Electric arc fused additive manufacturing method for multidirectional steel connection

A technology of additive manufacturing and steel joints, applied in the field of additive manufacturing, can solve the problems of easy local deformation of formed parts and difficulty in directly forming irregular curved surfaces, so as to avoid shrinkage cavities, solve poor forming quality, and improve heat dissipation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

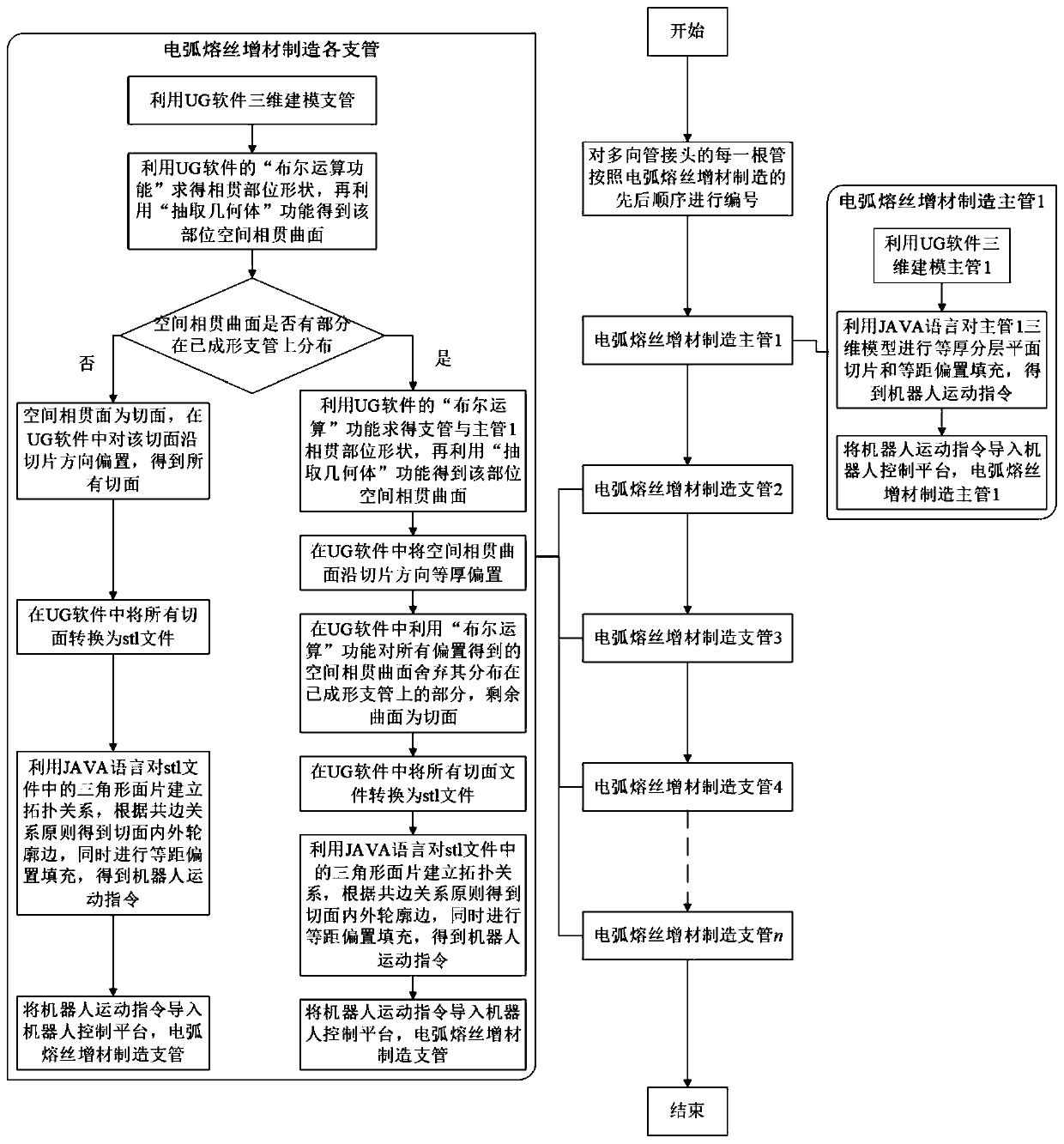

[0055] Using the multidirectional steel node arc fuse additive manufacturing method of the present invention to form a three-way steel node composed of two pipe bodies, both of which are round pipes, includes the following steps:

