Refrigerator door liner sealing groove forming die

A technology for refrigerators and forming molds, which is applied to household components, household appliances, and other household appliances. It can solve problems such as strain on the sealing groove, affect the final quality of the product, and scratches, so as to prevent local deformation and demoulding. safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

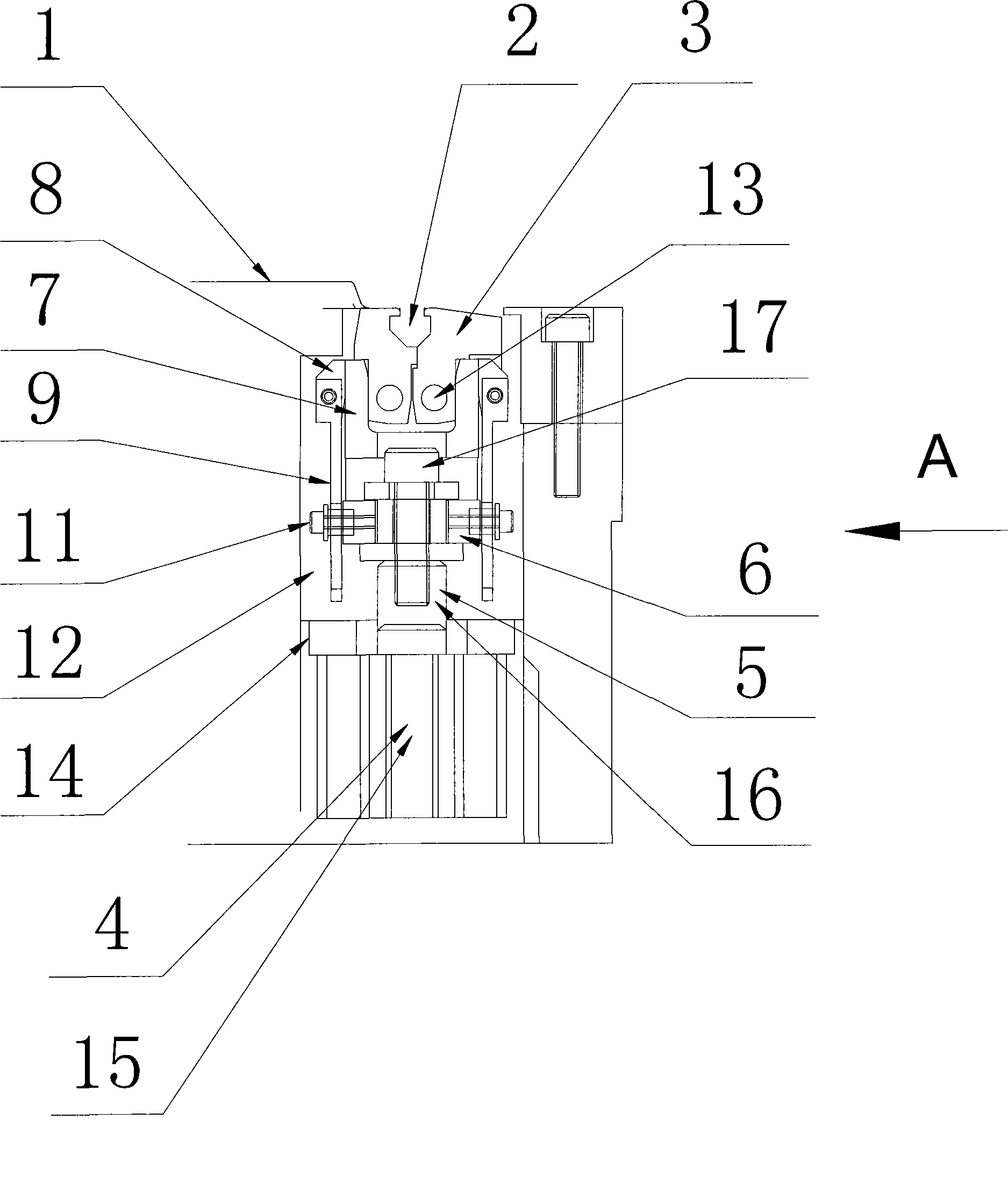

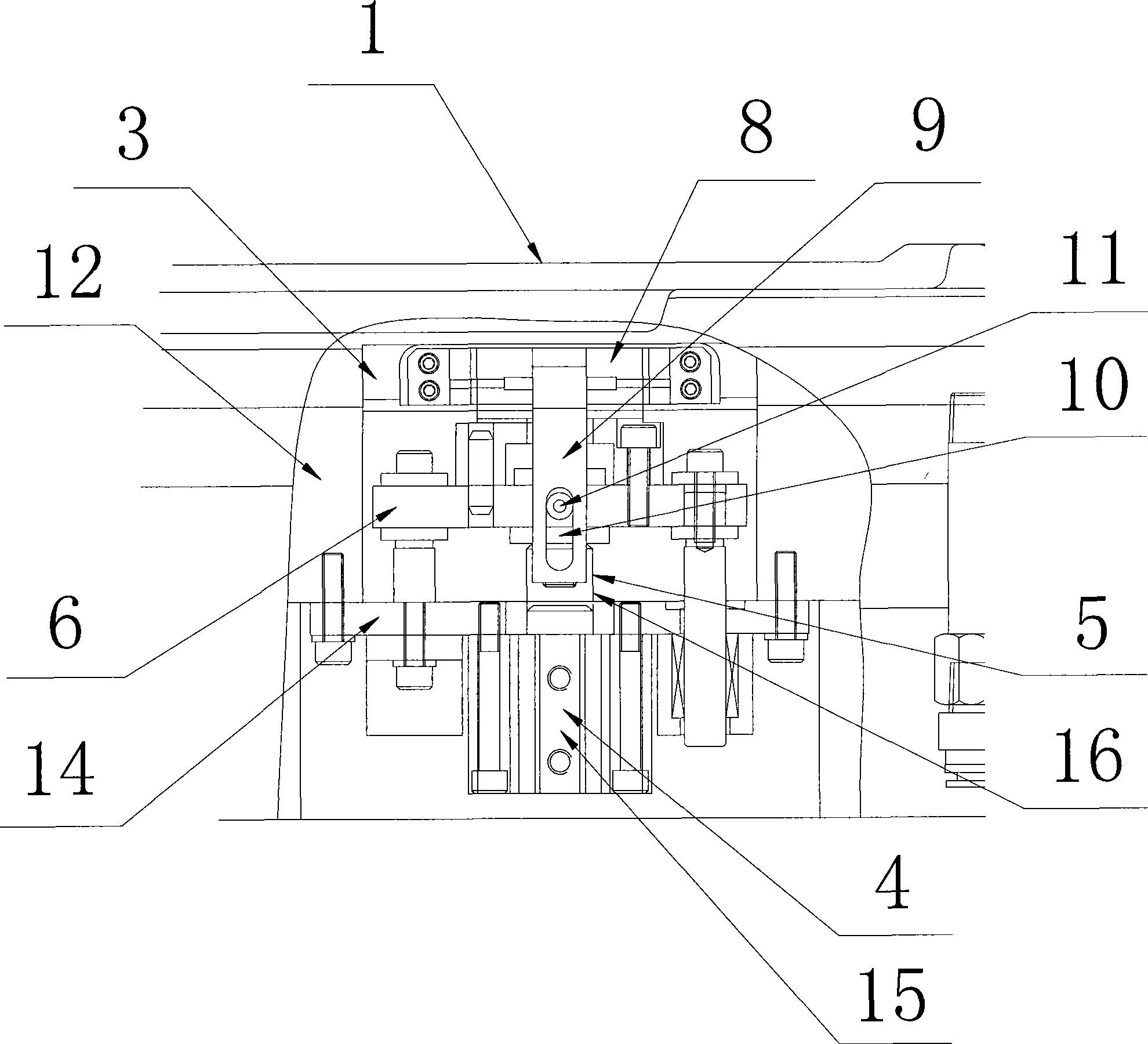

