Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Avoid local deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photothermographic recording material coatable from an aqueous medium

InactiveUS6143488AImprove imaging effectImprove stabilityRadiation applicationsPhotothermographic systemsSilver iodideWater dispersible

A process for producing a photothermographic recording material having a support and a photo-addressable thermally developable element containing photosensitive silver halide in catalytic association with a substantially light-insensitive silver salt of an organic carboxylic acid, an organic reducing agent for the substantially light-insensitive silver salt of an organic carboxylic acid in thermal working relationship therewith and a binder including a water-soluble binder, a water-dispersible binder or a mixture of a water-soluble binder and a water-dispersible binder, comprising the steps of: (i) producing an aqueous dispersion or aqueous dispersions containing photosensitive silver halide, a substantially light-insensitive silver salt of an organic carboxylic acid, an organic reducing agent for the substantially light-insensitive silver salt of an organic carboxylic acid and a binder including a water-soluble binder, a water-dispersible binder or a mixture of a water-soluble binder and a water-dispersible binder; (ii) coating the aqueous dispersion or aqueous dispersions onto a support thereby forming a photo-addressable thermally developable element on the support, wherein at least 80 mol % of the photosensitive silver halide is silver iodide and the aqueous dispersion further contains or the aqueous dispersions further contain a diazine compound.

Owner:AGFA HEALTHCARE NV

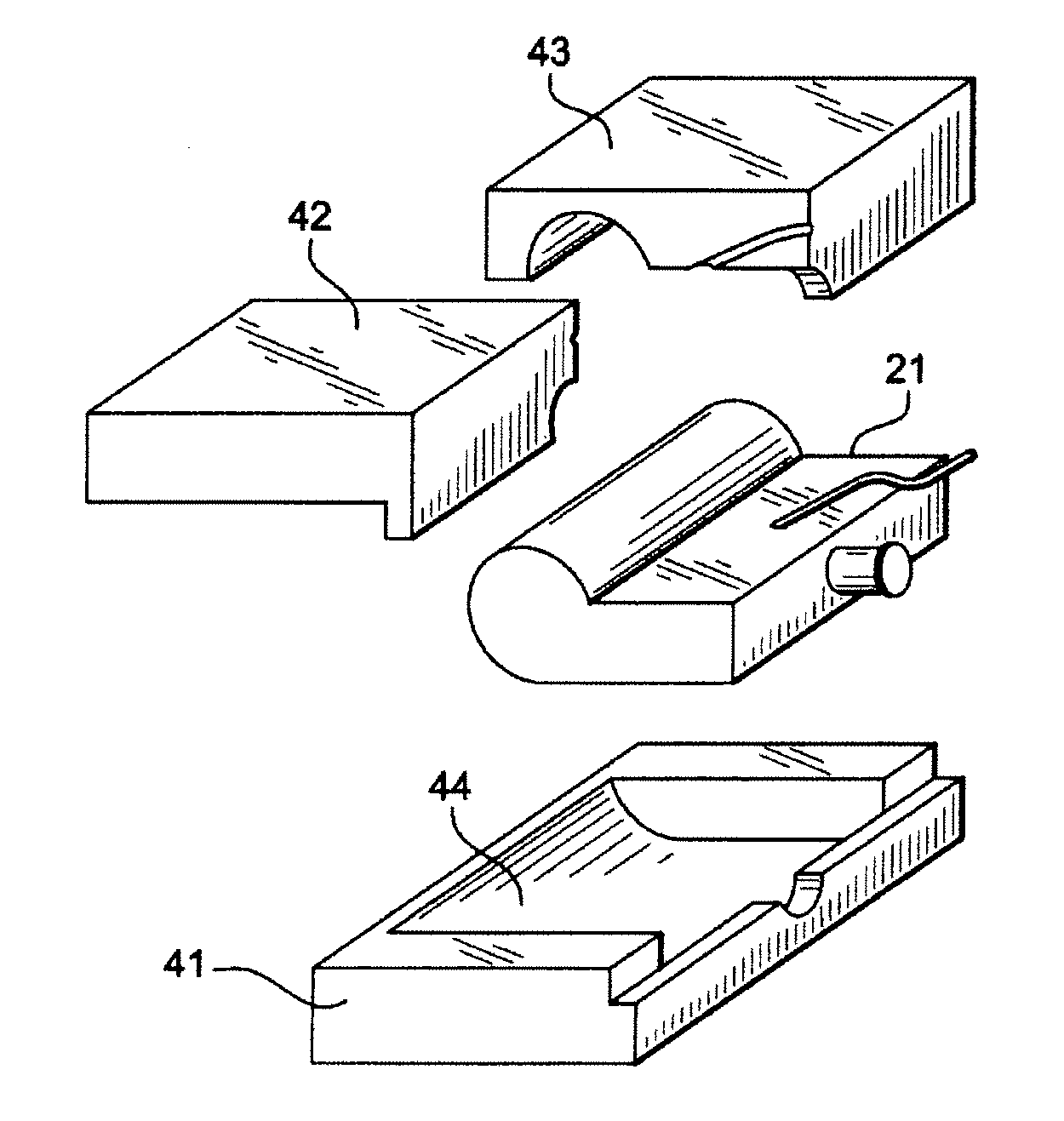

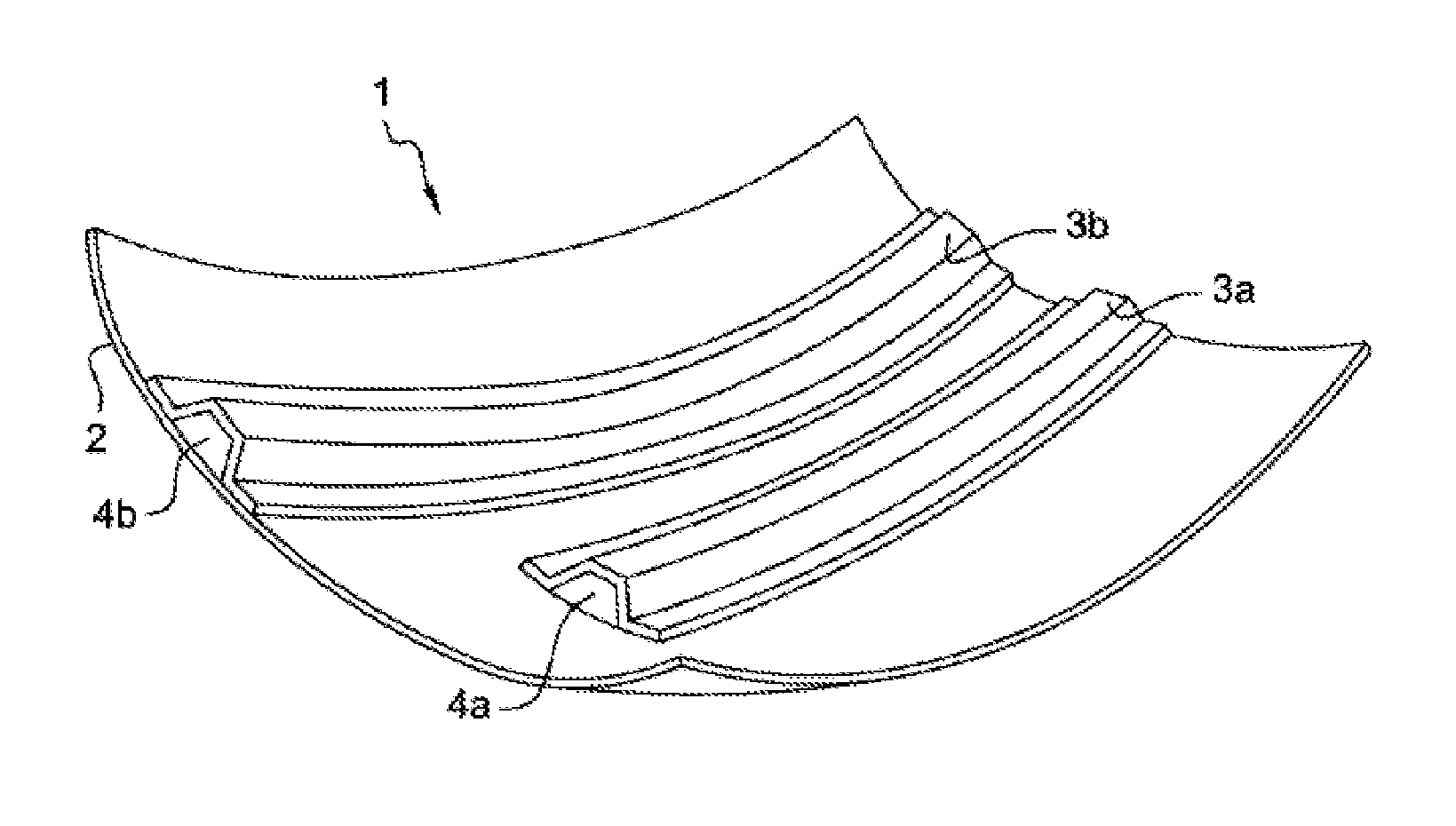

Method for producing structures of complex shapes of composite materials

InactiveUS20090309268A1Easy to controlImprove material stabilityLaminationLamination apparatusControl mannerThermal expansion

A method for producing a composite material part having a so-called non-strippable shape includes producing mold components, or cores, which are to be extracted from the part after the composite material has been cured. In a first step a core is produced from an elastomeric bladder the granular solid material and the bladder is depressurized. In a second step, after setting the core and the composite material the volume of the core is modified in a controlled manner for example by selecting the solid granular material based on its thermal expansion properties or by acting on the pressure in the bladder.

Owner:EADS FRANCE

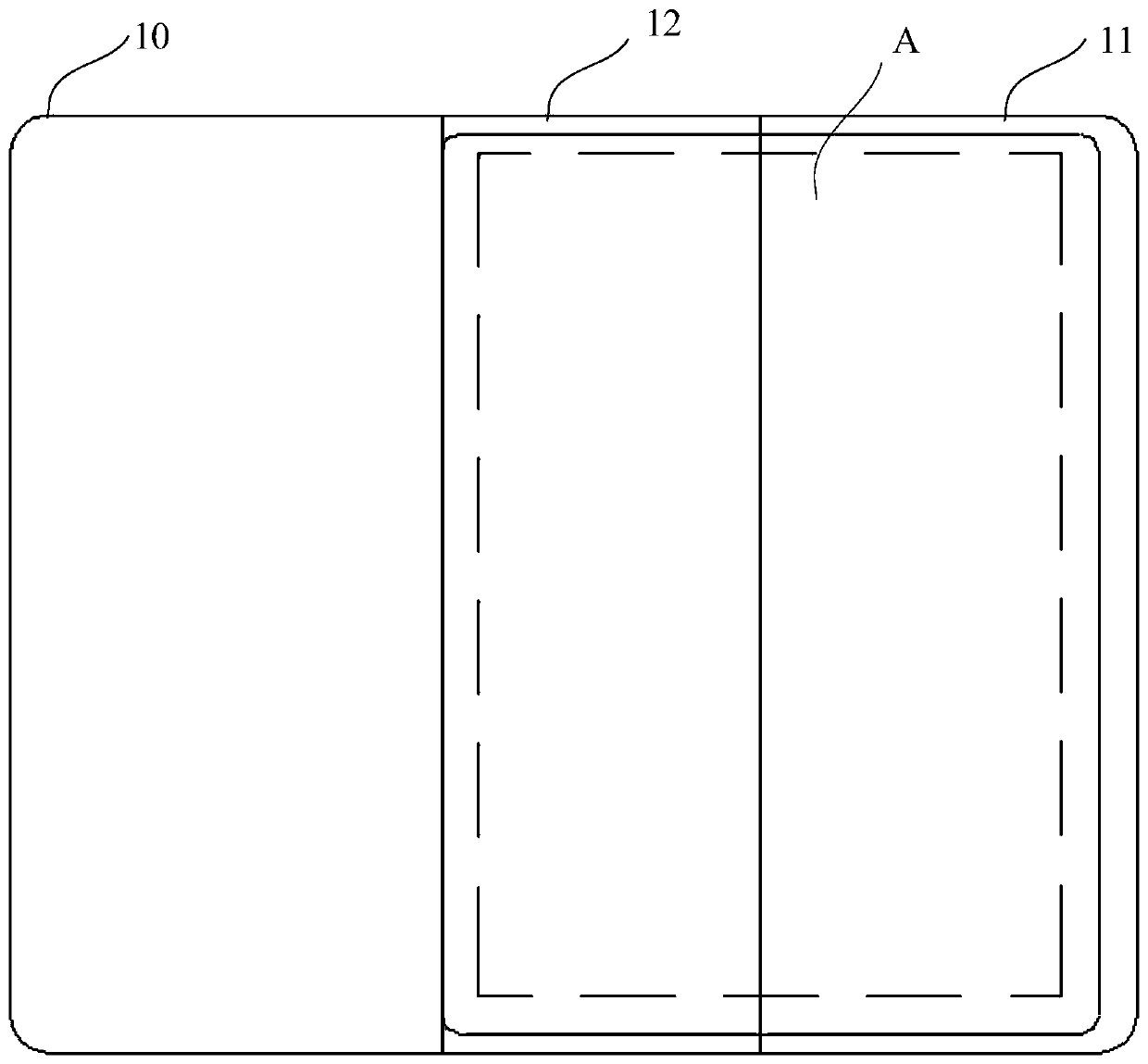

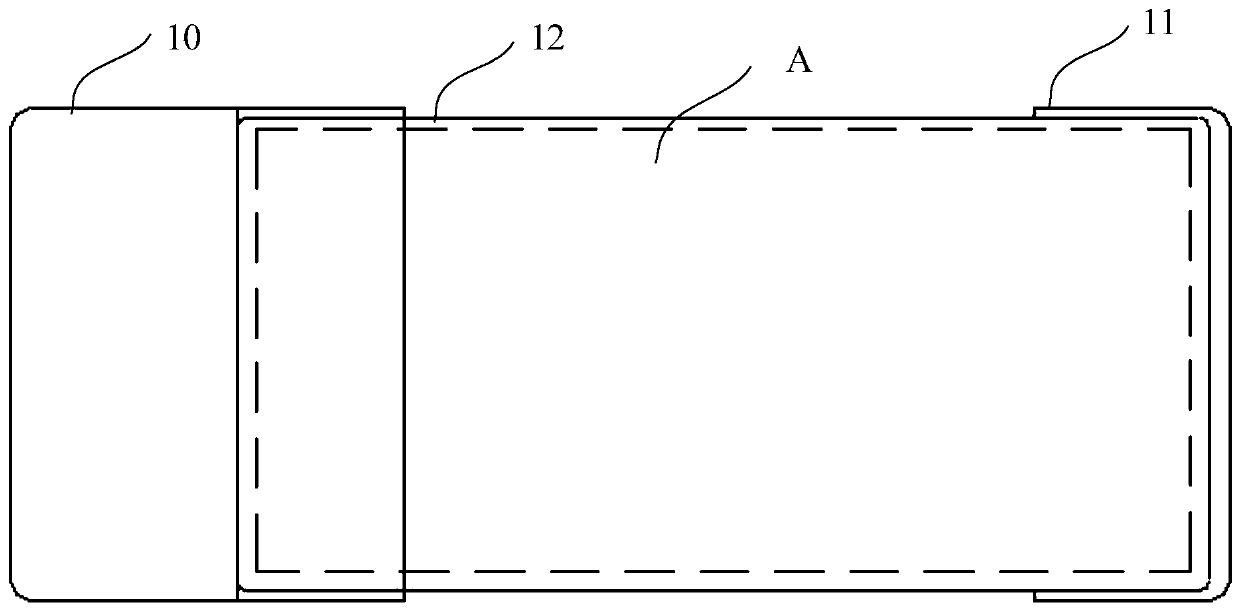

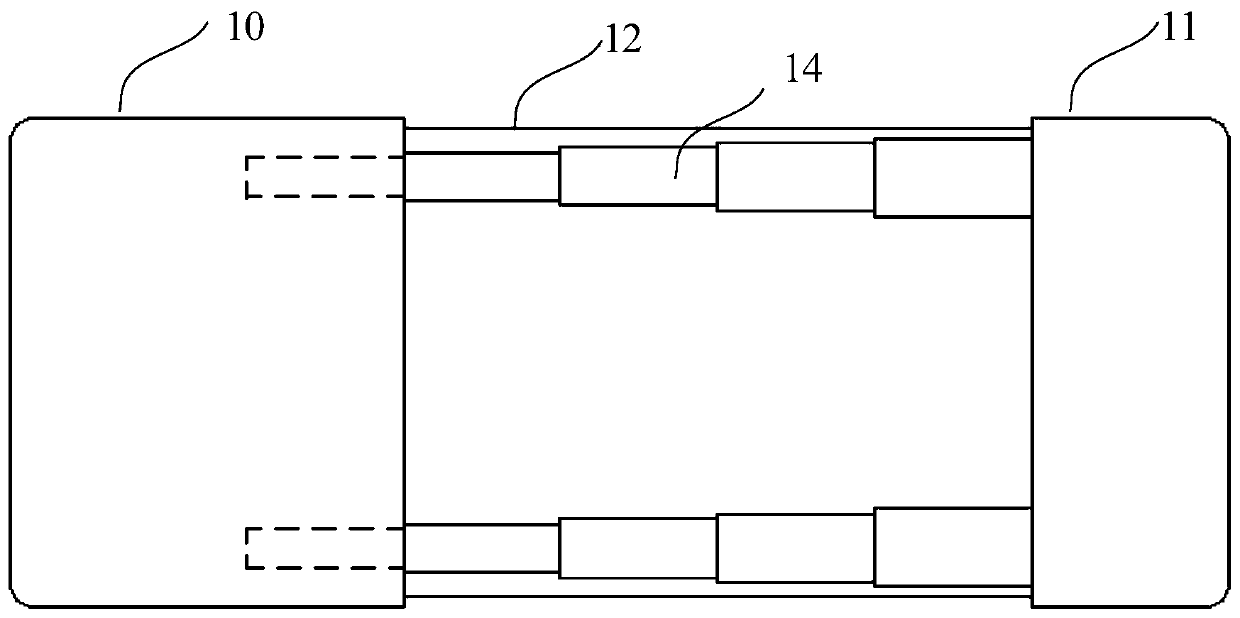

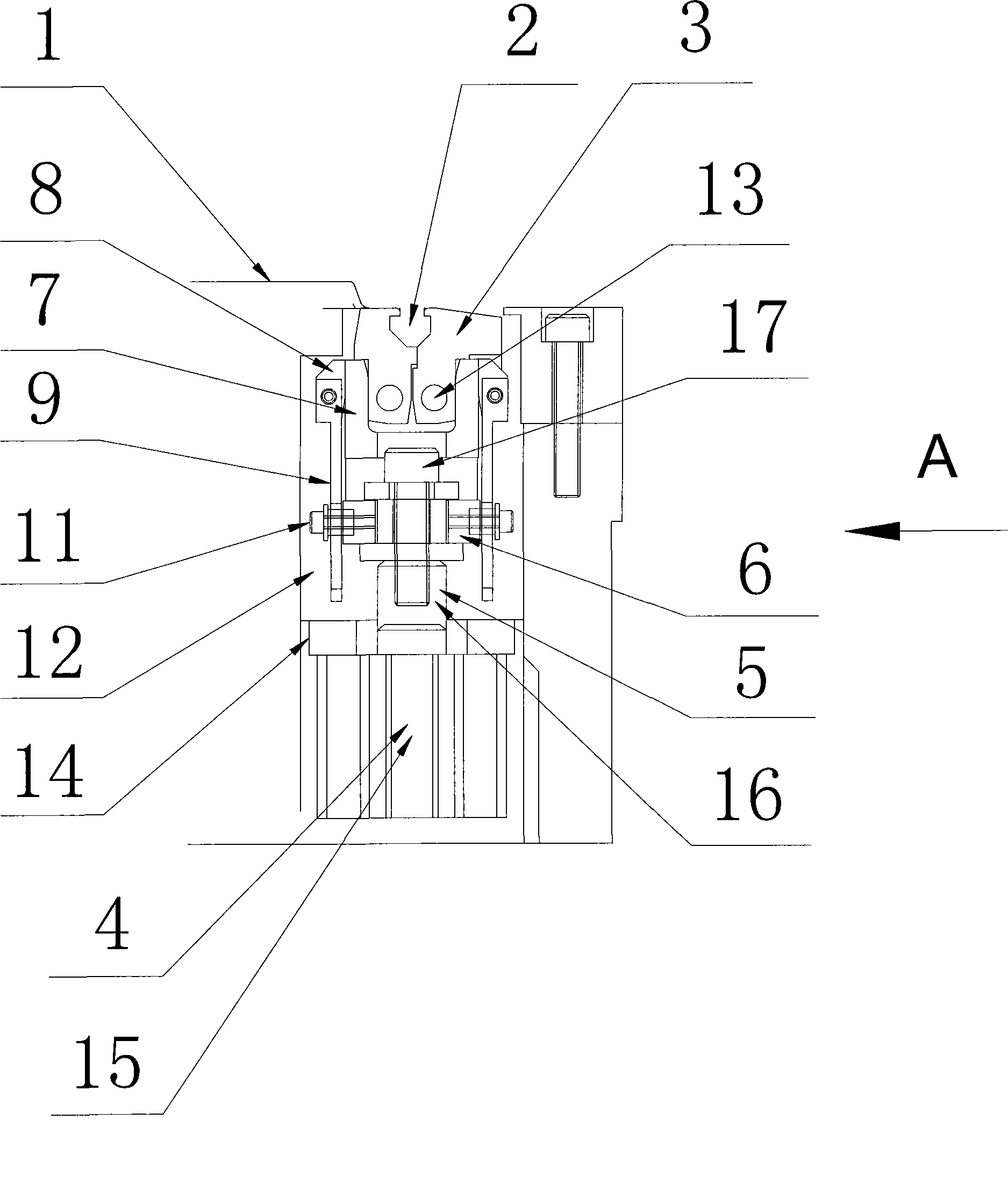

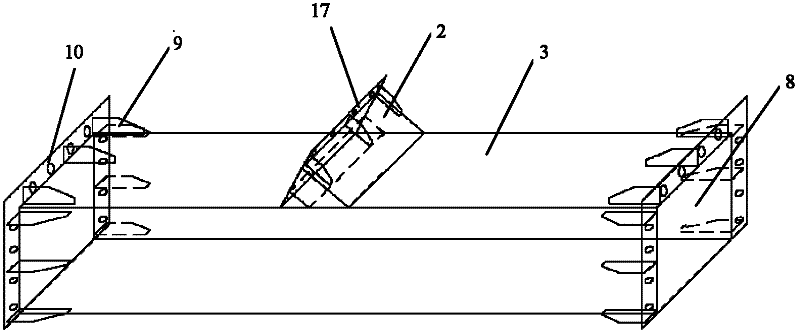

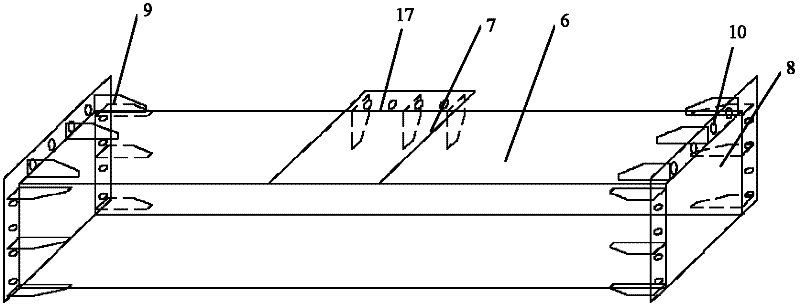

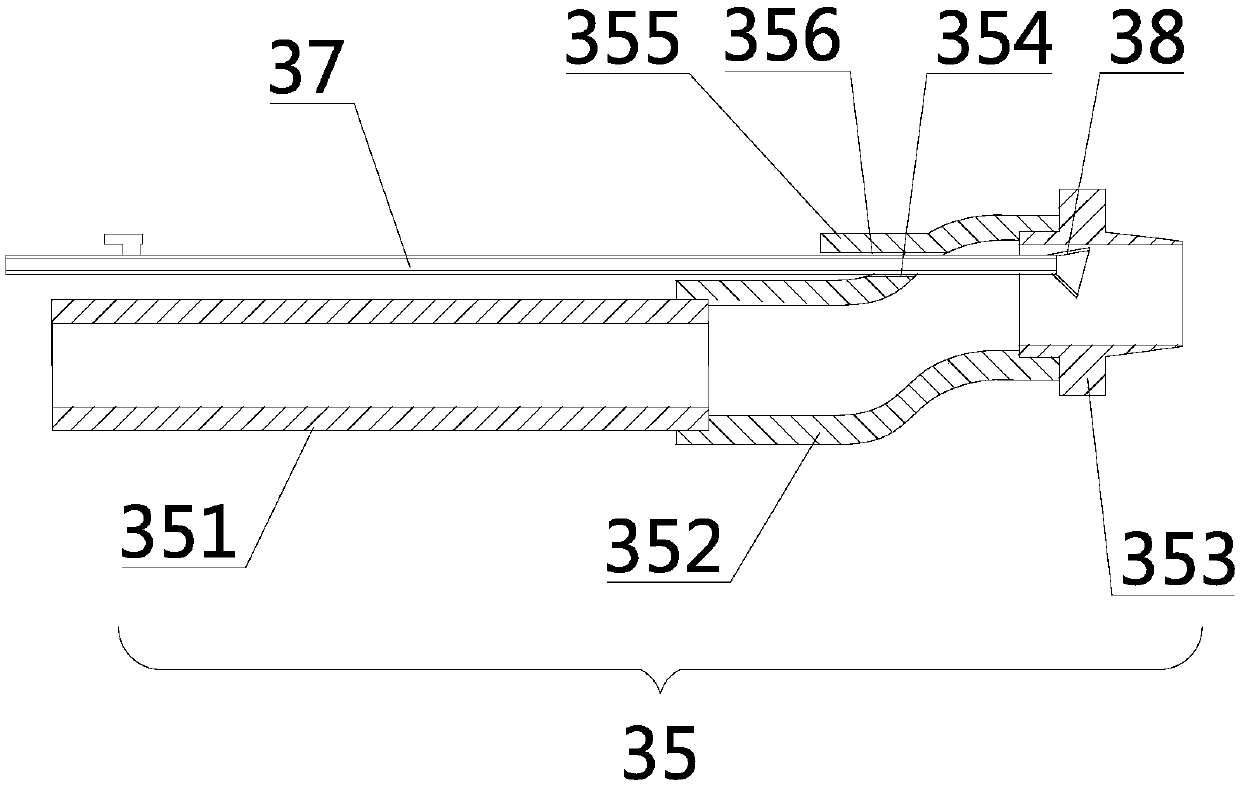

Display device and electronic equipment

ActiveCN111599278AImprove support strengthAvoid local deformationDigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceElectronic equipment

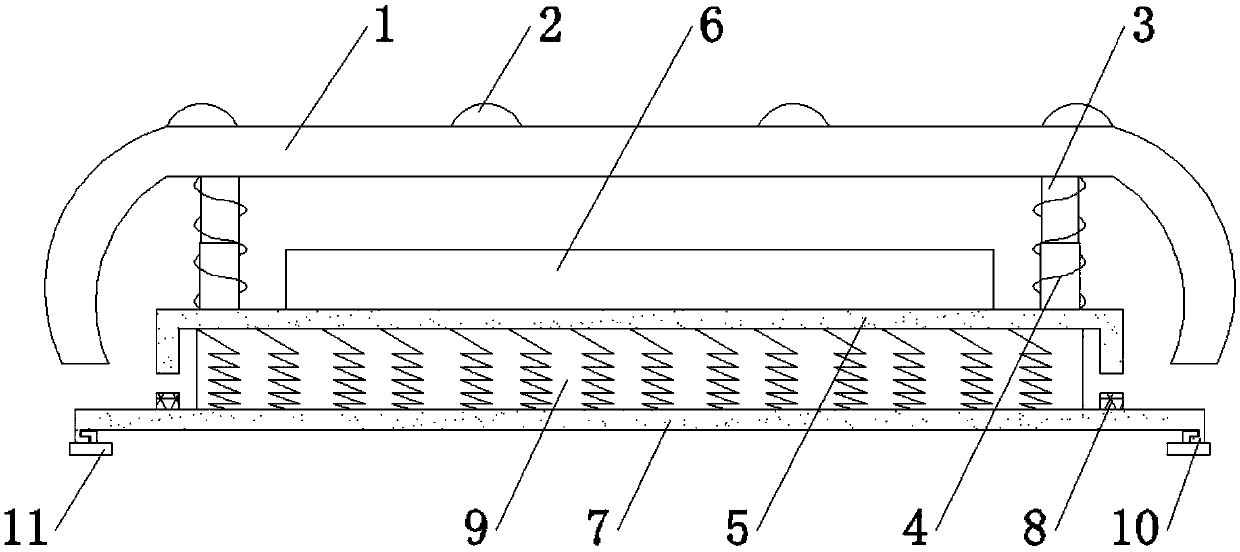

The invention provides a display device and electronic equipment. The display device comprises a first shell, a second shell, a flexible screen, a supporting belt and a telescopic rod. The first shelland the second shell are oppositely arranged, an opening is formed in the position, opposite to the second shell, of the first shell, one end of the flexible screen is rolled in the first shell, andthe other end of the flexible screen extends out of the opening and is fixed to the second shell, one end of the supporting belt is rolled in the first shell, the other end of the supporting belt extends out of the opening and is fixed to the second shell, and the part, extending out of the first shell, of the supporting belt is attached to the bottom of the flexible screen, the telescopic rod isarranged at the bottom of the supporting belt, one end of the telescopic rod is fixed to the first shell, and the other end of the telescopic rod is fixed to the second shell. In the embodiment of theinvention, the supporting rod and the supporting belt can be used for supporting the flexible screen, local deformation of the flexible screen is avoided, and touch operation on the flexible screen is facilitated.

