to 100 DEG C. The above rubber composition can be suitably used for producing a tire tread which offers a balance in high degree of low fuel consumption, wet grip characteristics, mechanical strength, abrasion resistance and low temperature impact resistance.

Owner:ZEON CORP

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

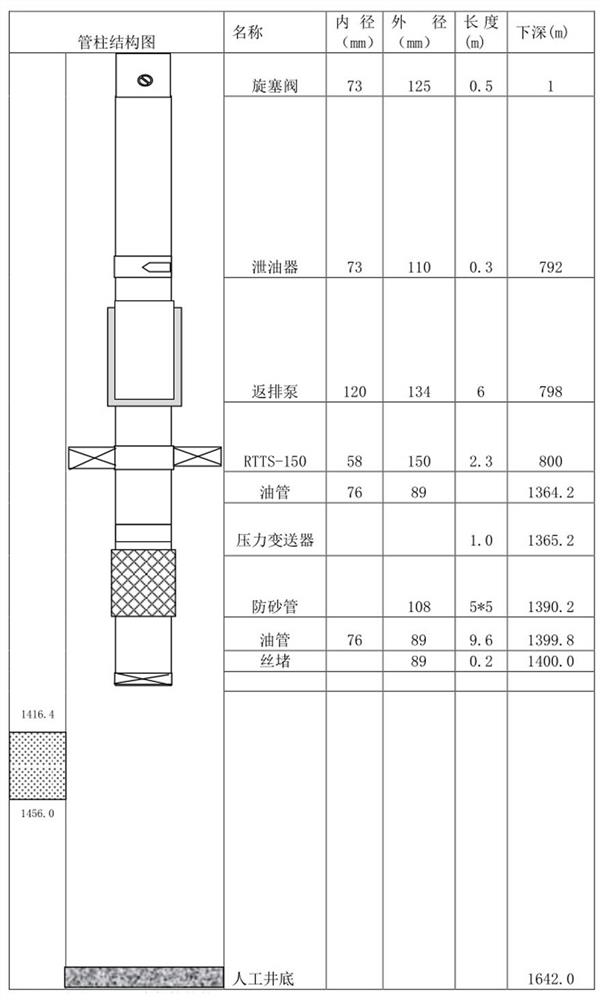

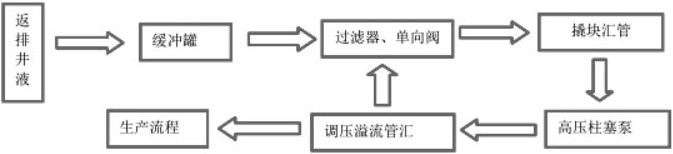

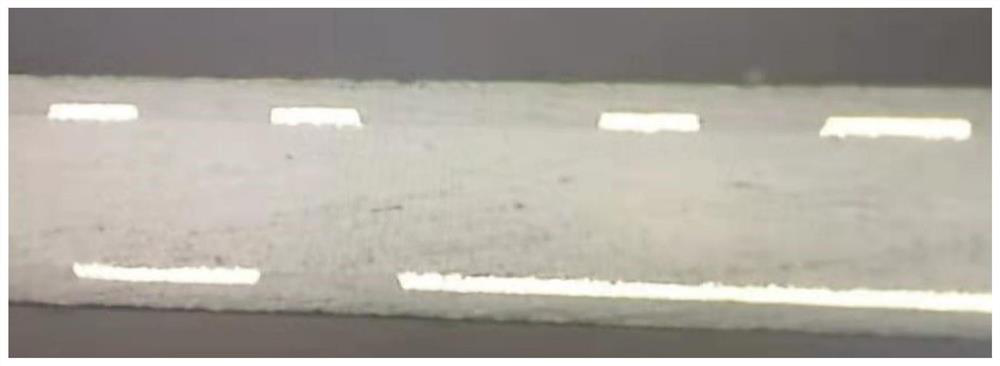

Oil field negative pressure flowback blockage removal process

InactiveCN112127858AAvoid cloggingSolve the dredging of seepage channelsConstructionsFluid removalOil fieldOil well

The invention provides an oil field negative pressure flowback blockage removal process, and belongs to the technical field of oil well flowback blockage removal. According to the oil field negative pressure flowback blockage removal process, the flowback pump negative pressure flowback blockage removal process is optimized and implemented, and meanwhile the technical problems about blockage removal of stratum impurities and near-well blockage, dredging of a seepage channel and improvement of single-well productivity are solved; and meanwhile, when the process is applied to blockage removal ofnew and old wells on the sea, ship-assisted implementation is not needed, limitation of environmental factors is avoided, flowback well fluid obtained after blockage removal can be directly introduced into a flowback well fluid online treatment device and is fed into the subsequent production process after being filtered, and the process has the remarkable advantages of being low in cost, low inconstruction pressure, low in safety risk point and the like.

