Nano-grade Y type zeolite synthesized from kaolin and its preparation metod

A kaolin, nano-scale technology, applied in the field of nano-scale Y-type zeolite and its preparation, can solve the problems of agglomeration, difficulty in filtration, poor hydrothermal stability, etc., and achieve the effects of good dispersion, energy saving, and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of zeolite provided by the invention comprises the following steps:

[0025] (1) Convert kaolin to metakaolin by roasting and dehydrating at 500-690°C, pulverize it, and then make it into a powder with a particle size of less than 230 microns,

[0026] (2) Add sodium silicate, directing agent, sodium hydroxide solution and water to metakaolin powder to make a ratio of (1-2.5) Na 2 O:Al 2 o 3 :(4~9)SiO 2 :(40~100)H 2 The reaction raw material of O, wherein the weight ratio of directing agent and metakaolin is 0.1~1.0,

[0027] (3) crystallize the reaction raw material obtained in step (2) under stirring at 88-98° C., then filter and dry.

[0028] In the method, raw kaolin powder is roasted at a relatively low temperature to obtain metakaolin, and the kaolin used is selected from hard kaolin, soft kaolin or coal gangue, and its average particle size is less than 4 microns, so it is raw soil without molding treatment. The calcination temperatur...

example 1

[0043] The nanoscale Y-type zeolite of the present invention is prepared.

[0044] (1) Preparation of directing agent: get 250 grams of sodium silicate solution (containing 20.05% by weight of SiO 2 , 6.41 wt% Na 2 (0), slowly add 120 grams of sodium metaaluminate solution (containing 3.15% by weight of Al) under rapid stirring at 30°C 2 o 3 , 21.1 wt% Na 2 O), stirred for 1 hour, and aged at 20°C for 48 hours to obtain a directing agent. The composition of the directing agent is 16Na 2 O:Al 2 o 3 : 15SiO 2 : 320H 2 O.

[0045] (2) Preparation of zeolite

[0046] Kaolin with an average particle size of 4 μm (Suzhou, Yangshan brand, China Kaolin Company, crystal content is 80% by weight), roasted at 660 ° C for 3 hours to obtain metakaolin powder, pulverized to make metakaolin powder with a particle size of less than 230 μm .

[0047] Get 500 grams of pulverized metakaolin powder, add 2000 grams of sodium silicate solution (containing 20.05% by weight of SiO 2 , 6....

example 2

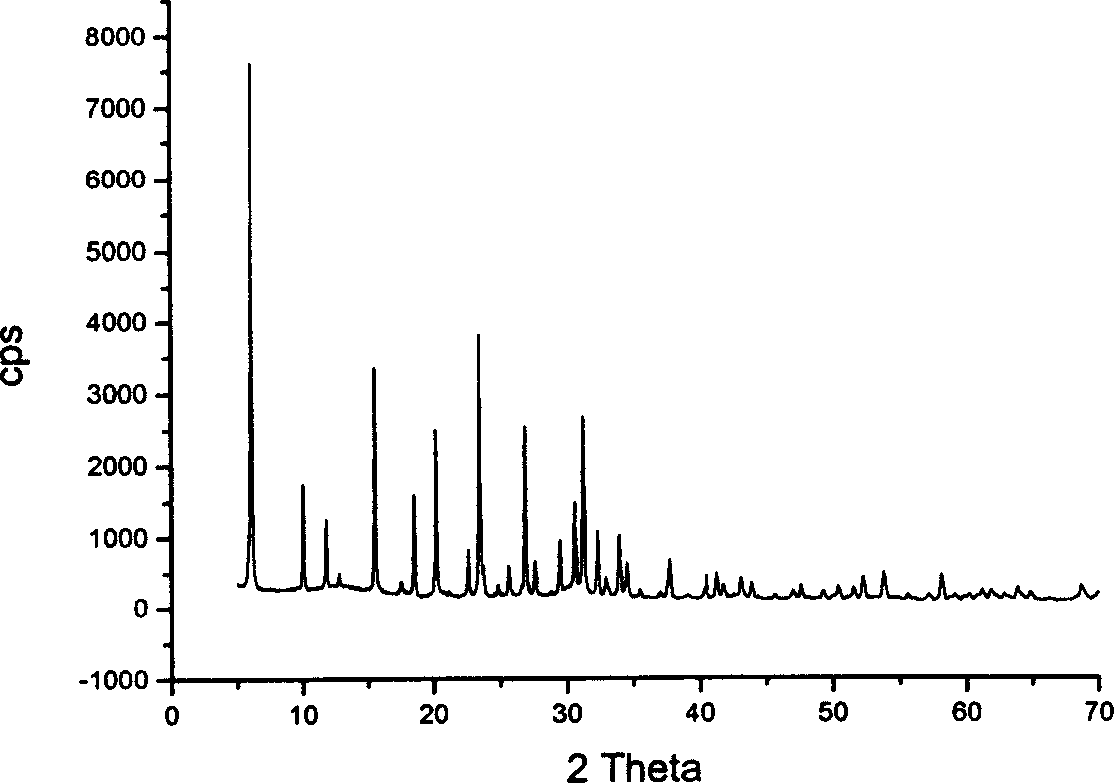

[0049] Zeolite Y-2 was prepared according to the method of Example 1, except that the raw material kaolin was roasted at 680° C. for 4 hours, and the stirring speed was 600 rpm when the reaction raw material was crystallized. X-ray diffraction measurement of NaY content in Y-2 is 52.4% by weight, its physical and chemical properties are shown in Table 1, and the X-ray diffraction spectrum is shown in figure 1 , field emission scanning electron microscope (SEM) photos of different magnifications are shown in Figure 2-5 .

[0050] From figure 1 As can be seen from the X-diffraction spectrum of the present invention, the zeolite of the present invention has a characteristic peak of NaY, and the content of NaY can be deduced from the height of the characteristic peak.

[0051] 5000x magnification SEM from Y-2 figure 2 As can be clearly seen in , the zeolites of the present invention consist of nested spheres with a diameter of less than 3000 nm. SEM with 20000x magnification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com