Super steel reinforced by precipitation of nano intermetallic compound, and preparation method for same

A precipitation-strengthening, nano-metal technology, applied in the field of superalloys, can solve the problems of high cost of power plants, no mechanical properties, and high nickel cost, and achieve the effects of excellent comprehensive performance, good oxidation resistance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

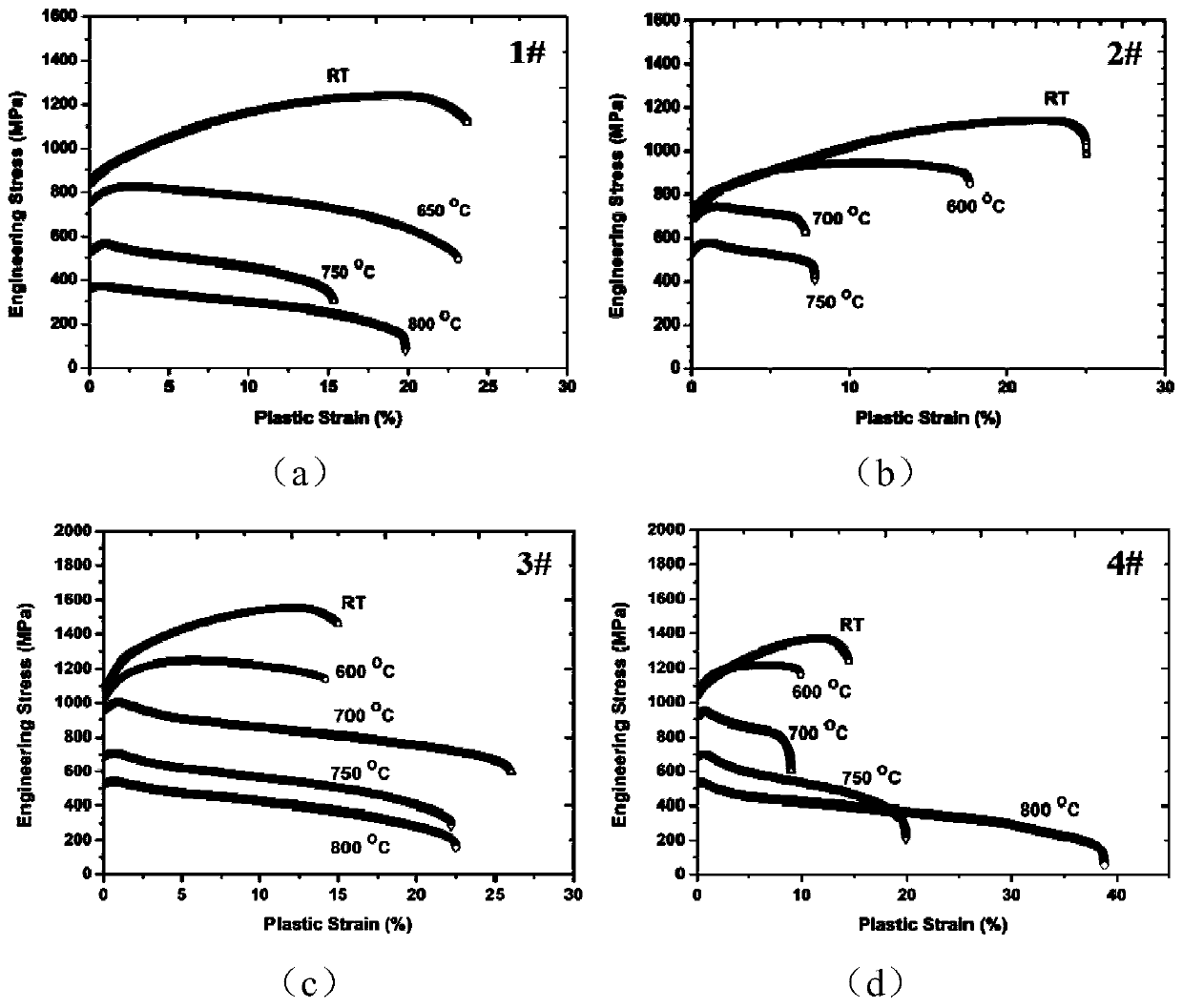

[0057] The ratio of alloy raw materials is shown in Table 1, and the specific preparation method includes the following steps:

