Radio frequency heat dissipation plastic, preparation method thereof and repeater box body using radio frequency heat dissipation plastic

A radio frequency and plastic technology, applied in the field of repeater boxes, can solve the problems of ununiform performance, increased electrical signal transmission loss, high mechanical strength, etc., and achieve excellent mechanical strength, uniform low dielectric properties, and excellent heat dissipation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0106] The present invention will be described more specifically by the following examples, but the following examples are not intended to limit the scope of the present invention, but should be interpreted as helpful for understanding the present invention.

[0107] Preparation Example 1: Preparation of the first filler

[0108] First, in order to prepare the first filler, cellulose nanofibrils were used as high-strength fillers and tetrahydroxysilane (TEOS) was treated as an inorganic coating precursor at a weight ratio of 1:30, reacted for 8 hours, and the reacted high The strength filler was aged for 1.5 hours to prepare the inorganic coating formed on the surface of the high strength filler such as image 3 and Figure 4 First filler shown. In this case, in the prepared first filler, the average cross-sectional diameter of the high-strength filler is 10 μm, and the average thickness of the inorganic coating is 15 nm. With respect to 100 parts by weight of the high-stren...

Embodiment 1

[0111] Example 1: Preparation of radio frequency heat dissipation plastic

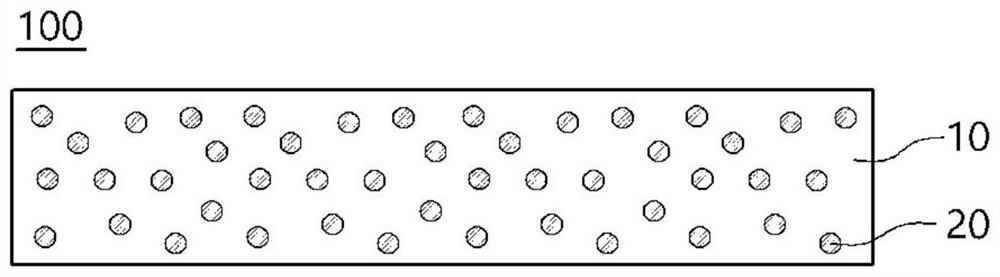

[0112] With respect to 100 parts by weight of polypropylene (PP) as the main ingredient resin, mix the first filler of 7 parts by weight prepared according to the above-mentioned preparatory example 1 and the second filler of 100 parts by weight prepared according to the above-mentioned preparatory example 2, pass 15 Twin-screw extruder for synthesis to prepare as figure 2 RF thermal plastic shown.

Embodiment 2~21 and comparative example 1~2

[0114] The preparation is carried out in the same manner as in Example 1, but by changing the average cross-sectional diameter of the high-strength filler in the first filler, the average thickness of the inorganic coating, the content of the inorganic coating, the content of the first filler, whether it is included or not, and the content of the second filler The radio frequency heat dissipation plastics shown in Table 1 to Table 4 are prepared according to the average particle size, content and inclusion or not.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com