Owner:SHENGLI OILFIELD DONGRUN MACHINERY ENG

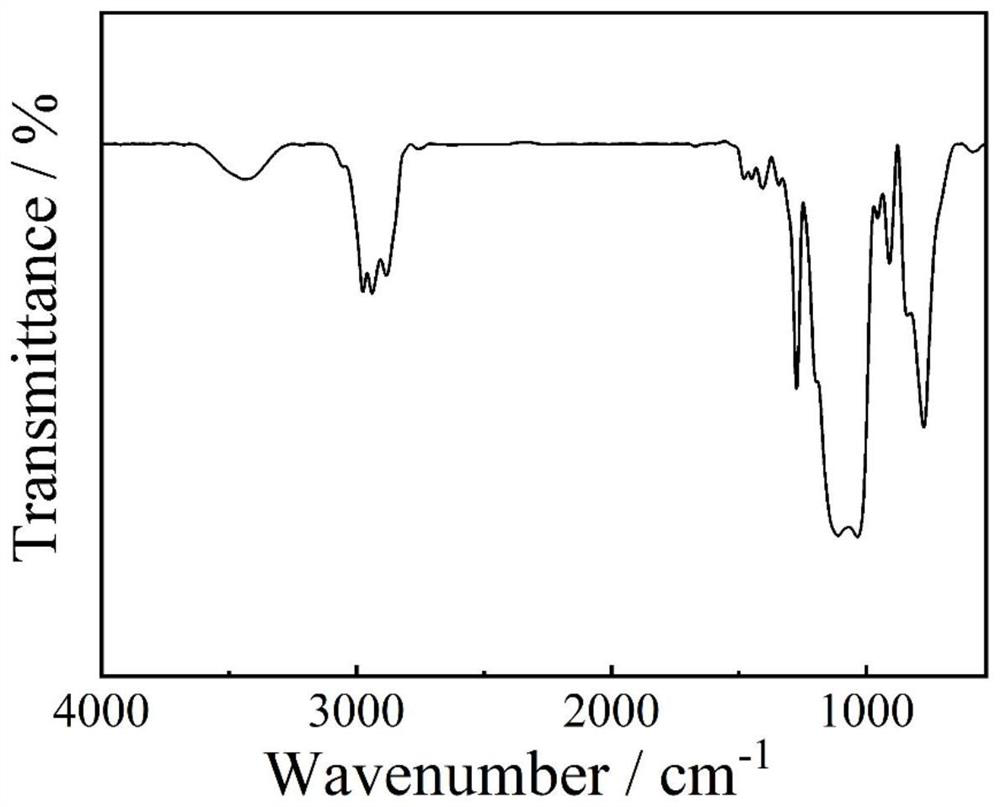

Hyperbranched epoxy oligosiloxane sand-fixing material as well as preparation method and application thereof

ActiveCN113861988ALow viscosityNo residueOther chemical processesOrganic fertilisersFirming agentReactive diluent

The invention discloses a hyperbranched epoxy oligosiloxane sand-fixing material as well as a preparation method and application thereof. The chemical sand stabilization material is composed of a component A and a component B. The component A is prepared from the following components in parts by weight: 50 to 80 parts of hyperbranched epoxy oligosiloxane, 15 to 50 parts of reactive diluent and 2 to 20 parts of additive. The component B comprises the following components in parts by weight: 80-90 parts of an amine curing agent, 2-20 parts of a hydrophobic curing agent and 2-20 parts of an accelerant. The chemical sand stabilization material has the characteristics of low viscosity, high wettability and reactivity, can consolidate various sands in situ without selection, and has the characteristics of local material utilization, small amount, high efficiency, convenience in construction and emergency repair and construction. The material can be applied to deep reinforcement of landforms such as island construction, coastal mud flat and desert gobi, lays a foundation for construction of infrastructures such as roads, bridges and buildings, and realizes effective utilization of sandy soft foundations.