Owner:BOE TECH GRP CO LTD

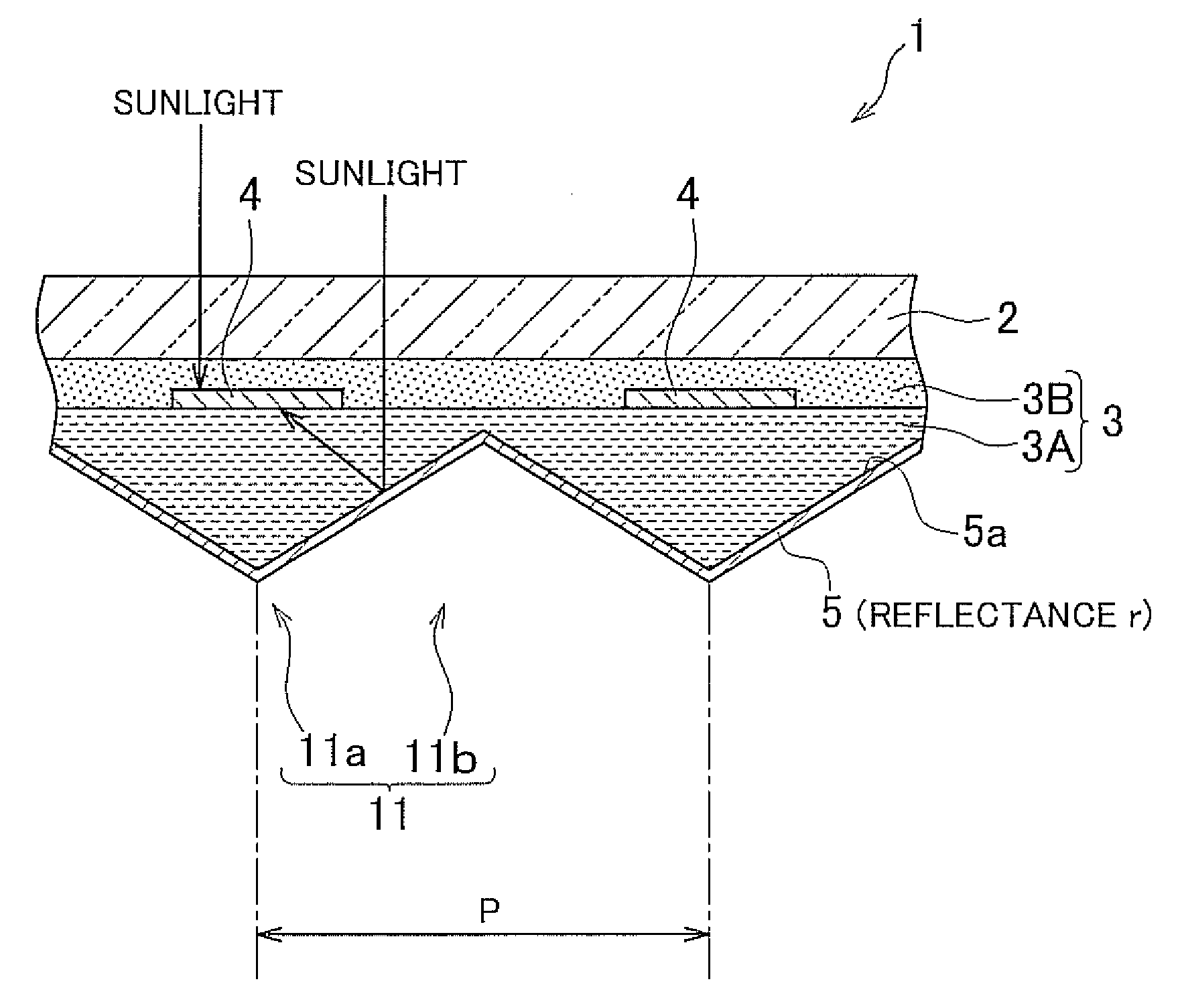

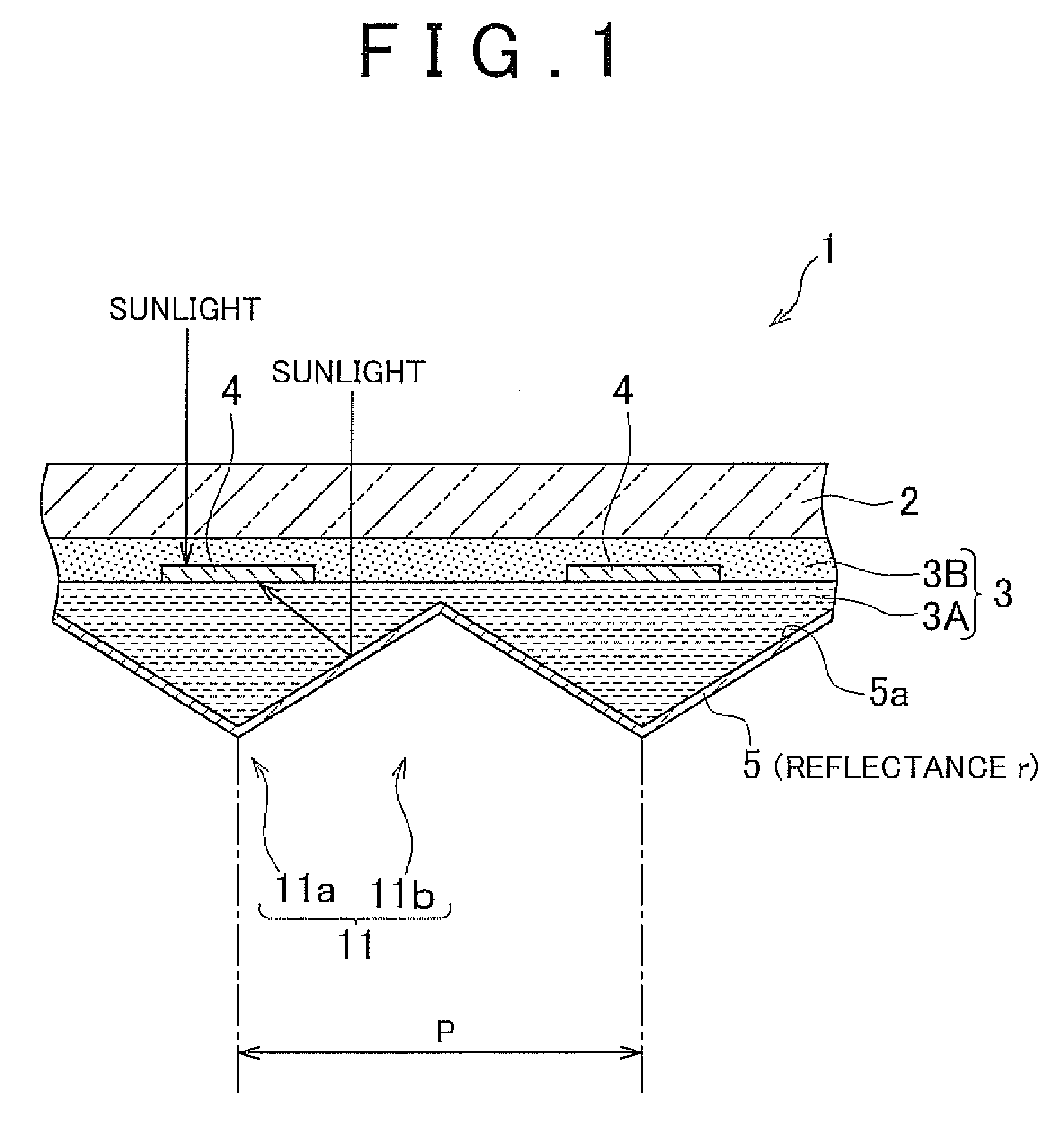

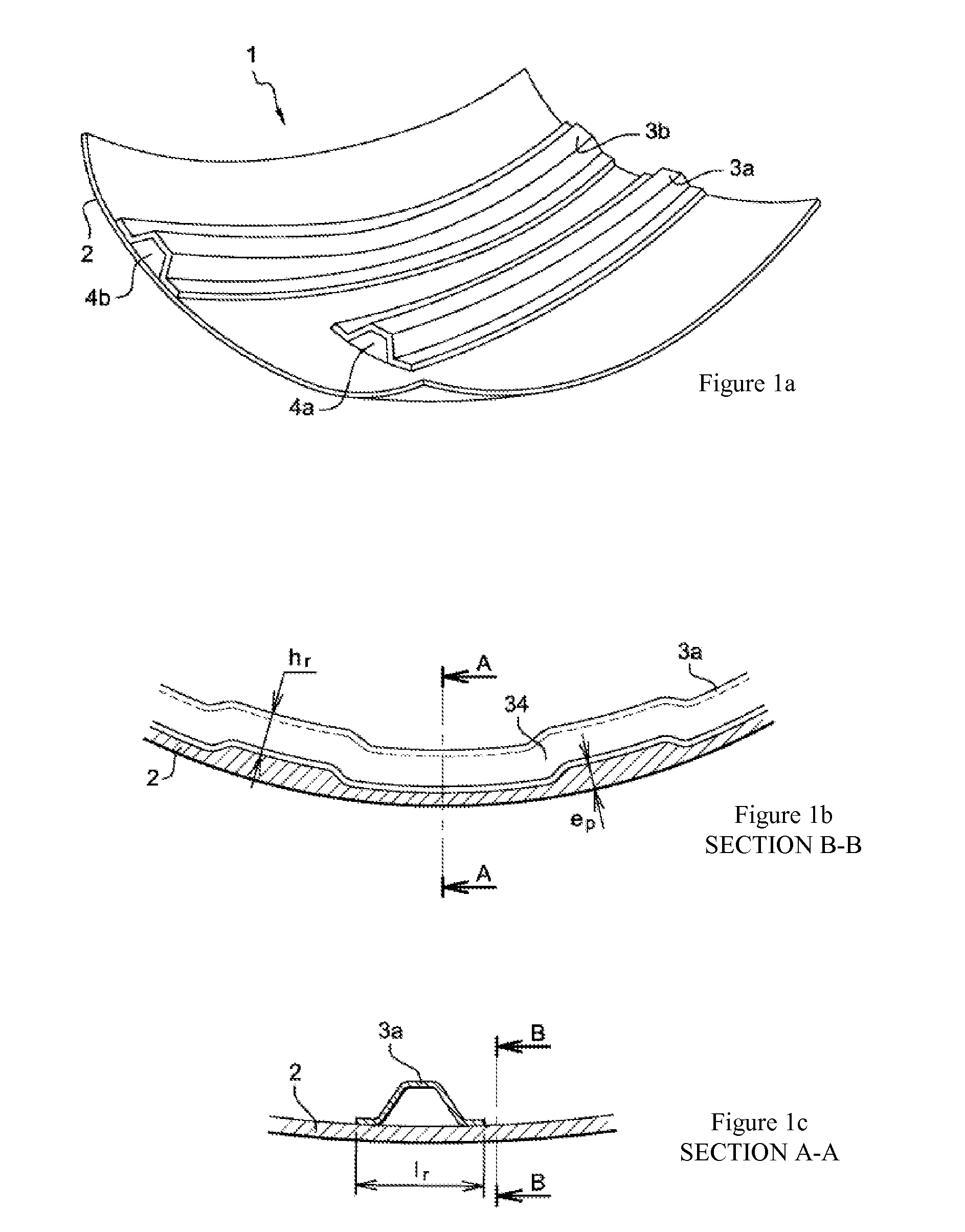

Solar cell module

InactiveUS20100252107A1Maintaining long-term reliabilityReduce lossesPhotovoltaic supportsPhotovoltaic energy generationEngineeringSolar cell

A solar cell module includes: a reflector; a encapsulant that includes a first corrugated portion that corresponds to a corrugated shape of the reflector; and a solar cell that is encapsulated in the encapsulant, wherein the encapsulant is fixed to the reflector and the solar cell; and at least one of a surface of the encapsulant fixed to the reflector and a surface of the encapsulant fixed to the solar cell is provided with a second corrugated portion that has a smaller protrusion than a protrusion of the first corrugated portion.

Owner:TOYOTA JIDOSHA KK

Method of producing stiffened panels made of a composite and panels thus produced

InactiveUS20090309264A1Increase pressureImprove temperature uniformityEfficient propulsion technologiesWood working apparatusFiberShell molding

A stiffened panel made of a composite includes a skin and at least one stiffener having a more or less closed volume. In order for the fibres of the composite to be held in place during fibre deposition and during pressure application while the resin of the composite is being cured, a moulding core is placed between the fibres at the position of the more or less closed volume of the stiffener. The moulding core includes a flexible bladder filled with a granular solid material, the thermal expansion coefficient of which is close to that of the composite used to produce the stiffened panel. The pressure in the bladder is increased before the composite is cured, so as to compensate for the forces applied for compressing these fibres during production of the panel.

Owner:EADS FRANCE

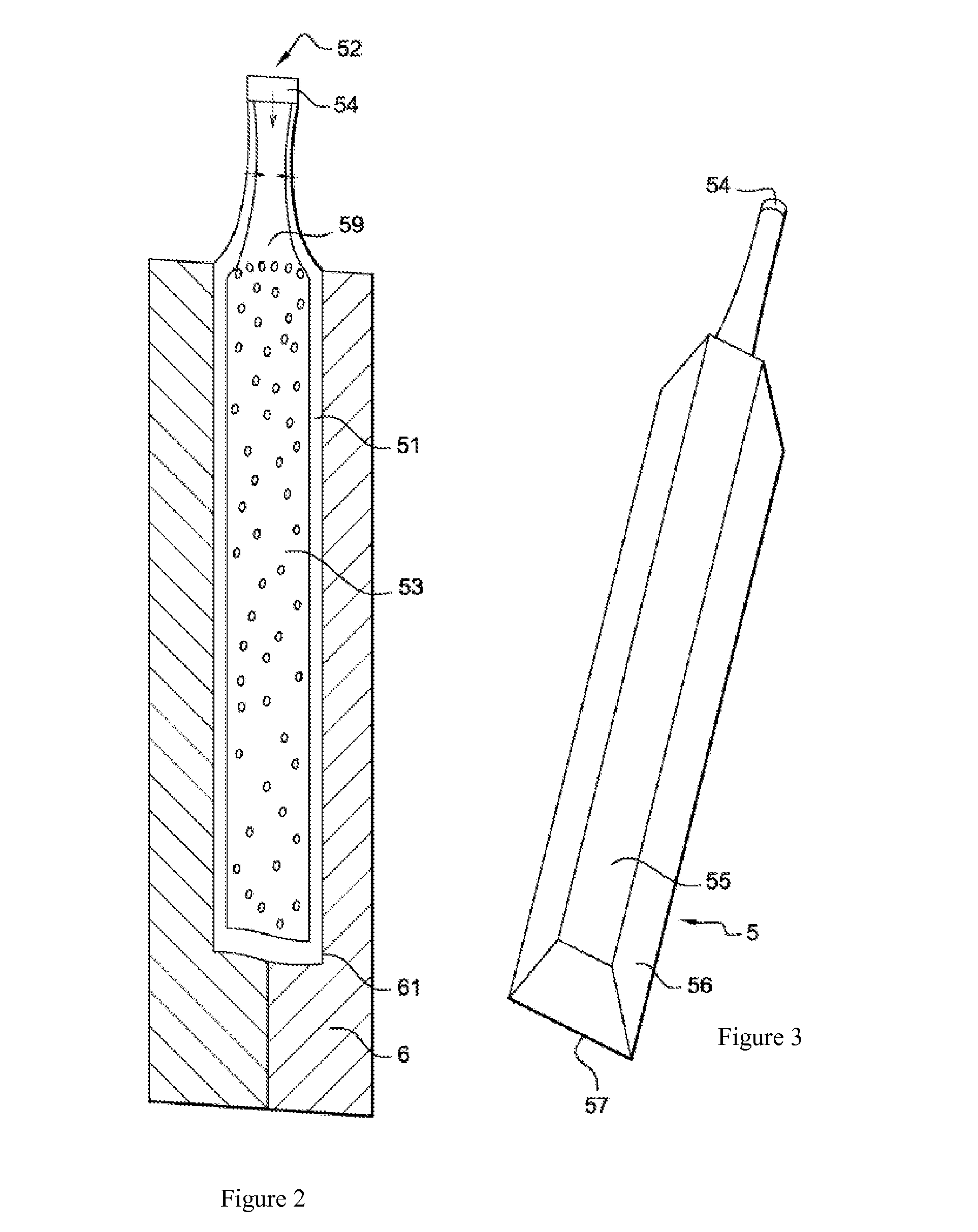

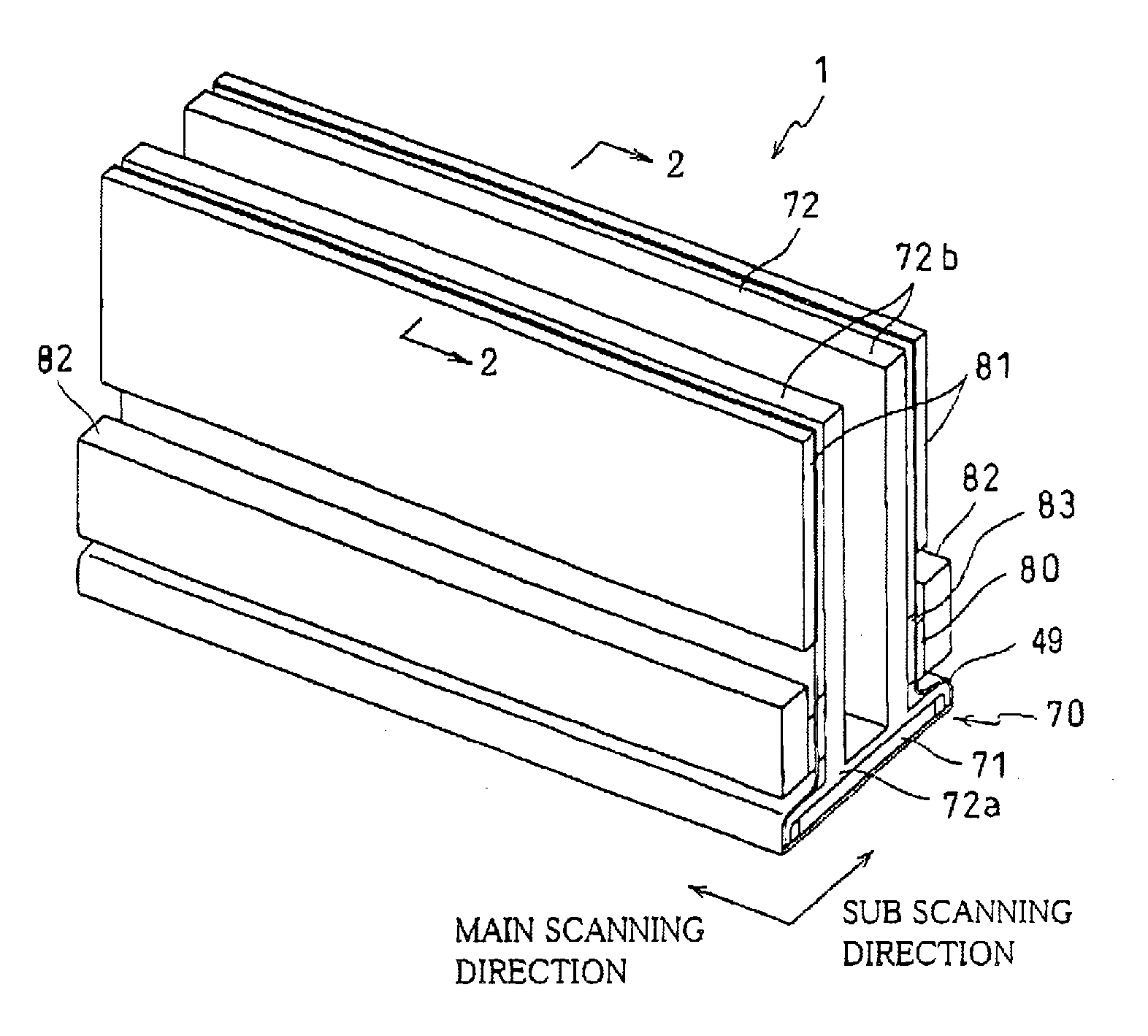

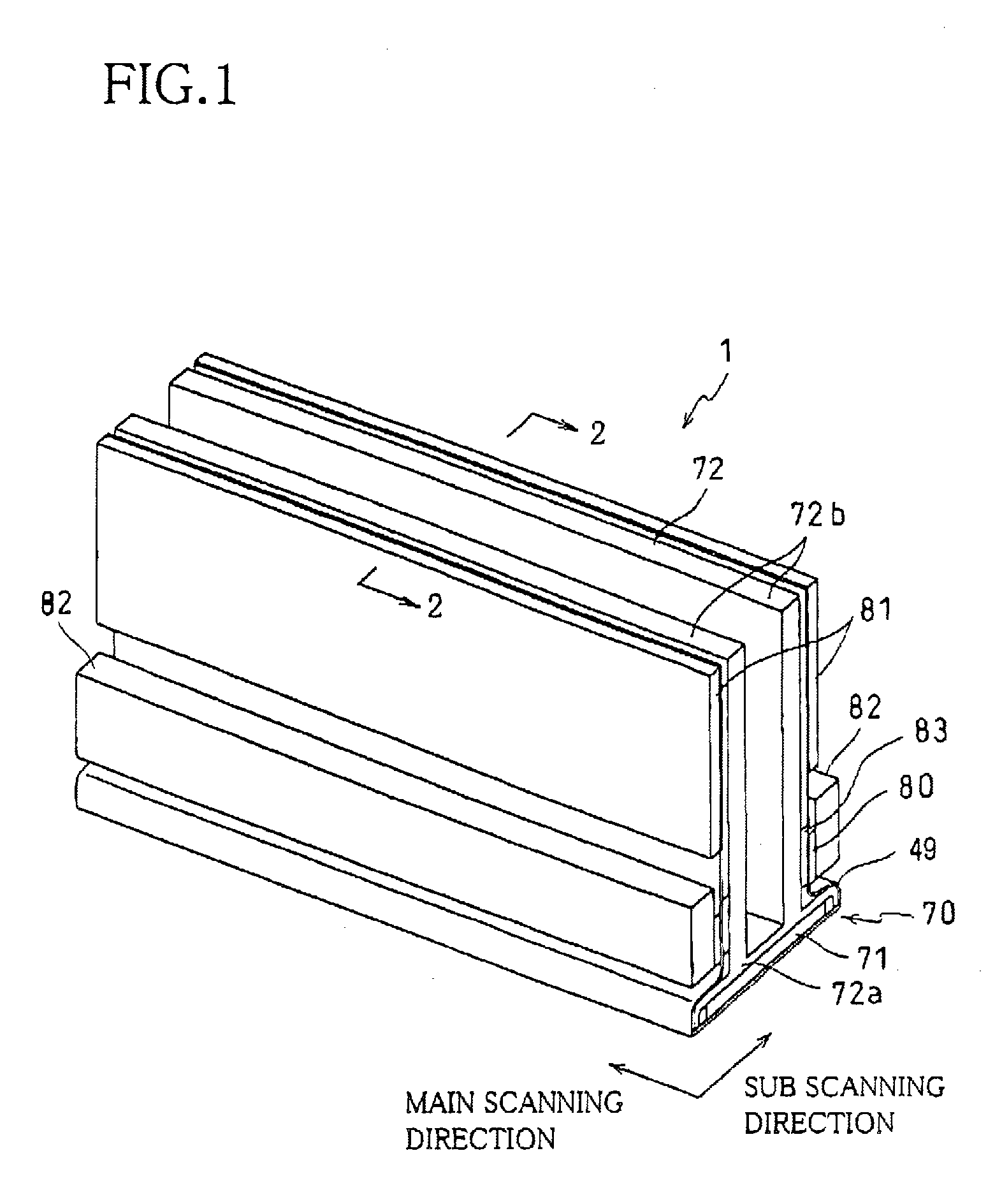

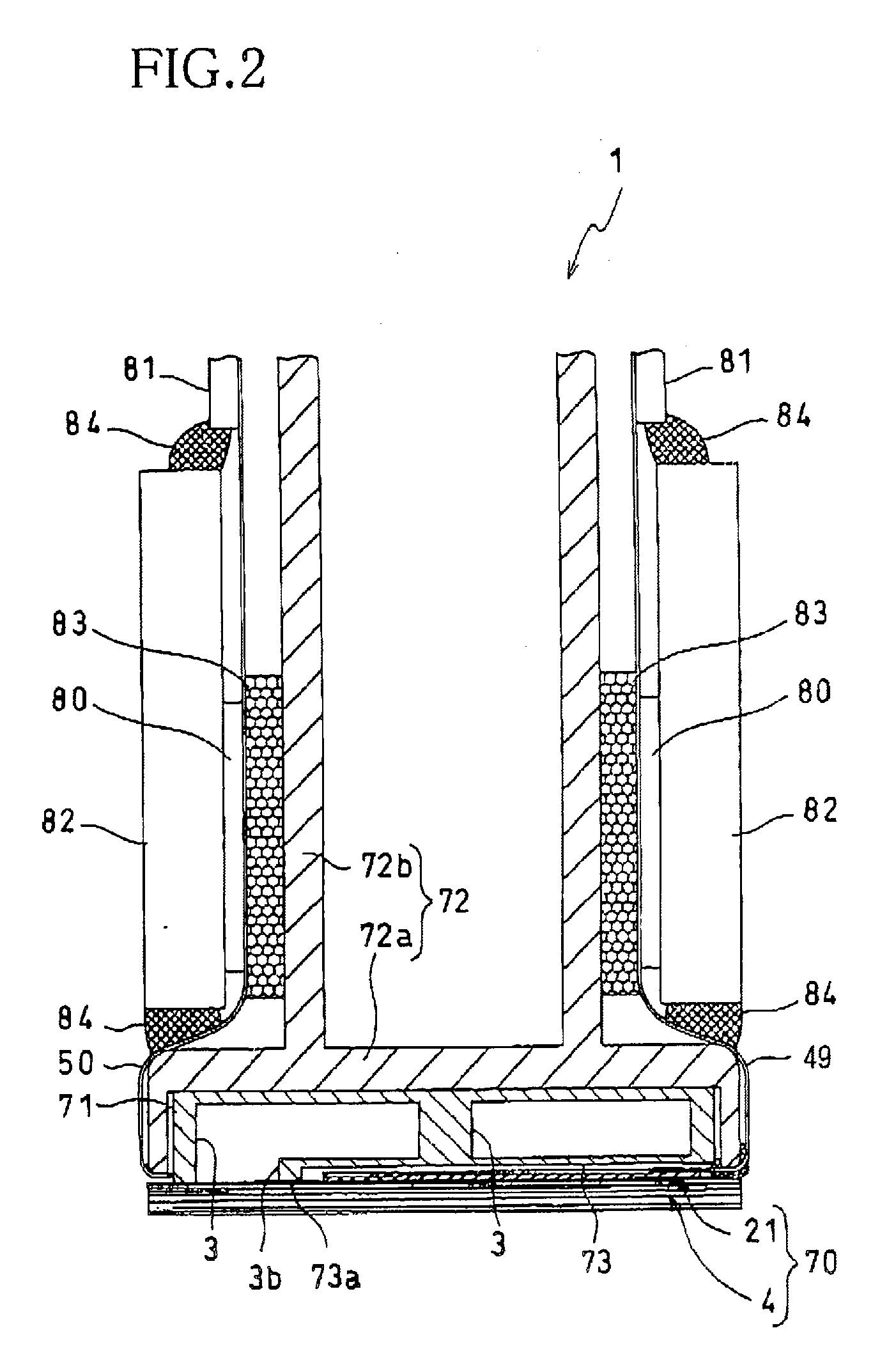

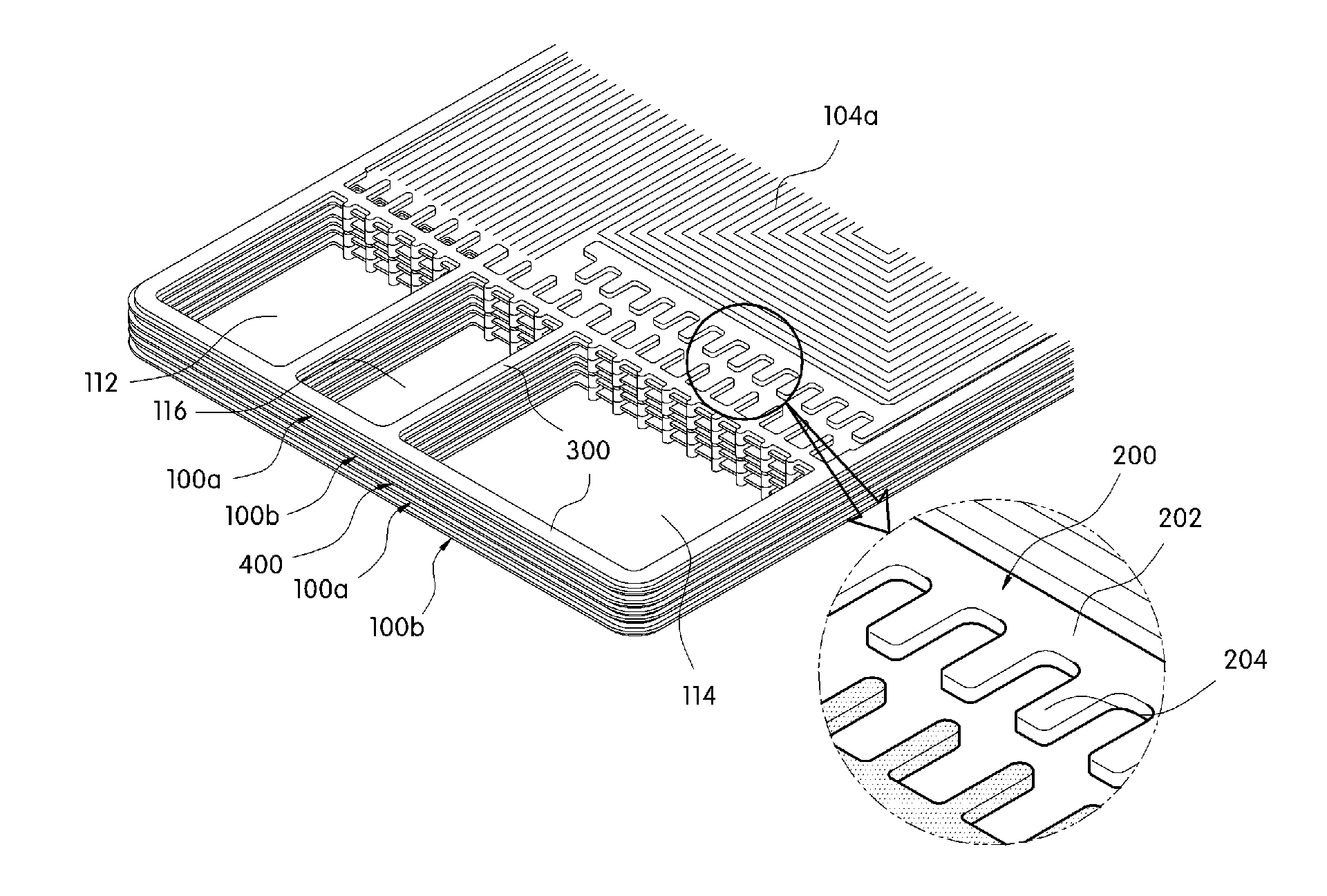

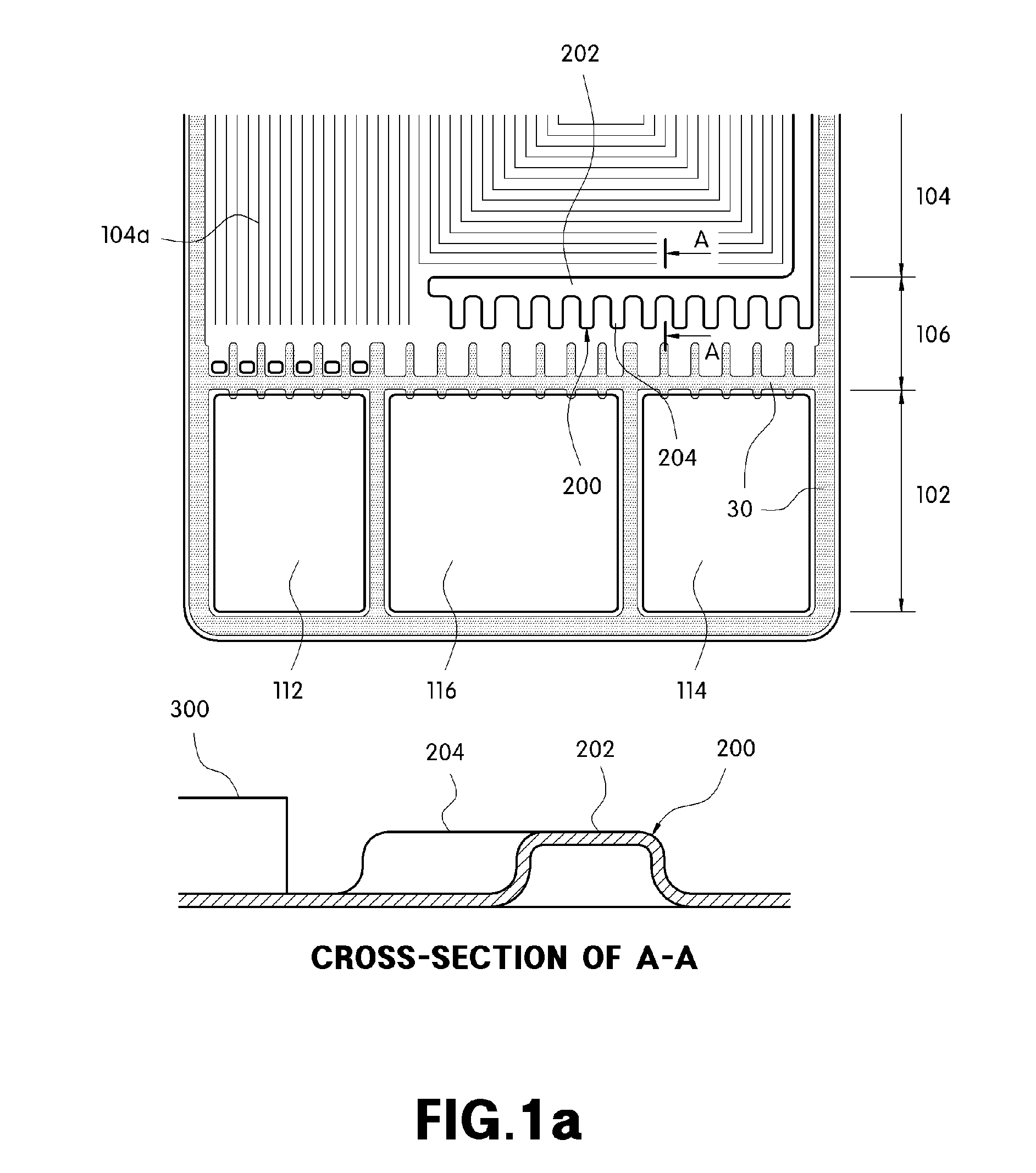

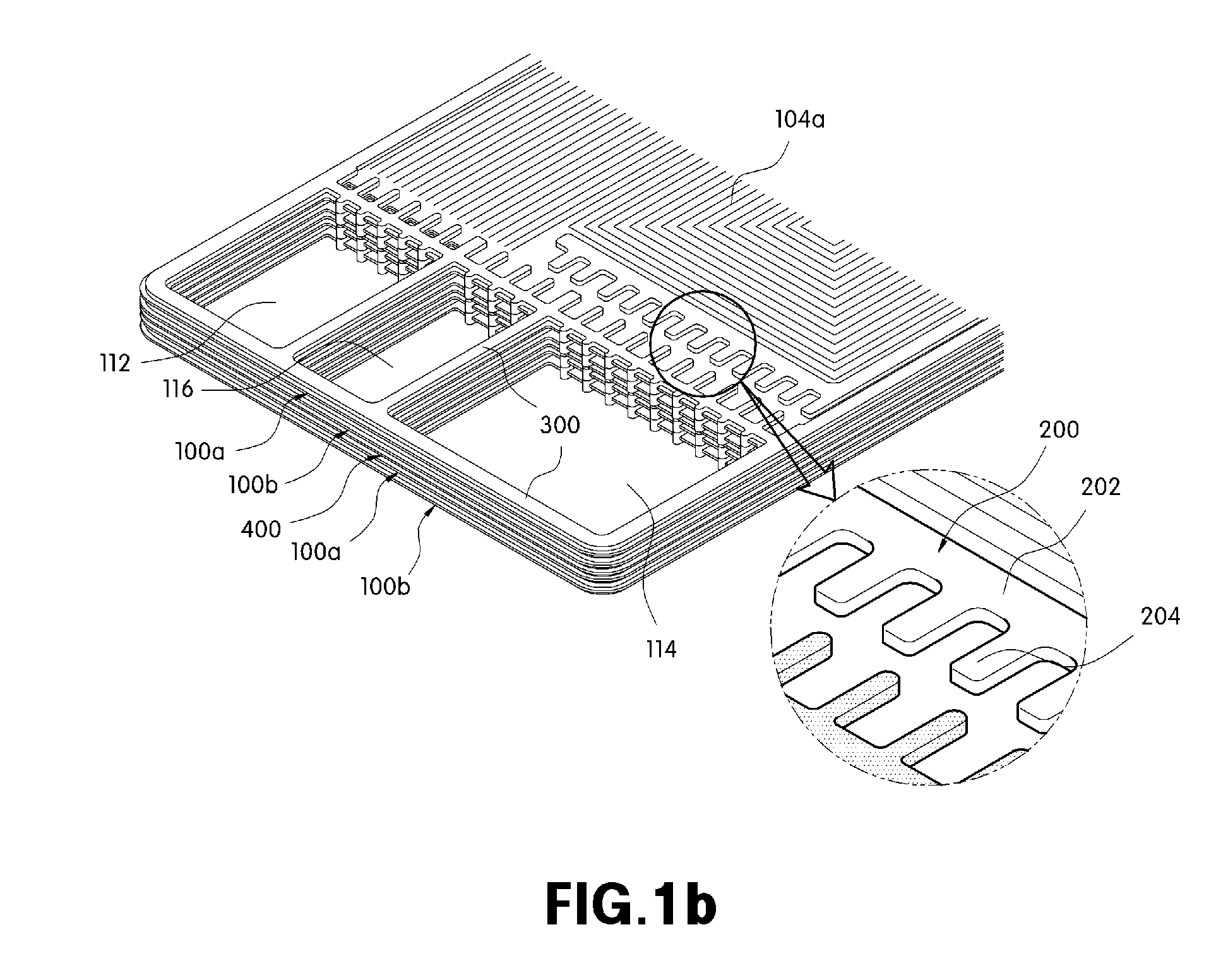

Inkjet Head and Process of Manufacturing the Inkjet Head

ActiveUS20060132551A1Avoid local deformationAvoid failureInking apparatusManufacturing technologyEngineering

