Technique of electrolytic oxidation for treating waste water of containing phenol

A technology of electrolytic oxidation and treatment process, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of small size of equipment, major market development prospects, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

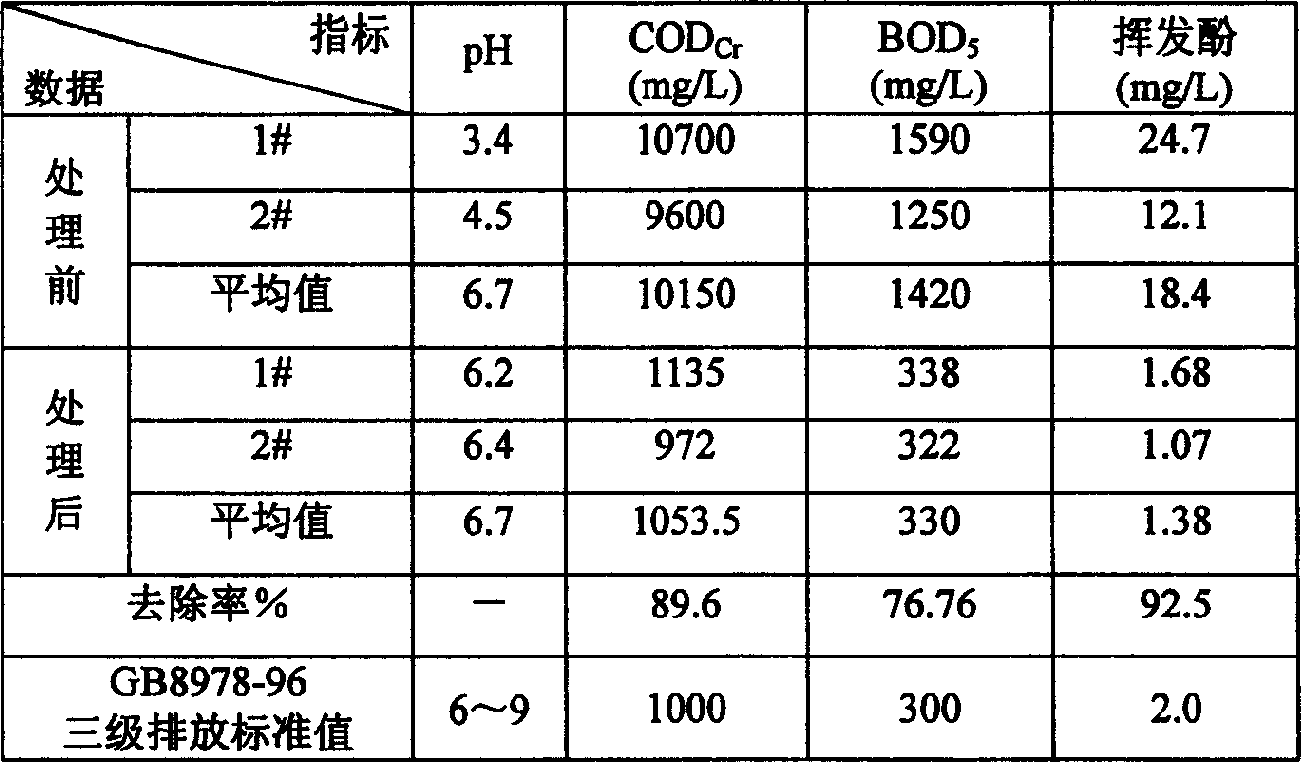

Embodiment 1

[0019] The embodiment and working principle of the present invention are: non-stirring, internal circulation, double synergistic electrolytic oxidation treatment process for wastewater containing phenol 12.1mg / L and 24.7mg / L, using polypropylene plate and frame electrolytic cell, using Ti-based PbO 2 The catalytic electrode is the anode, the stainless steel is the cathode, and the phenol-containing wastewater is the electrolyte. By electrolyzing the water in it, a strong oxidizing group is generated at the anode—hydroxyl radical·OH, and the cathode obtains electrons to generate H. 2 o 2 , the synergistic effect of the negative and positive poles realizes the deep oxidation and decomposition of phenol pollutants, so as to achieve the purpose of electrolytic oxidation treatment of phenol-containing wastewater; among them, the number of anode plates is 1, and the number of cathode plates is 2. The anodes and cathodes are arranged alternately and adjacent to each other. The distan...

