Target material suspension mechanism and ion sputtering coating device

A technology of suspension mechanism and coating equipment, applied in the field of optical communication components, can solve the problem of inconvenient operation of the target suspension mechanism, and achieve the effects of preventing water leakage and air leakage, good effect and improving use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

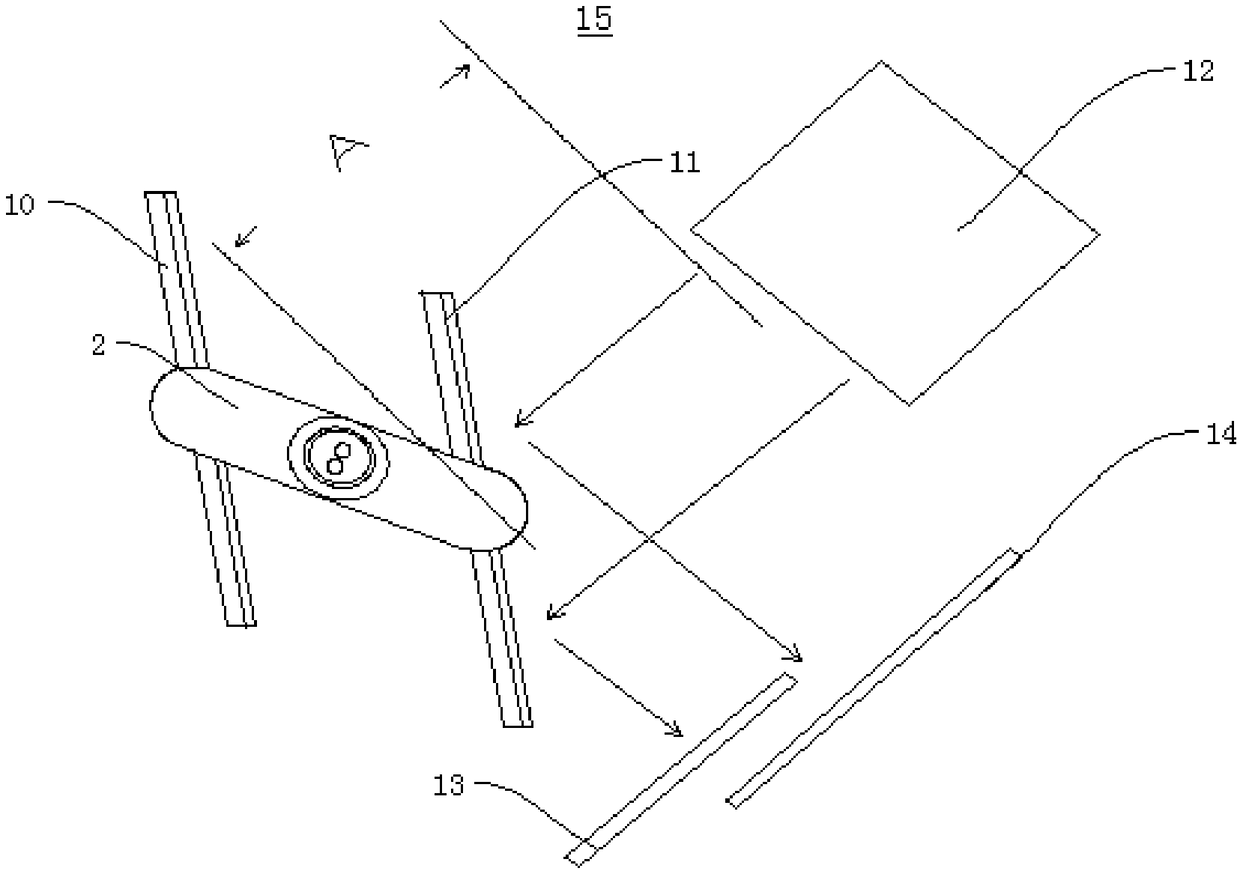

[0045] This embodiment provides an ion sputtering coating device 15, the specific structure of which is described below.

