Nanocrystalline high-entropy alloy powder and preparation method thereof

A technology of high-entropy alloys and nanocrystals, applied in the field of powder metallurgy, can solve the problems of high energy consumption and large investment in equipment, and achieve the effects of simple equipment, improved powder activity, and accelerated solid-state diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

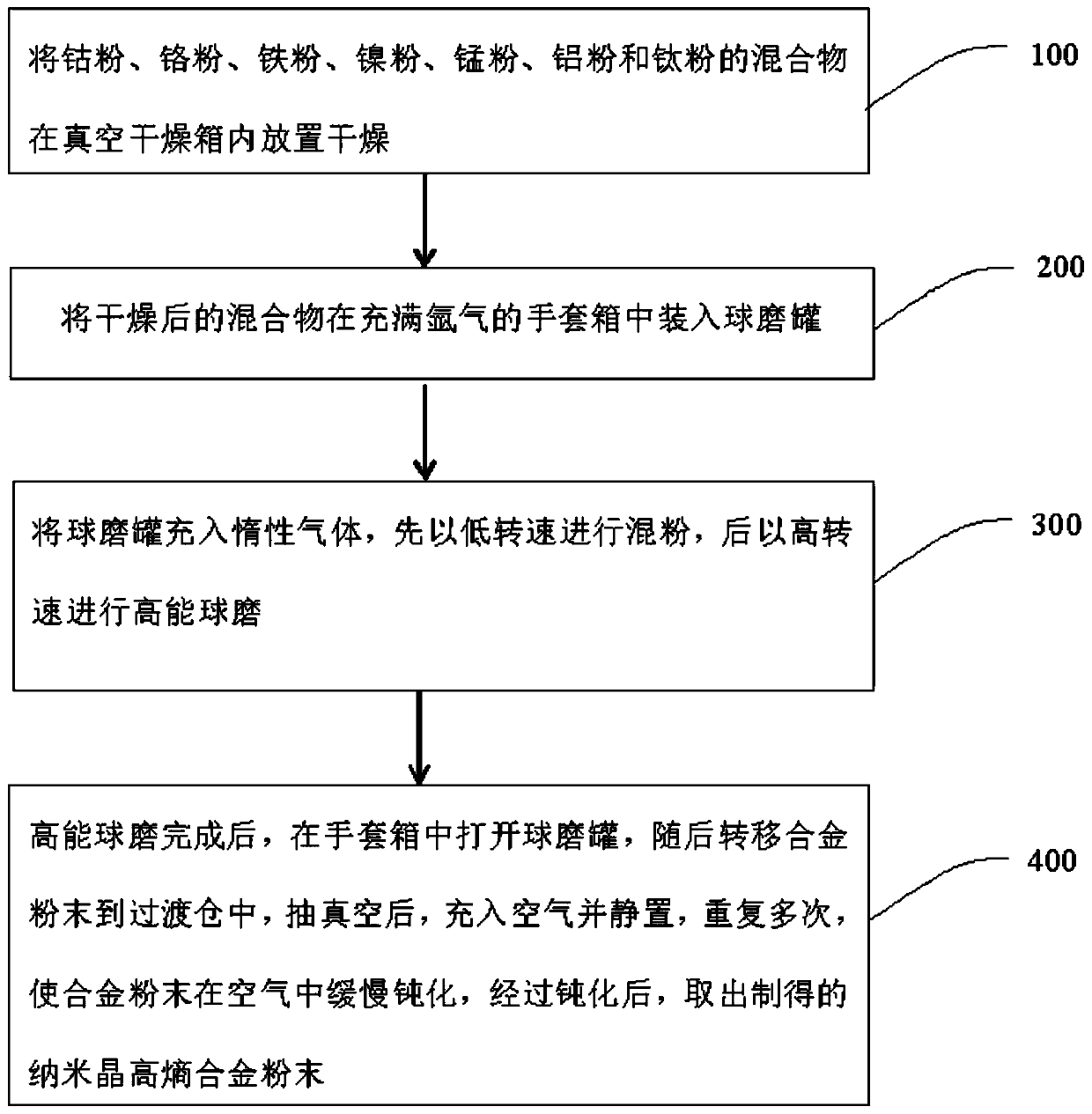

[0029] The invention discloses a preparation method of nanocrystalline high-entropy alloy powder, such as figure 1 As shown, the method comprises the steps of:

[0030] 100. Place the mixture of cobalt powder, chromium powder, iron powder, nickel powder, manganese powder, aluminum powder and titanium powder in a vacuum drying oven to dry;

[0031] 200. The dried mixture is packed into a ball mill jar in a glove box full of argon;

[0032] 300. Fill the ball mill tank with inert gas, first mix powder at low speed, and then perform high-energy ball milling at high speed;

[0033] 400. After the high-energy ball milling is completed, open the ball milling tank in the glove box, and then transfer the alloy powder to the transition chamber. After vacuuming, fill it with air and let it stand. Repeat several times to slowly passivate the alloy powder in the air. After passivation, the prepared nanocrystalline high-entropy alloy powder is taken out.

[0034] Among them, the mass ra...

Embodiment 1

[0035] Embodiment 1: Preparation of CoCrFeNi high-entropy alloy powder:

[0036] According to the above implementation steps, in a glove box filled with argon, put cobalt powder, chromium powder, iron powder, and nickel powder in an equiatomic ratio together in a ball milling tank, fill the ball milling tank with argon gas, and put it on a planetary ball mill According to the following ball milling parameters, high-energy ball milling is carried out: stainless steel is used for ball milling, the ball diameter is 16mm, and the mass ratio of ball to material is 5:1. Firstly, the metal powder is mixed at a low speed of 200rpm for 6 hours to mix the metal powders evenly, and then high-speed 300rpm high-energy ball milling is carried out. 84h. After the high-energy ball milling is completed, the ball milling tank is opened in a glove box filled with argon, and the obtained nanocrystalline CoCrFeNi high-entropy alloy powder is taken out after the transition chamber is passivated.

...

Embodiment 2

[0038] Example 2: Al 0.3 CoCrFeNi High Entropy Alloy

[0039] According to the above implementation steps, in a glove box filled with argon, put aluminum powder, cobalt powder, chromium powder, iron powder, and nickel powder into the ball mill tank together, the aluminum powder accounts for 7 at.%, and other metals account for 23.25 at. %. Fill the ball mill tank with argon gas, and perform high-energy ball milling on the planetary ball mill according to the following ball mill parameters: stainless steel is used for the ball mill, the diameter of the ball is 16mm, the mass ratio of the ball to material is 5:1, and the powder is mixed at a low speed of 200rpm for 6 hours Mix the metal powders uniformly, and then perform high-speed 300rpm high-energy ball milling for 60h. After the high-energy ball milling is completed, open the ball milling tank in a glove box filled with argon, and take out the prepared nanocrystalline Al after the passivation of the transition chamber. 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com