An inkjet head including an ink channel unit defining a network of ink channels which provides at least one common ink chamber and a plurality of nozzles held in communication with the at least one common ink chamber. The ink channel unit includes a laminated structure body that is provided by a plurality of metal plates superposed on each other. The laminated structure body has at least the at least one common ink chamber and an atmosphere communication channel which diverges from the network of ink channels. The atmosphere communication channel extends toward an exterior of the laminated structure body, so as to open outside the laminated structure body. The atmosphere communication channel is sealed at its opening. Also disclosed is a process of manufacturing the inkjet head.

Owner:BROTHER KOGYO KK

Preparation method of low heat expansion carbon fiber reinforced resin matrix composite material mold

The invention relates to a preparation method of a low heat expansion carbon fiber reinforced resin matrix composite material mold, belonging to the technical field of composite material preparation. The method is capable of forming a molding surface with a VARI (Vacuum Assisted Resin Infusion) technique, and ensuring low heat expansion performance of the mold by controlling the carbon fiber laying direction, precuring temperature, postcuring manner and postprocessing manner of the molding surface. With the adoption of the VARI technique, when a vacuum pressure reaches to 0.1MPa, carbon fiber cloth is compressed by vacuum, so that the product is internally dense after resin is guided in the product, and the volume content of composite material fibers is ensured; and meanwhile, bubbles between carbon fiber cloth layers are removed so as to ensure that the content of internal pores of the composite material is as few as possible and ensure the strength of the composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

