Hydraulic-driving mode based in situ tensile/compression testing platform under scanning electron microscope

A driving method and scanning electron microscope technology, applied in the electromechanical field, can solve the problems of small load range, lack of credibility of macroscopic materials, lack of macroscopic cross-scale in-situ mechanical testing, etc., to achieve large output load and good structural compatibility. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

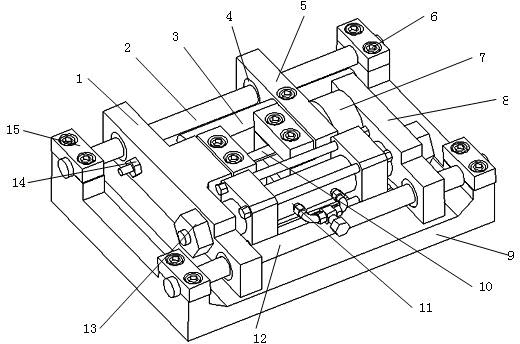

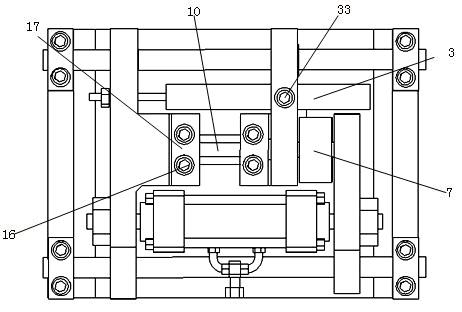

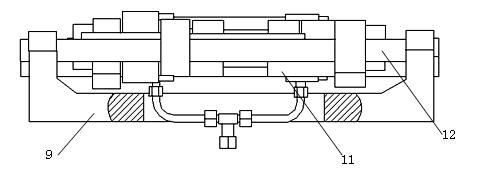

[0027] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0028] see Figure 1 to Figure 6 , the in situ tension / compression test platform under the scanning electron microscope based on the hydraulic drive mode of the present invention includes a hydraulic drive unit, a load / displacement signal detection and control unit, and a clamping and supporting unit; the hydraulic drive unit consists of a hydraulic cylinder 11 , oil tank 26, oil filter 27, motor 28, hydraulic pump 29, relief valve 30, throttle valve 31 and electro-hydraulic servo valve 32, wherein, the output end piston rod 23 of the hydraulic cylinder 11 is connected by the piston rod The screws 13 are rigidly connected to the clamp body support frame I1 and the force sensor support frame 8 respectively, the oil inlet pipeline 25 and the oil outlet pipeline 20 are respectively connected to the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com