Owner:SOUTH CHINA UNIV OF TECH

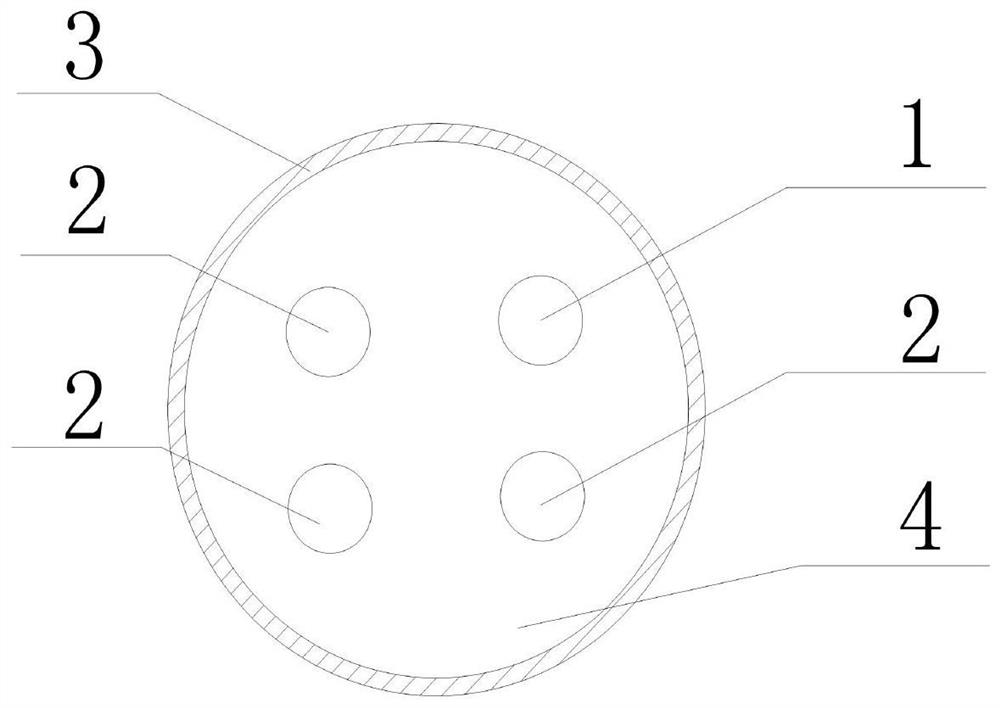

Transmission display module and driving method thereof

InactiveCN106816089AHigh mechanical strengthUniform mechanical strengthStatic indicating devicesPlanar/plate-like light guidesLight guideRefractive index

The invention discloses a transmission display module and a driving method thereof. The transmission display module comprises a transparent display panel, a first light source module, a second light source module, and at least an adhesion layer. The first light source module and the second light source module are respectively configured on two opposite surfaces of the transparent display panel, wherein the first light source module comprises a first light guide plate and a first light source, and the second light source module comprises a second light guide plate and a second light source. The adhesion layer at least adheres the transparent display panel and the first light guide plate, and the refractive index of the adhesion layer is lower than the refractive index of the first light guide plate. The transmission display module has ideal mechanical strength and uniform light emission. In addition, the driving method for the transmission display module provides a plurality of display modes through controlling on-off of the first light source and the second light source and timing sequence of the transparent display panel.

Owner:CHAMP VISION DISPLAY INC

Unitized composites utilizing melted synthetic fibers to achieve rough or abrasive attributes and decorative effects

InactiveUS20110214827A1Large absorbencyShort fiber airlaidNon-fibrous pulp additionNatural cellulose pulp/paperMaterials scienceSynthetic fiber

A manufacturing process for making short fiber low denier unitized composite fabrics with abrasive features includes steps of depositing an assembly comprising one or more layers of fibrous material and optionally one or more layers of non-fibrous material, at least one of the outer layers containing a multicompartment synthetic fiber, and activating at least one component of the multicomponent fiber to impart an abrasive attribute to the outer surface.

Owner:MARKETING TECH SERVICE

Trigger of tool switch and production technique of trigger.