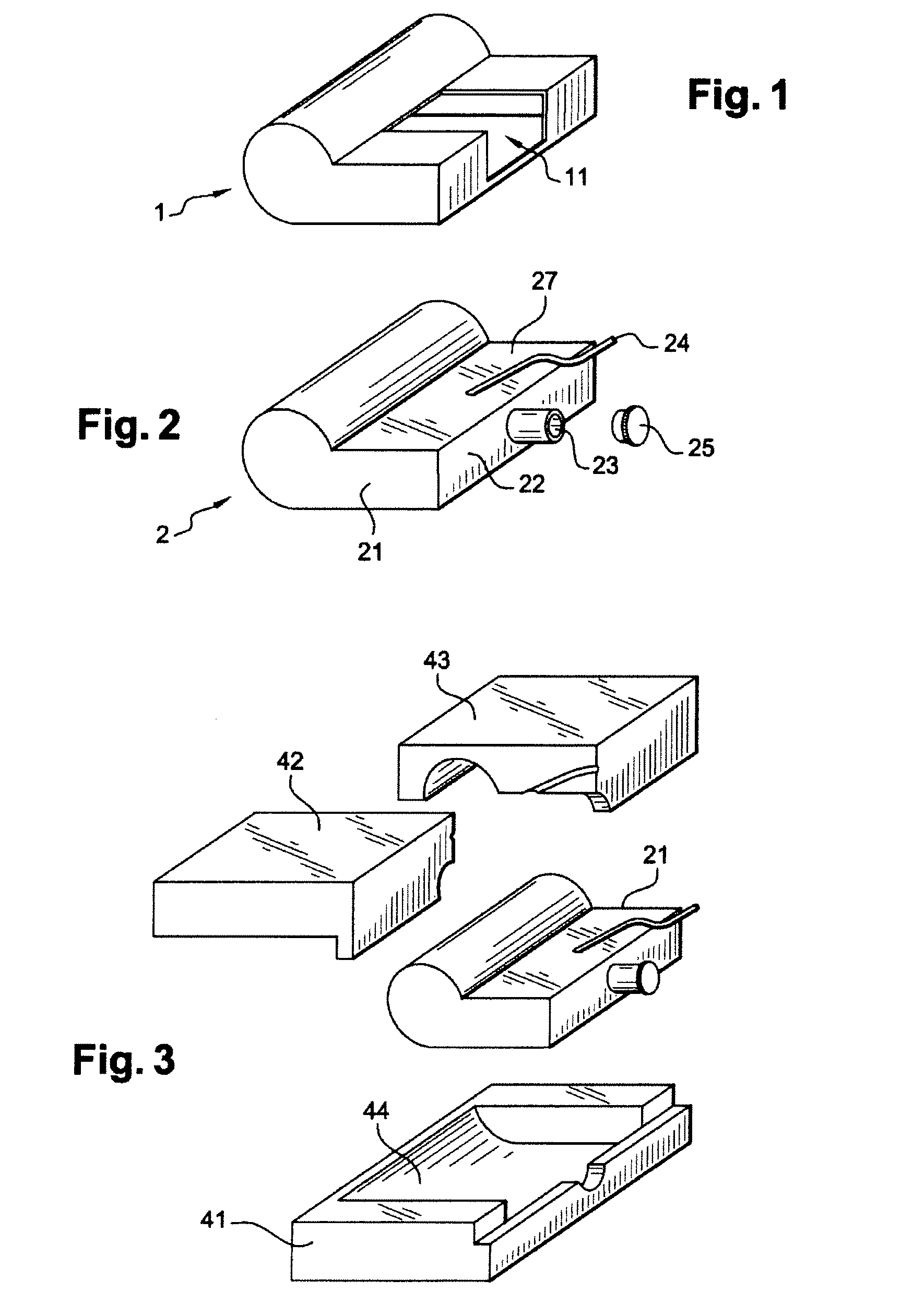

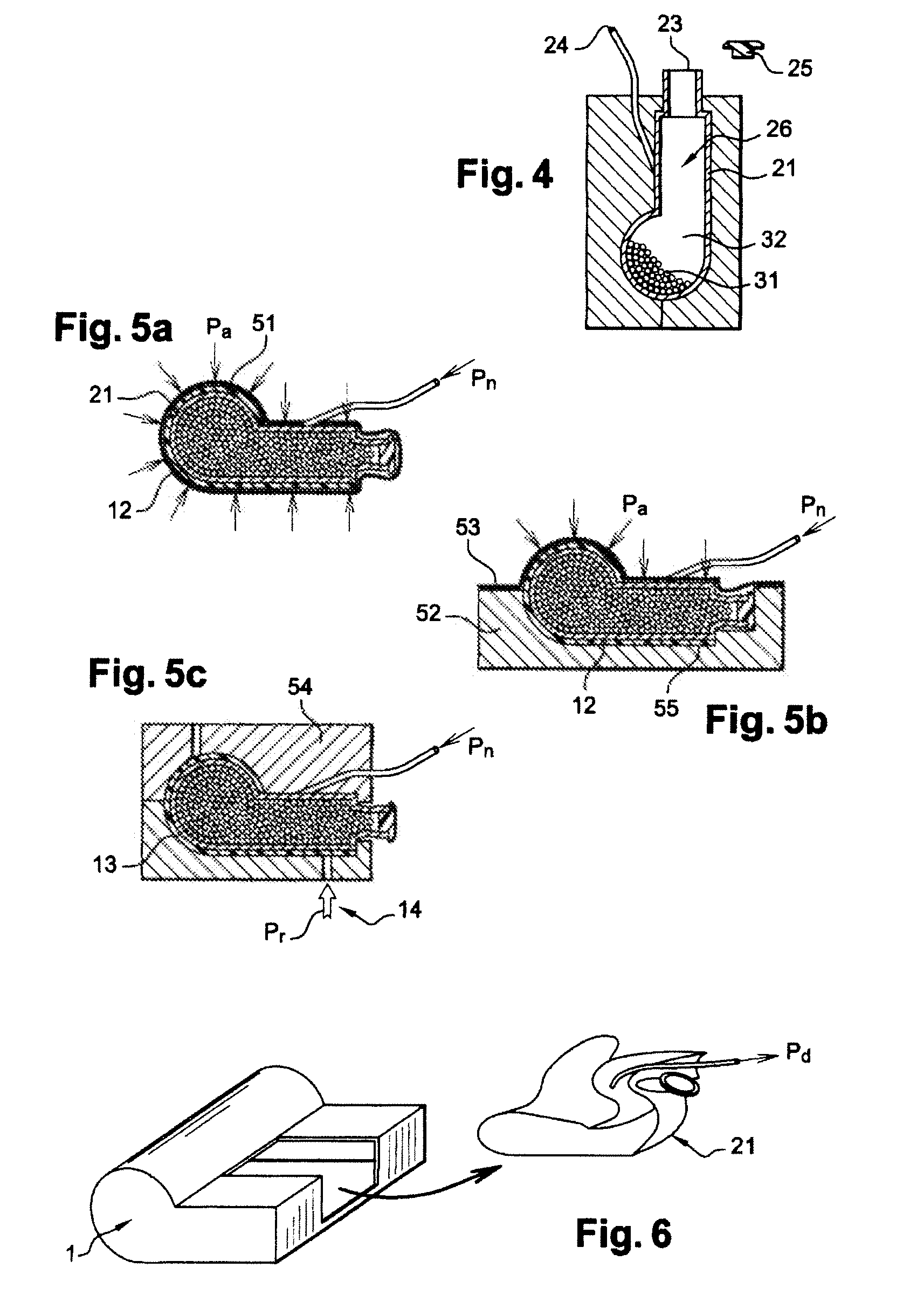

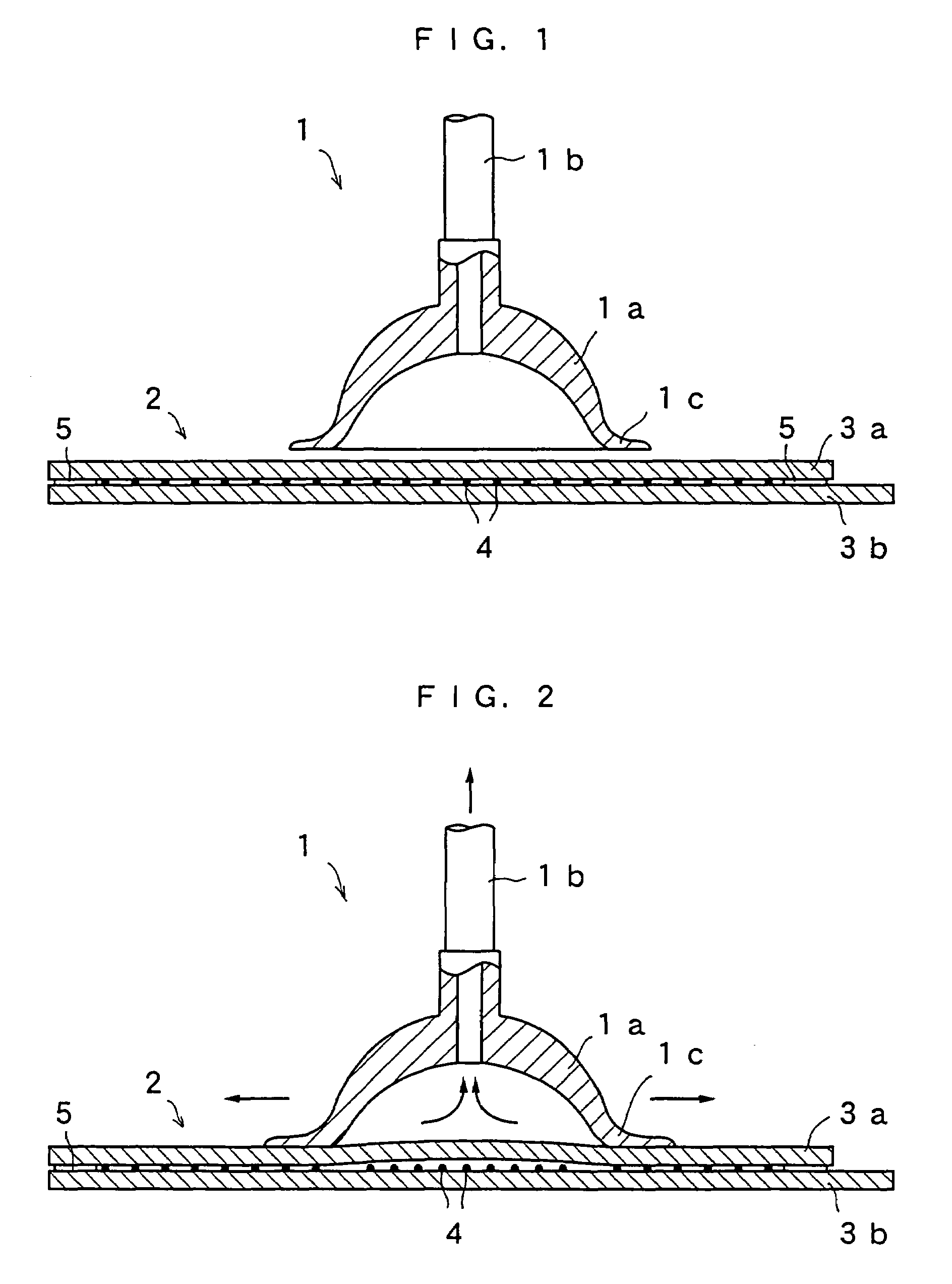

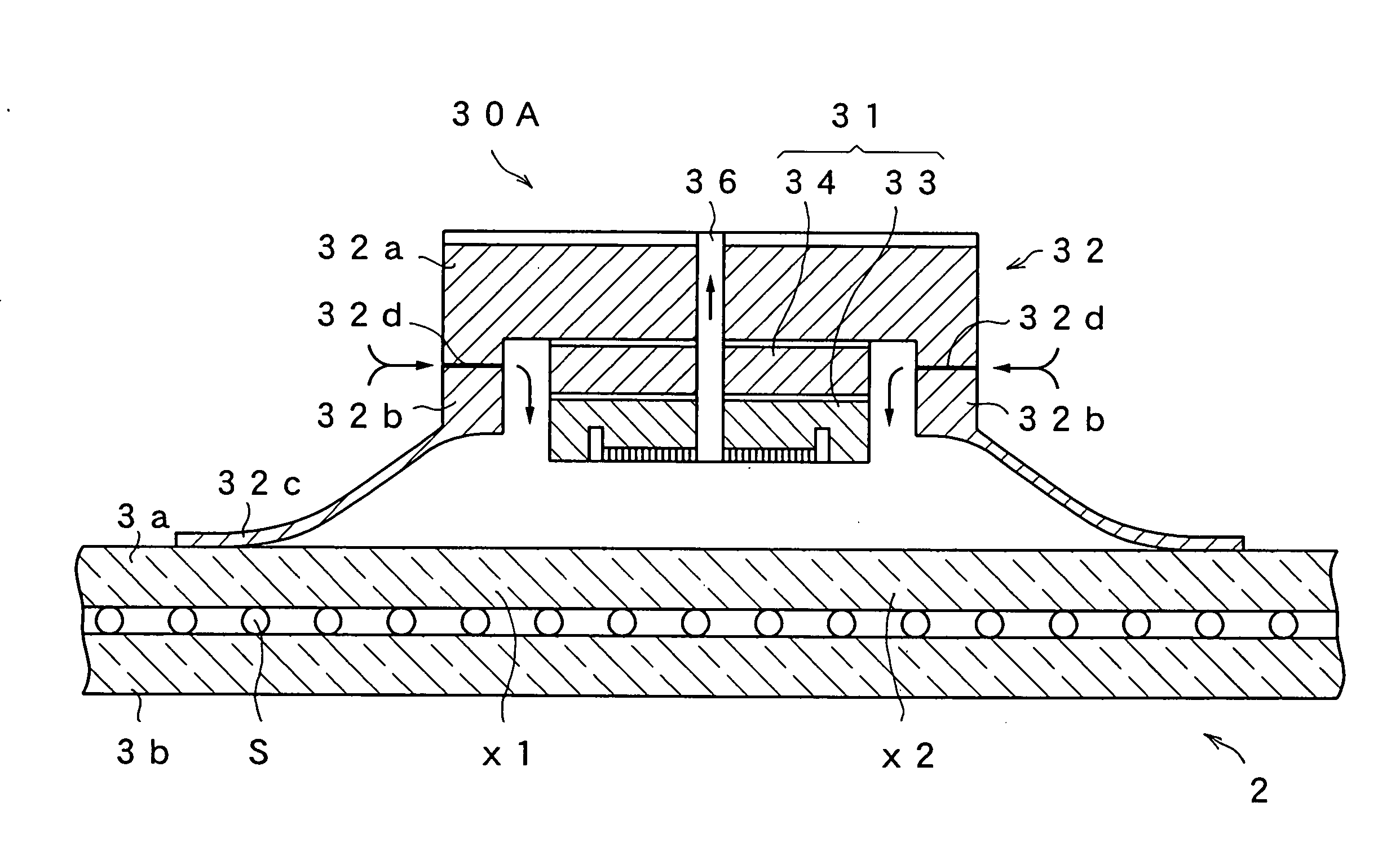

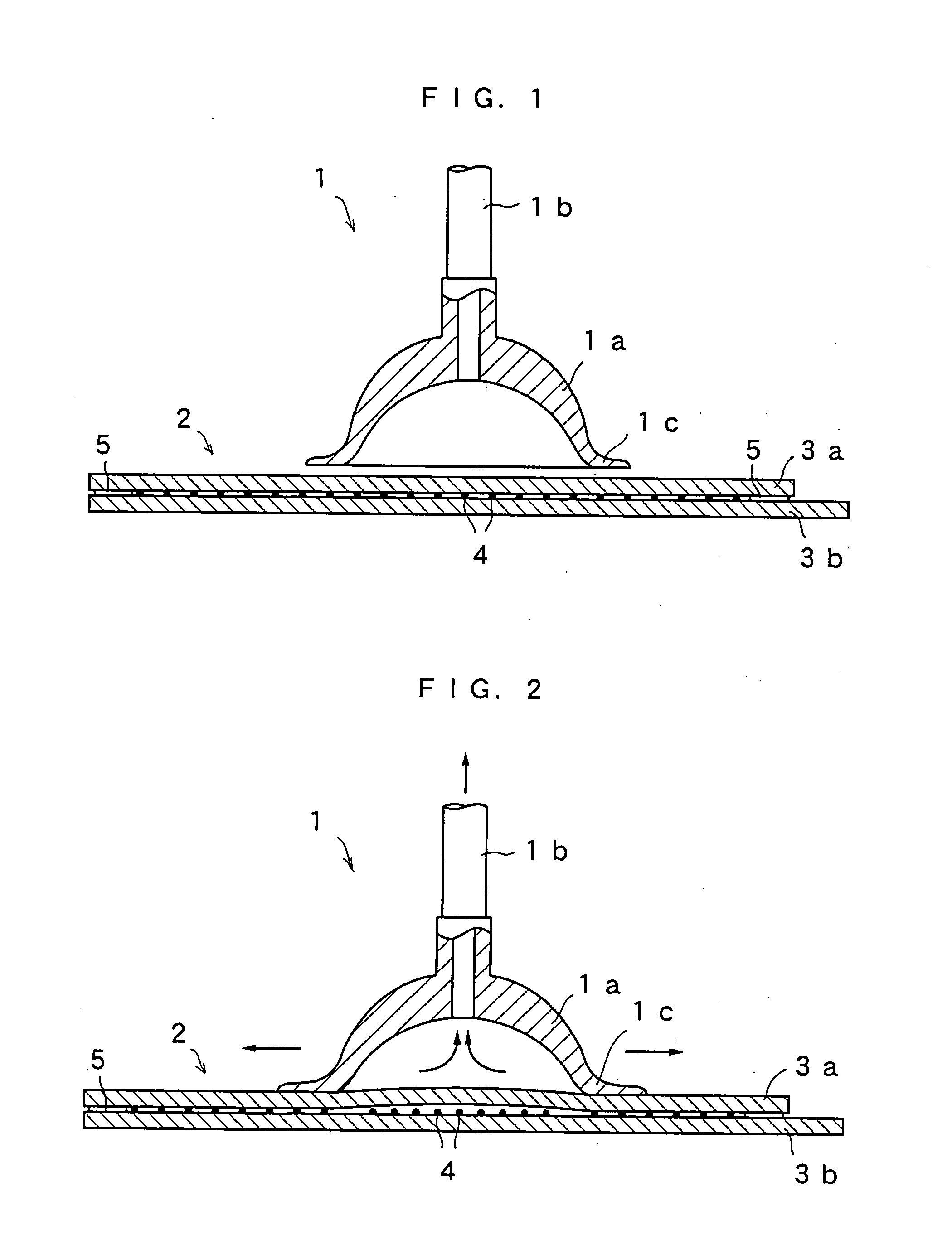

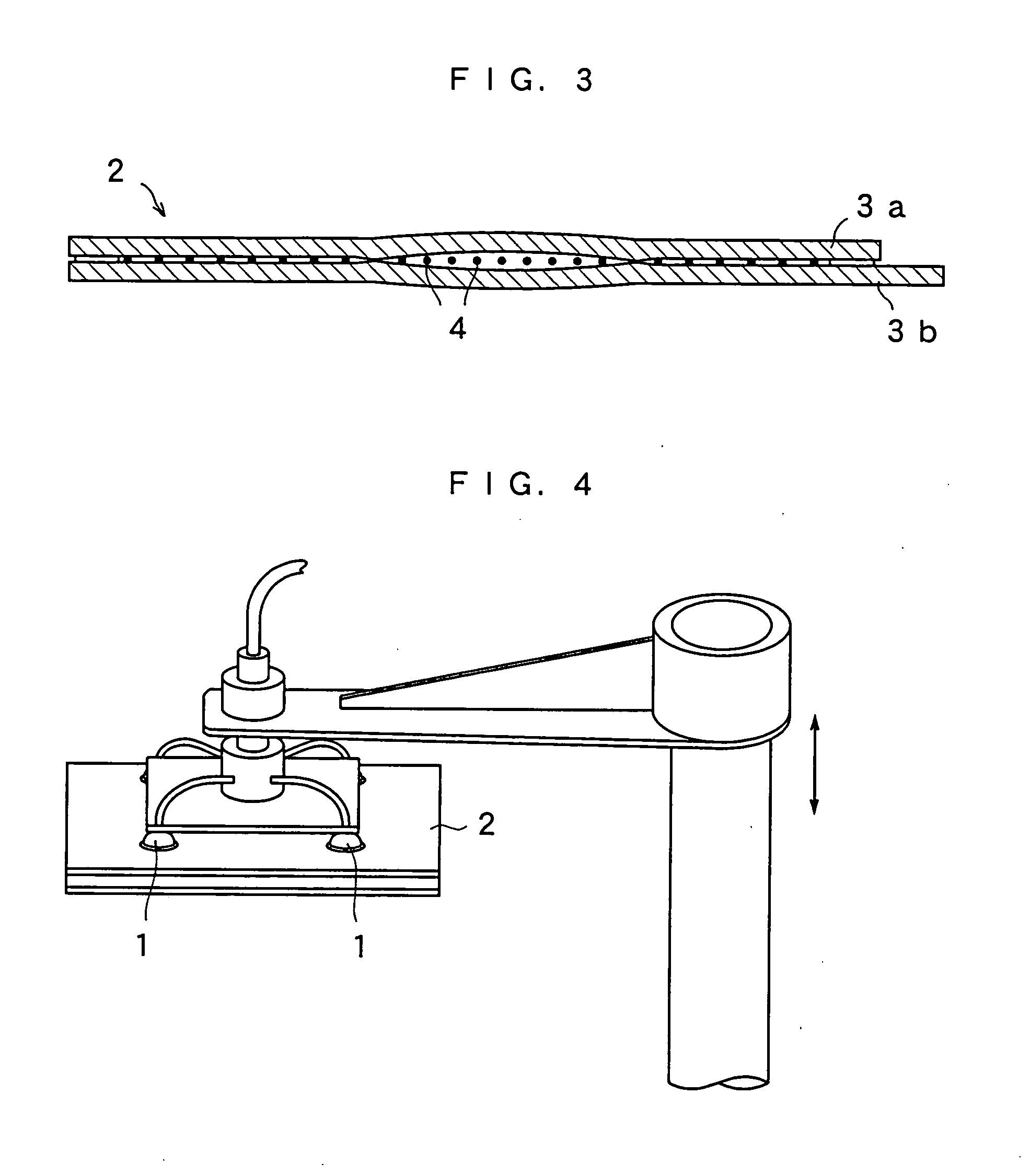

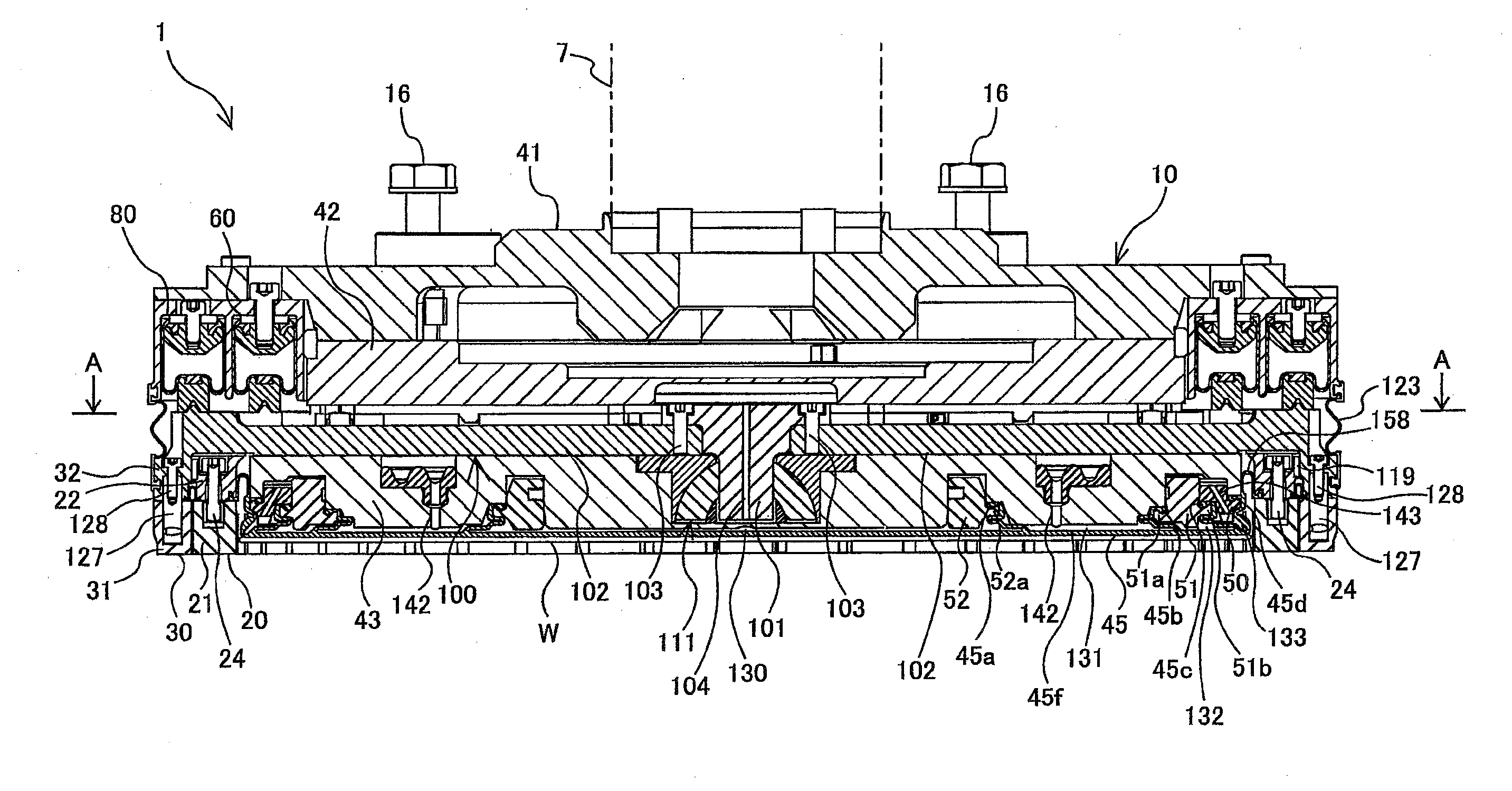

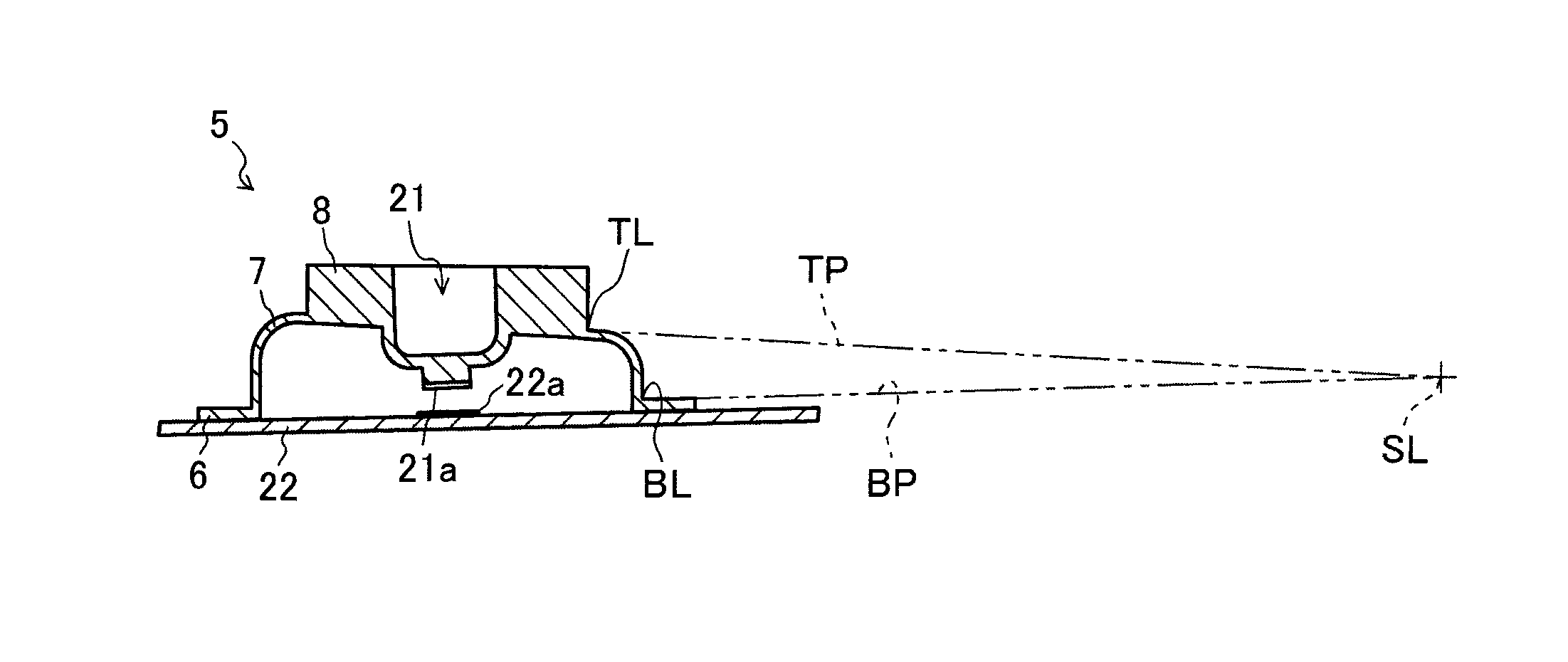

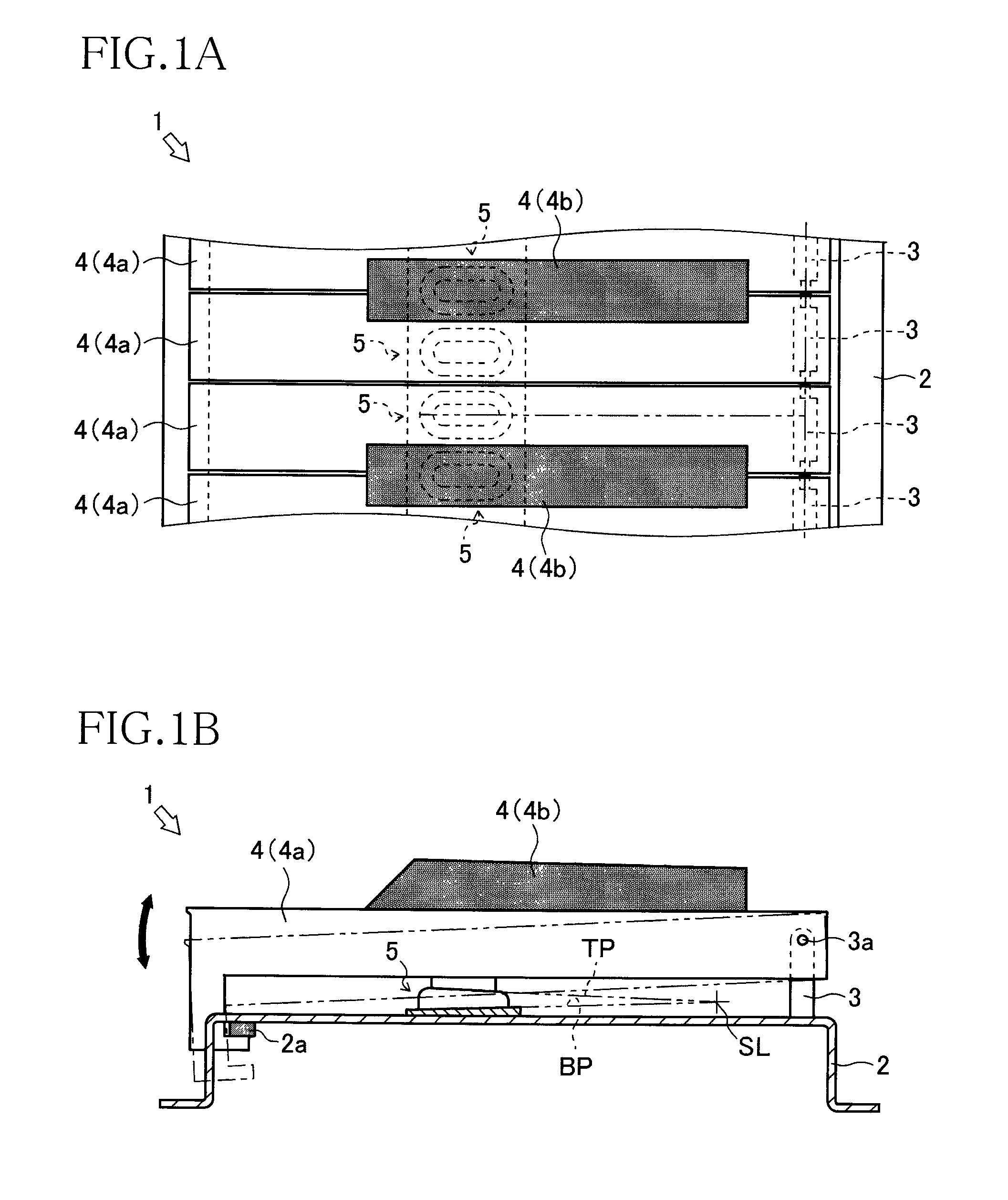

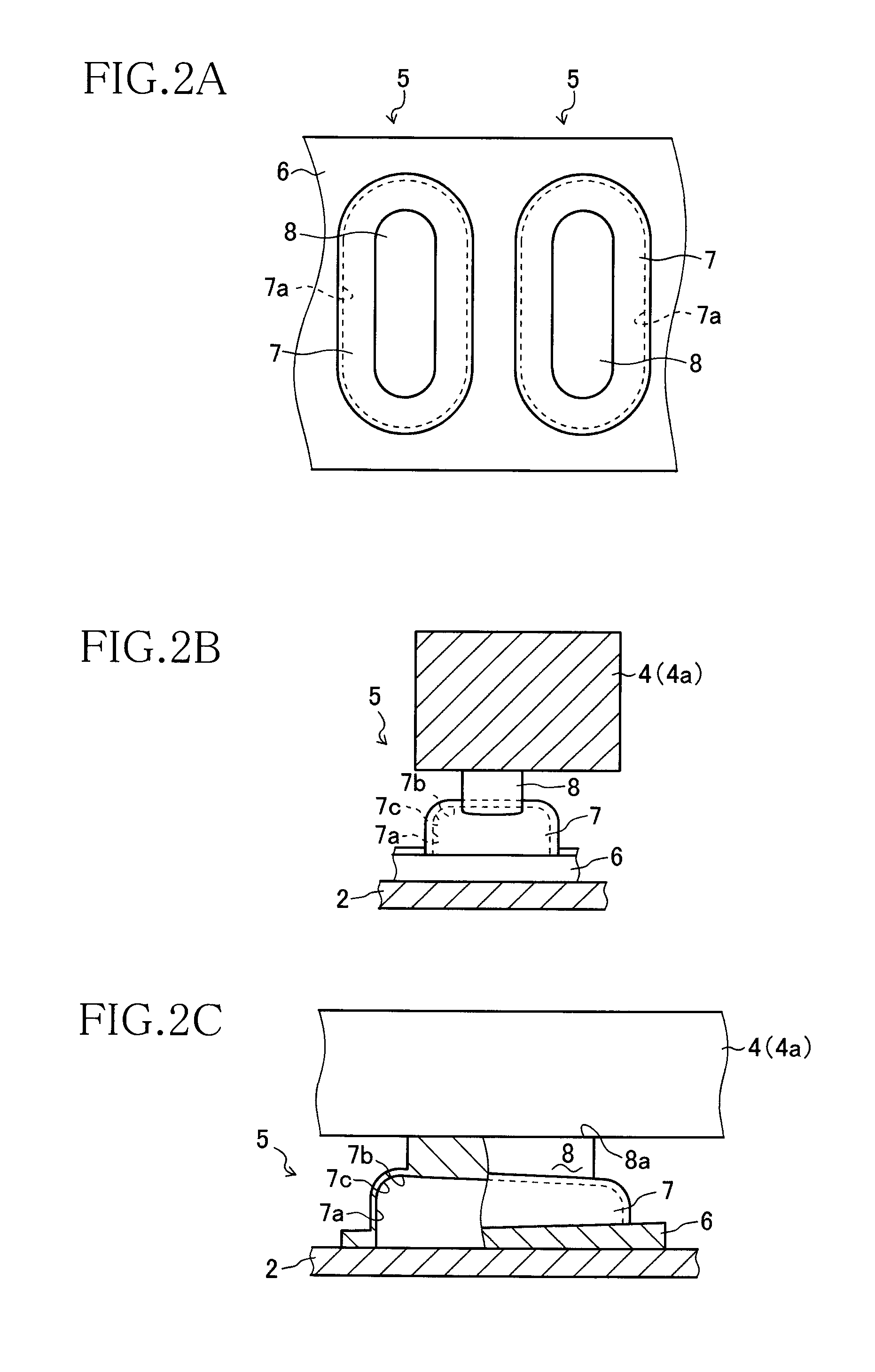

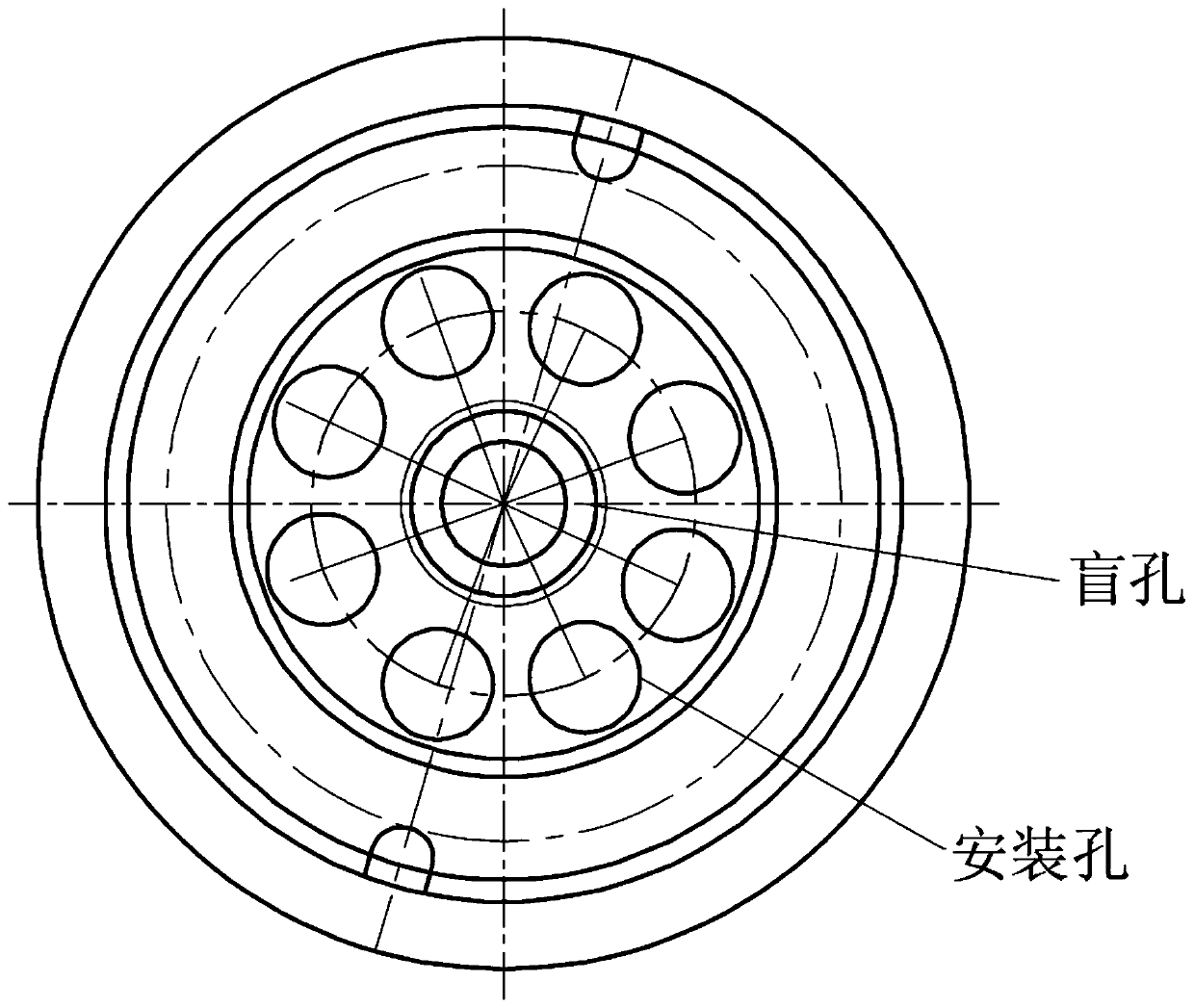

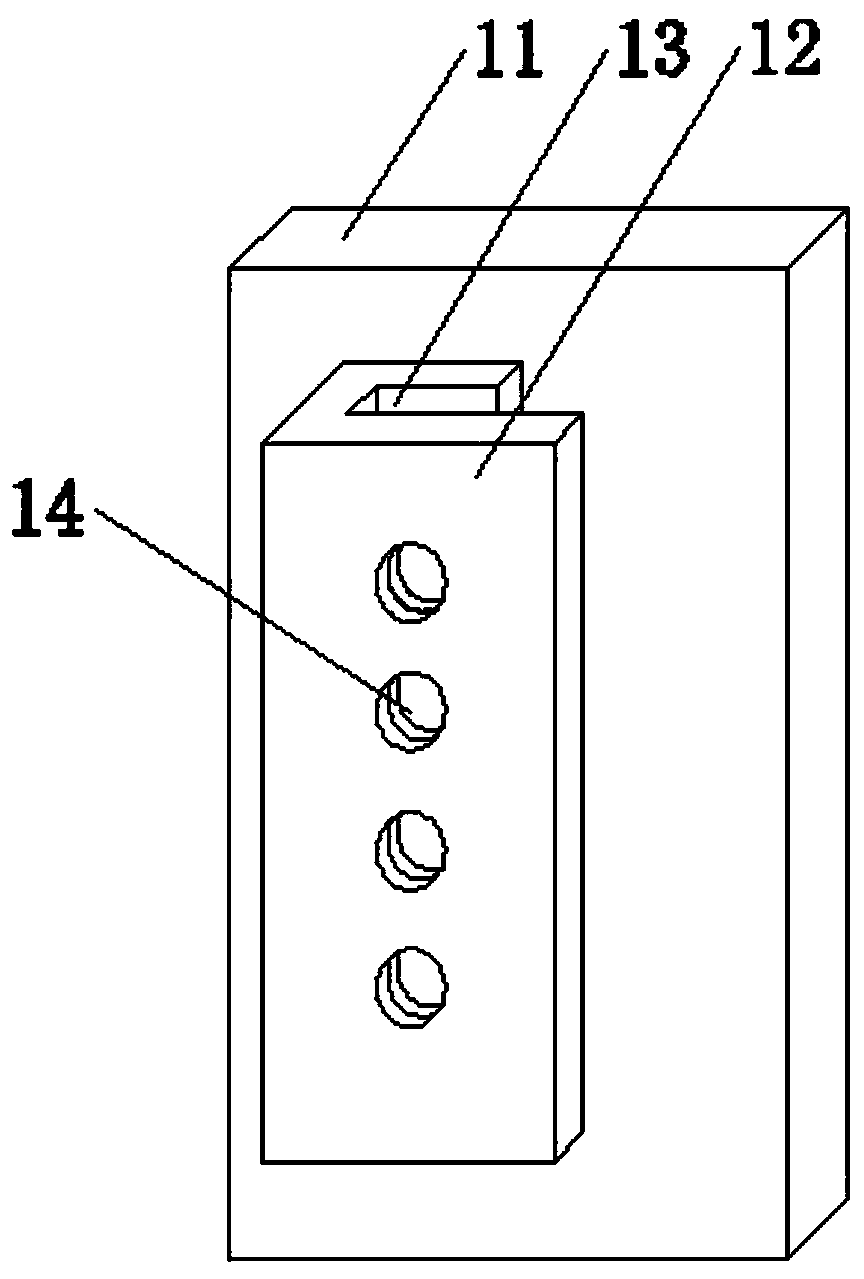

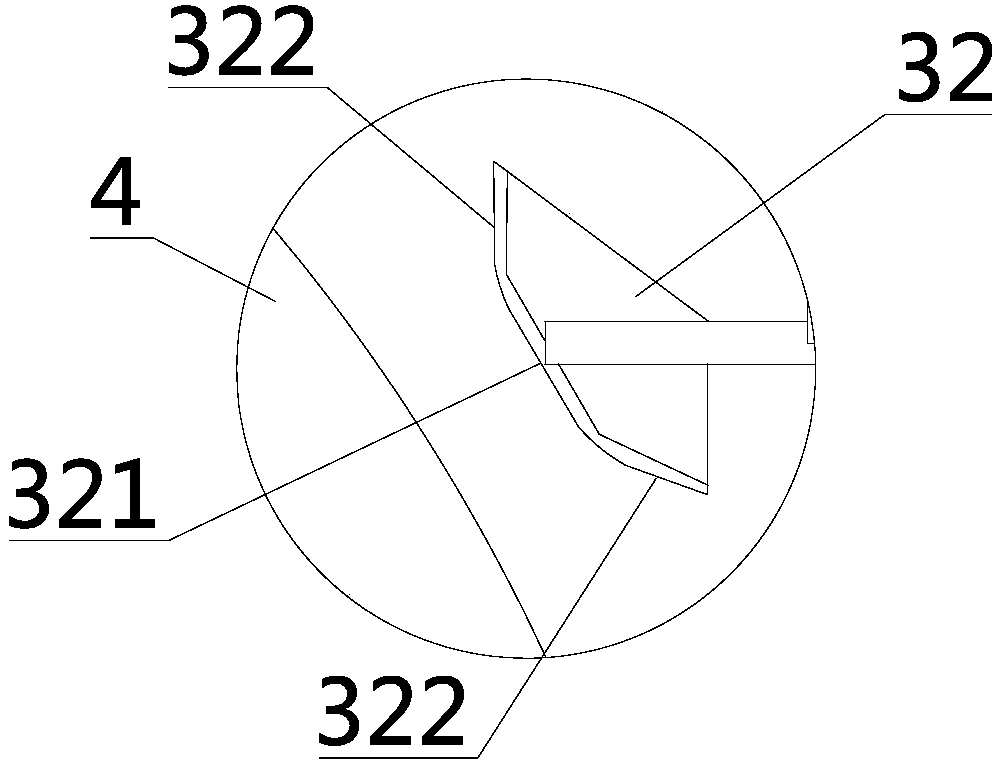

Vacuum suction head

InactiveUS7726715B2Avoid local deformationPreventing occurrence of variationGripping headsSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

An etchable plate-shaped material is used as a vacuum suction pad 31. On one surface thereof, a large number of independent protruded portions and recessed portions are formed to provide a suction part 33b. Further, a periphery of the suction part is annularly formed to provide an airtight part 33a. When the vacuum suction pad 31 comes close to a substrate to be sucked, a skirt pad 32 with a slit 32d is integrally formed in the shape of a hemmed hat using an elastic member, in order to block outside air into a peripheral space of the vacuum suction pad 31. With this arrangement, it is possible to prevent the substrate from being locally deformed when the substrate is sucked by discharging air from a suction port 36 and to widen a clearance between the vacuum suction pad and the substrate such as a liquid crystal panel, at which the suction is possible.

Owner:MITSUBOSHI DIAMOND IND CO LTD

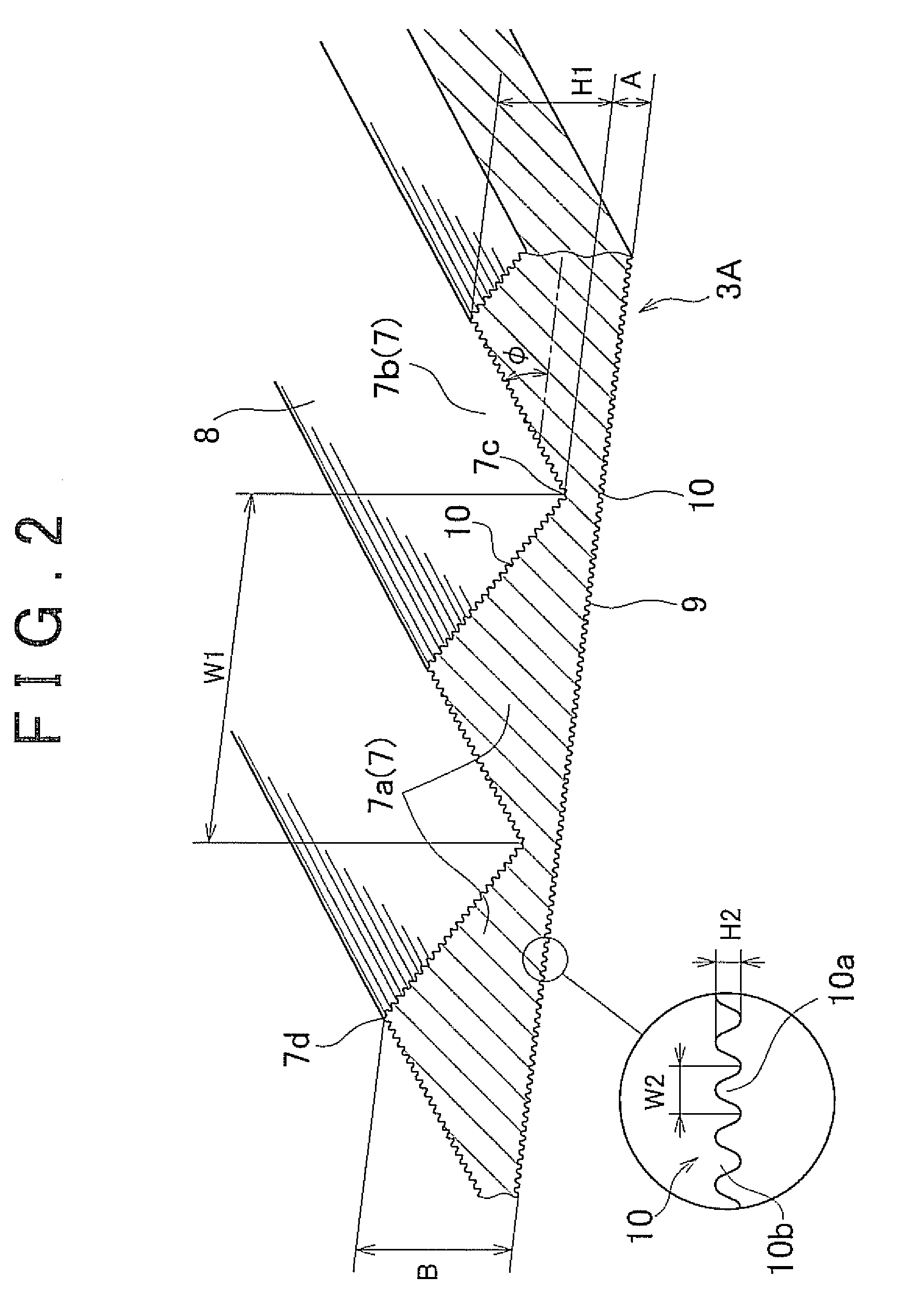

Separator for fuel cell

ActiveUS20110033782A1Avoid local deformationCell component detailsCollectors/separatorsFuel cellsEngineering

The present invention preferably provides a separator for a fuel cell, in which a strength reinforcing means is integrally formed in a region, which is not supported by a gasket, over the region from manifolds, through which reactant gases and coolant are supplied, to a reaction flow field, in which a reaction takes place, thus suitably preventing local deformation of the separator.