[0058] (1) Under an Ar gas atmosphere, each alloy element is melted and mixed uniformly according to the composition ratio in Table 1, and the melt is poured into an alloy ingot;

[0059] (2) placing the ingot at 1100°C to 1200°C for a homogenization treatment for not less than 4 hours, and then water quenching;

[0060] (3) After being released from the furnace, it is cold-rolled along the longitudinal direction, and the reduction rate is not less than 60%. No heat treatment required during rolling;

[0061] (4) Subsequent standard heat treatment:

[0062] (a) Recrystallization annealing: keep warm at 900°C to 1100°C for 1 hour, then water cool to room temperature;

[0063] (b) Aging treatment: heat preservation at 700° C. to 800° C. for 4 to 50 hours, then water cool to room temperature.

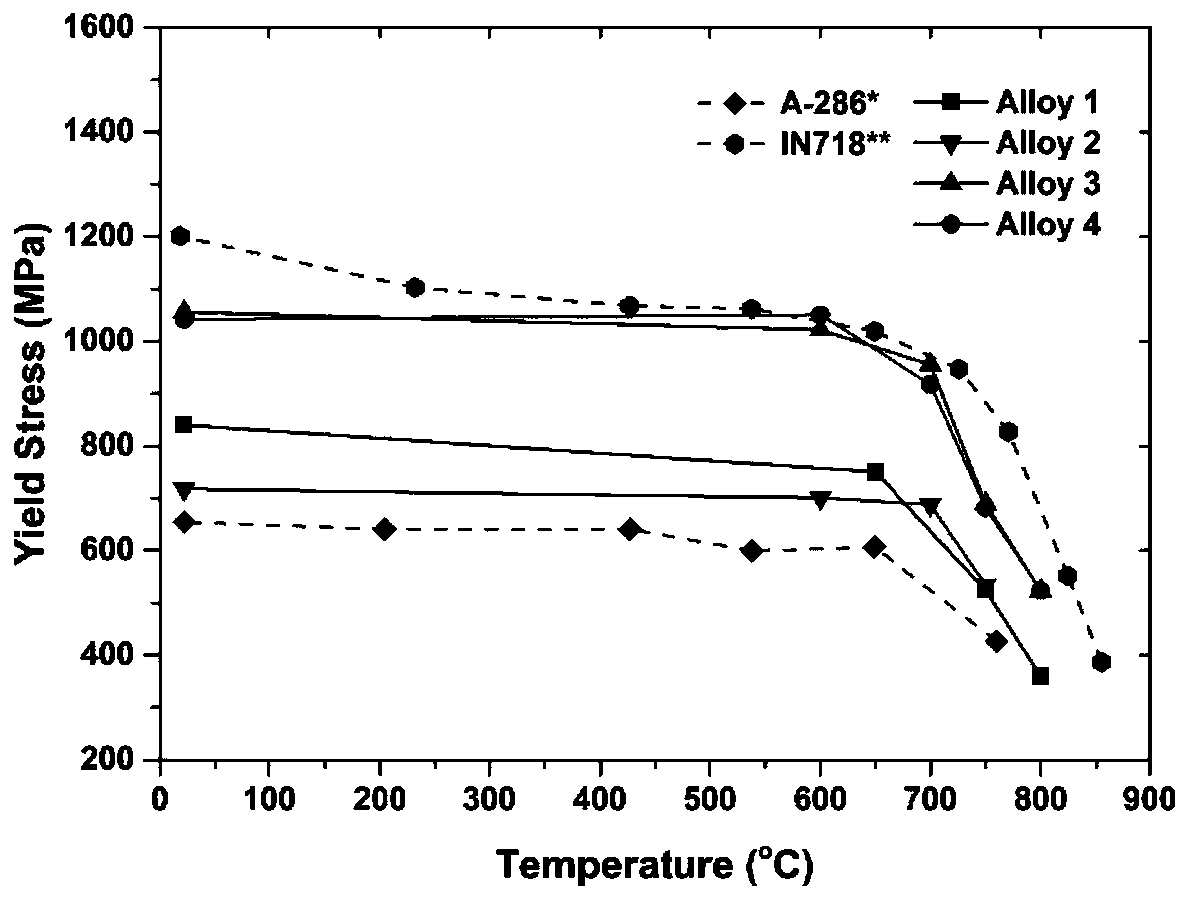

[0064] Taking iron-based alloy A-286 and nickel-based s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com