The invention discloses a trigger of a tool switch and a production technique of the trigger. The trigger is prepared from, by weight, 20-35 parts of zinc borate, 0.5-4 parts of nano lanthanum oxide, 2-15 parts of magnesium oxide, 0.5-4 parts of nano cerium oxide, 1-5 parts of graphite fibers, 5-15 parts of chromium, 3-8 parts of nickel powder, 5-10 parts of attapulgite, 8-13 parts of manganese, 15-35 parts of aluminum powder, 20-40 parts of iron oxide and 1200-1600 parts of iron powder. The production technique of the trigger comprises the steps that when the temperature of a blast furnace reaches 200-350 DEG C, the raw materials are added, and a fluxing agent is added into the blast furnace at the same time; when the temperature of the blast furnace reaches 700-800 DEG C, a refining agent is added; when the temperature of the blast furnace reaches 700-800 DEG C again, a modificator is added for modification; and when the temperature of the blast furnace reaches 720-770 DEG C, slagging-off and discharging out of the furnace are conducted, and pouring is conducted rapidly, so that the trigger is obtained. The production technique is simple and environmentally friendly; the machined trigger has good performance in the aspects of tensile strength, bending strength, percentage elongation after fracture and the like, and market requirements are met completely.

Owner:桐乡市搏腾贸易有限公司

Aromatic vinyl polymer resin composition and its molding

InactiveUS20060094821A1Improve smoothnessImprove balanceFlexible coversWrappersPolymer sciencePolymer chemistry

Provided are an aromatic vinyl polymer resin composition capable of being molded into resin foam sheets having good surface smoothness and glossiness well balanced with the mechanical strength thereof even when the expansion ratio in molding is increased, and resin foam sheets and containers of the composition. The resin composition comprises (A) from 80 to 98% by mass of an aromatic vinyl polymer resin having a weight-average molecular weight measured through GPC of from 200,000 to 400,000, a ratio of weight-average molecular weight to number-average molecular weight ranging from 2.2 to 3.6, a number of branches of from 0.1 to 1.0 in one molecule having an absolute molecular weight of 1,190,000 measured through GPC-MALLS, and a melt flow rate of from 1.5 to 3.5 g / 10 min, and (B) from 2 to 20% by mass of a styrene-diene block copolymer or its hydrogenate. This is molded into a resin foam sheet through extrusion foaming, and the sheet is thermoformed into containers.

Owner:IDEMITSU KOSAN CO LTD

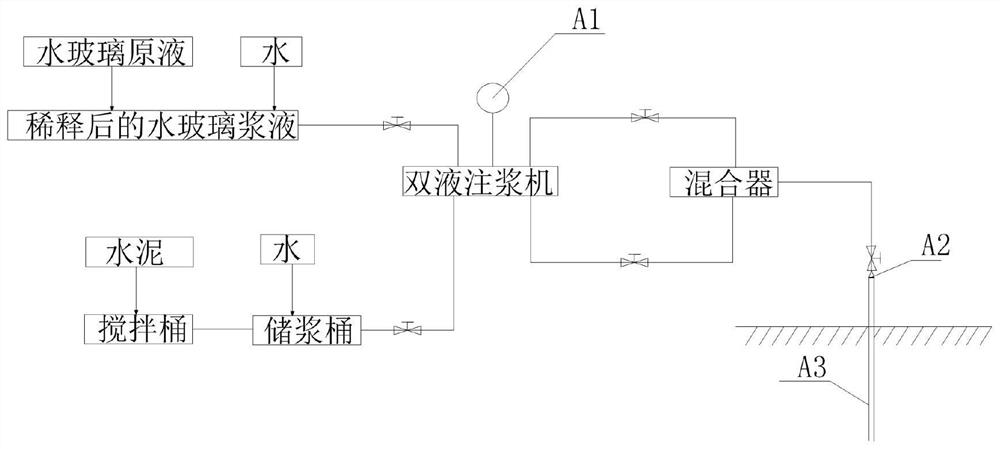

A double-liquid grouting construction method

The invention discloses a double-liquid grouting construction method, which is characterized by comprising the following steps: 1) installing a first grouting pipe and at least one second grouting pipe at a place to be grouted; Inject the grout into the first grouting pipe, stop grouting when the grout overflows from the mouth of the first grouting pipe, and then pour the grout into the second grouting pipe after the grout is in a gel state; 3) When the grouting flow in the second grouting pipe reaches 15L / min~20L / min, the grouting is continued after 5min~10min, and then the grouting is stopped. This method can not only quickly reinforce the area with low soil strength, but also the mechanical strength of the reinforced soil body is uniform, and the soil body can maintain self-stable after excavation, which meets the construction safety requirements.

