High temperature resistant protective film for PC plate protection and preparation method thereof

A high-temperature-resistant protective film and PC board technology, which is applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor temperature resistance of protective film materials, complicated preparation process, and high adhesion , to achieve the effect of good product release effect, good thickness uniformity and stable adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

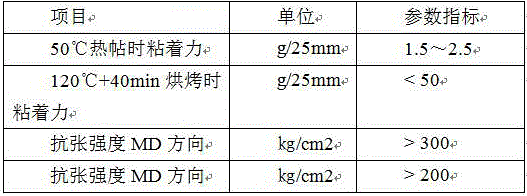

Image

Examples

Embodiment 2

[0014] Embodiment 2, the surface layer is made of: modified polypropylene 2.4wt%, polyethylene 2.8wt%, polypropylene 14.8wt%; the middle layer is made of: polyethylene 60wt%; the adhesive layer is made of: high temperature resistant polyethylene 2wt%, Metallocene polymer 18wt%.

Embodiment 3

[0015] Embodiment 3, the surface layer is composed of: modified polypropylene 1.8wt%, polyethylene 1.8wt%, polypropylene 16.4wt%; the middle layer is composed of: polyethylene 60wt%; the adhesive layer is composed of: high temperature resistant polyethylene 8wt%, Metallocene polymer 12wt%.

Embodiment 4

[0016] Example 4, the surface layer is composed of: modified polypropylene 1.8wt%, polyethylene 3.4wt%, polypropylene 14.8wt%; the middle layer is composed of: polyethylene 60wt%; adhesive layer: high temperature resistant polyethylene 8wt%, metallocene Polymer 12wt%.

[0017] It is worth mentioning that the purpose of adding modified polypropylene to the surface layer of the present invention is as follows: 1. To play a release function, improve the roughness of the surface layer of the product, and prevent the product from stacking after the PC board is pasted. 2. Improve the compatibility between the surface layer material and the middle layer material, and avoid the delamination of the material during blister molding.

[0018] The purpose of adding polyethylene in the middle layer is to reduce the hardness of the product and reduce the cost of the product.

[0019] The purpose of adding high-temperature-resistant polyethylene to the adhesive layer material is to improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com