Owner:HYUNDAI MOTOR CO LTD +1

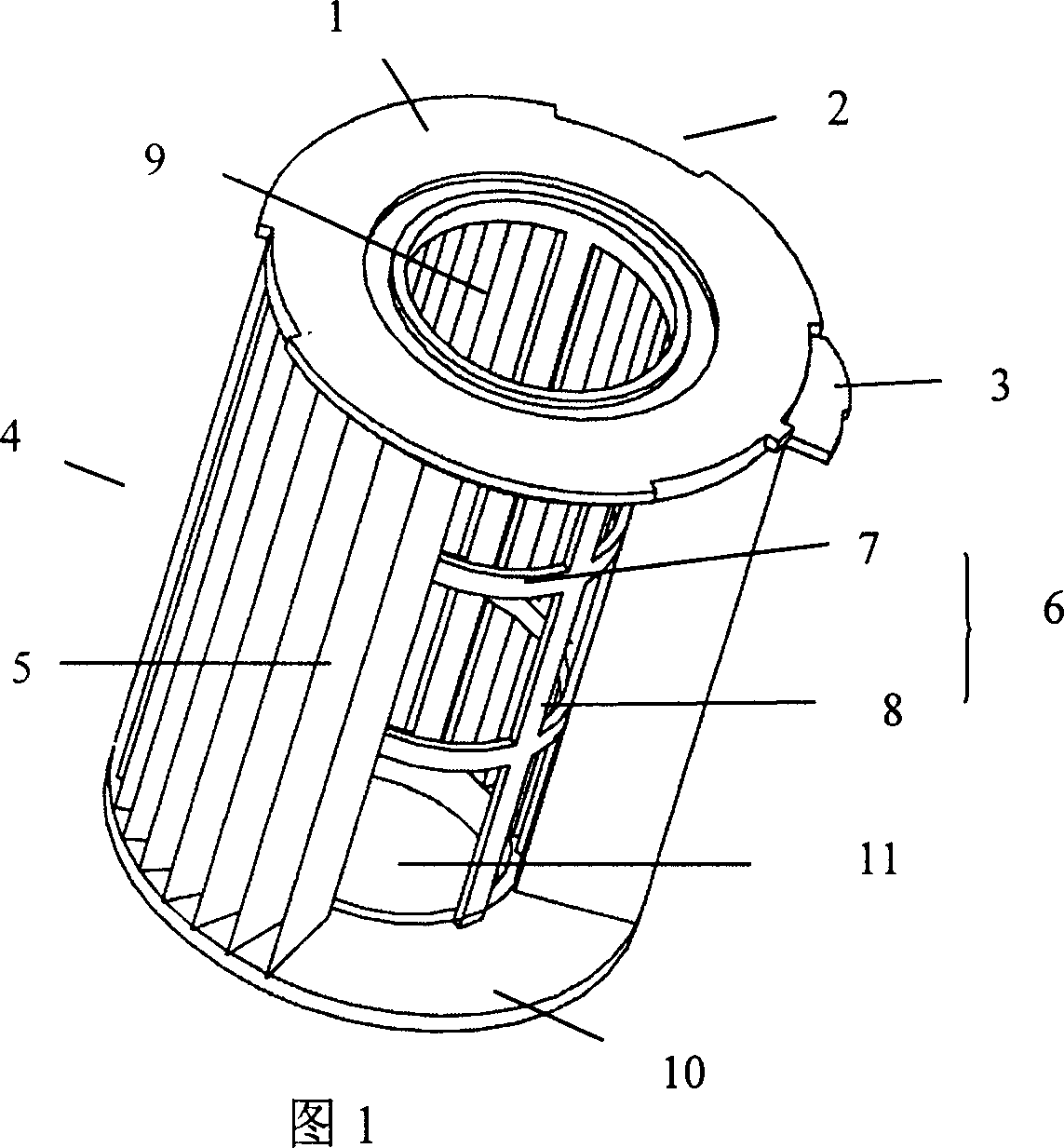

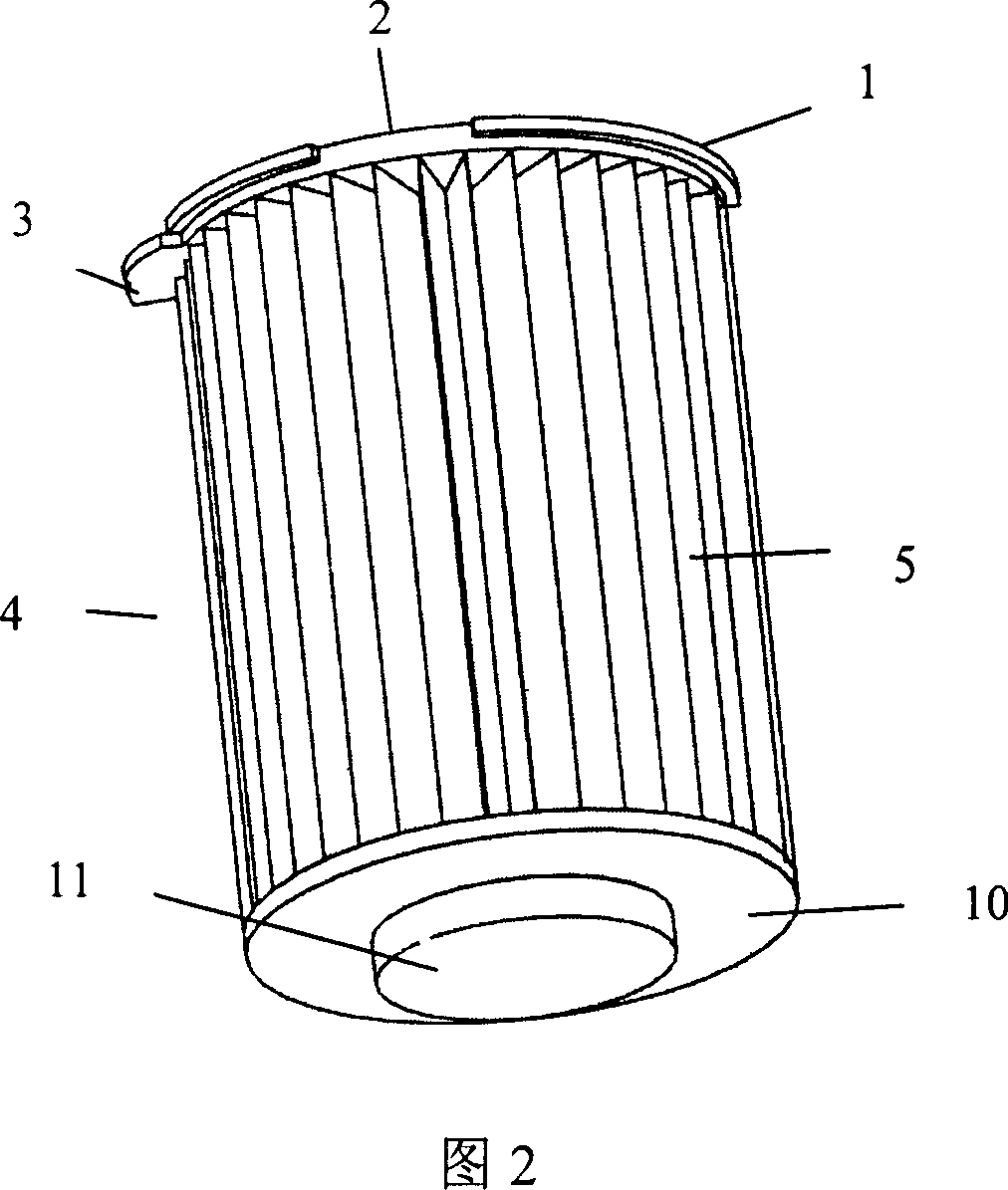

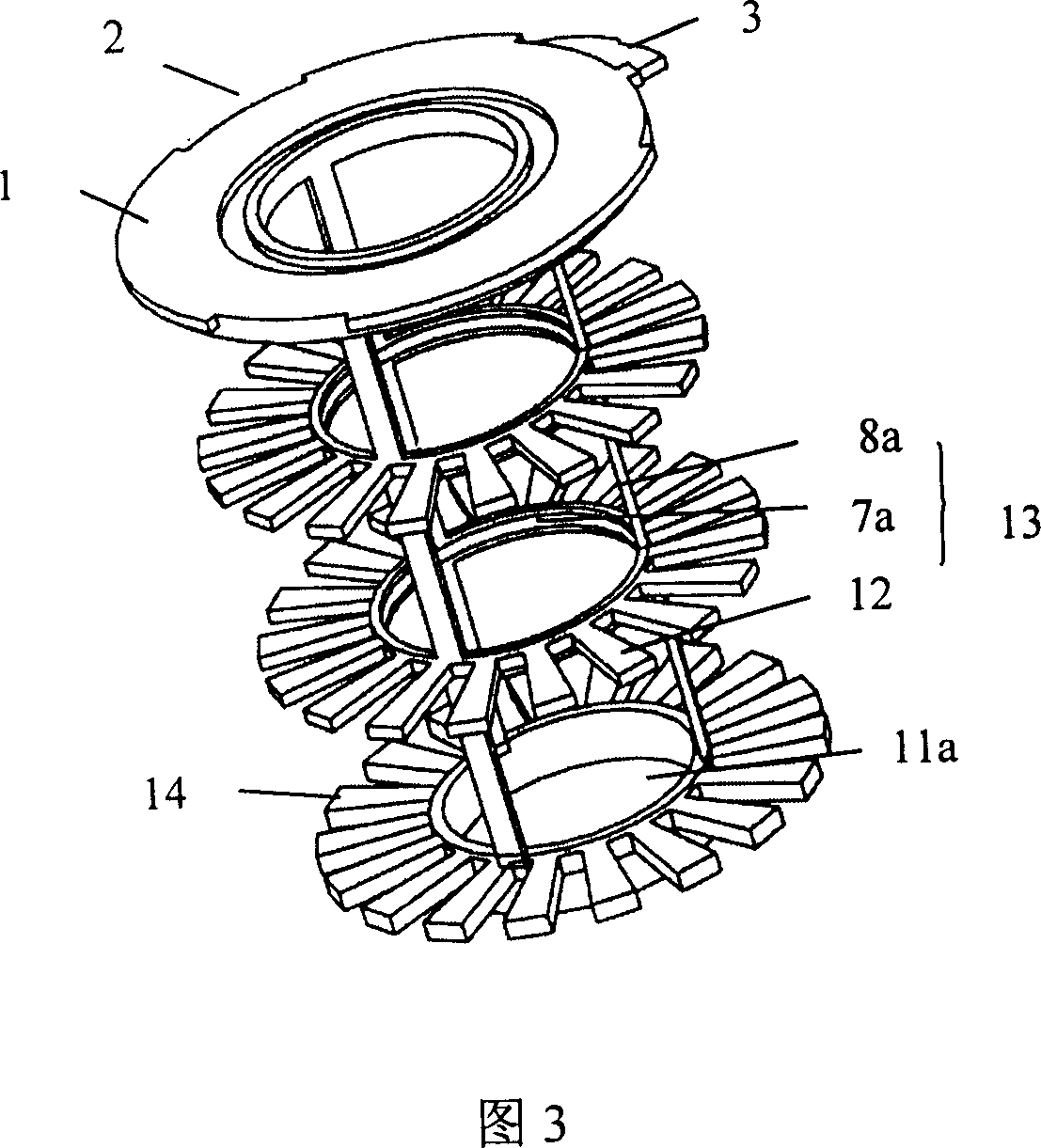

Filter element for dust collector

The invention discloses a filter core structure of cleaner, which comprises the following parts: upper rack with concentric round central hole and bottom flute chassis on two ends of filter core, hollow frame with hoop and rod between upper rack and chassis, hollow rack periphery between rack bottom loop groove and round chassis, cylinder-shaped filter paper cylinder with continuous folding equal-wave fold, wherein the fold displays trapezoid, the chassis forms trapezoidal rack, the trapezoidal rack is also formed on the periphery of hollow frame of rod.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

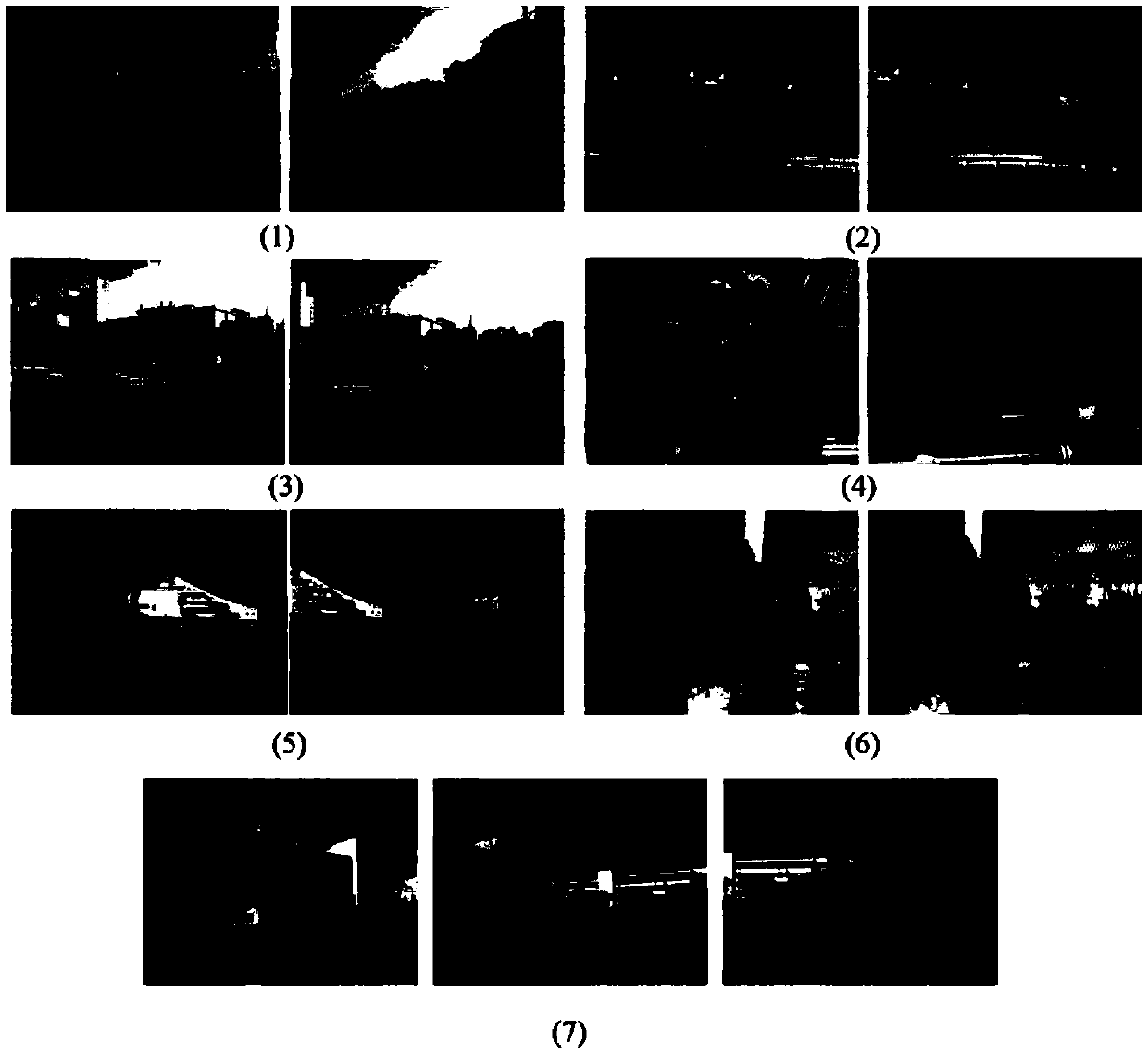

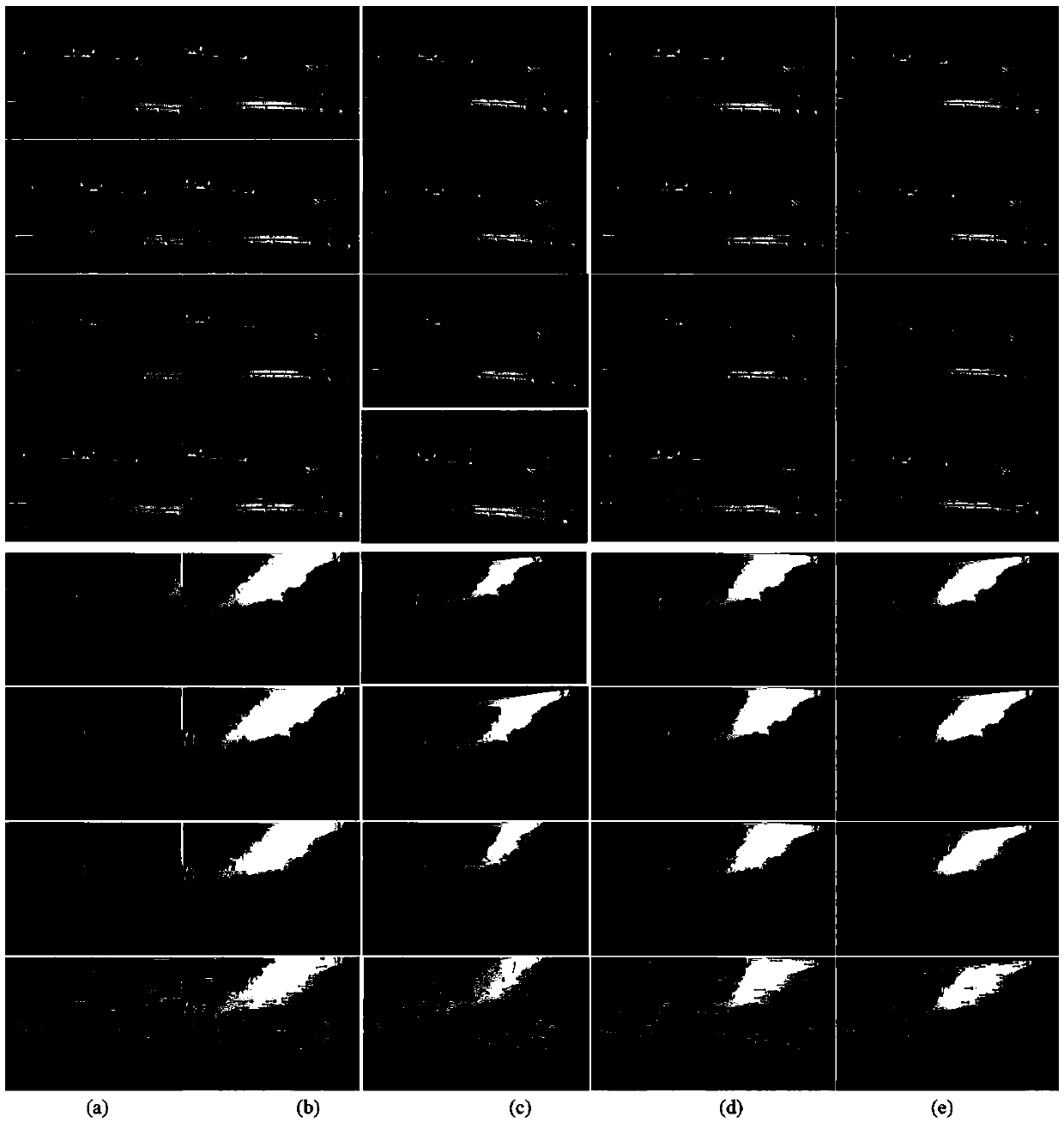

Stereo image stitching method based on content of images

InactiveCN105678687AEfficient splicingNo artificial ghostingGeometric image transformationParallaxImaging processing

The invention belongs to the technical field of stereo images, being able to realize effective stitching of stereo images, avoiding local deformation and reasonably reducing the vertical parallax. The invention relates to a stereo image stitching method based on content of images. The method comprises the steps: utilizing a consistent homography matrix after optimization to perform pre-deformation on the left and right images; utilizing an image tuning and warping method based on contents to optimize image stitching and avoid distortion of vision; and at last, utilizing a lookup algorithm based on kerf and a multi-tape mixed algorithm to acquire the final image stitching result. The stereo image stitching method based on content of images is mainly used for image processing.

