Method and apparatus of producing fibrous aggregate

A technology of fiber aggregates and manufacturing methods, applied in fiber processing, dry spinning, non-woven fabrics, etc., can solve problems such as large amount of fiber, discrete amount of fiber, and small amount of fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

[0085] (1) Preparation of spinning dope

[0086] A spinning dope (viscosity: 1200 mP·s) was prepared. Polyacrylonitrile with a weight average molecular weight of 400,000 was dissolved in N,N-dimethylformamide to a concentration of 12 mass%.

[0087] (2) Preparation of manufacturing device

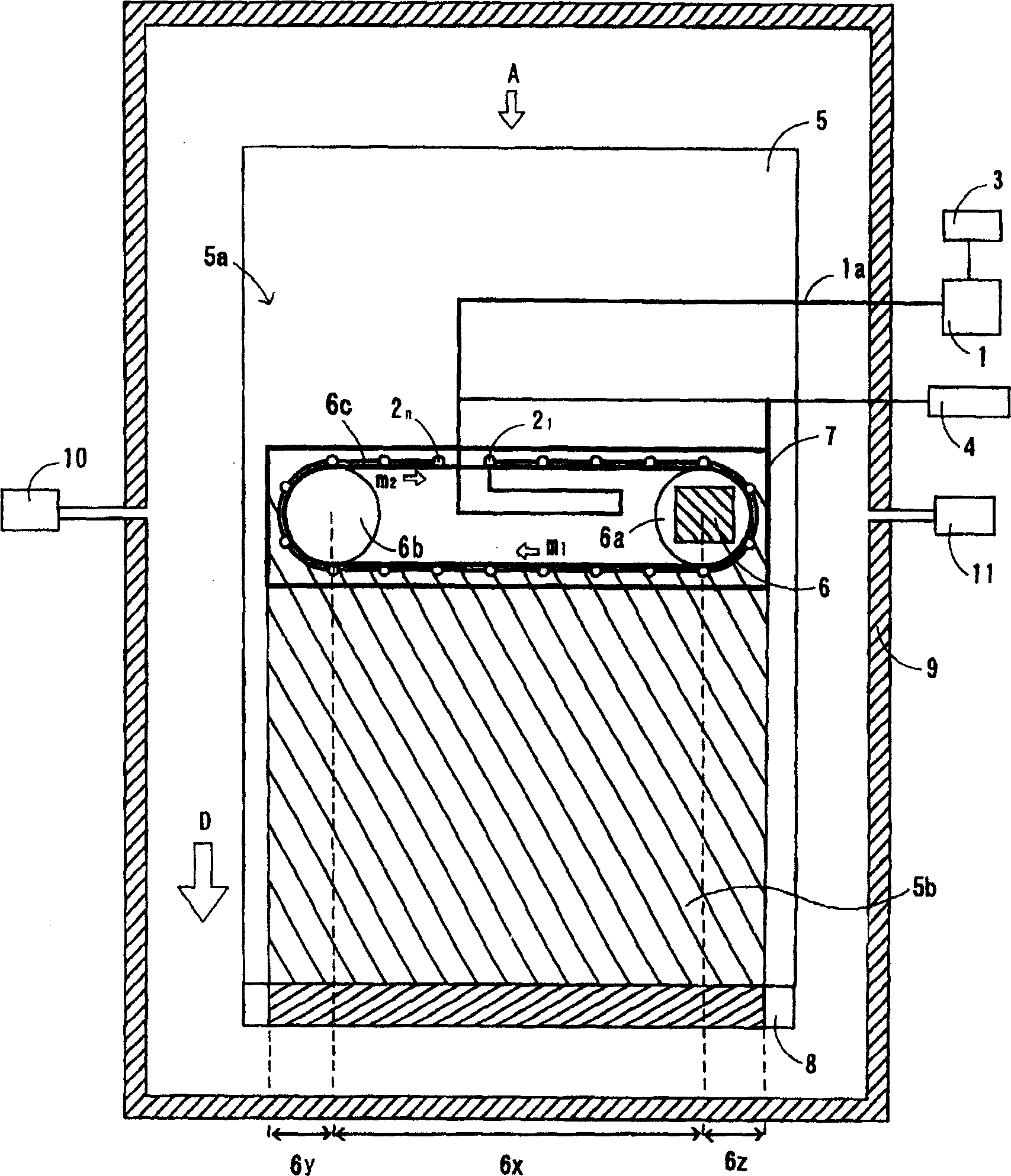

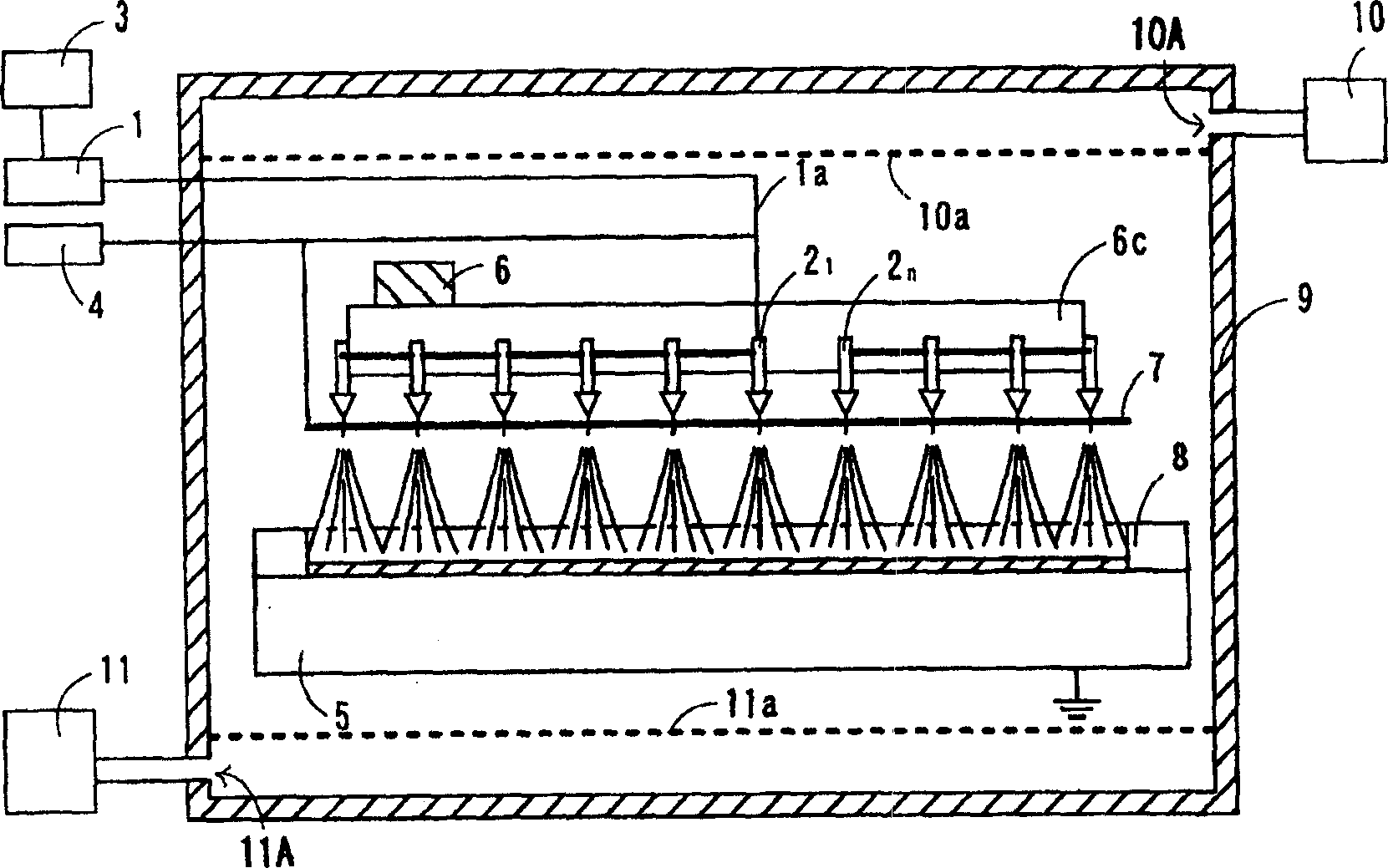

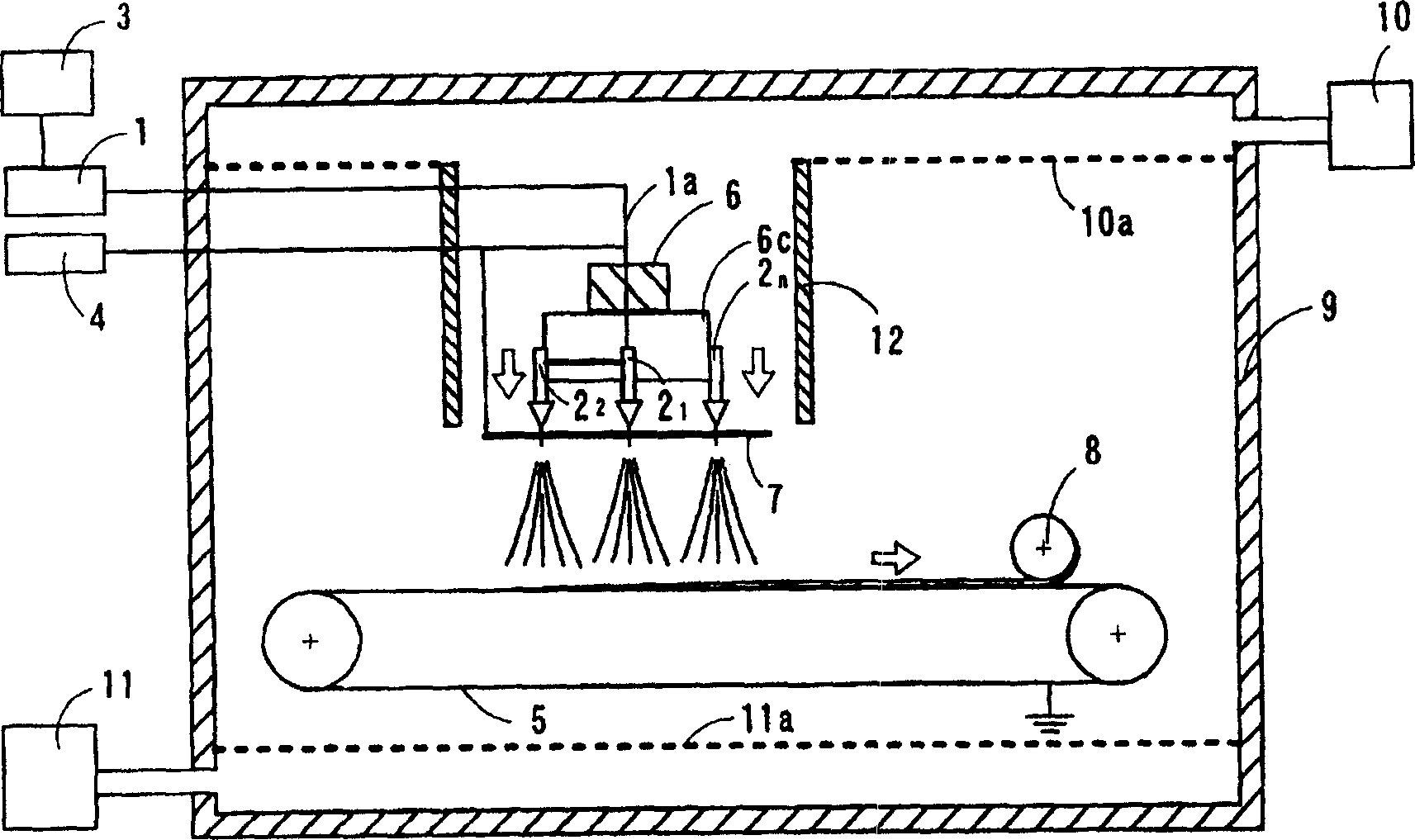

[0088] Prepare figure 1 and figure 2 Fabrication setup shown. That is, nozzle group 2 consisting of 14 nozzles 1 ~2 14 (Needle-shaped nozzles made of stainless steel with an inner diameter of 0.4mm) are fixed on the chain-shaped support body 6c at a pitch of 60mm, the support body 6c is bridged between the first sprocket 6a and the second sprocket 6b, and the nozzle group 2 1 ~2 14 Set in an oblong shape (major diameter: 480 mm, short diameter: 140 mm). Furthermore, the drive motor (movement mechanism 6) is attached to the 1st sprocket 6a.

[0089] Next, a micropump (manufactured by Micropump Co., Ltd.: micropump FC-513; pump head: 188, 1rpm=0.017mL type; control part= Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com