Preparation process and application of solder resist adhesive layer

A preparation process and technology of solder mask, applied in the field of H05K, can solve the problems of uniformity of dry film thickness, unevenness of coating thickness, lower production efficiency, etc., and achieve good bonding effect, good developing effect, and good opening high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

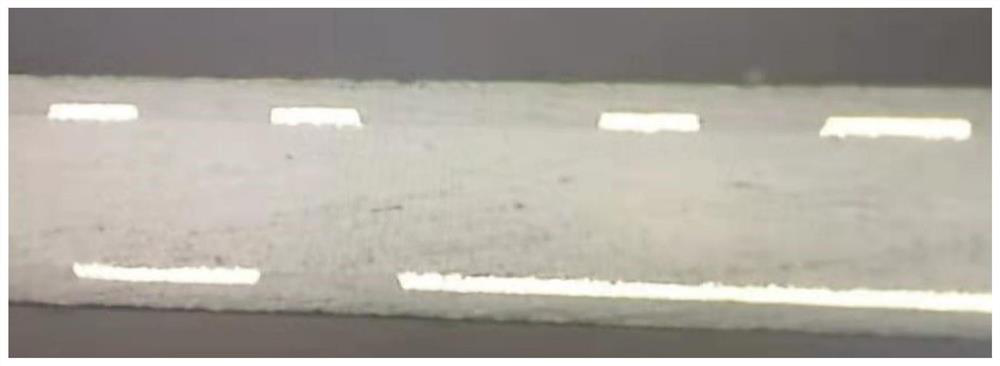

Image

Examples

Embodiment 1

[0063] Embodiment 1 of the present invention provides a preparation process of a solder resist adhesive layer, which is as follows: add ethylene glycol monomethyl ether to the coating film reactant obtained by mixing to make the viscosity reach 20cPs, and then spray it on the coating material with 5m Coating at a speed of / min to obtain a wet adhesive layer, and then drying at 40°C for 30 minutes to obtain a solder resist adhesive layer, and then bonding the surface of the solder resist adhesive layer to the protective film at 40°C to obtain a 60 μm solder resist adhesive layer; in parts by weight, 18 parts of models are kpl-12365 in the film reactant, purchased from Shandong Kepler Biotechnology Co., Ltd. epoxy acrylic resin, 18 parts of pentaacrylate dipentaerythritol, 8 parts of purchased T31 epoxy resin curing agent from Jinan Linhai Chemical Co., Ltd., 25 parts of talcum powder purchased from Kuandian Manchu Autonomous County Sanxing Mining Co., Ltd., and 14 parts of N-met...

Embodiment 2

[0066] Embodiment 2 of the present invention provides a preparation process of a solder resist adhesive layer, which is as follows: add ethylene glycol monomethyl ether to the coating film reactant obtained by mixing to make the viscosity reach 20000cPs, and then place it on the coating material at 20m Coating at a speed of 1 / min to obtain a wet adhesive layer, and then drying at 150 ° C for 1 min to obtain a solder resist adhesive layer, and then attach the surface of the solder resist adhesive layer to the protective film at 100 ° C to obtain a 60 μm solder resist adhesive layer; in parts by weight, 18 parts of models are kpl-12365 in the film reactant, purchased from Shandong Kepler Biotechnology Co., Ltd. epoxy acrylic resin, 18 parts of pentaacrylate dipentaerythritol, 8 parts of purchased T31 epoxy resin curing agent from Jinan Linhai Chemical Co., Ltd., 25 parts of talcum powder purchased from Kuandian Manchu Autonomous County Sanxing Mining Co., Ltd., and 14 parts of N-...

Embodiment 3

[0069] Embodiment 3 of the present invention provides a preparation process of a solder resist adhesive layer, which is as follows: add ethylene glycol monomethyl ether to the coating film reactant obtained by mixing to make the viscosity reach 10000cPs, and then apply it on the coating material with 12m Coating at a speed of / min to obtain a wet adhesive layer, and then drying at 120°C for 10 minutes to obtain a solder resist adhesive layer, and then bonding the surface of the solder resist adhesive layer and the protective film at 65°C to obtain a 60μm solder resist adhesive layer; in parts by weight, 18 parts of models are kpl-12365 in the film reactant, purchased from Shandong Kepler Biotechnology Co., Ltd. epoxy acrylic resin, 18 parts of pentaacrylate dipentaerythritol, 8 parts of purchased T31 epoxy resin curing agent from Jinan Linhai Chemical Co., Ltd., 25 parts of talcum powder purchased from Kuandian Manchu Autonomous County Sanxing Mining Co., Ltd., and 14 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com