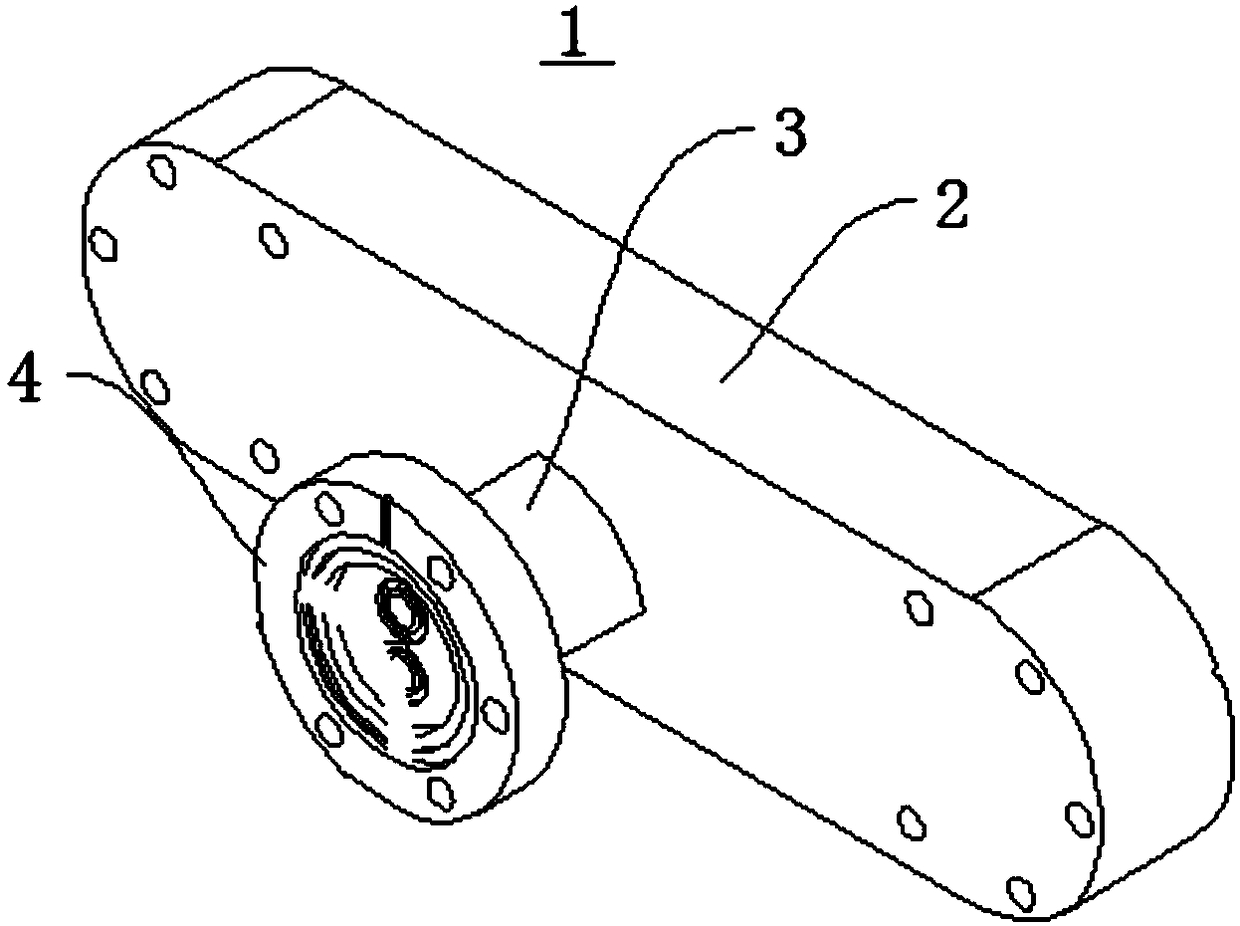

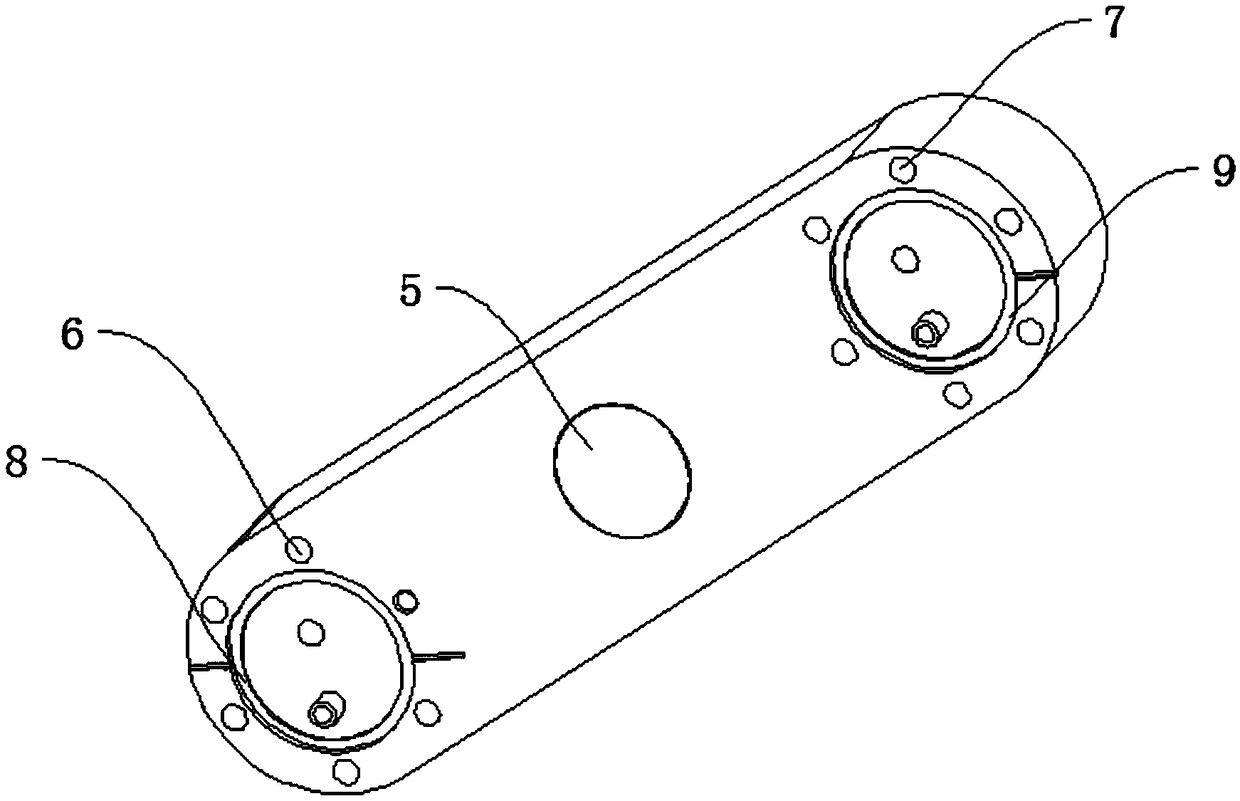

[0046] Please refer to figure 1 , with reference to Figure 2 to Figure 11 , The ion sputtering coating equipment 15 includes a first target 10, a second target 11, a sputtering ion source 12, a film thickness correction device 13, a workpiece to be processed 14, a support platform and the above target suspension mechanism 1; The ion source 12, the target material suspension mechanism 1, the film thickness correction device 13 and the workpiece 14 to be processed are all arranged on the support platform at intervals; the first target material 10 is connected to the first connecting hole 6 by installing a plurality of screws One end of the water separation flange 2 is connected, and the second target 11 is connected with the other end of the water separation flange 2 by installing a plurality of screws in a plurality of second connection holes 7; the sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com