Sapphire substrate polishing device and process

A sapphire substrate and polishing device technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of reduced flatness, reduced chip reliability, increased leakage current, etc., and improved accuracy , the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

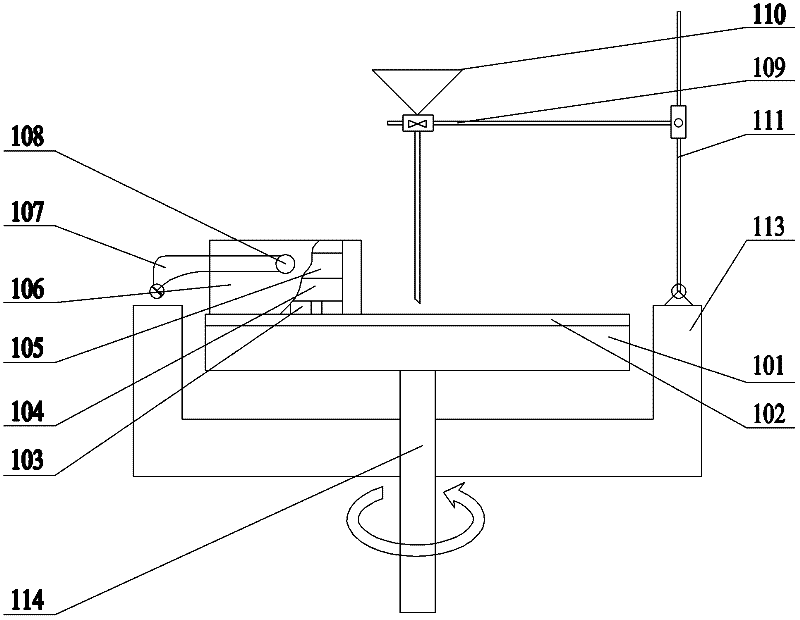

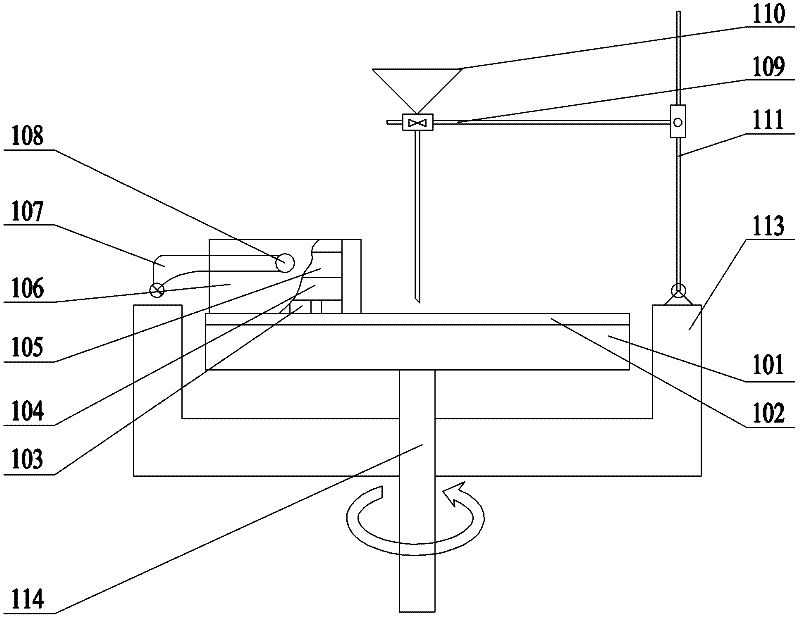

[0033] a, the 9Cr18 stainless steel polishing table 101 of Φ 380mm is installed on the rotating shaft 114 of the polishing device, and the crystal wafer 112 of 20mm * 20mm * 1mm is adhered on the polishing table 101 with ultraviolet glue, and the gap between the sheets is 0.5mm. into a crystal polishing pad 102;

[0034] b. Fix the abrasive supply mechanism on the frame 113, add 450ml of high-purity SiO with a particle size of 70nm 2 powder;

[0035] c. Start the rotating shaft 114 of the polishing table 101 to keep the rotating speed of the polishing table 101 at 30 r / min. Open the material control valve of the abrasive supply mechanism to make SiO 2Abrasives are continuously supplied to the crystal polishing pad 102 at a flow rate of 6ml / min, and after 10 minutes, the rotating shaft 114 and the abrasive supply mechanism are closed to evenly distribute the abrasives on the crystal polishing pad 102 in advance;

[0036] d, 4 pieces of sapphire substrates 103 to be polished ...

Embodiment 2

[0040] a, the 9Cr18 stainless steel polishing table 101 of Φ 380mm is installed on the polishing device rotating shaft 114, the regular hexagonal crystal chip 112 of side length 15mm, thickness 1mm is adhered on the polishing table 101 with ultraviolet glue, and the gap between sheet and sheet is 1mm, glued into a crystal polishing pad 102;

[0041] b. Fix the abrasive supply mechanism on the frame 113, add 350ml of high-purity SiO with a particle size of 80nm 2 powder;

[0042] c. Start the rotating shaft 114 of the polishing table 101 to keep the rotating speed of the polishing table 101 at 60 r / min. Open the material control valve of the abrasive supply mechanism to make SiO 2 Abrasives are continuously supplied to the crystal polishing pad 102 at a flow rate of 4ml / min. After 15 minutes, the rotating shaft 114 and the abrasive supply mechanism are closed, and the abrasives are evenly distributed on the crystal polishing pad 102 in advance;

[0043] d, 4 pieces of sapphi...

Embodiment 3

[0047] a, the 9Cr18 stainless steel polishing table 101 of Φ 380mm is installed on the polishing device rotating shaft 114, and the regular octagon crystal chip 112 of side length 10mm, thickness 1mm is adhered on the polishing table 101 with ultraviolet glue, and the gap between sheet and sheet is 2mm, glued into a crystal polishing pad 102;

[0048] b. Fix the abrasive supply mechanism on the frame 113, and add 300ml of high-purity SiO with a particle size of 90nm 2 powder;

[0049] c. Start the rotating shaft 114 of the polishing table 101 to keep the rotating speed of the polishing table 101 at 90 r / min. Open the material control valve of the abrasive supply mechanism to make SiO 2 Abrasives are continuously supplied to the crystal polishing pad 102 at a flow rate of 3ml / min. After 20 minutes, the rotating shaft 114 and the abrasive supply mechanism are closed, and the abrasives are evenly distributed on the crystal polishing pad 102 in advance;

[0050] d, 4 pieces of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com