Radial classification porous titanium alloy part and 3D printing preparing method thereof

A hierarchical porous, 3D printing technology, applied in additive processing and other directions, can solve the problem of single and repeated porous titanium microporous structure, and achieve the effect of easy adjustment of pore size, uniform transition of mechanical strength, and good osseointegration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

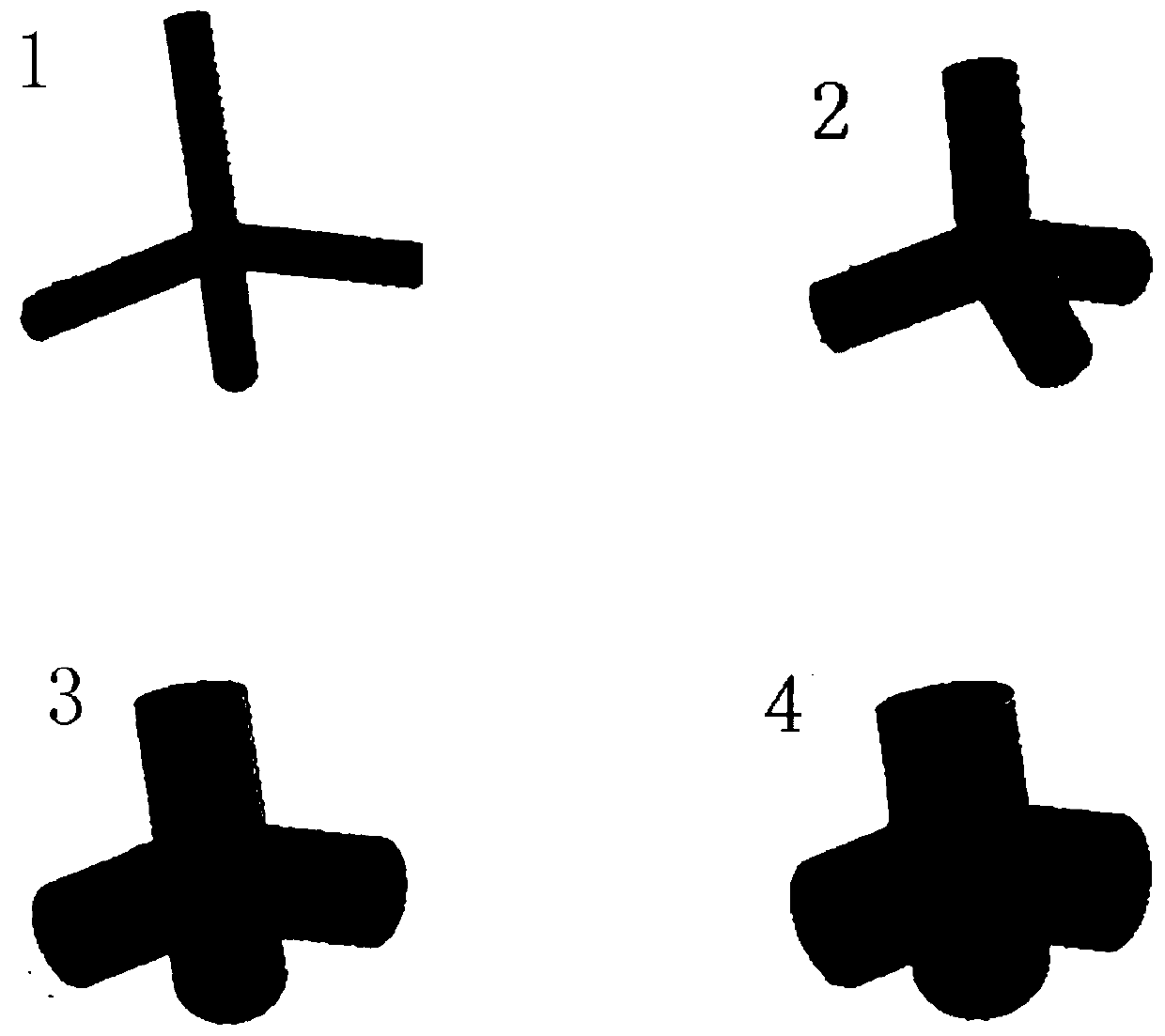

[0052] This embodiment proposes a radially graded porous titanium alloy part, such as Figure 1A , 1B , 1C and figure 2 As shown, the present embodiment is a high-strength porous TC4 titanium alloy material, and the pore structure is composed of linear arrays of unit cells A, unit B, unit C and unit D with gradual gradients; each of the unit cells A , unit cell B, unit cell C and unit cell D are all connected by four cylindrical titanium alloy columns with the same length, and the height of the titanium alloy column (cylinder) is 1mm; among them, the diameter of the titanium alloy column of unit cell A is The diameter of the titanium alloy column of unit cell B is 0.2mm, the diameter of the titanium alloy column of unit cell C is 0.3mm, and the diameter of the titanium alloy column of unit cell D is 0.4mm. The unit cell A is arrayed in the innermost layer, providing the minimum density and the largest equivalent pore size, and the array width is 6mm; the unit cell B and unit...

Embodiment 2

[0057] This embodiment proposes a radially graded porous titanium alloy part, such as Figure 1A , 1B As shown in and 1C, the present embodiment is a pure titanium porous material, and the pore structure is composed of linear arrays of unit cells A, unit B, unit C and unit D with gradual gradients; each of the unit cells A, unit cell B. Unit cell C and unit cell D are both composed of four cylindrical pure titanium columns with the same length. The height of the pure titanium column is 0.6mm; the diameter of the pure titanium column of unit cell A is 0.1mm, and that of The diameter of the pure titanium column is 0.15 mm, the diameter of the pure titanium column of the unit cell C is 0.2 mm, and the diameter of the pure titanium column of the unit cell D is 0.3 mm. The unit cell A is arrayed in the innermost layer, providing the minimum density and the largest equivalent pore size, and the array width is 3 mm; the unit cell B and unit C are arrayed in the second inner layer in ...

Embodiment 3

[0062] This embodiment proposes a radially graded porous titanium alloy part, such as Figure 1A , 1B As shown in and 1C, the present embodiment is a porous titanium alloy part of Ti-5Cu porous material, and the pore structure is composed of a linear array of unit cells A, unit B, unit C and unit D with gradual gradients; each of the Unit cell A, unit cell B, unit cell C, and unit cell D are all connected by four cylindrical titanium alloy columns with the same length, and the height of the titanium alloy column is 1mm; among them, the diameter of the titanium alloy column in unit cell A is The diameter of the titanium alloy column of unit cell B is 0.3mm, the diameter of the titanium alloy column of unit cell C is 0.4mm, and the diameter of the titanium alloy column of unit cell D is 0.6mm. The unit cell A is arrayed in the innermost layer, providing the minimum density and the largest equivalent pore size, and the array width is 5mm; the unit cell B and unit C are arrayed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com