Heating device and chemical vapor deposition system

A chemical vapor deposition and heating device technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that cannot meet the temperature uniformity of epitaxial substrates, etc., and achieve the improvement of photoelectric uniformity and increase the temperature The effect of uniformity and good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

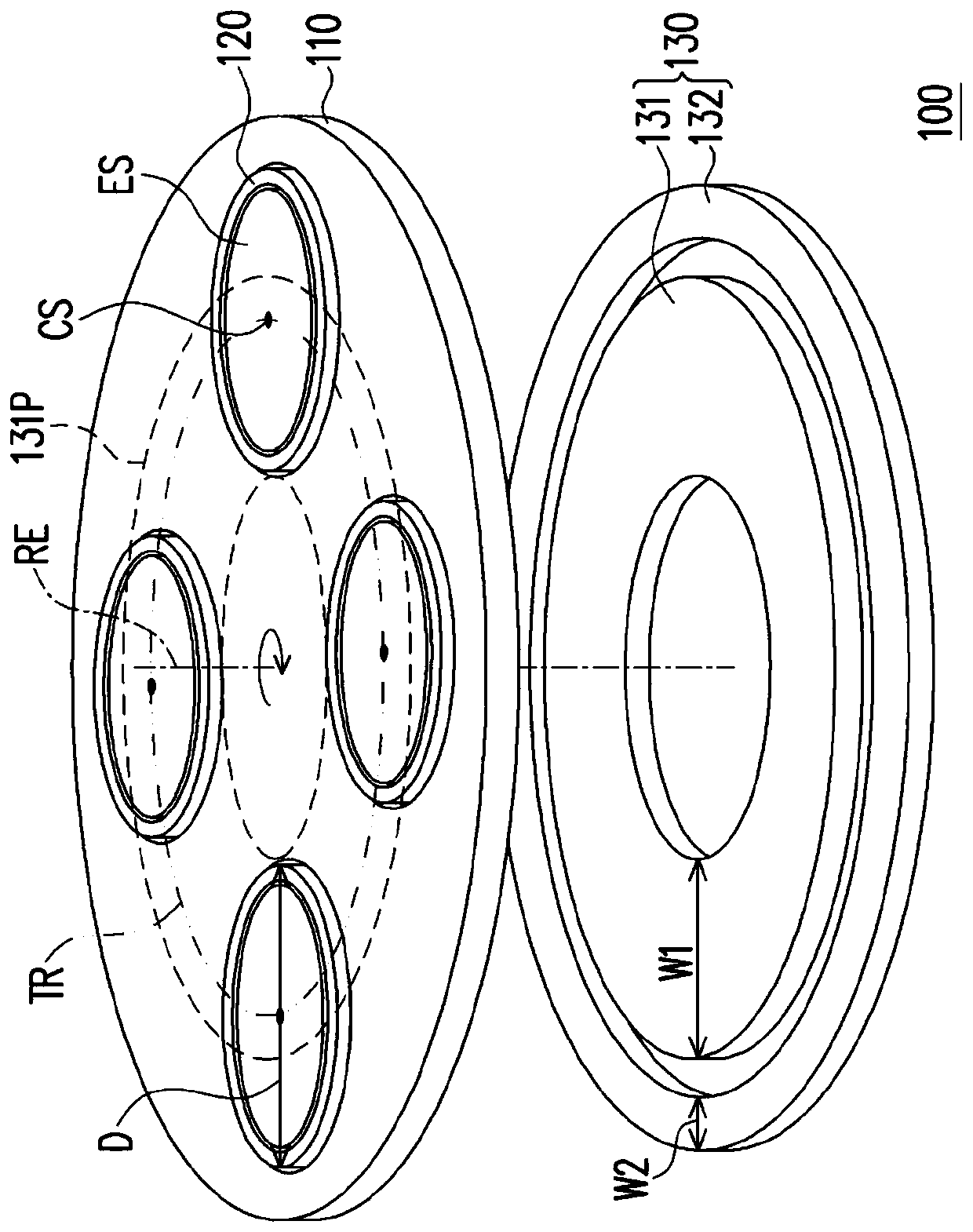

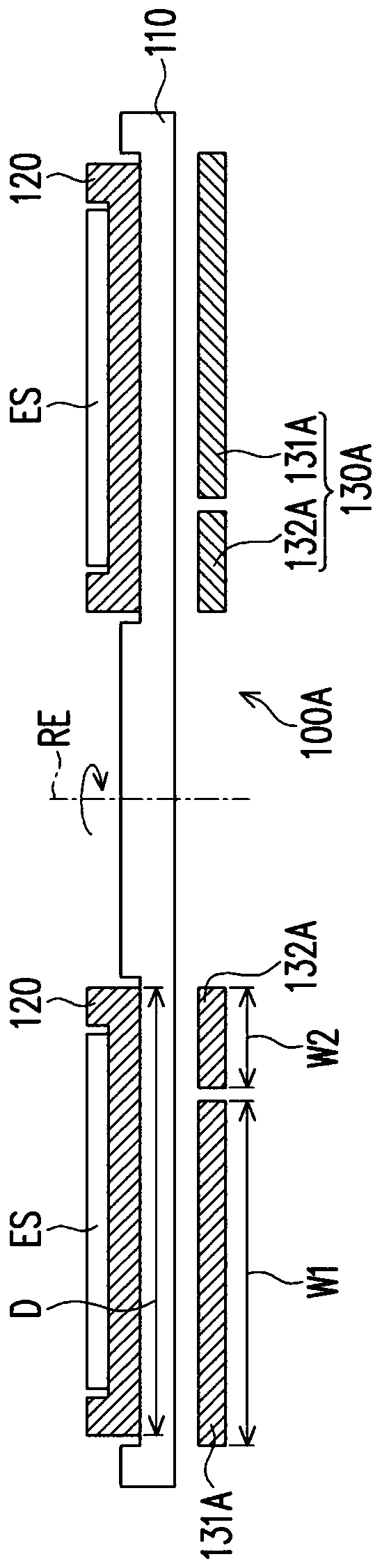

[0063] figure 1 is a partially exploded schematic diagram of the heating device of the first embodiment of the present invention. figure 2 is a schematic cross-sectional view of a chemical vapor deposition system according to an embodiment of the present invention. Please refer to figure 1 and figure 2 , the chemical vapor deposition system 1 includes a chamber 50 , a heating device 100 , an air inlet unit 20 and a rotary driving mechanism 30 . The heating device 100 includes a stage 110 , a plurality of trays 120 and a heater 130 . The carrier plate 120 is configured to position the epitaxial substrate ES on the carrier platform 110 . The carrier plate 120 and the heater 130 are respectively disposed on opposite sides of the carrier platform 110 . Specifically, the carrying platform 110 has a first surface 110a and a second surface 110b opposite to each other, and a plurality of grooves 110g disposed on the first surface 110a. The carrier plates 120 are respectively dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com