Sewage treatment method and device based on hydrate water vapor adsorption method

A sewage treatment device and hydrate technology, which are applied in the field of sewage treatment methods and devices based on a hydrate water vapor adsorption method, can solve the problems of secondary pollution cost, high energy and low efficiency, and high energy consumption, and achieve the reduction of sewage treatment costs, Improve processing economy and overcome the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

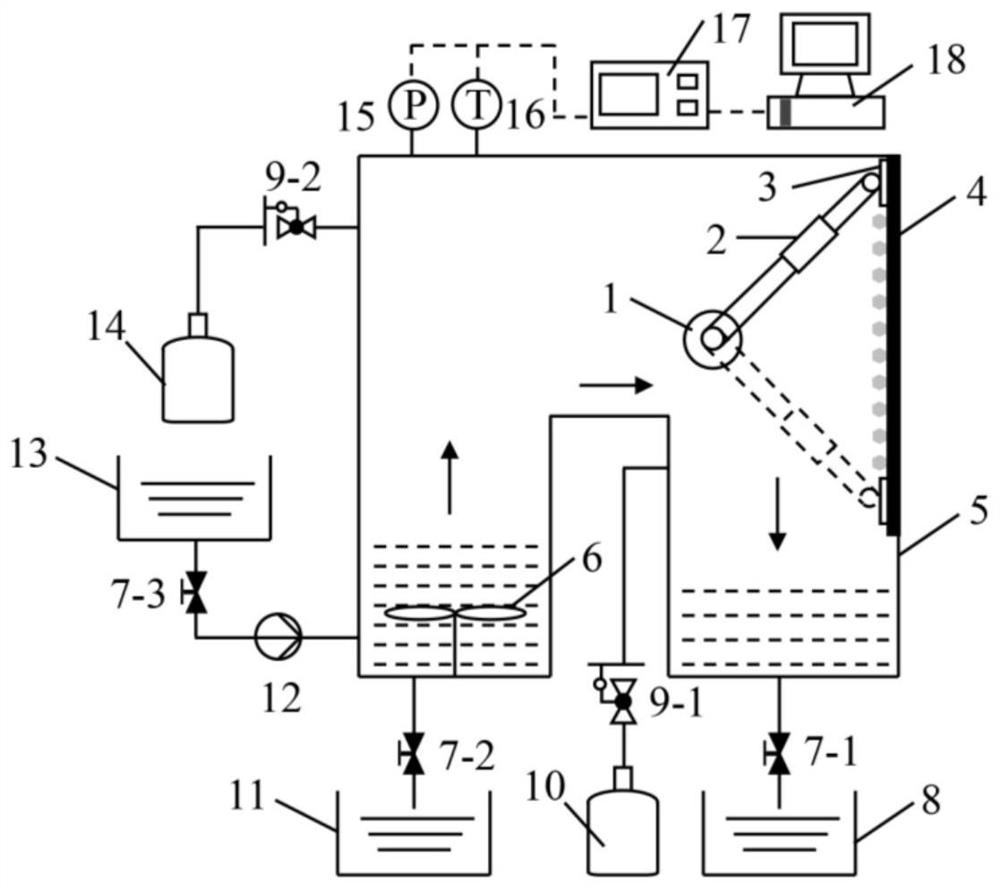

[0032] A sewage treatment system based on a hydrate water vapor adsorption method includes a sewage evaporation area, a hydrate generation area, a hydrate decomposition area, and a data acquisition and control system:

[0033] The sewage evaporation zone includes the reactor body 5, the magnetic stirrer 6, the second one-way valve 7-2, the third one-way valve 7-3, the waste liquid tank 11, the water pump 12 and the sewage storage tank 13. The sewage storage tank 13 is connected with the reactor body 5 through the third one-way valve 7-3 and the water pump 12; the reactor body is equipped with a magnetic stirrer 6, and the bottom is connected to the waste water through the second one-way valve 7-2. The liquid tank 11 is connected;

[0034] The hydrate generation area includes a motor 1, a telescopic rod 2, a scraper 3, a cooling coil 4, a second pressure reducing valve 9-2, a gas cylinder 14, a pressure sensor 15 and a temperature sensor 16. The motor 1 is installed Inside the...

Embodiment 2

[0043] This embodiment adopts the method of the sewage treatment system based on the hydrate water vapor adsorption method, and its steps are as follows:

[0044] Turn on the water pump 12 and the third one-way valve 7-3, the sewage stored in the sewage storage tank 13 is the complex waste water containing inorganic salts and organic pollutants discharged from the petroleum refinery, the total organic carbon content is 187.7mg / L, the sodium The ion concentration is 2248.0 mg / L, and the wastewater from the petroleum industry is transported to the reactor body 5 through the pump 12. The temperature of the wastewater is 25°C, the flow rate of the wastewater is 2.0 m / s, and the transport volume of the wastewater is 70% of the volume of the wastewater evaporation area of the reactor body 5. After the water intake is completed, close the water pump 12 and the third one-way valve 7-3; open the second pressure reducing valve 9-2, select propane as the gas hydrating agent, and the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com