Owner:河南省恺福实业有限公司

Negative-pressure flowback blockage removal process for oil field

The invention provides a negative-pressure flowback blockage removal process for an oil field, and belongs to the technical field of flowback blockage removal of oil wells. According to the negative-pressure flowback blockage removal process for the oil field, the problems of compaction and blockage pollution caused by slurry filtrate invasion and perforation are further solved while the negative-pressure flowback blockage removal process for a flowback pump is optimized and implemented, and the single-well productivity is effectively improved; meanwhile, an acidification blockage removal stepis introduced into the flowback blockage removal process, and pollutants in slurry filtrate in a near-wellbore area are effectively removed; in addition, when the flowback blockage removal process isapplied to blockage removal of new and old wells on the sea, ship-assisted implementation is not needed, the process is not limited by environmental factors, flowback well fluid obtained after blockage removal can be directly introduced into a flowback well fluid online treatment device, and the flowback well fluid is filtered and then sent to a subsequent production process; and the process hasthe remarkable advantages of being low in cost, construction pressure and safety risk point and the like.

Owner:SHENGLI OILFIELD DONGRUN MACHINERY ENG

Preparation process and application of solder resist adhesive layer

ActiveCN113825322AGood thickness uniformityUniform mechanical strengthPrinted circuit dryingNon-metallic protective coating applicationInitiationFilm coating

The invention relates to the technical field of H05K, and concretely relates to a preparation process and application of a solder resist adhesive layer. The preparation process of the solder resist adhesive layer comprises the following steps: adding a glycol ether substance into a film coating reactant obtained by mixing to enable the viscosity of the film coating reactant to reach 20-20000 cPs, then coating a coating material with the film coating reactant to obtain a wet adhesive layer, and then drying to obtain the solder resist adhesive layer, thereby obtaining the solder resist adhesive layer. The coating reactant comprises acidic photosensitive resin, a polymeric monomer, an initiation reactant, a cured product, a natural filler and a solvent. The solder resist adhesive layer obtained by the invention is high in flatness, uniform in thickness and good in adhesiveness with a circuit board.

