Method for predicting evolvement and performances of structure of strip steels in hot rolled proces

A hot rolling process and performance prediction technology, applied in the field of strip rolling, can solve problems that have not been reported, and achieve the effects of simple operation, easy debugging, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

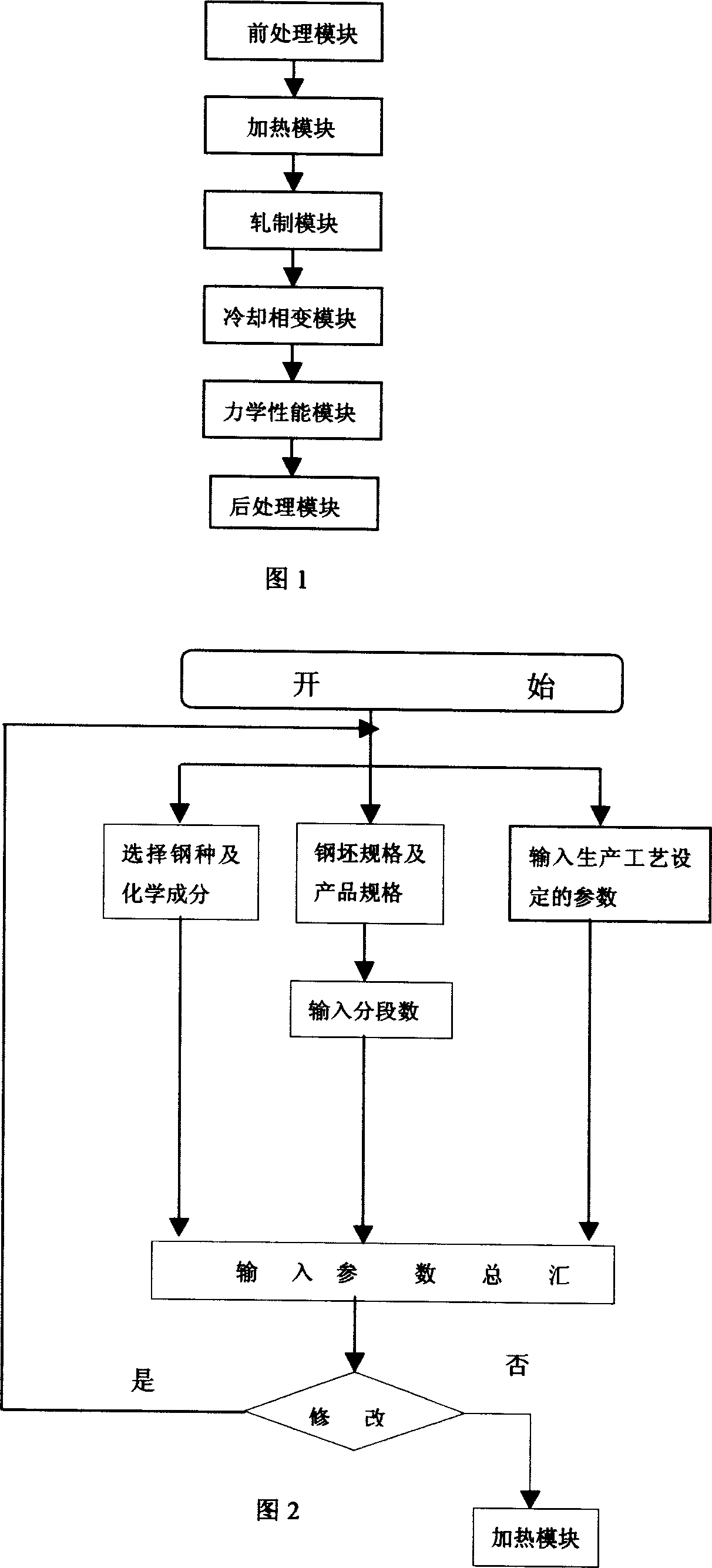

[0024] As shown in Figure 1, the present invention takes ordinary carbon steel as the research object, and establishes a systematic physical metallurgical model. The post-processing consists of six modules. The function of the pre-processing module is to read the process parameters required for the hot rolling process from the database and provide initial conditions for the subsequent process; the heating module, rolling module, cooling phase change module and mechanical properties The module is to complete the dynamic simulation of each metallurgical physical quantity in the hot rolling process, and predict the final structure and performance of the strip; the function of the post-processing module is to complete the display and output of the simulation results of the hot rolling process; the details are as follows:

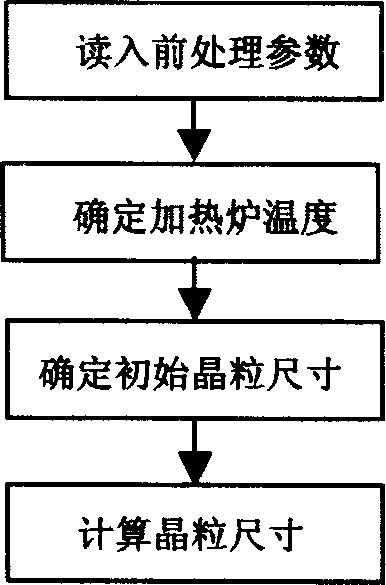

[0025] As shown in Figure 2, the specific process of the pretreatment module is: first read the production process parameters from the database, such as: the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com