Thermally conductive polypropylene-based composite material and preparation method thereof

A composite material and polypropylene-based technology, applied in the field of composite materials, preparation of thermally conductive polypropylene-based composite materials, and thermally conductive polypropylene-based composite materials, can solve the problems of increasing production costs and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the embodiments.

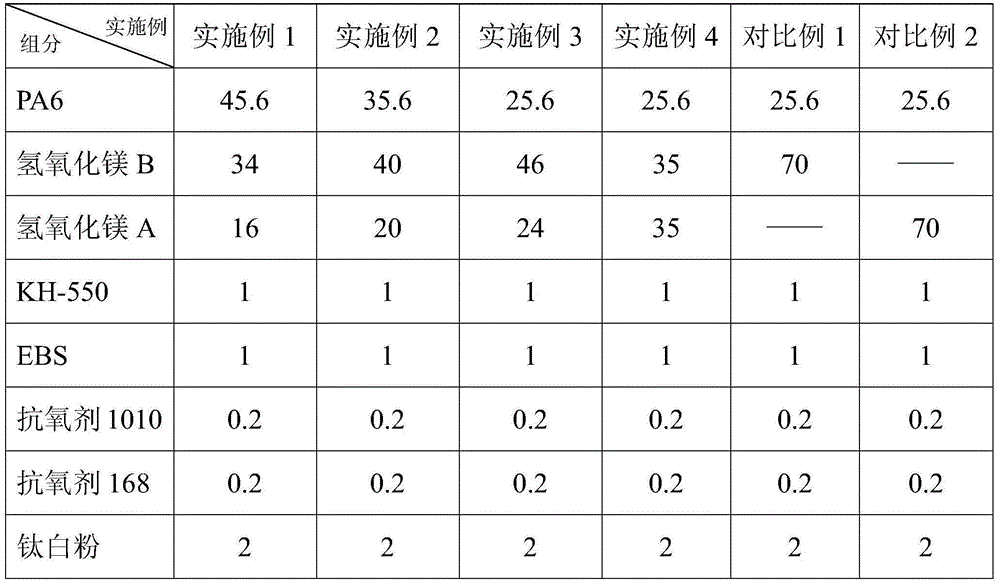

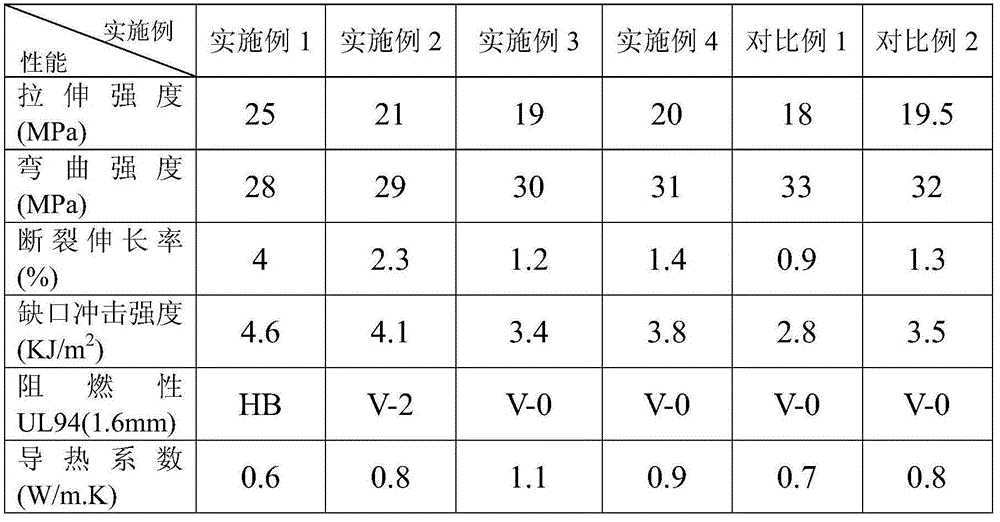

[0051] The components and contents of the thermally conductive polypropylene-based composite materials of Examples 1 to 4 and Comparative Examples 1 and 2 are shown in Table 1. Among them, PP (polypropylene) is the base resin, and the melt index of PP is 4-10g / min, specifically 8g / min; the coupling agent is KH-550, the antioxidant is a mixture of 1010 and 168; the lubricant is EBS (N,N'-ethylene bis-stearamide), the whitening agent is titanium dioxide.

[0052] The thermally conductive fillers include magnesium hydroxide A and magnesium hydroxide B, the particle size of magnesium hydroxide A is 200-1500 mesh, and the particle size of magnesium hydroxide B is 5000-12000 mesh; The diameter is arbitrarily selected within the above-mentioned range. Specifically, the particle diameter of magnesium hydroxide A is 800 meshes, and the particle diameter of magnesium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com