Owner:常州硕成半导体材料有限公司

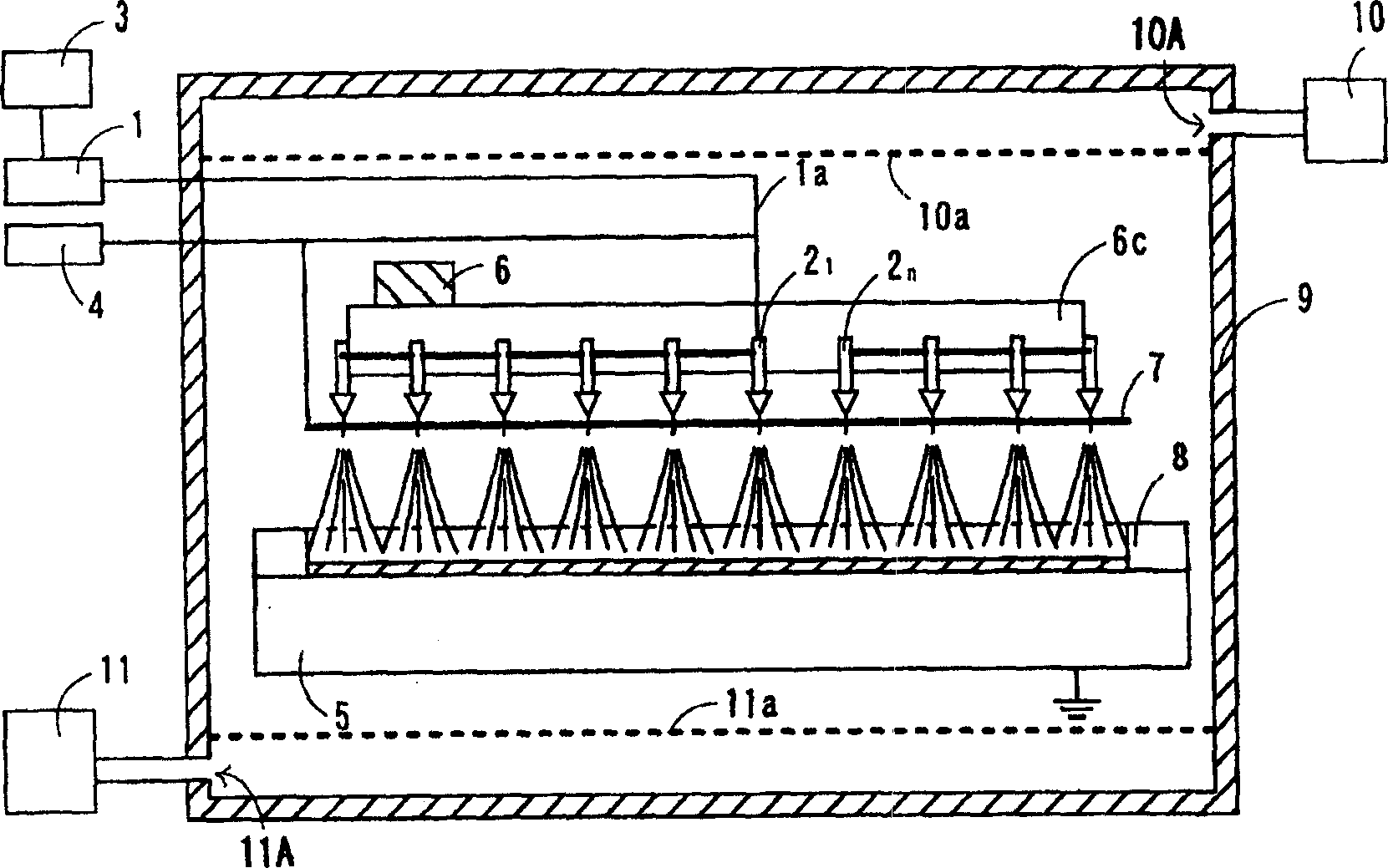

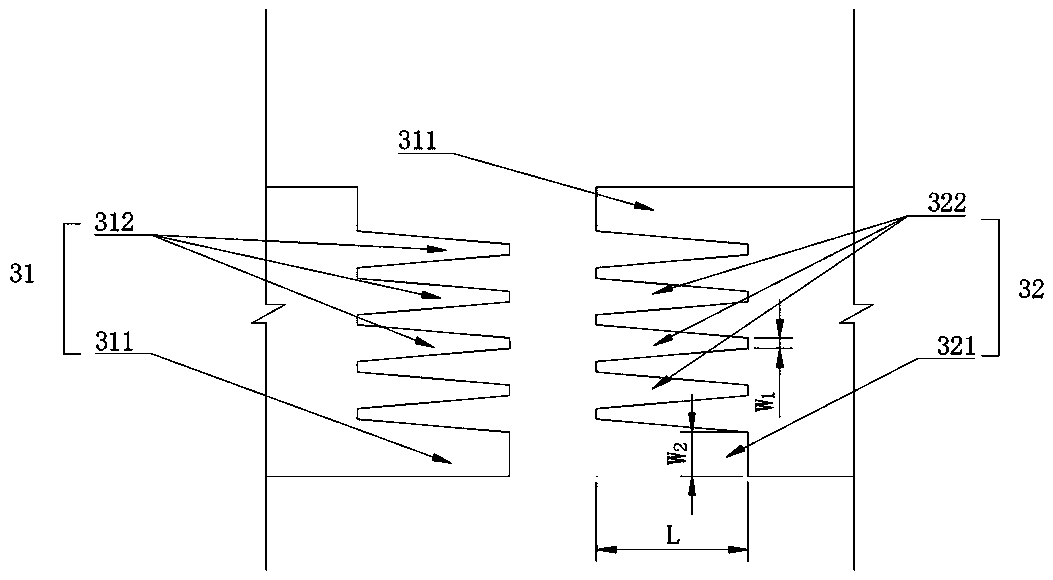

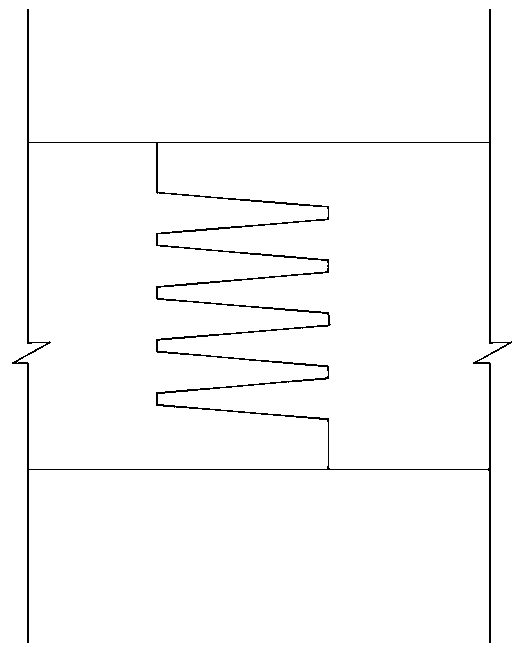

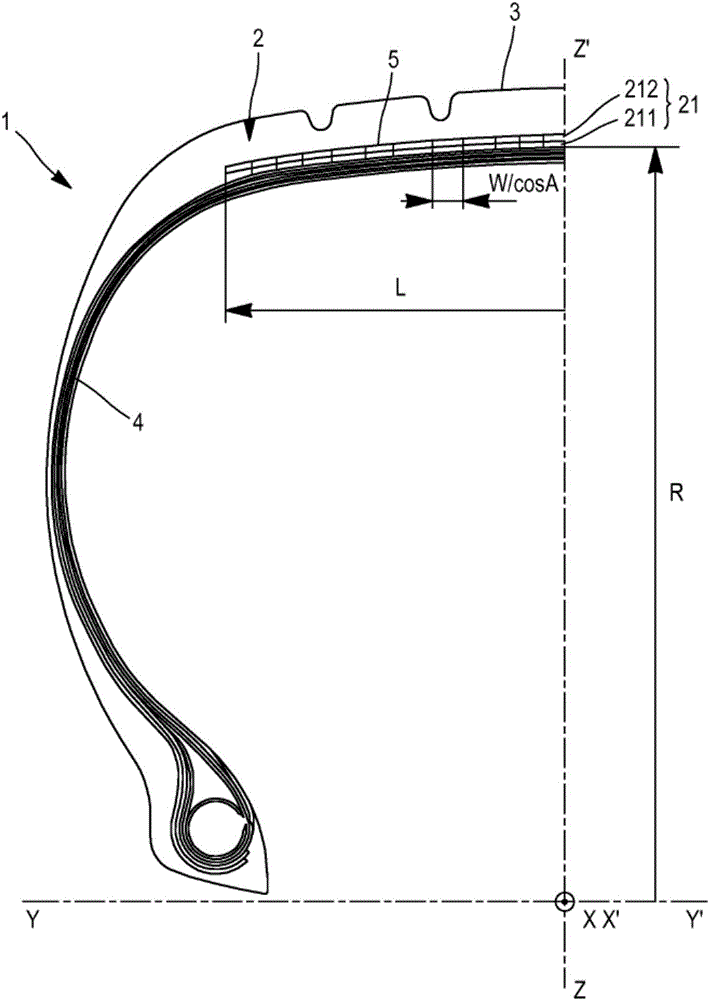

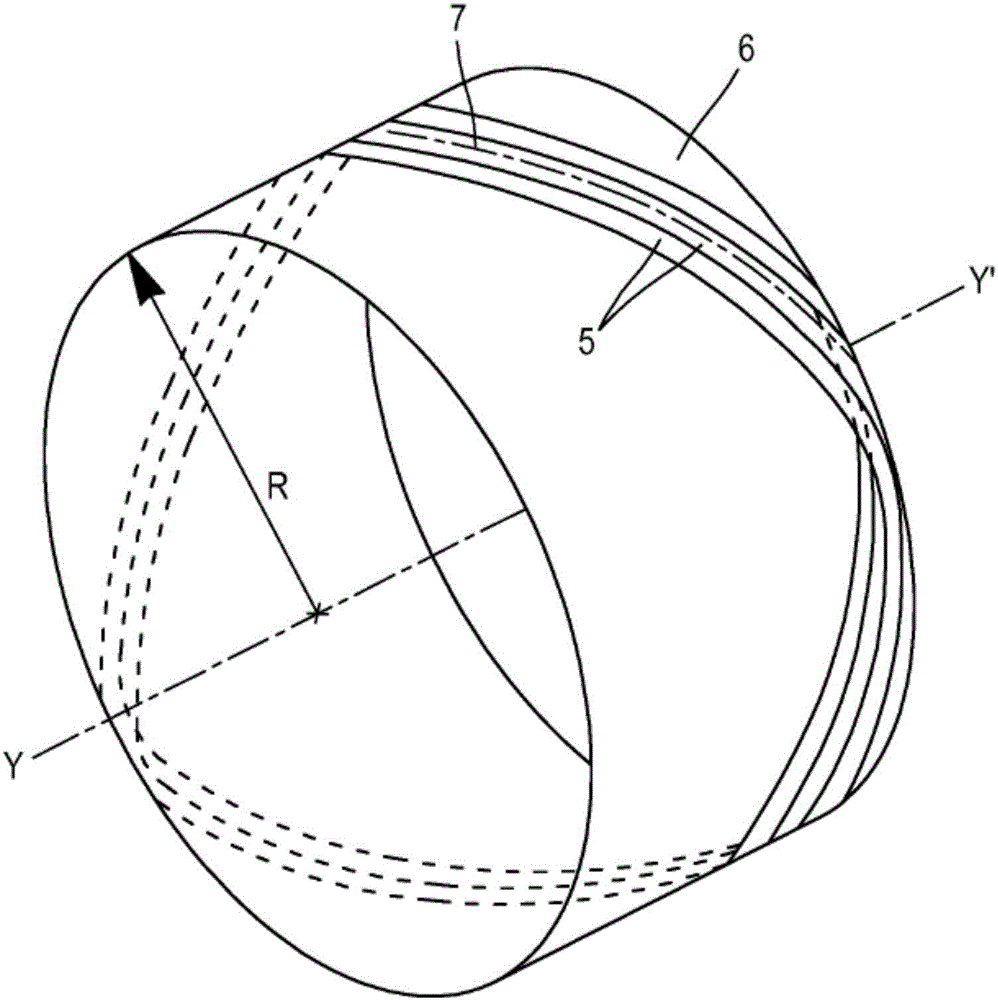

Crown reinforcement for airplane tire

ActiveCN106029353ALow steering stiffnessSmall width valueTyresPneumatic tyre reinforcementsRotational axisJet aeroplane

The present invention relates to an airplane tire and, particularly, to the crown reinforcement thereof. The airplane tire (1) includes a working reinforcement (2) located radially inside a tread (3) and radially outside a carcass reinforcement (4). The working reinforcement (2) includes at least one working dual ply (21) consisting of two radially stacked working layers (211, 212). The working dual ply (21) consists of the circumferential zigzag winding of a strip (5) having a width W over a cylindrical laying surface (6) with radius R and having, for a rotational axis, the rotational axis (YY') of the tire along a periodic curve (7). The periodic curve (7) has a period P and forms an angle A with the circumferential direction (XX') of the tire within the equatorial plane (XZ) of the tire. The circumferential zigzag winding of the strip (5) includes N periods P of the