Membrane electrode and preparation method thereof

A membrane electrode and preparation step technology, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as affecting pore structure, affecting oxygen transmission, swelling of perfluorosulfonic acid resin, etc., and achieves high ion exchange capacity, low equivalent weight, The effect of strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

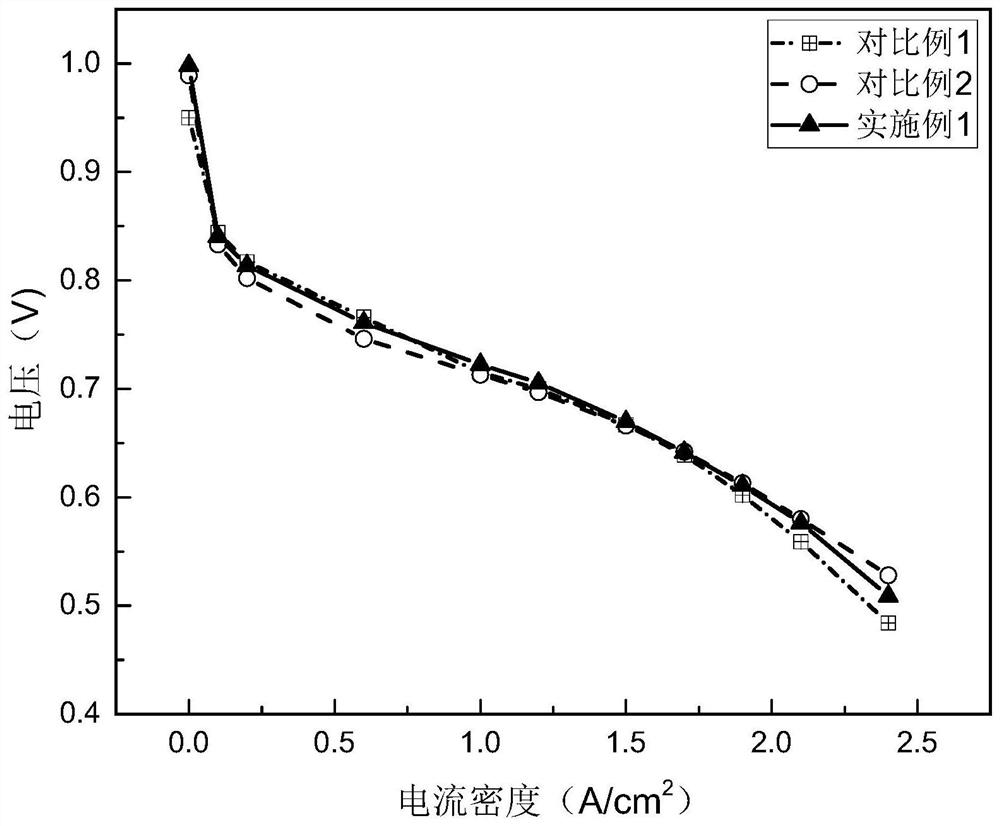

Embodiment 1

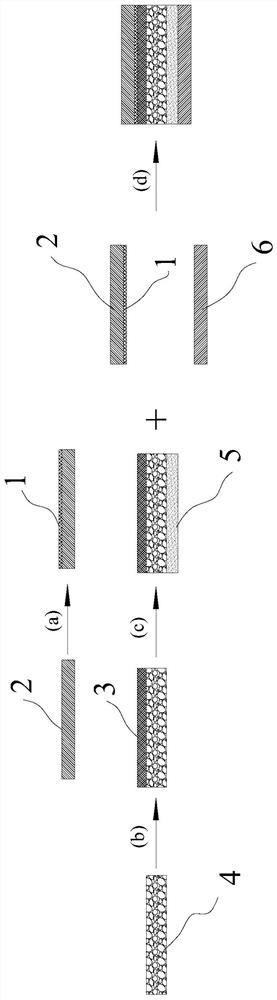

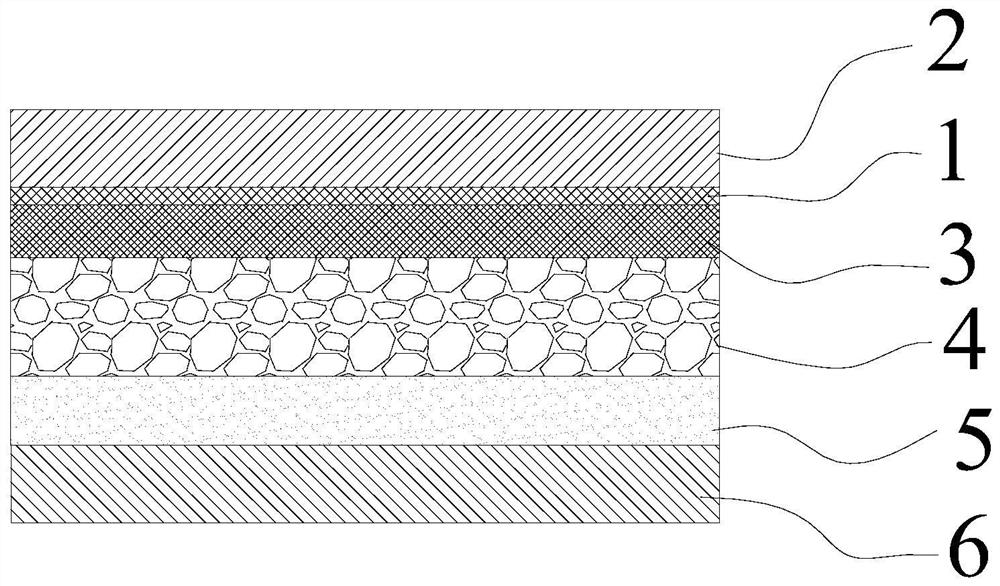

[0022] like figure 1 , the preparation method of membrane electrode comprises the following steps:

[0023] (a) Preparation steps of outer sublayer 1

[0024] The outer layer cathode catalyst slurry is coated on one side of the cathode gas diffusion layer 2 by the method of slit coating, and after being dried by hot air at 90° C., a prefabricated cathode gas diffusion layer with an outer sublayer 1 is formed. The outer sublayer 1 The platinum loading was 0.10 mg / cm2 and the thickness was 3.7 μm.

[0025] The outer layer cathode catalyst slurry is prepared by mixing the following raw materials by mass percentage: 5-12% of platinum and carbon particle catalyst, 4-8% of perfluorosulfonic acid resin and 80-91% of solvent.

[0026] Wherein, the commercialized Aquivion D79 perfluorosulfonic acid resin with an equivalent weight of about 800 is selected for the perfluorosulfonic acid resin resin, and the Tec10F50e produced by Japan's Tanaka Precious Metals (TKK) is selected for the ...