Owner:TIANJIN UNIV

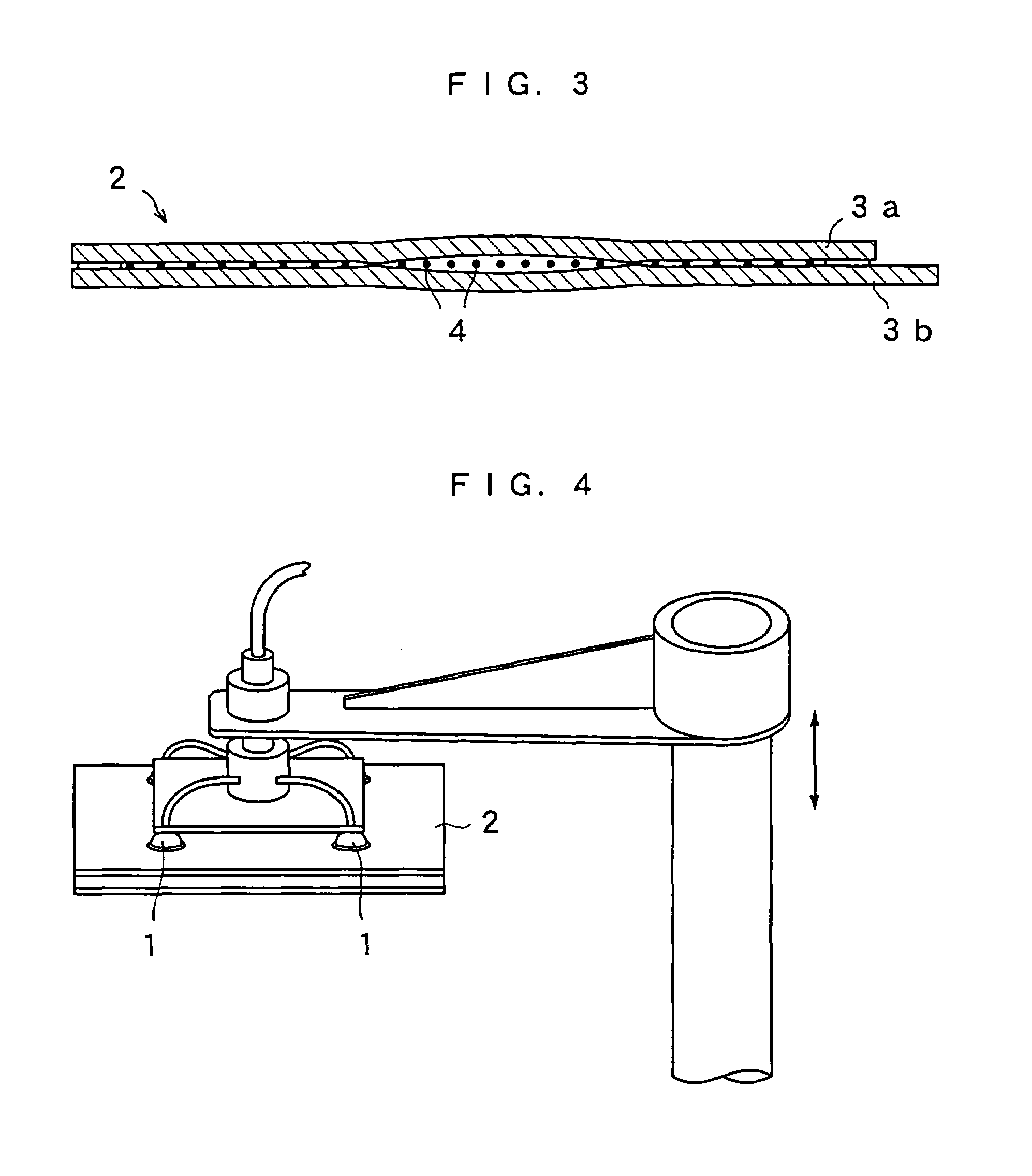

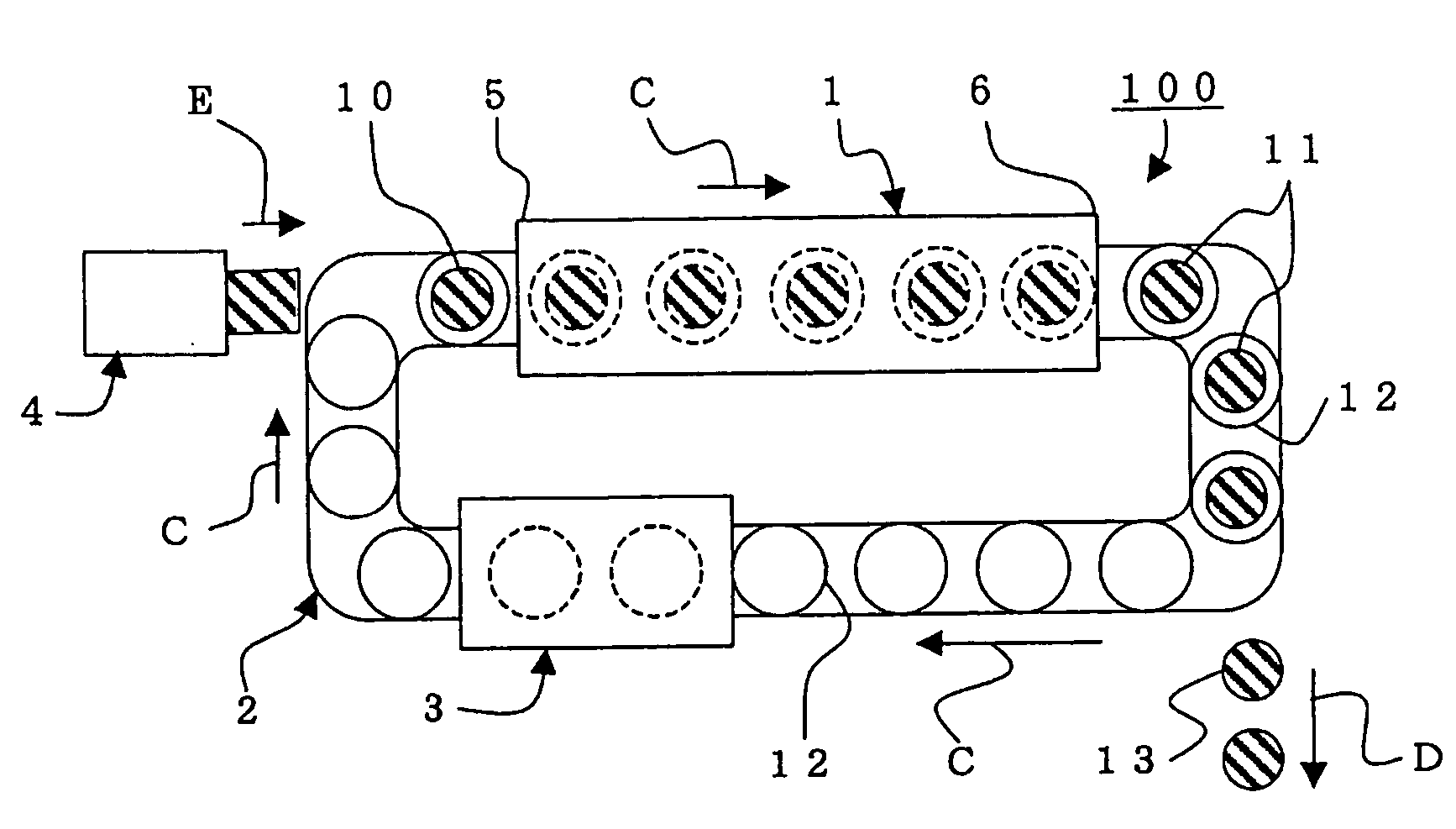

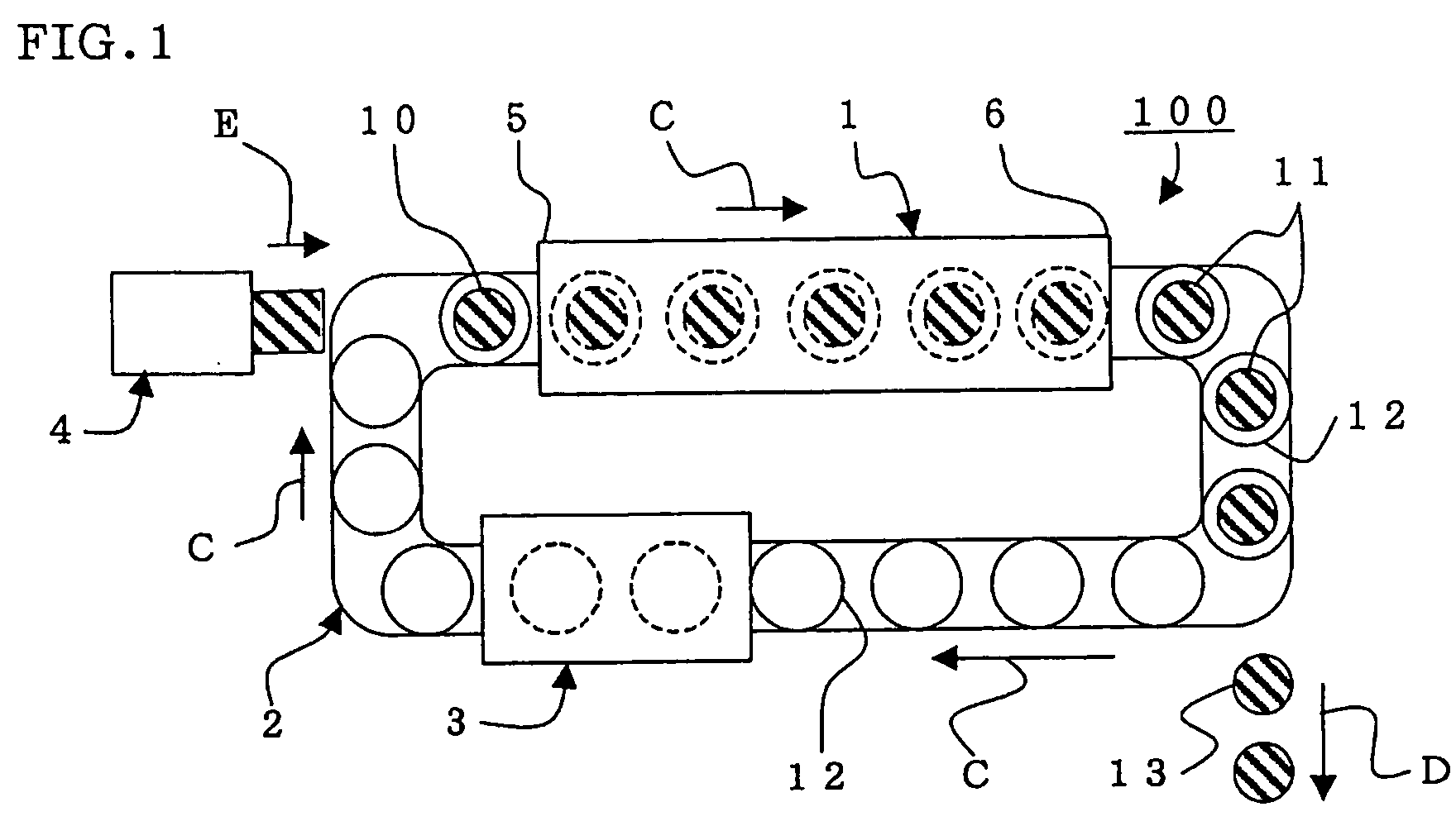

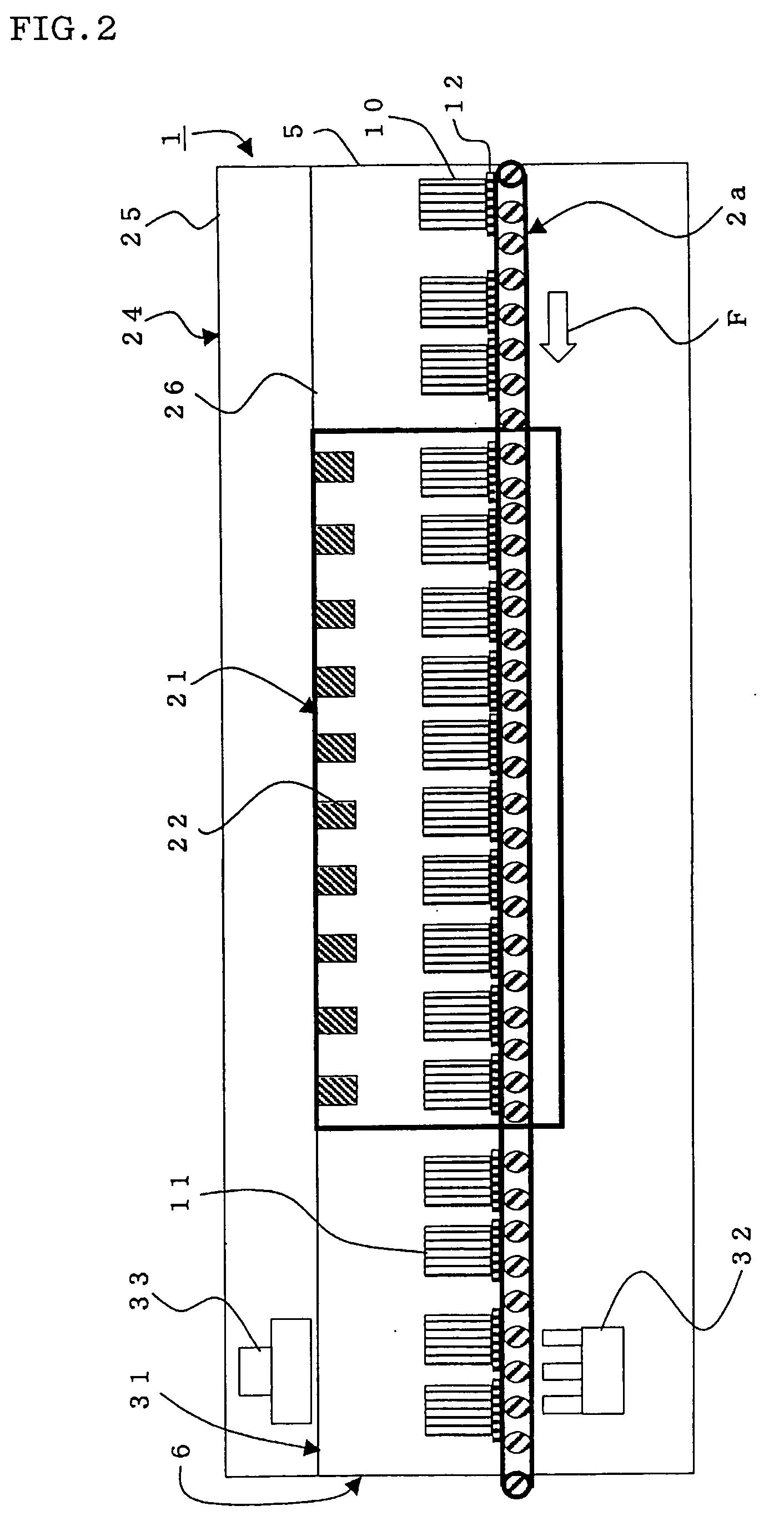

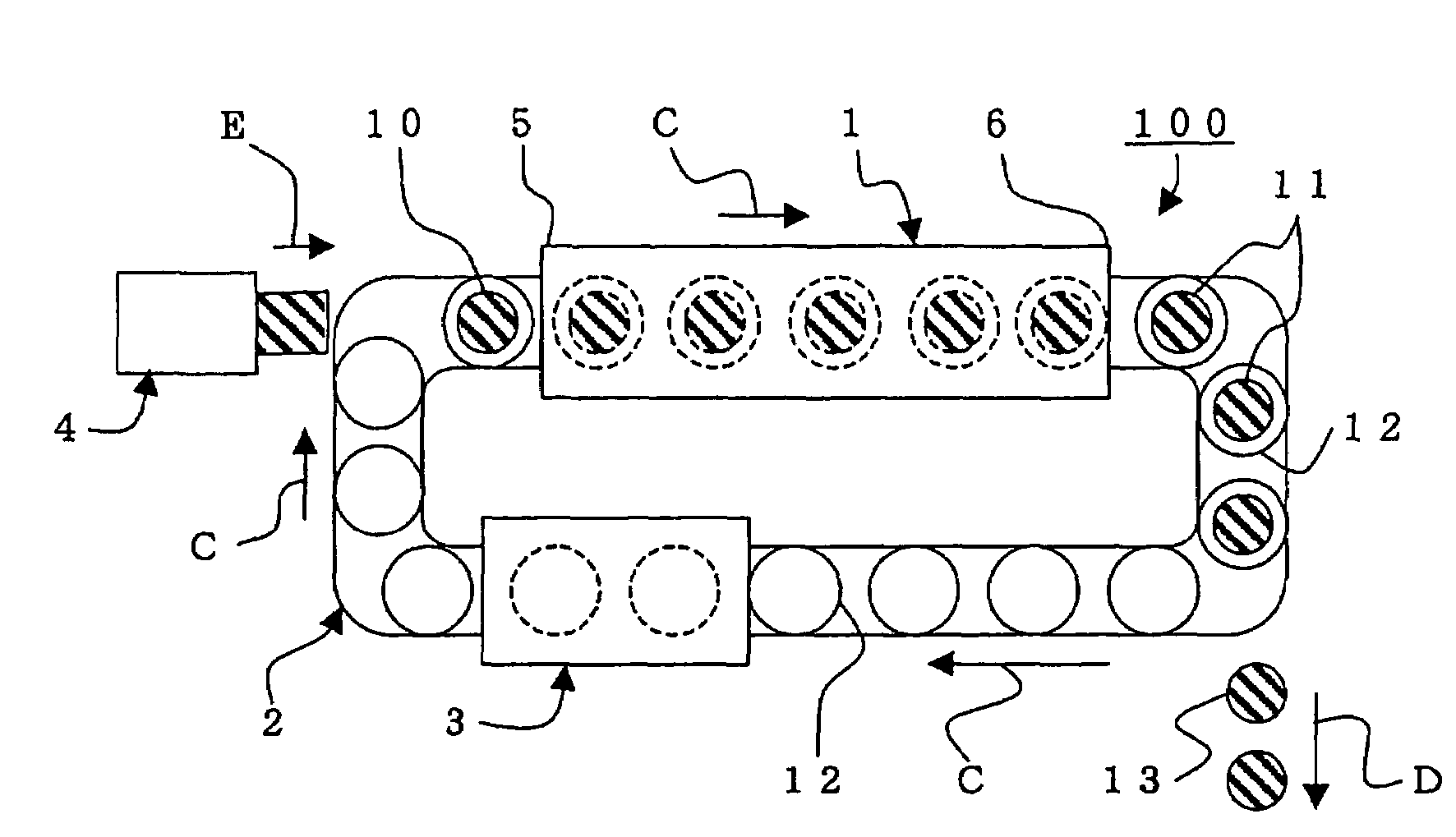

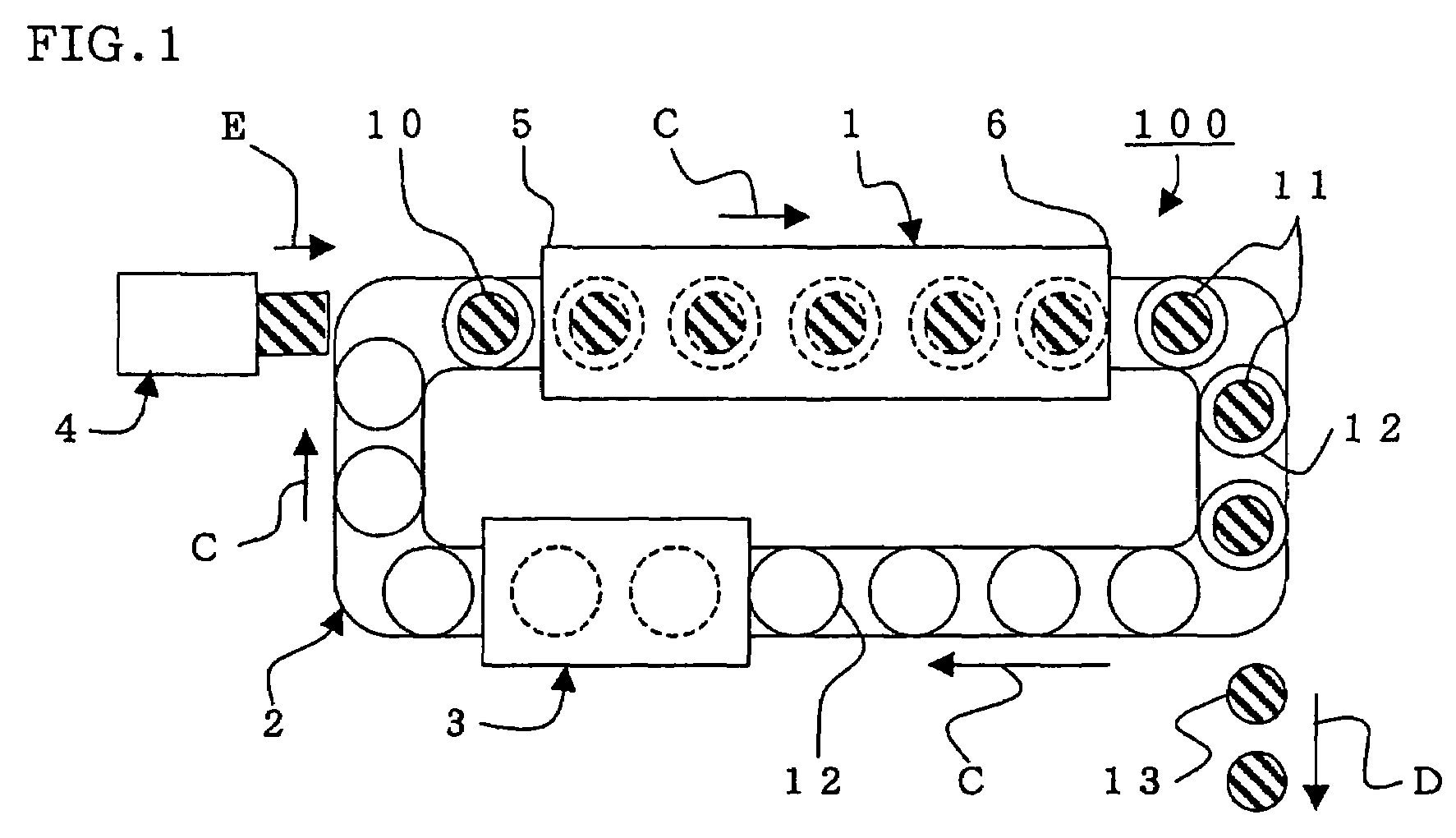

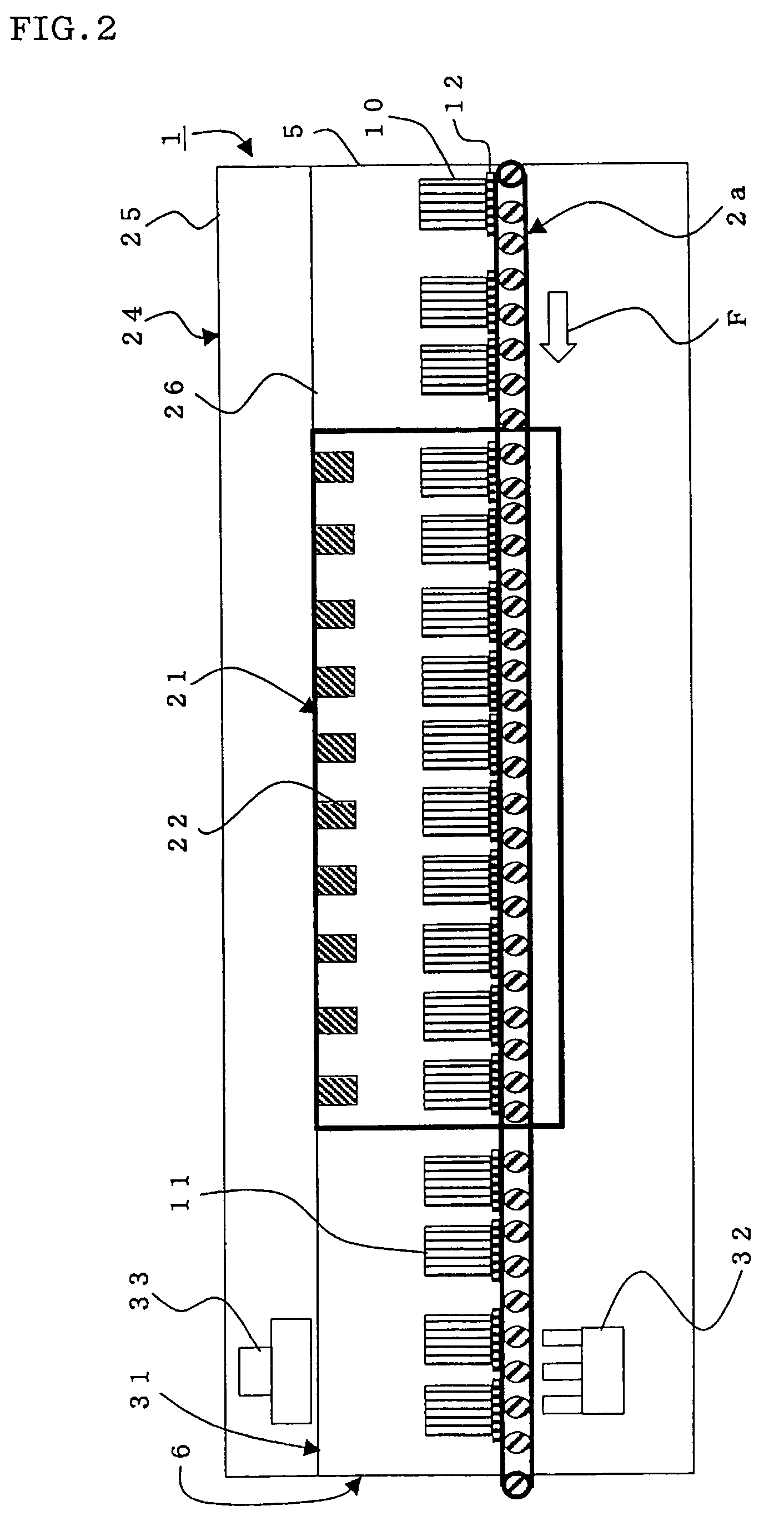

Method for drying honeycomb formed structure

ActiveUS20060283039A1Avoid deformationPartly driedDielectric heatingDrying using combination processesHoneycombHoneycomb like

The invention provides a honeycomb formed structure drying method including causing undried honeycomb formed structures 10 placed on stands 12 to pass through a drying apparatus 1, thereby drying the undried honeycomb formed structures through high-frequency heating, to thereby form dried honeycomb formed structures 11; removing the dried honeycomb formed structures 11 from the stands 12; cooling the stands 12 which have been heated dried in the drying apparatus 1 are cooled to a temperature lower than the gelation temperature of the undried honeycomb formed structures 10; placing newly formed undried honeycomb formed structures 10 on the cooled stands 12; drying the undried honeycomb formed structures by passing through the drying apparatus 1; and repeating these operations. The honeycomb formed structure drying method prevents deformation such as warpage of partition walls of honeycomb formed structures during drying thereof.

Owner:NGK INSULATORS LTD

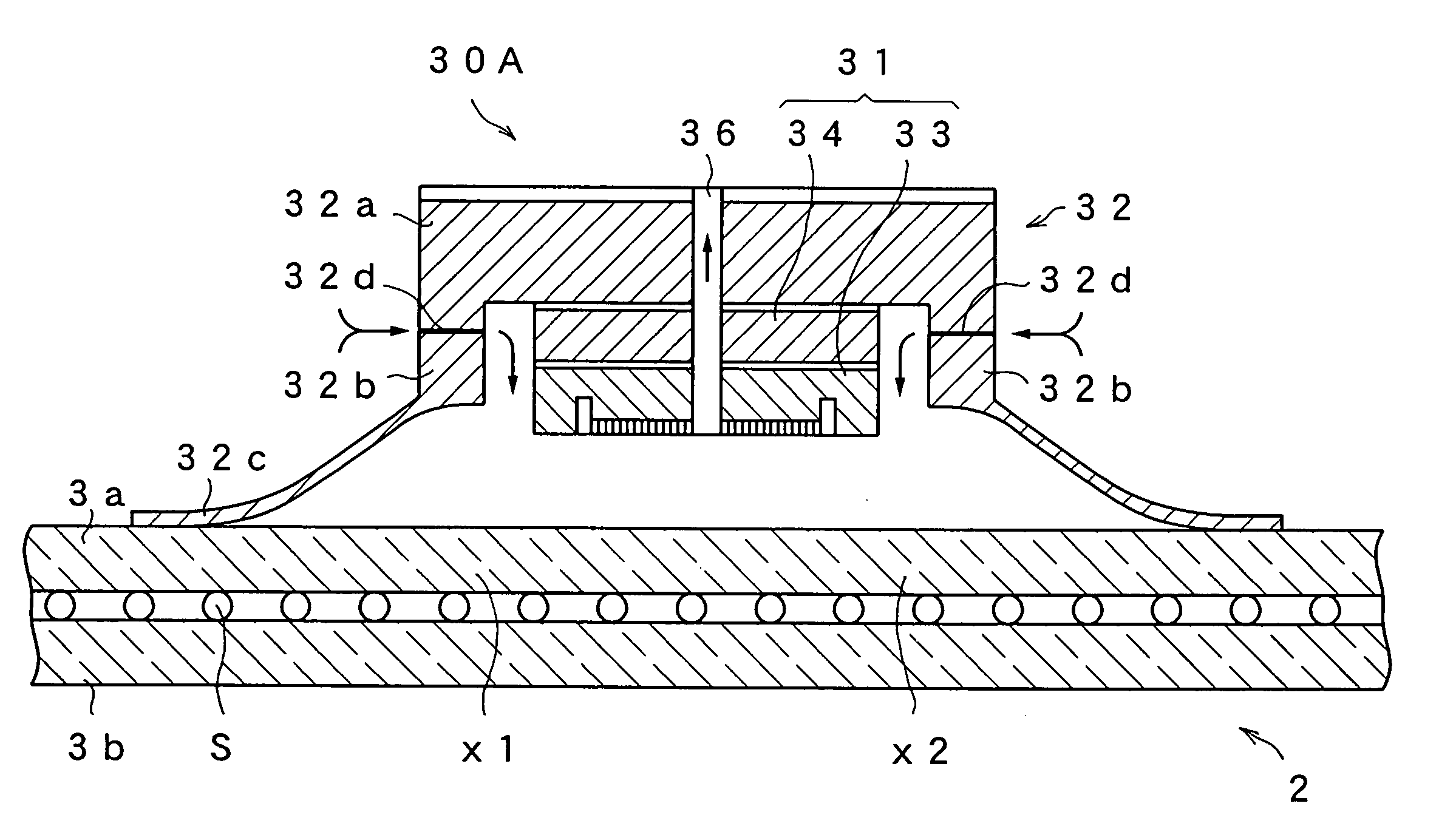

Vacuum suction head

InactiveUS20060232085A1Avoid local deformationPreventing occurrence of variationGripping headsSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

An etchable plate-shaped material is used as a vacuum suction pad 31. On one surface thereof, a large number of independent protruded portions and recessed portions are formed to provide a suction part 33b. Further, a periphery of the suction part is annularly formed to provide an airtight part 33a. When the vacuum suction pad 31 comes close to a substrate to be sucked, a skirt pad 32 with a slit 32d is integrally formed in the shape of a hemmed hat using an elastic member, in order to block outside air into a peripheral space of the vacuum suction pad 31. With this arrangement, it is possible to prevent the substrate from being locally deformed when the substrate is sucked by discharging air from a suction port 36 and to widen a clearance between the vacuum suction pad and the substrate such as a liquid crystal panel, at which the suction is possible.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Photothermographic recording material coated from an aqueous medium

InactiveUS6143481AImprove imaging effectEasy to wearX-ray/infra-red processesTransportation and packagingMethacrylateWater dispersible

A photothermographic recording material comprising a support and a photo-addressable thermally developable element comprising photosensitive siver halide in catalytic association with a substantially light-insensitive silver salt of an organic carboxylic acid, an organic reducing agent for the substantially light-insensitive silver salt of an aliphatic carboxylic acid in thermal working relationship therewith and a binder, characterized in that the binder comprises a non-proteinaceous water-soluble binder, a non-proteinaceous water-dispersible binder (preferably a comprising a diene, styrene, an acrylate or a methacrylate monomer) or a mixture of a non-proteinaceous water soluble binder and a non-proteinaceous water-dispersible binder and the photo-addressable thermally developable element is capable of being coated from an aqueous medium and is capable of producing images stable to light without a wet-processing step; a process for producing the photothermographic recording material and a photo-thermographic recording process therefor.

Owner:AGFA HEALTHCARE NV

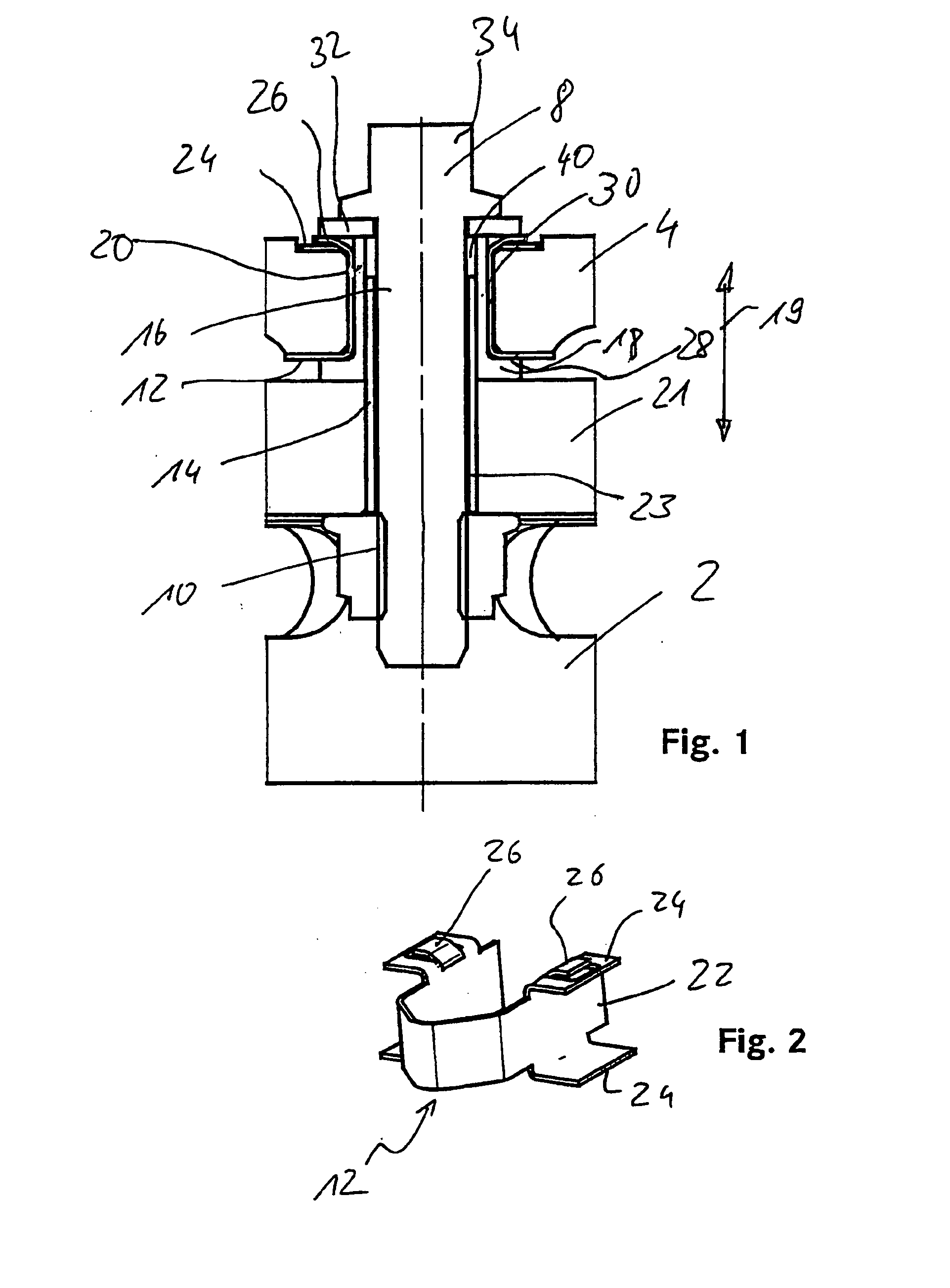

Brake disk comprising a friction ring and a linking element

ActiveUS20070181388A1Low production costAvoid corrosionAxially engaging brakesBraking discsMechanical engineeringThermal expansion

The invention relates to a brake disk comprising a friction ring (2) and a linking element (4) which are interconnected by means of a screwing arrangement (6). The screwing arrangement (6) encompasses a screw, a nut, and an intermediate element (12). Said intermediate element (12) prevents direct contact between the friction ring (2) and the linking element (4). Also provided is a sleeve element (14) that is disposed on a shaft (16) of the screw (8). A sliding block (18) is plugged onto the sleeve element (14). The intermediate element (12) at least partly encloses the sliding block such that thermal expansions acting in a radial direction can be compensated by a relative movement between the sliding block (18) and the intermediate element (12). The intermediate element also has a springy effect in an axial direction, by means of which mechanical and thermal stresses can be compensated in said axial direction.

Owner:FRENI BREMBO SPA

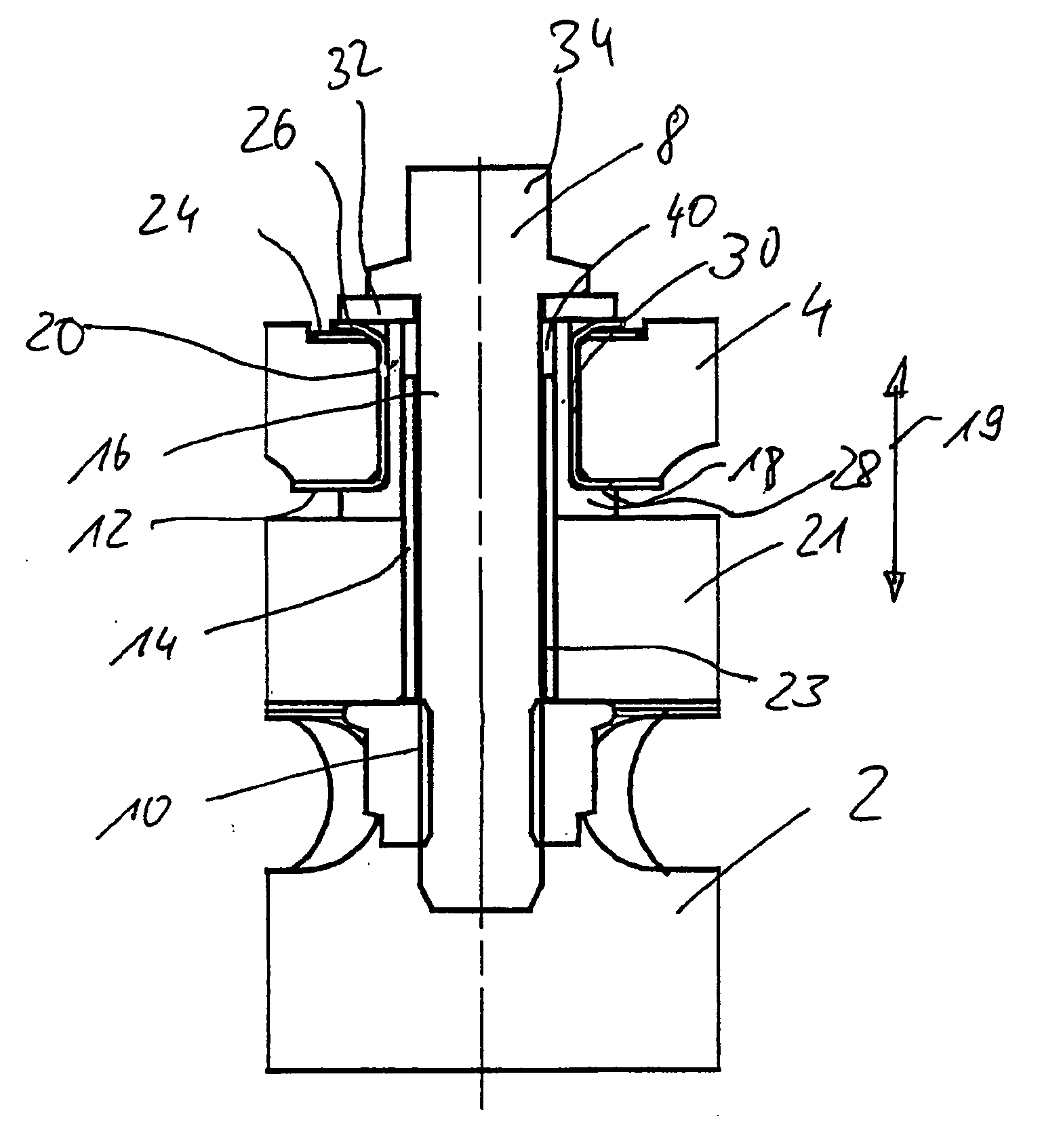

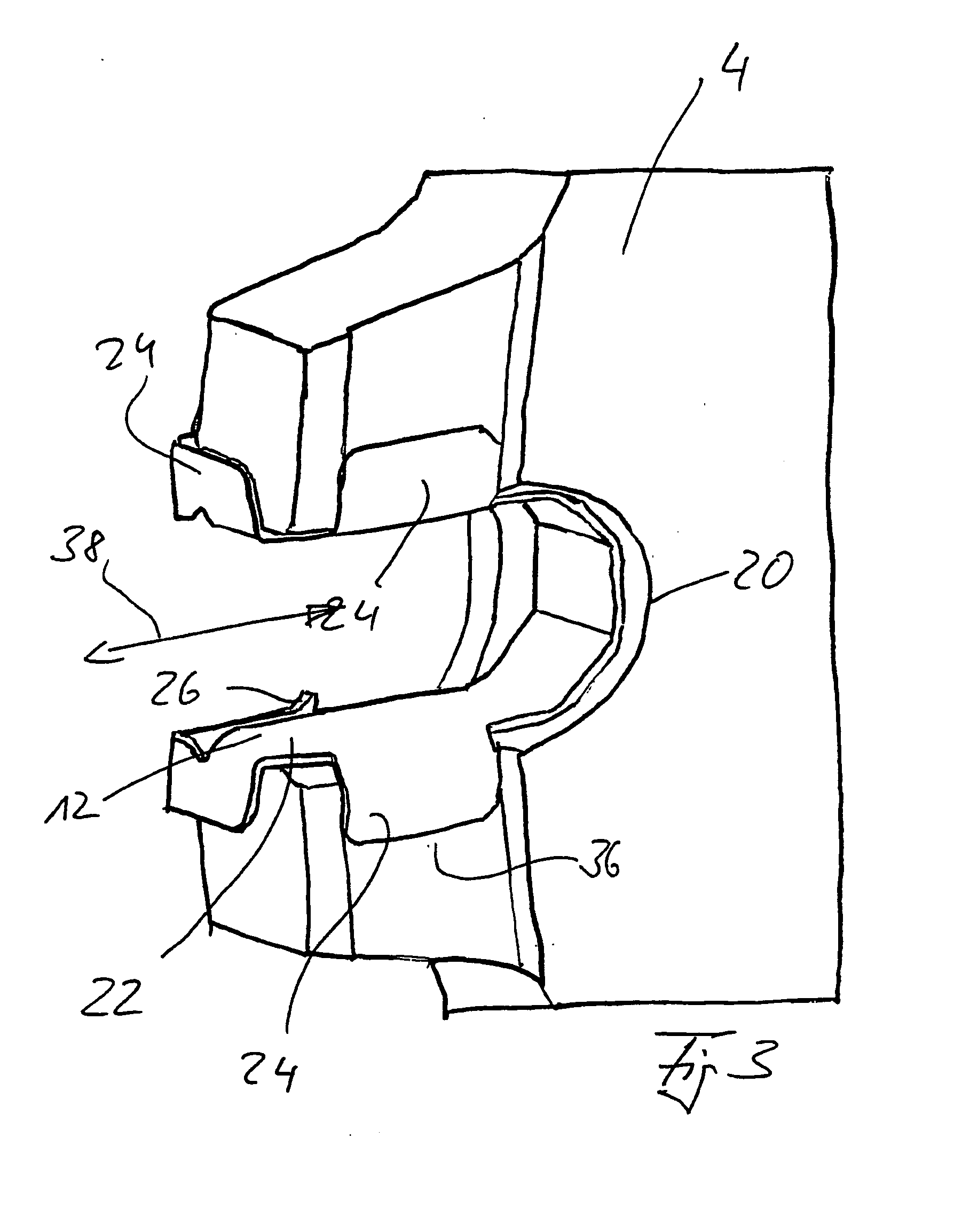

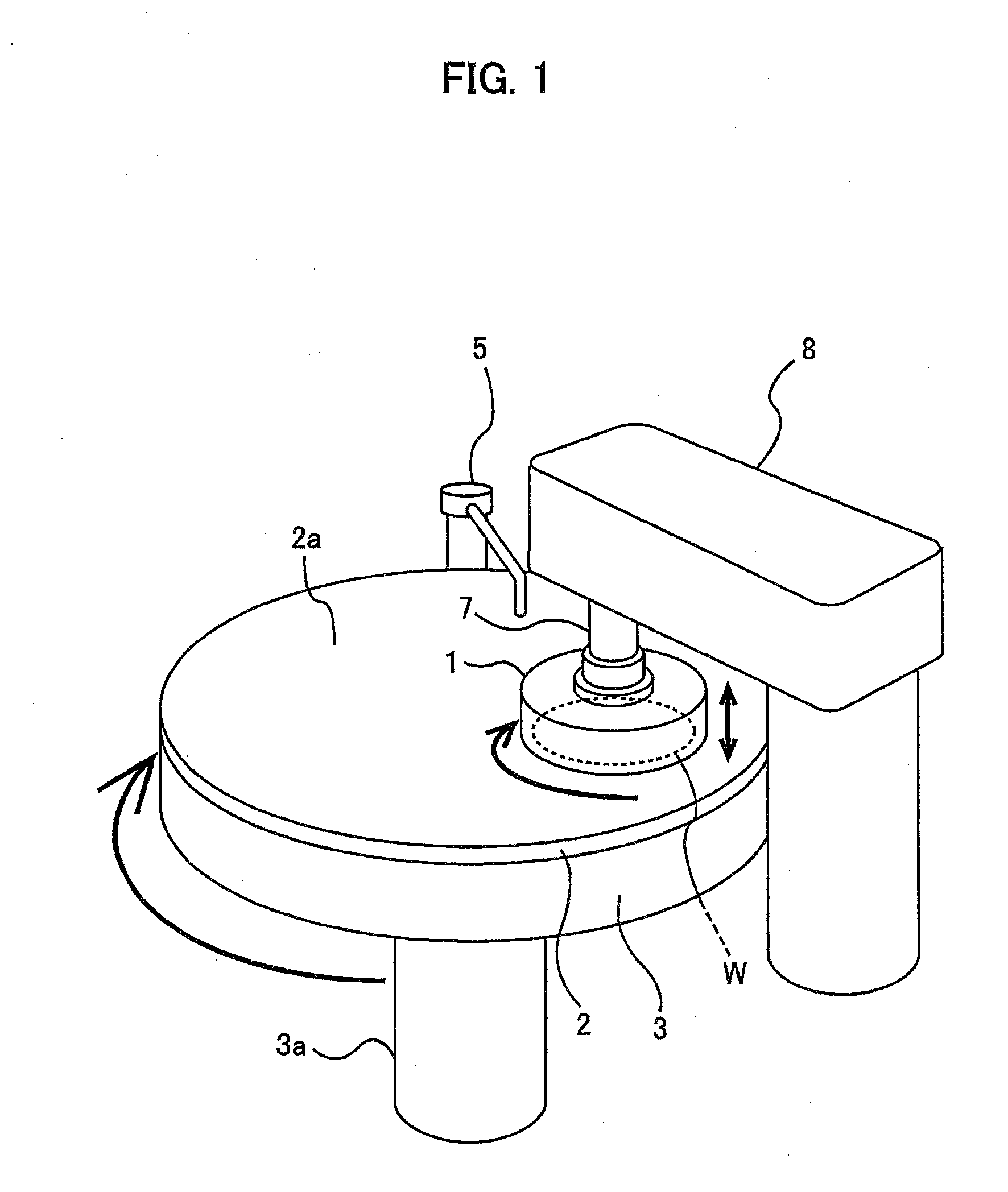

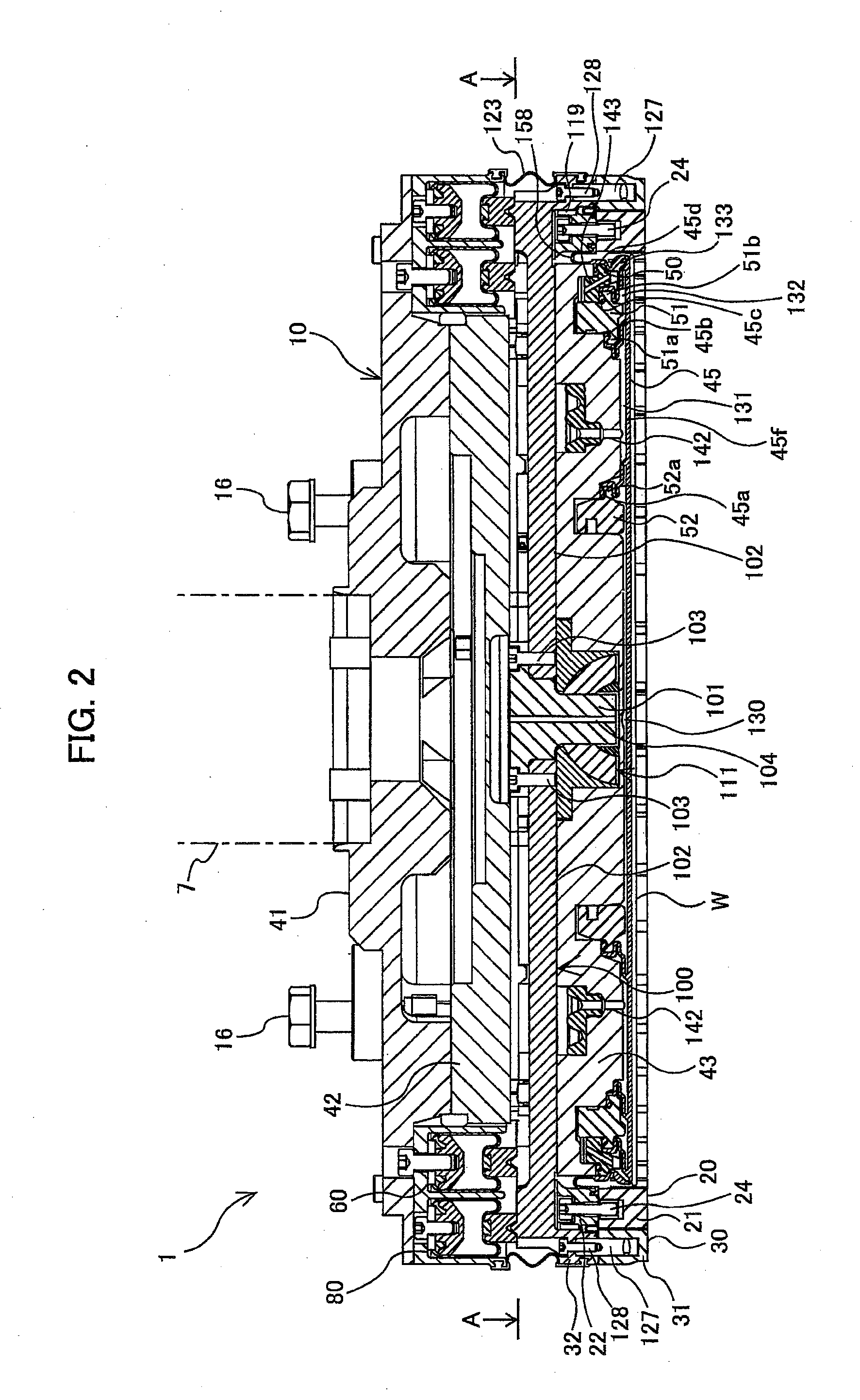

Substrate holder, polishing apparatus, and polishing method

ActiveUS20130196573A1Reduce stepsImprove wear resistancePolishing machinesRevolution surface grinding machinesEngineeringRetaining ring

The substrate holder is a device for holding a substrate and pressing it against a polishing pad. The substrate holder includes: an inner retaining ring vertically movable independently of the top ring body and arranged around the substrate; an inner pressing mechanism to press the inner retaining ring against the polishing surface of the polishing pad; an outer retaining ring to vertically movable independently of the inner retaining ring and the top ring body; an outer pressing mechanism to press the outer retaining ring against the polishing surface; and a supporting mechanism to receive a lateral force applied to the inner retaining ring from the substrate during polishing of the substrate and to tiltably support the outer retaining ring.

