Acid-corrosion-resistant X70MS pipeline steel hot rolled coil and manufacturing method thereof

A manufacturing method and pipeline steel technology, applied in the field of metal smelting, can solve the problems of hydrogen-induced cracking, increased alloy cost, stress corrosion cracking, etc., and achieve the effects of reducing segregation, high product competitiveness, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

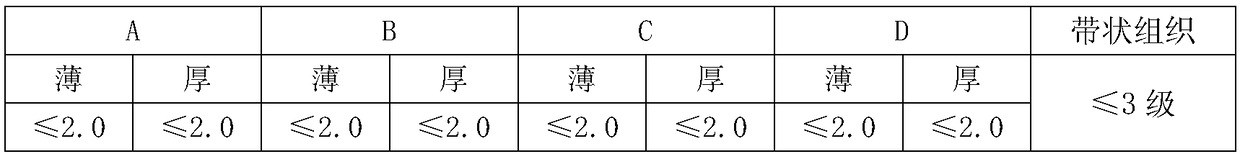

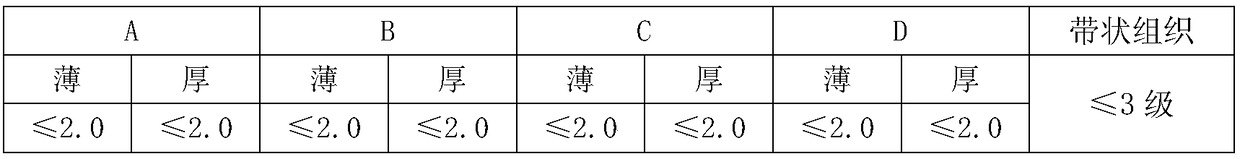

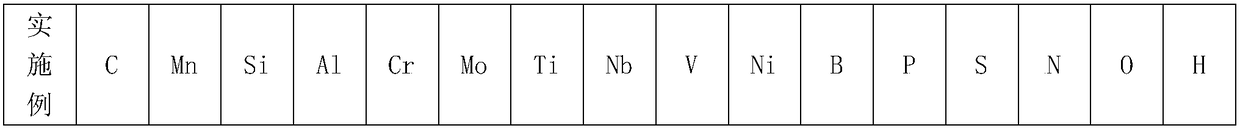

[0021] The invention provides an acid corrosion-resistant X70MS pipeline steel hot-rolled coil, which comprises the following components in terms of mass percentage: C: 0.03-0.10%; Mn: 1.10-1.40%; Si: 0.10-0.20%; Al: 0.010- 0.030%; Cr: 0.15-0.55%; Mo: 0.15-0.45%; Ti: 0.005-0.025%; Nb: 0.050-0.080%; V: 0.020-0.040%; Ni: 0.15-0.30%; P≤0.012%; S≤0.0020%; N≤0.0060%; O≤0.0018%; H≤0.0005%; the balance is Fe and unavoidable inclusions.

[0022] In order to obtain good comprehensive properties of acid corrosion-resistant X70MS pipeline steel, the molten steel must have good purity and low C content to reduce segregation and inclus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com