Embodiment 2

[0037] Change the platinum loading of outer sublayer 1 in step (a) of Example 1 to 0.05 mg / cm 2 , the thickness is 1.9 μm, and the platinum loading of the inner sublayer 3 in step (b) of Example 1 is changed to 0.3 mg / cm 2 , with a thickness of 11.2 μm. The steps are the same as those in the first embodiment.

Embodiment 3

[0039] Change the platinum loading of outer sublayer 1 in step (a) of Example 1 to 0.15 mg / cm 2 , the thickness is 5.6 μm, and the platinum loading of the inner sublayer 3 in step (b) of Example 1 is changed to 0.20 mg / cm 2 , with a thickness of 7.4 μm. The steps are the same as those in the first embodiment.

[0040]The thicknesses of the inner sublayer 3 and the outer sublayer 1 can be adjusted according to requirements, but the thickness of the outer sublayer 1 needs to be less than half the thickness of the cathode catalyst layer (ie, the outer sublayer 1 and the inner sublayer 3). According to practice, if the high-equivalent perfluorosulfonic acid resin is thick, on the one hand, the waterproof effect is not good, and on the other hand, it is not easy to achieve in the coating process and industrial production. Even if it can be achieved, the coating is prone to defects. Thereby affecting the performance of the membrane electrode. Further preferably, the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com