Owner:EBARA CORP

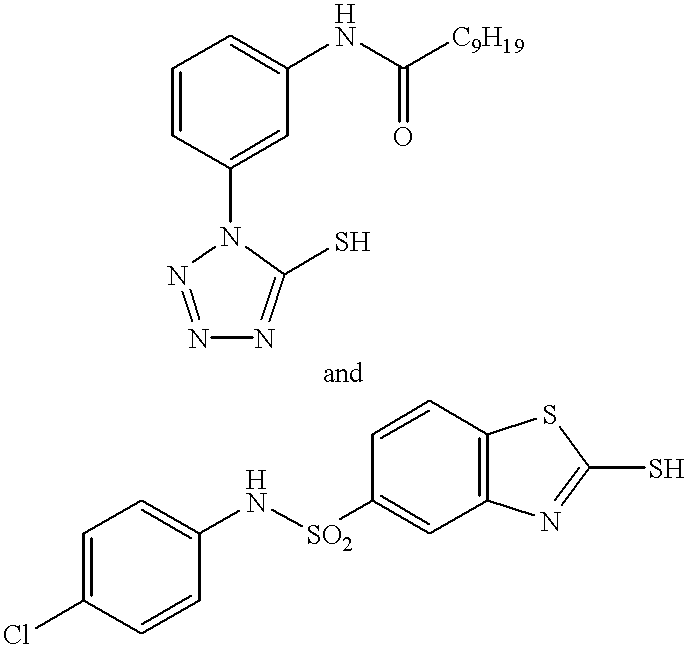

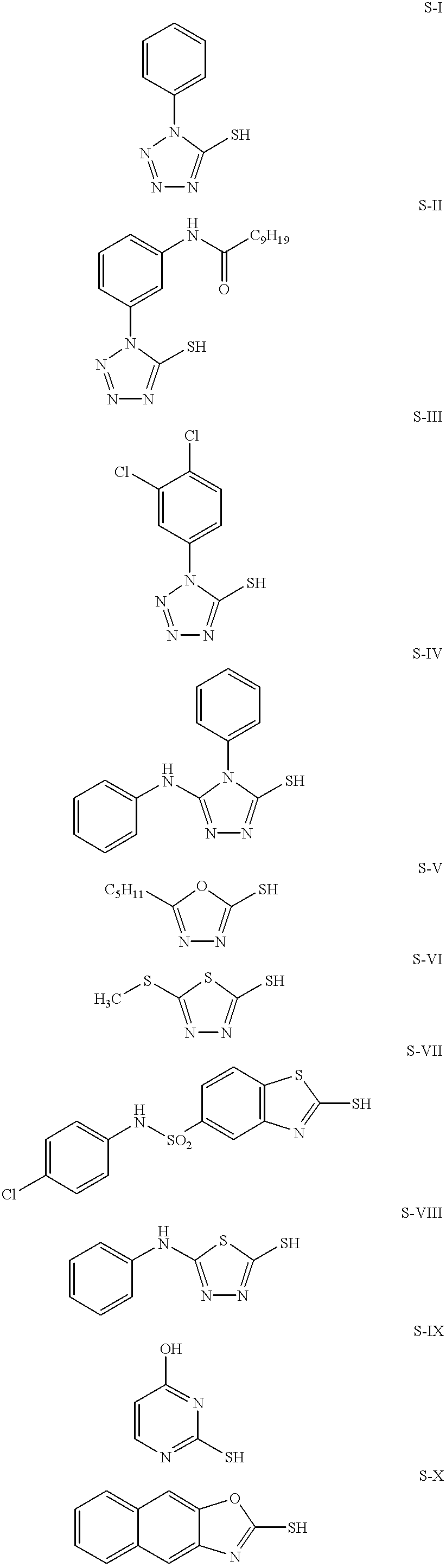

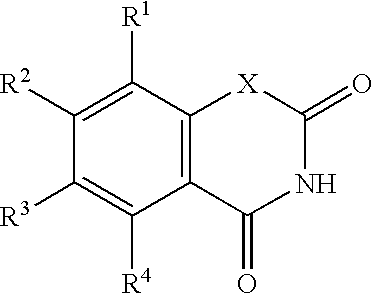

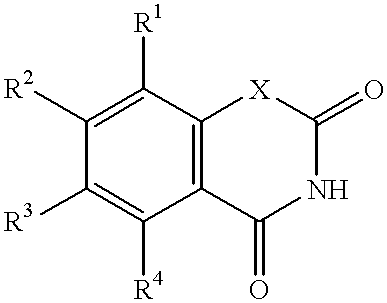

Substantially light-insensitive thermographic recording material with improved stability and image-tone

InactiveUS6348308B1Image stabilizationImprove reaction speedDiffusion transfer processesRadiation applicationsHydrogenCounterion

A substantially light-insensitive monosheet recording material comprising a support and a thermosensitive element containing a substantially light-insensitive organic silver salt, an organic reducing agent therefor in thermal working relationship therewith and a binder, wherein the thermosensitive element further contains an unsaturated carbocyclic or heterocyclic stabilizer compound substituted with a -SA group where A is hydrogen, a counterion to compensate the negative charge of the thiolate group or a group forming a symmetrical or an asymmetrical disulfide and the recording material is capable of producing prints with a numerical gradation value defined as the quotient of the fraction (2.5-0.1) / (E2.5-E0.1) greater than 2.3 , where E2.5 is the energy in Joule applied in a dot area of 87 mumx87 mum of the imaging layer that produces an optical density value of 2.5, and E0.1 is the energy in Joule applied in a dot area of the imaging layer material that produces an optical density value of 0.1.

Owner:AGFA NV

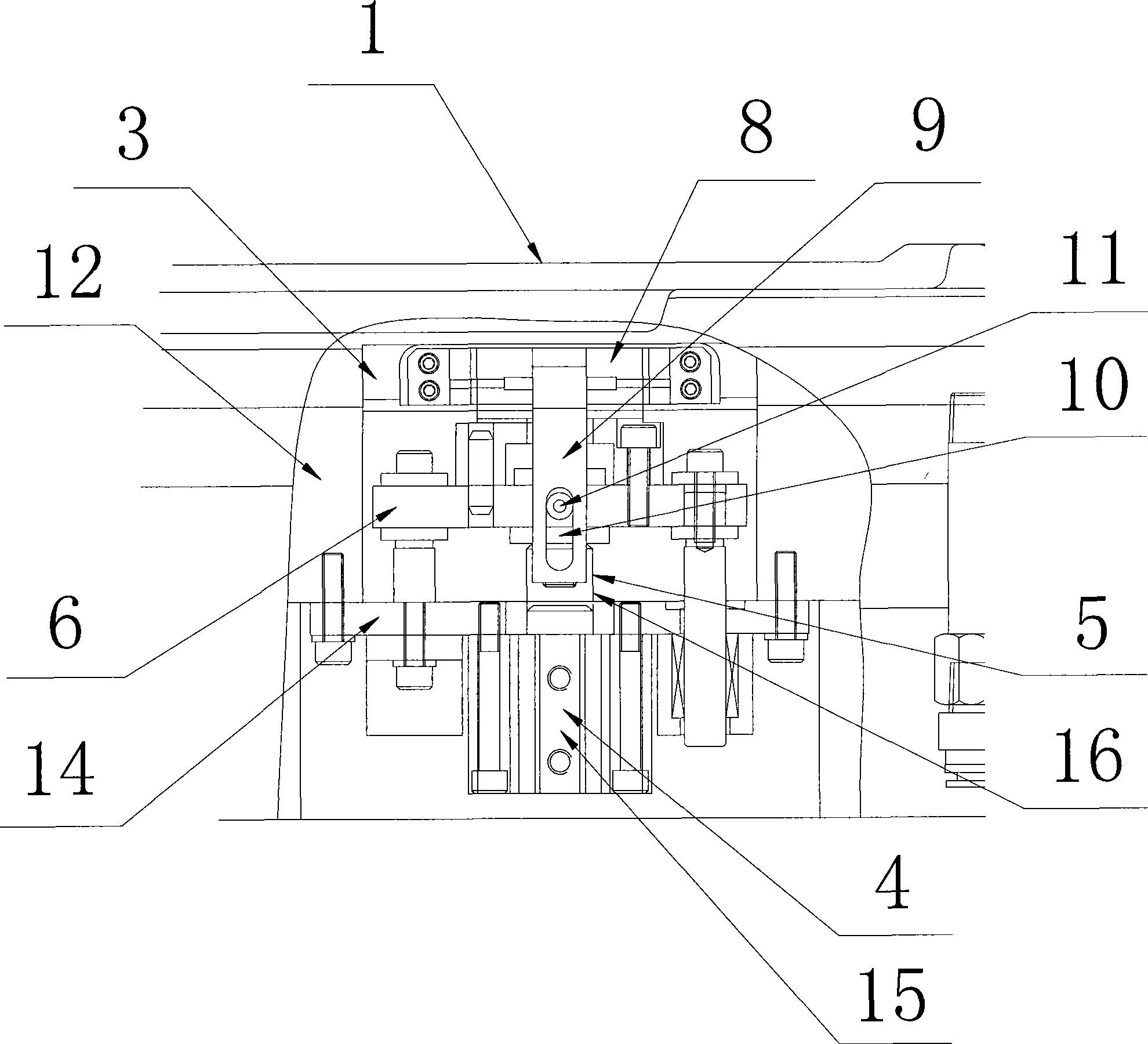

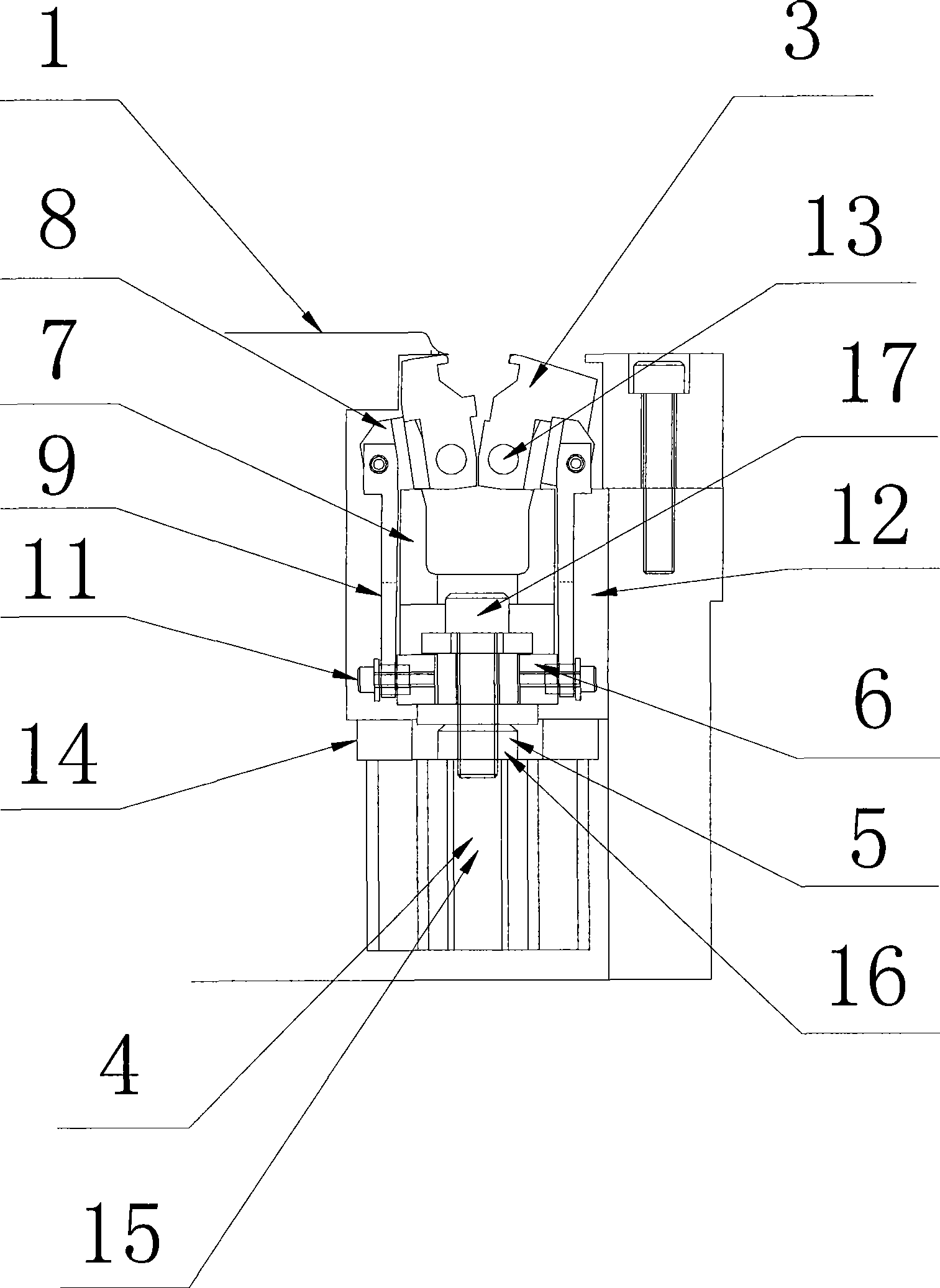

Refrigerator door liner sealing groove forming die

InactiveCN101462356AAvoid local deformationThe demoulding process is safe and stableDomestic articlesMovable typeEngineering

Owner:昆山市三建模具机械有限公司

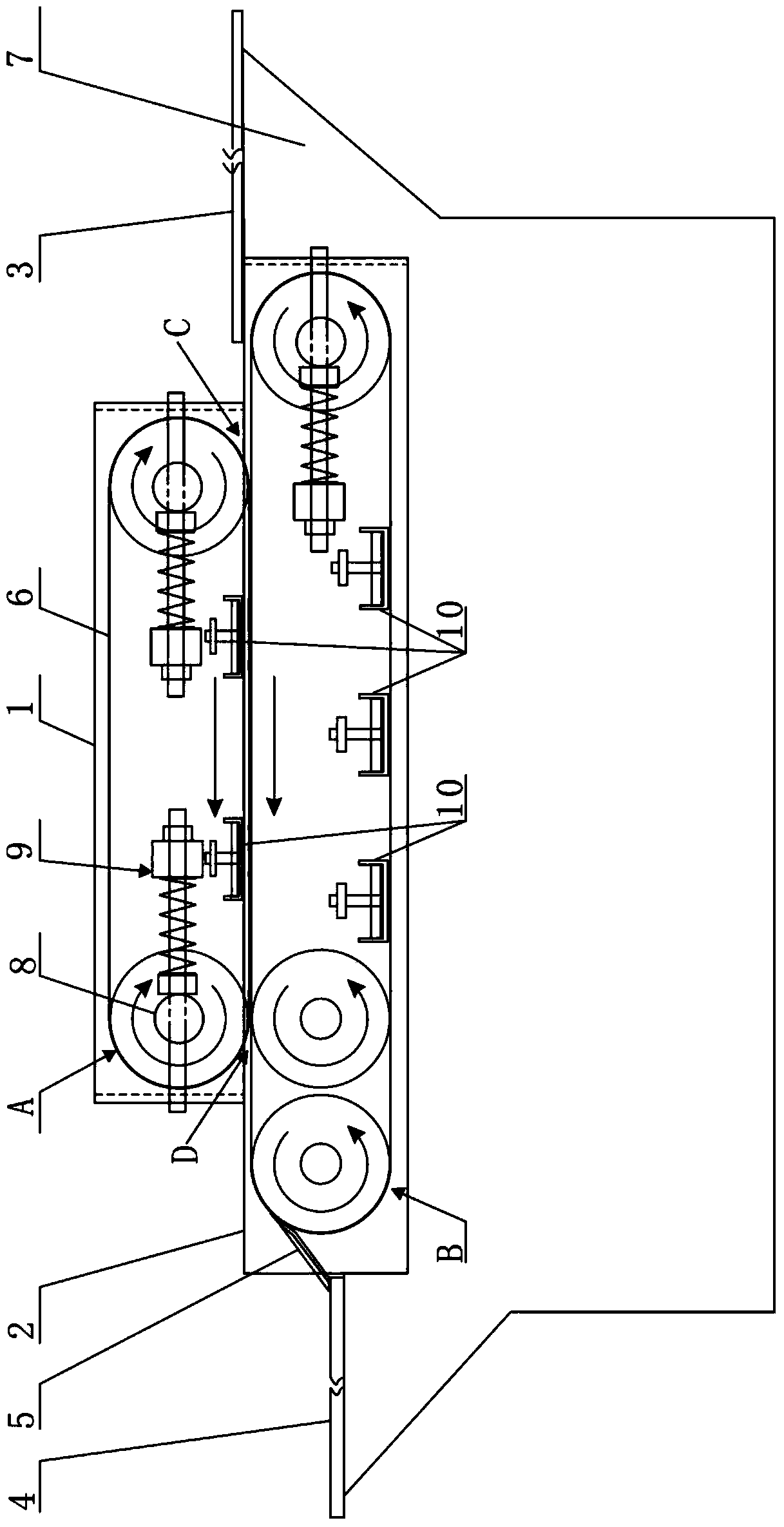

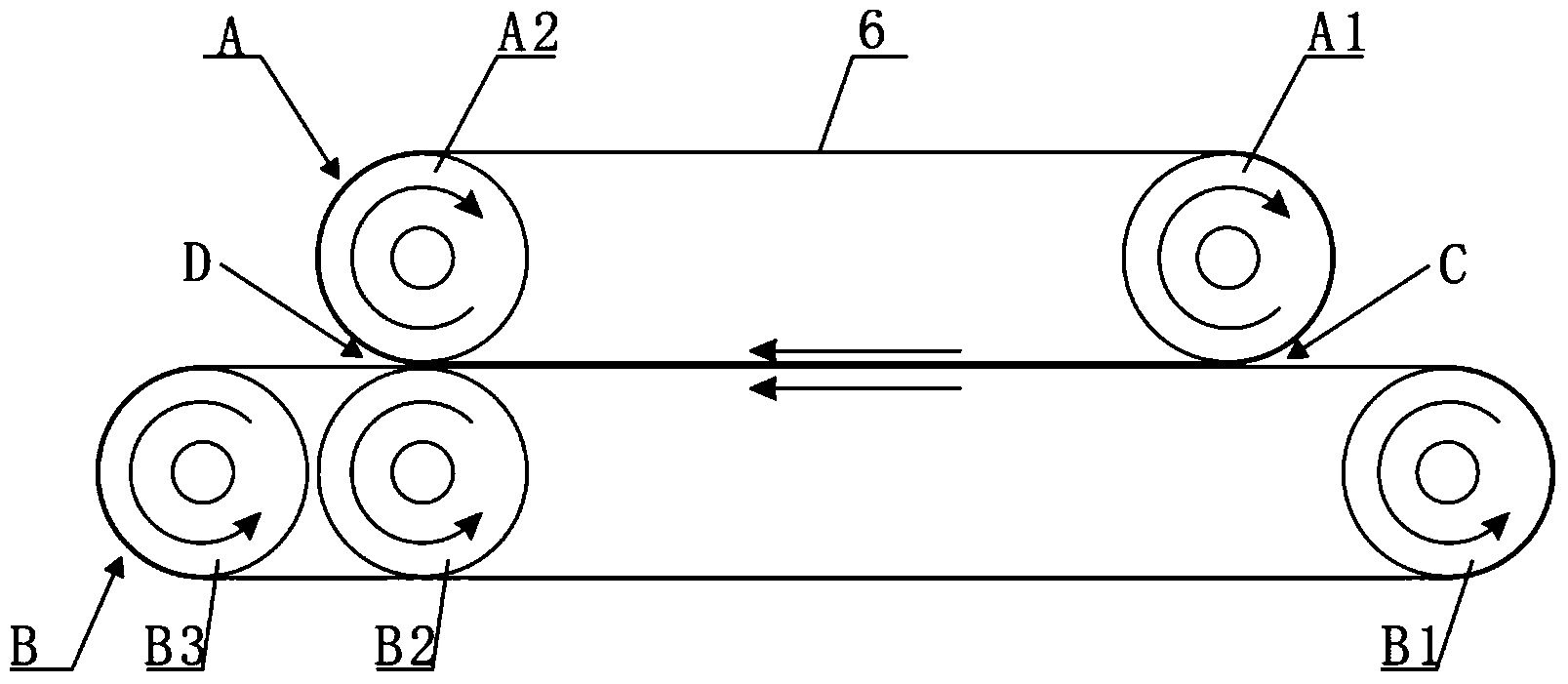

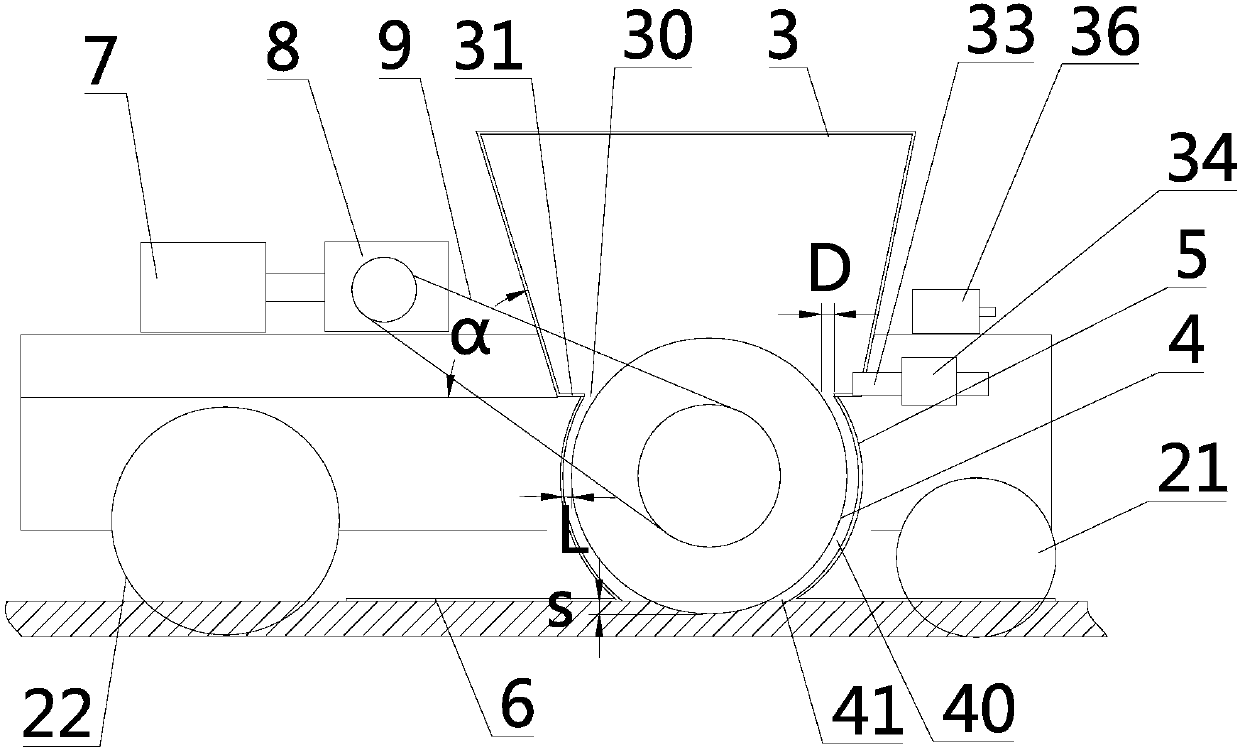

Drum type leather gluing machine and production process thereof

ActiveCN104070764AQuality assuranceAvoid local deformationLaminationLamination apparatusConveyor beltSizing

The invention discloses a drum type leather gluing machine. The drum type leather gluing machine comprises an upper conveyor belt and a lower conveyor belt which are arranged up and down and mutually matched for conveying and compacting leather and lining cloth, wherein a leather conveying channel is formed between the upper conveyor belt and the lower conveyor belt, the lower conveyor belt is longer than the upper conveyor belt, two ends of the lower conveyer belt both exceed the upper conveyor belt, and a lower roller II matched with an upper roller I for extruding the leather and the lining cloth is arranged in a position of the lower conveyor belt, which corresponds to the upper roller I. The invention further discloses a production process of the drum type leather gluing machine. The production process comprises the steps of arranging the leather and the lining cloth to be bonded on the conveyor belts, preheating, conveying into the leather conveying channel, heating, extruding, and cooling and sizing after outputting from the conveying channel. According to the drum type leather gluing machine and the production process thereof, the leather and the lining can be prevented from locally deforming and misplacing so that the leather and the lining cloth are flat and are firmly bonded, and the percent of pass is increased to 100 percent.

Owner:四川非意欧国际皮革制品有限公司

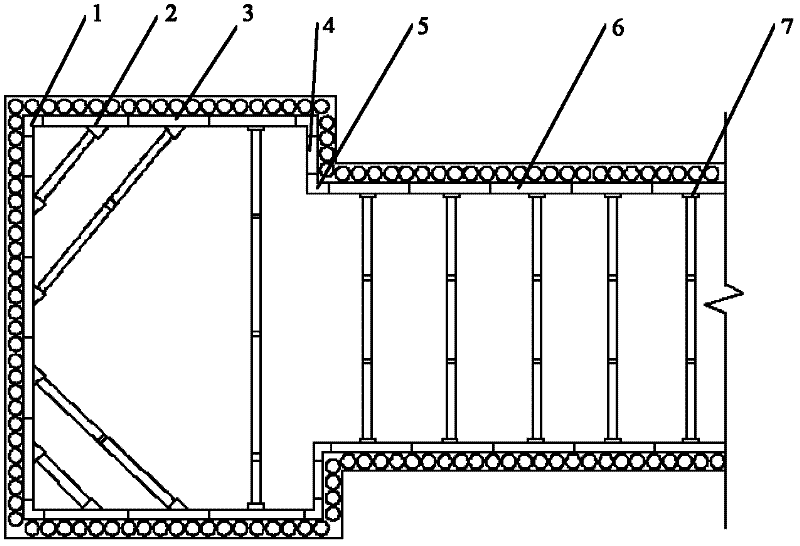

Enclosing purlin comprising square steel pipe and light concrete for supporting foundation pit

The invention relates to an enclosing purlin comprising a square steel pipe and light concrete for supporting a foundation pit. The enclosing purlin comprises the square steel pipe, light concrete, an end plate and support ribs, and replaces the original steel enclosing purlin, so as to reduce the consumption of steel material and cost. No cavity is formed in the light concrete, so as to enlarge partial rigidity and effectively avoid partial deformation; the end plate is used for sealing and connecting the enclosing purlin, so as to ensure better integrity of the whole support structure of the foundation pit; and the support ribs are used for preventing excessive deformation of a flange plate and prolonging the service life of the light concrete. During construction, a triangular bracket (small bracket) is erected, then an external member of the enclosing purlin is mounted, and finally, a steel bracing strut is erected and is connected with the enclosing purlin through the flange plate so as to be prevented from falling down. The enclosing purlin has the advantages of convenience in connection, high economical efficiency, reutilization, guaranteed rigidity, and excellent application value.