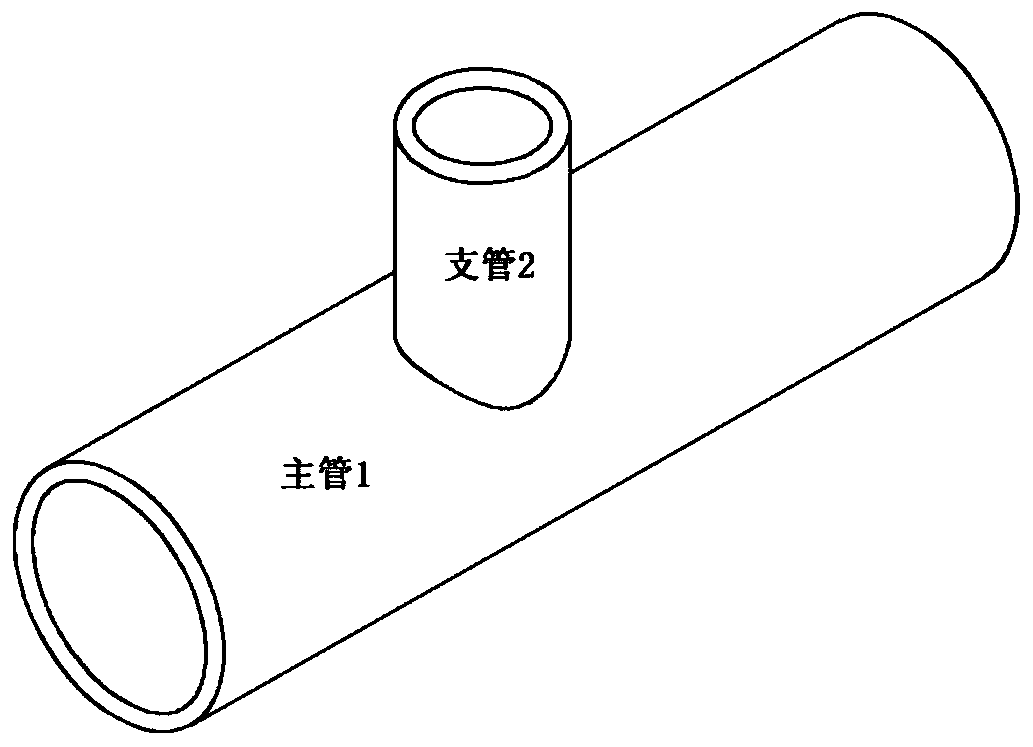

[0056] Step 1: Number the main pipes and branch pipes in the drawing of the three-way steel joint according to the order of arc fuse additive manufacturing. The main order is: the main pipe number is 1, and the branch pipe number is 2, such as figure 2 shown;

[0057] Step 2: Carry out three-dimensional modeling in UG software according to the specified size of the main pipe 1 in the drawing of the three-way steel joint. In this embodiment, the inner diameter of the main pipe 1 is 243mm and the outer diameter is 267mm;

[0058] Step 3: For the 3D model of the main pipe 1, plan the stacking path by means of equal-thickness layered plane slicing and equidistant offset filling:

[0059] Use the plane slicing program written in JAVA language to slice ...

Embodiment 2

[0072] Using the multi-directional steel node arc fuse additive manufacturing method of the present invention to form a four-way steel node composed of three pipe bodies, all of which are round pipes, includes the following steps:

[0073] Step 1: Number the main pipe and the two intersecting branch pipes in the drawing of the four-way steel joint according to the order of arc fuse additive manufacturing. The main order is: the main pipe is numbered 1, and the two branch pipes are respectively numbered 2 , 3, such as Figure 6 shown;

[0074] Step 2: According to the method in Example 1, the arc fuse additively manufactures the three-way steel node where the main pipe 1 and the branch pipe 2 intersect. The inner diameter is 136mm and the outer diameter is 154mm;

[0075] The process parameters corresponding to the wire material selected for the four-way steel node arc fuse additive manufacturing are used for processing and manufacturing. In this embodiment, low-alloy high-st...

Embodiment 3

[0087] Utilizing the multi-directional steel node electric arc fuse additive manufacturing method of the present invention to form a five-directional steel node composed of four tube bodies, the four tube bodies contain three round tubes and one square tube, including the following steps:

[0088] Step 1: Number the main pipe in the drawing of the five-way steel joint and the three branch pipes intersecting on the main pipe according to the order of arc fuse additive manufacturing. The main order is: the main pipe is numbered 1, and the three branch pipes are respectively numbered 2, 3, 4, such as Figure 10 shown;

[0089] Step 2: According to the method in Example 2, the arc fuse additively manufactures the four-way steel joint of the main pipe 1, the branch pipe 2, and the branch pipe 3. In this embodiment, the inner diameter of the main pipe 1 is 220 mm, and the outer diameter is 240 mm. , branch pipe 2 inner diameter is 115mm, and outer diameter is 135mm, and branch pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com