periodic curve (7) over a number T of circumferences 2 Pi R of the cylindrical laying surface (6). According to the invention, the number N of periods P of the periodic curve (7) is an integer that fits the following conditions: (a) N*(W / sin A)=2*Pi*R; (b) N*P=2*Pi*R*T, where T is an integer, (c) N*T is the lowest common multiple of N and T, and the ratio T / N is 1.8 to 2.2.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Radio frequency heat dissipation plastic, preparation method thereof and repeater box body using radio frequency heat dissipation plastic

PendingCN114423816ASmall dispersionGood dispersionHeat-exchange elementsRecord carriers used with machinesPolymer resinEngineering

A radio frequency (RF) heat dissipating plastic is provided. The radio frequency heat dissipation plastic according to one embodiment of the present invention comprises: a polymer matrix comprising a polymer resin; and a first filler dispersed in the polymer matrix and including a high-strength filler and an inorganic coating layer, the high-strength filler being a polymer having at least one hydroxyl group in a repeating unit, and the inorganic coating layer being formed on at least a portion of the surface of the high-strength filler. Accordingly, because the radio frequency heat dissipation plastic contains the first filler, the radio frequency heat dissipation plastic simultaneously shows the effects of low dielectric constant and excellent mechanical strength. Moreover, even if the composition is designed to have a low dielectric constant and excellent mechanical strength, the composition exhibits excellent heat dissipation performance due to the inclusion of the second filler for improving heat dissipation characteristics. In addition, since the first filler and the second filler have excellent dispersibility, uniform low dielectric characteristics, mechanical strength, and heat dissipation characteristics are exhibited over the entire region. According to the radio frequency heat dissipation plastic which shows uniform low dielectric characteristics, mechanical strength and heat dissipation characteristics in the whole area, performance reduction or function loss of a repeater box body which is possibly influenced in the aspect of transmitting and receiving high-frequency-band signals according to dielectric constants can be reduced to the maximum extent; therefore, the material can be widely applied to various articles in the whole industry.

Owner:AMOGREENTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com