Owner:BEIJING UNIV OF TECH

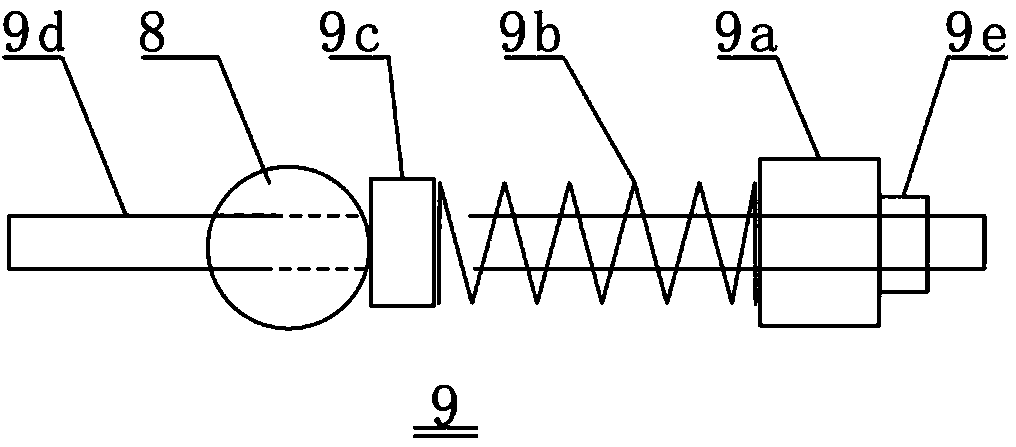

Reaction force generator

ActiveUS20150220105A1Avoid local deformationImprove feelEmergency actuatorsLimiting/preventing/returning movement of partsEngineeringMechanical engineering

Owner:YAMAHA CORP

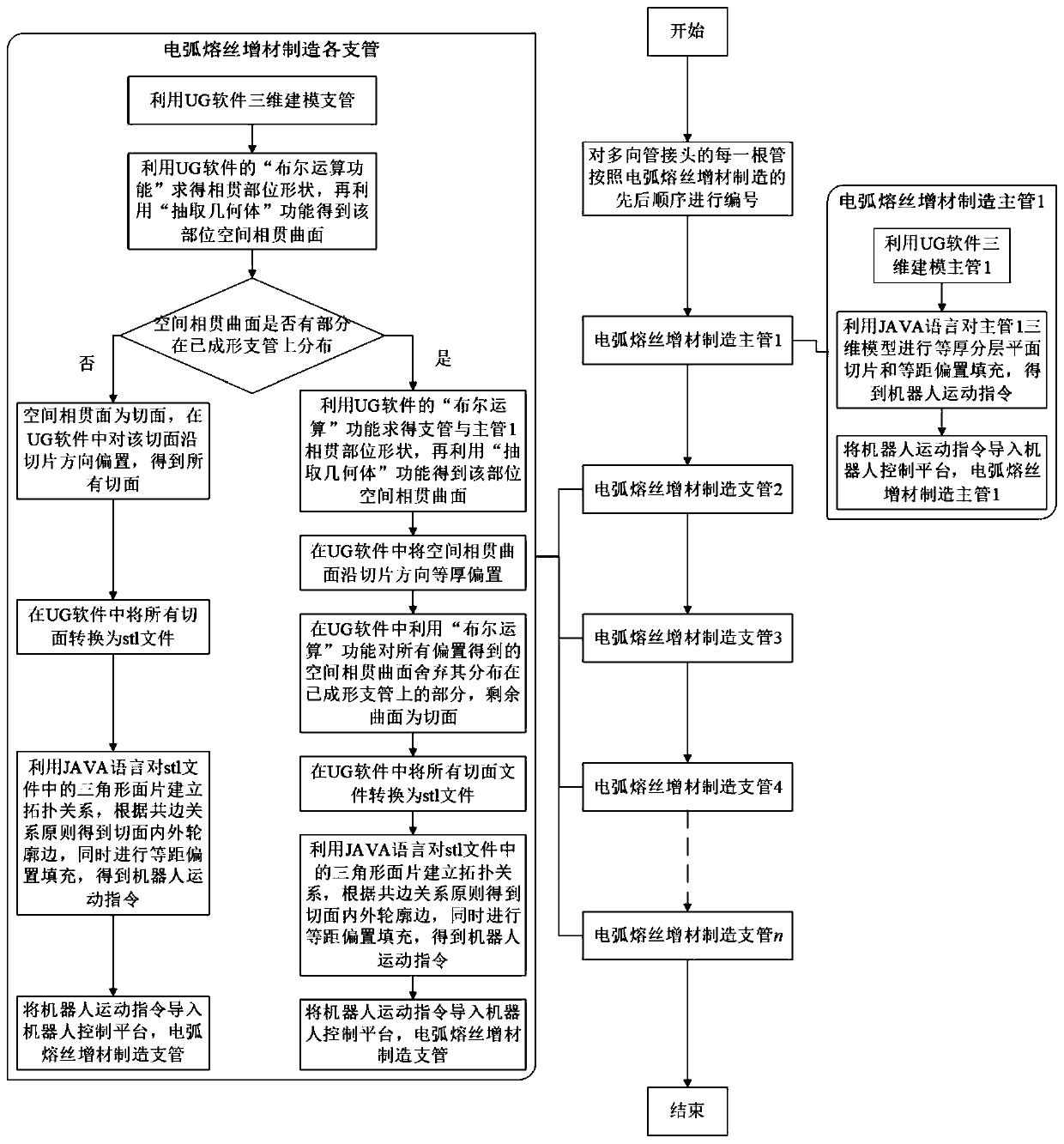

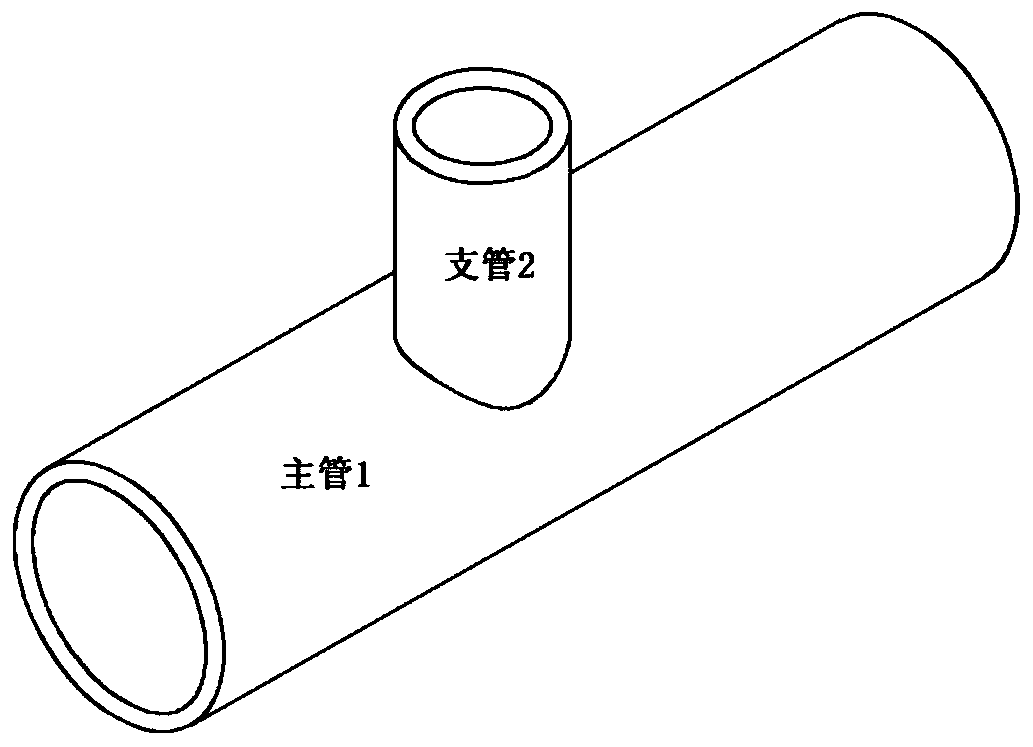

Electric arc fused additive manufacturing method for multidirectional steel connection

ActiveCN110802302AAvoid local deformationEfficient direct formingAdditive manufacturing apparatusWelding accessoriesManufacturing technologyEngineering

The invention belongs to the field of additive manufacturing, and discloses an electric arc fused additive manufacturing method for a multidirectional steel connection. The method comprises the following steps of S1, performing three-dimensional modeling on the multidirectional steel connection to obtain a main pipe model and all branch pipe models of the multidirectional steel connection; S2, planning a stacking path of the main pipe model in a manner of equal-thickness hierarchy planar slicing and equidistant biased filling, and generating a corresponding motion command according to the stacking path; S3, planning a stacking path of each branch pipe model in the manner of equal-thickness hierarchy planar slicing and equidistant biased filling, and generating corresponding motion commandsaccording to the stacking paths; and S4, controlling electric arc fused additive manufacturing equipment to perform main pipe forming according to the stacking path of the main pipe model, and controlling the electric arc fuse additive manufacturing equipment according to the motion commands of the stacking paths of all the branch pipe models to manufacture all branch pipes on a main pipe. The method avoids the defects that the shrinkage cavity defect and the shrinkage porosity defect are liable to generate during monoblock casting, weldability is poor during welding, and the like, and overcomes the problem that curved surface forming is hard to directly realize by an electric arc fused additive manufacturing technology, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for drying honeycomb formed structure

ActiveUS7320183B2Avoid deformationPartly driedDielectric heatingDrying using combination processesHoneycombHoneycomb like

Owner:NGK INSULATORS LTD

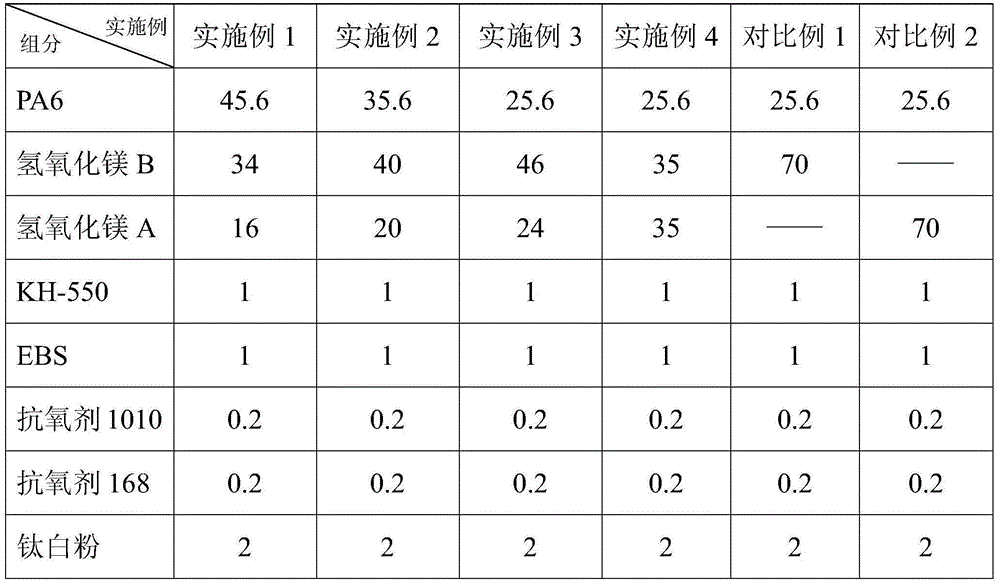

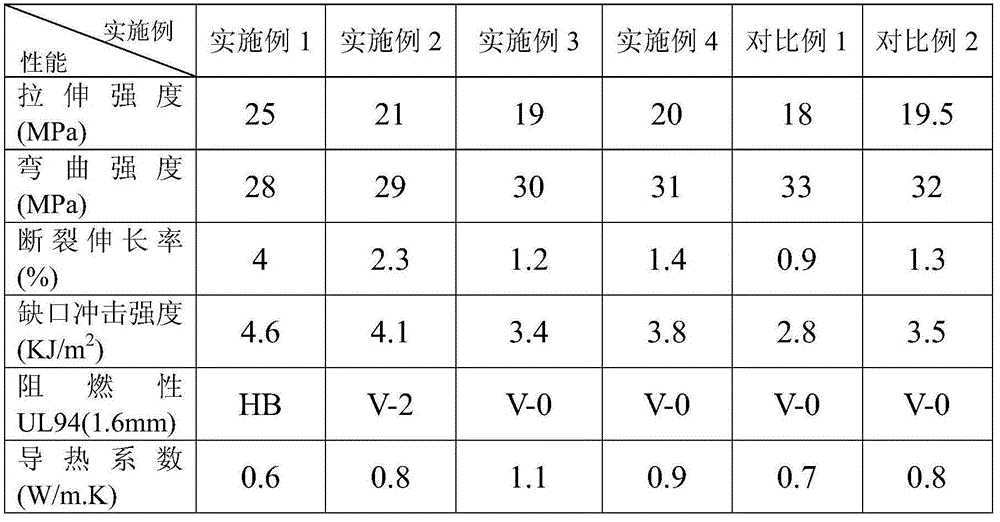

Thermally conductive polypropylene-based composite material and preparation method thereof

InactiveCN105086155AHigh thermal conductivityImprove thermal conductivityPolypropyleneLarge particle

The invention relates to a thermally conductive polypropylene-based composite material and a preparation method thereof. The thermally conductive polypropylene-based composite material comprises PP and a thermally conductive filler. The conductive filler comprises magnesium hydroxide A with particle diameter of 200-1,500 mesh and magnesium hydroxide B with particle diameter of 5,000-12,000 mesh. The conductive filler of the thermally conductive polypropylene-based composite material employs two kinds of magnesium hydroxide with different particle sizes for complex, so that the magnesium hydroxide particles with large particle diameter form a conductive network, and the magnesium hydroxide particles with small particle size are filled between the large particles to finely fill the conductive network, and to help improve the thermal conductivity of plastics. In addition, magnesium hydroxide belongs to halogen-free flame retardant, and after magnesium hydroxide is added to the PP, the PP gains improved thermal conductivity and certain flame retardance.

Owner:东莞市宝临塑胶有限公司

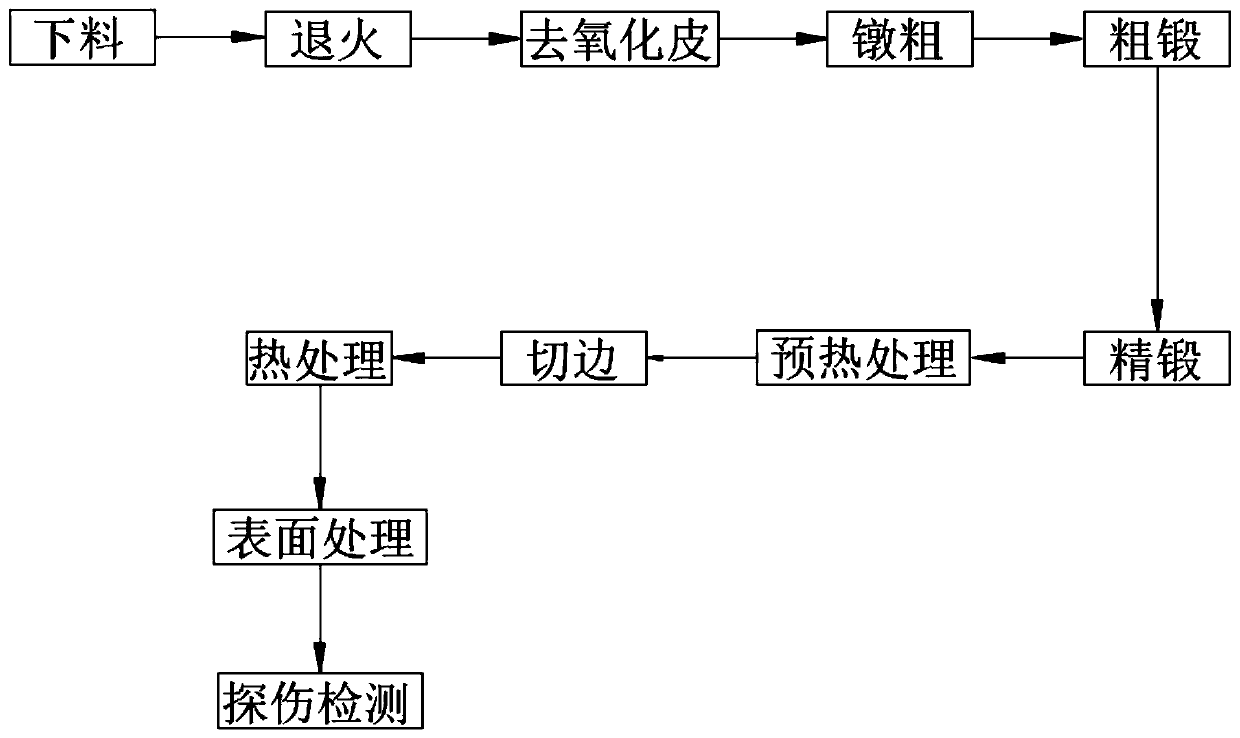

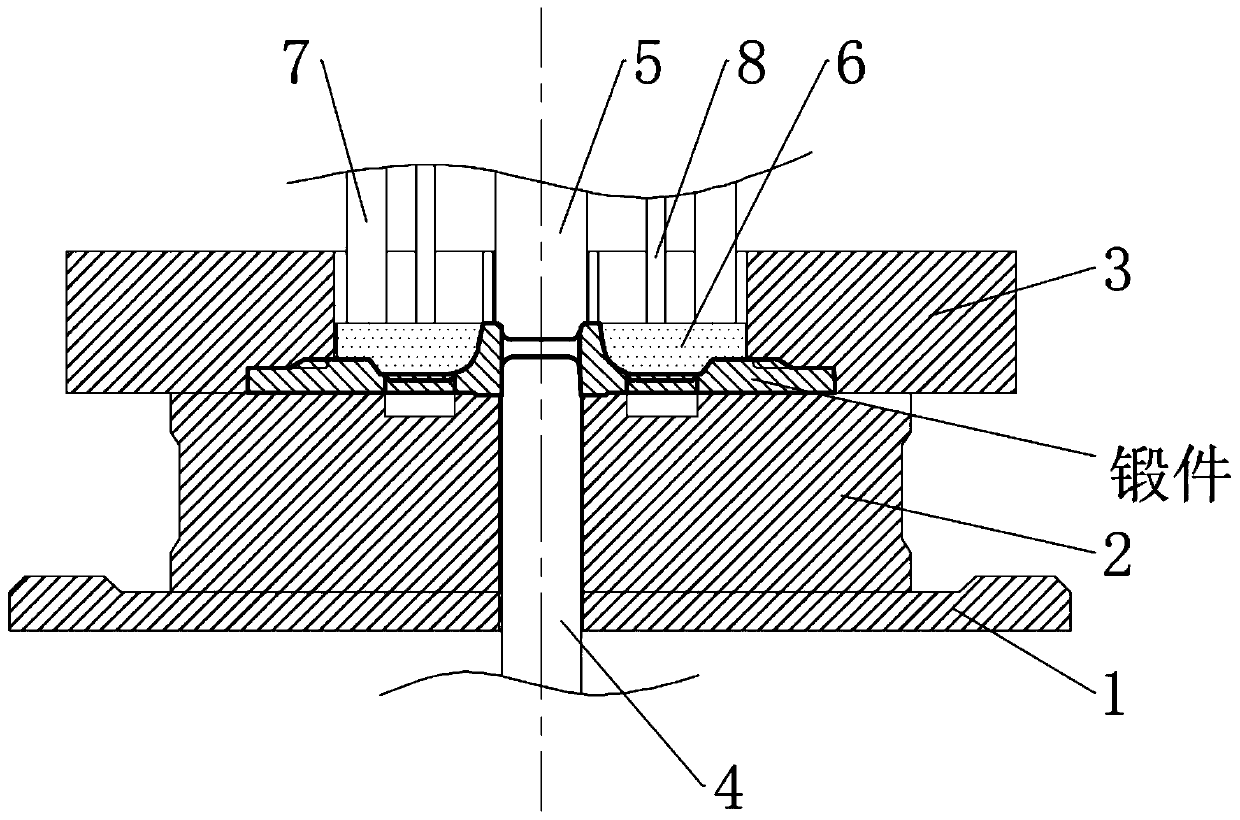

Forging technology for synchronous waste-removing and weight-reduction of forge piece

ActiveCN110722078AAvoid local deformationEasy to useForging/hammering/pressing machinesForging press detailsTemperature controlPunching

The invention discloses a forging technology for synchronous waste-removing and weight-reduction of a forge piece, and belongs to the technical field of forge piece processing. A weight-reduction partand an installation hole part of the forge piece can be achieved in the forging process; by installing a fractional punching mechanism in an existing precision forging die, the forge piece can be directly formed at a time in the forging process based on a thermal stress principle and a plastic deformation rule of the forge piece, and local deformation of the forge piece is prevented. Wastes are removed at a time, the machining difficulty and cumbersome operation brought by a machining process after forging are avoided, and the cost is further reduced; moreover, punching burrs on a non-machining surface can be avoided, and the whole machining workload is reduced; assisted by precise temperature control in the whole process, the shape of the flange hub forge piece can be obtained, dimensional deviations are not likely to be produced, structures in metal can be improved, the mechanical performance and the physical performance of the metal are improved, and therefore, the flange hub forgepiece higher in use performance and longer in life.

Owner:浙江众盈汽车零部件有限公司

Photothermographic recording material

InactiveUS6607872B1Improve imaging effectIncrease photosensitivityX-ray/infra-red processesPhotothermographic systemsWater dispersibleHeat sensitive

A photothermographic recording material comprising a photo-addressable thermally developable element coatable from aqueous media comprising a substantially light-insensitive organic silver salt, photosensitive silver halide in catalytic association with the substantially light-insensitive organic silver salt and a reducing agent in thermal working relationship with the substantially light-insensitive organic silver salt and a binder, characterized in that the binder comprises a water-soluble polymer, a water-dispersible polymer or a mixture of a water-soluble polymer and a water-dispersible polymer and particles of the photosensitive silver halide are non-aggregating in the photo-addressable thermally developable element and are uniformly distributed over and between particles of the substantially light-insensitive organic silver salt, at least 80% by number of the particles having a diameter, determined by transmission electron microscopy, of <=40 nm; and a recording process therefor.

Owner:AGFA HEALTHCARE NV

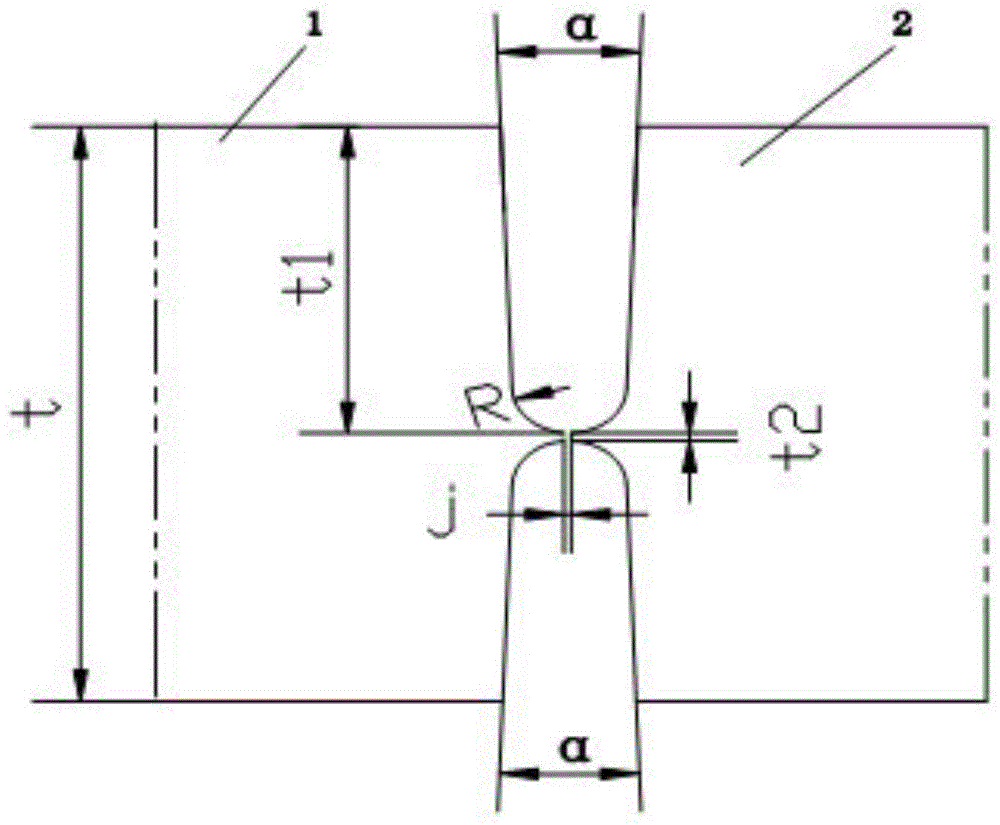

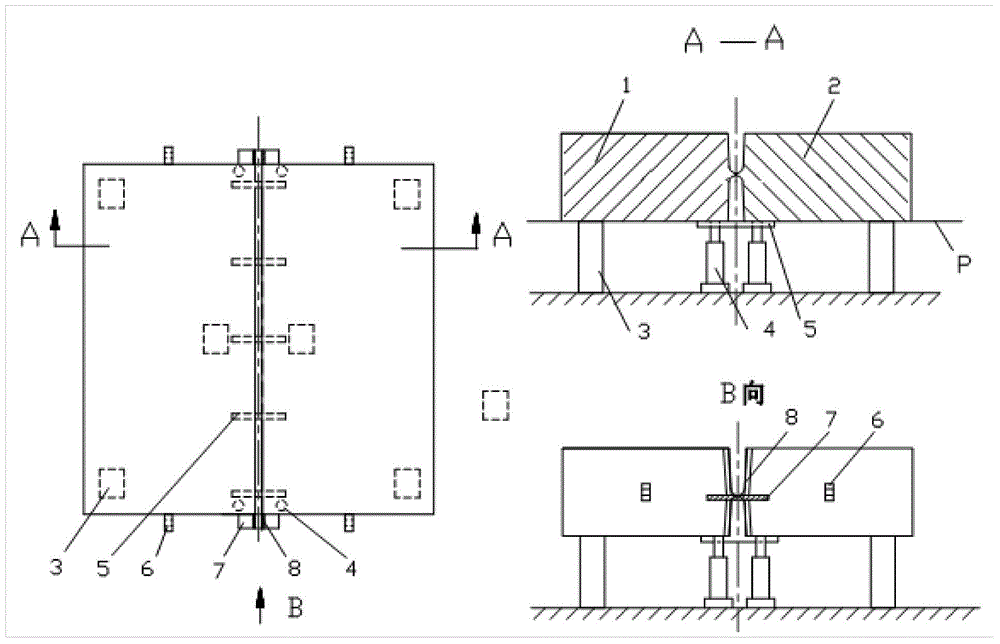

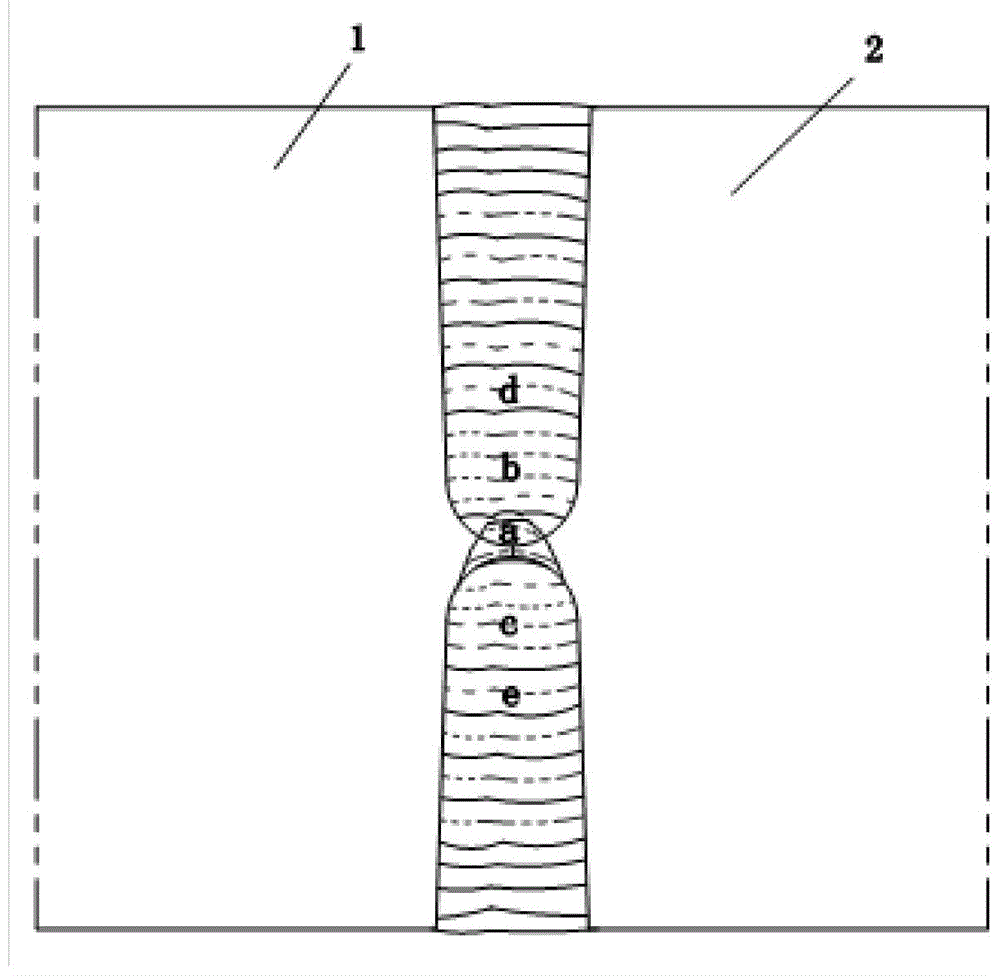

Method for controlling tailor welding deformation of large metal pipe plate

ActiveCN104148773AReduce welding restraintReduce consumptionArc welding apparatusFurnace typesSheet steelEngineering

Disclosed is a method for controlling tailor welding deformation of a large metal pipe plate. The diameter of the large metal pipe plate ranges from 5,000 mm to 10,000 mm, and the thickness of the large metal pipe plate ranges from 60 mm to 400 mm. GB150.2 steel plates are adopted as materials for tailor welding. A pipe plate blank is formed by two to three steel plates in a tailor welding mode, asymmetric narrow-gap U-shaped grooves are adopted in welding grooves, the size R of the grooves is equal to 10 mm to 12 mm, and welding fusion quality and back gouging can be improved conveniently. The depth t1 of the upper groove is 8 mm to 10 mm larger than that of the lower groove, and after back gouging, welding joints of the upper groove and the lower groove are filled with basically-identical metal. The root face t2 of the grooves is equal to 1 mm to 3 mm, the angle alpha of the grooves ranges from three degrees to five degrees, the root clearance j is equal to 0 mm to 2 mm, and therefore the filling amount of welding metal is reduced. According to the method, tailor welding deformation of the pipe plate can be controlled precisely, and the metal consumption amount of the pipe plate blank is reduced.

Owner:云南大为化工装备制造有限公司

Automobile bumper

The invention relates to the technical field of automobile protection, in particular to an automobile bumper. The automobile bumper comprises a U-shaped bumper body, a plurality of rubber blocks are arranged on the surface of the U-shaped bumper body, and a first protection plate is arranged below the U-shaped bumper body. The automobile bumper comprises the U-shaped bumper body, the first protection plate, a safety air bag, wave-shaped energy-absorption pads and a second protection plate. When impact force of collision is small, the U-shaped bumper body and the first protection plate directlyadopt telescopic rods and compression springs for preliminary buffer, and the impact force is further weakened through the wave-shaped energy-absorption pads; when the impact force of collision is excessively large, the safety air bag works; in addition, L-shaped clamping hooks are arranged on the lower portion of the second protection plate, and mounting plates and connecting blocks are arrangedon the lower portions of the L-shaped clamping hooks; and the L-shaped clamping hooks can slide in clamping hook sliding grooves in the connecting blocks and are fixed to the connecting blocks and threaded holes formed in the mounting plates through bolts, so that the height is adjusted, and the automobile bumper is prevented from colliding to the road surface.

Owner:合肥鑫诚轿车技术服务有限公司

Photothermographic recording material coatable from an acqueous medium

InactiveUS6187528B1Improve imaging effectEasy to wearX-ray/infra-red processesTransportation and packagingWater dispersibleWater soluble

A photothermographic recording material comprising a support and a photo-addressable thermally developable element comprising photosensitive silver halide in catalytic association with a substantially light-insensitive organic silver salt, an organic reducing agent for the substantially light-insensitive organic silver salt in thermal working relationship therewith and a water-soluble or water-dispersible binder, characterized in that the substantially light-insensitive organic silver salt is a silver salt of an organic carboxylic acid, the photo-addressable thermally developable element further comprises a non-ionic or anionic surfactant and the photo-addressable thermally developable element is coatable from an aqueous medium and is capable of producing stable images without a wet-processing step; a process for producing the photothermographic recording material and a photothermographic recording process therefor.

Owner:AGFA HEALTHCARE NV

Mortar painting vehicle

InactiveCN108035526AApply evenlyApply smoothly and evenlyBuilding constructionsCavity wallMaterials science

The invention discloses a mortar painting vehicle. The problems of low mortar painting efficiency and low painting quality are solved. According to the technical scheme for solving the problems, the vehicle mainly comprises a vehicle body, front wheels, back wheels and a mortar tank on the vehicle body, a mortar painting structure is arranged below the vehicle body and comprises a mortar roller, amortar roller shell and a mortar painting plate for flatly painting mortar, and an extrusion cavity which is communicated with an inner cavity of the mortar tank is formed in the mortar roller shell;the mortar roller is transversely arranged and rotatably connected to the cavity wall of the extrusion cavity, a mortar outlet is formed in the bottom of the extrusion cavity, and the bottom of the mortar roller extends 2-7 mm out of the mortar outlet; the mortar painting plate is tightly attached to the ground to be painted and extends outward from the edge of the mortar outlet, a mortar clapboard is arranged on the bottom of the mortar tank, and flow gaps for mortar in the mortar tank to flow into the extrusion cavity are formed in the peripheral side surfaces of the mortar clapboard and the mortar roller; the width D of the flow gaps is 10-50 mm, and the proportion of the spacing distance L between the mortar roller and the mortar roller shell to the width D of the flow gaps is 0.6-1.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com