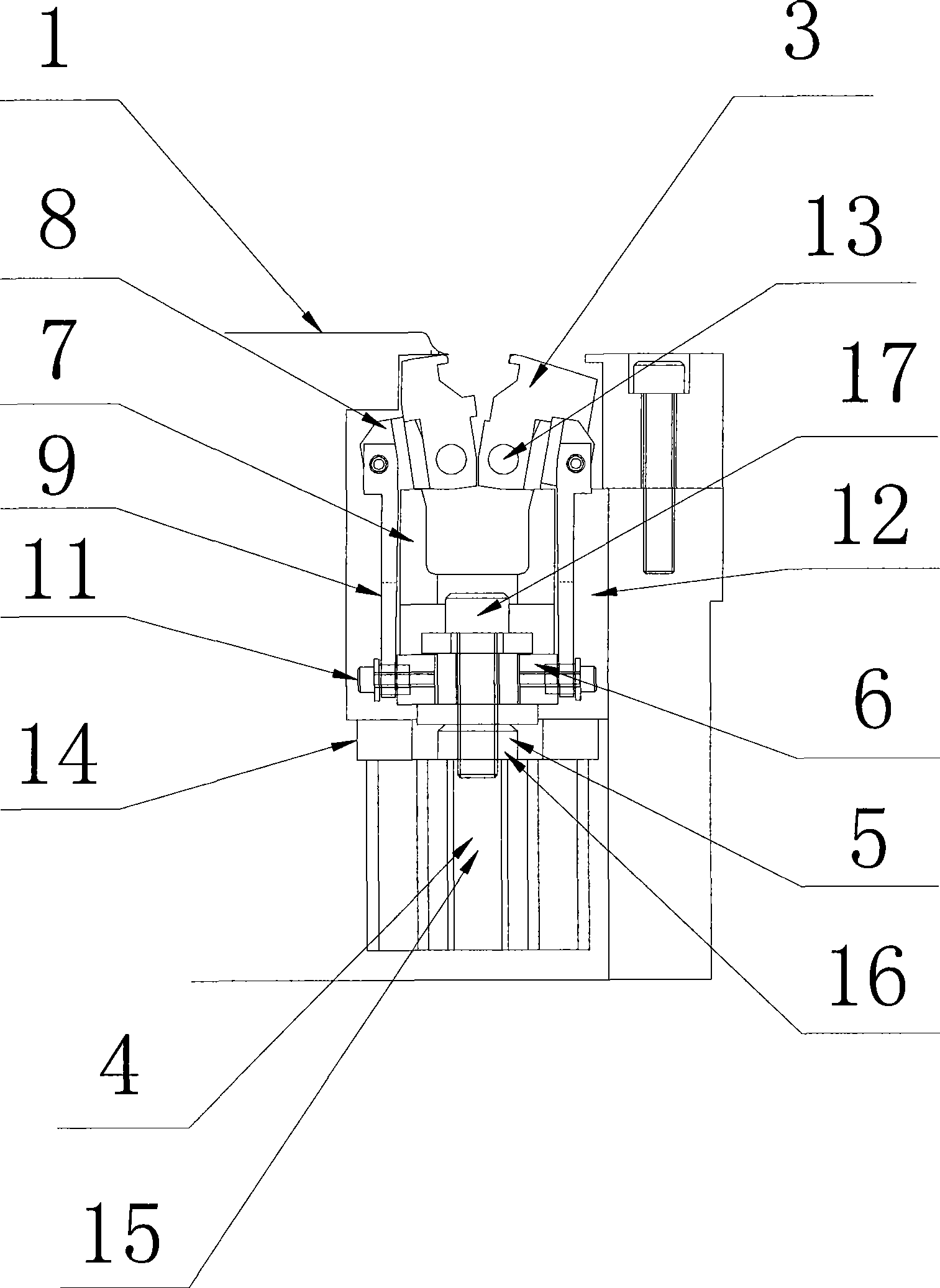

[0021] Example: Combine figure 1 , figure 2 with image 3 Shown is a specific embodiment of the refrigerator door gall sealing groove forming mold of the present invention, which is installed as an insert in the socket 12 around the body 1 of the refrigerator door gall plastic mold body 1, and includes two oppositely flipped buckles. Forming the turning bar 3 of the groove forming cavity 2 and at least one power device for driving the two turning bars 3 to move. This power device is composed of a driving element 4 and a transmission mechanism connecting the driving element 4 and the two turning bars. .

[0022] In this embodiment, both ends of each turning bar 3 are pinned in the slot 12 through a cylindrical pin 13, and at the same time, a mounting plate 14 located below the two turning bars 3 is fixed in the slot 12, and the driving element 4 is fixed on the slot 12. On the mounting plate 14, it includes an output head 5 that can be stretched up and down; and the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com