Embodiment 2

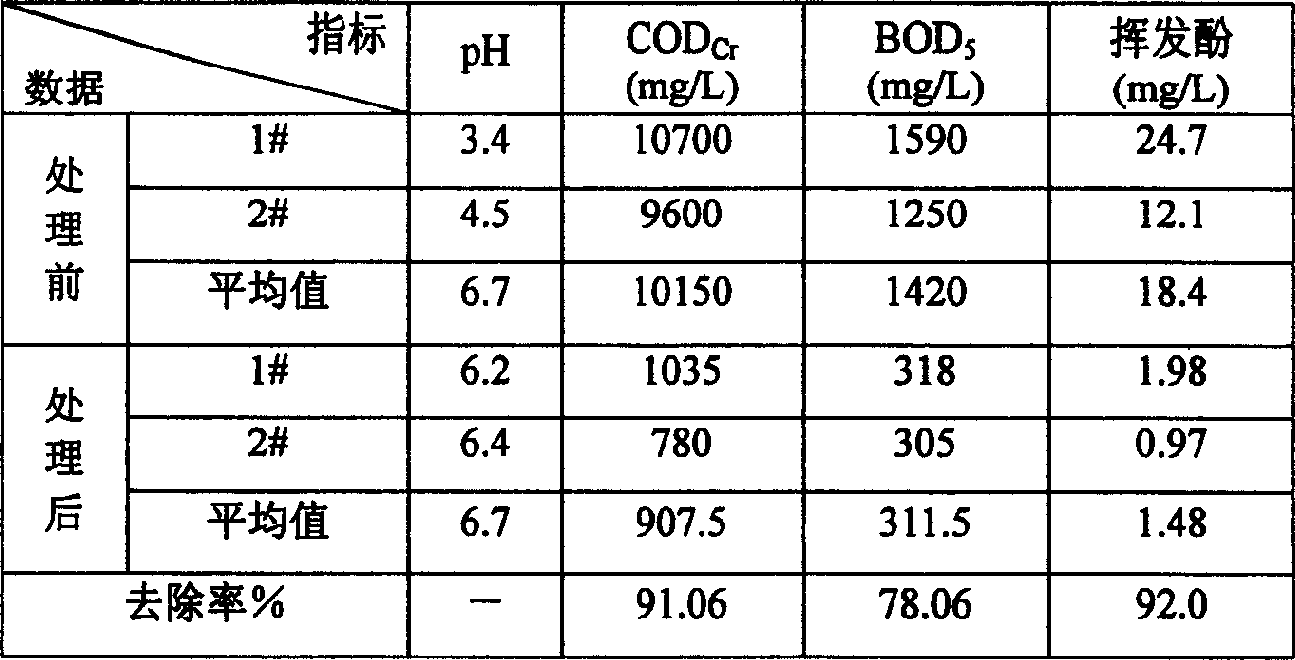

[0032] The embodiment and working principle of the present invention are: other conditions are the same as above, the number of anode plates is 2, the number of cathode plates is 3, the anodes and cathodes are arranged alternately, the distance between adjacent plates is 20mm, and the effective plate area of the anode and the cathode is 2400cm 2 , the electrolytic power supply adopts a steady current DC power supply, and the current density is 30mA / cm 2 , the hydraulic retention time in the electrolyzer is 60min, and the wastewater treatment results are shown in Table 2.

[0033] The anode reaction is:

[0034]

[0035] The cathode reaction is:

[0036]

[0037] The oxidative decomposition reaction of phenol is:

[0038]

[0039]

[0040] The results in Table 2 show that the electrolytic oxidation wastewater treatment process of the present invention can effectively treat phenol-containing wastewater, and the removal rate of volatile phenols is 92...

Embodiment 3

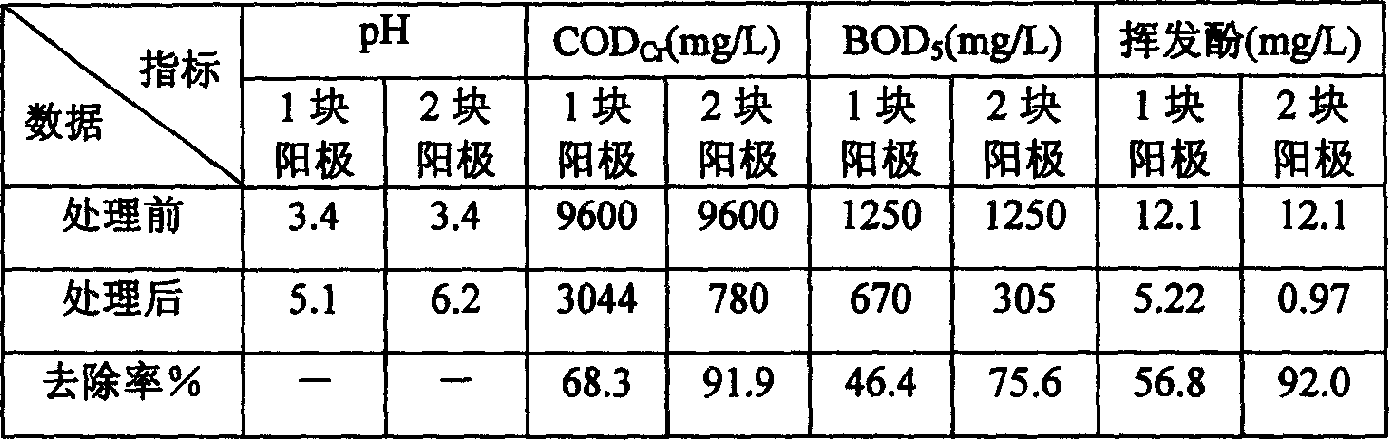

[0045] The embodiment and working principle of the present invention are as follows: non-stirred, internal circulation, double synergistic electrolytic oxidation treatment process for wastewater containing 12.1mg / L phenol, adopts polypropylene plate and frame electrolytic cell, and uses Ti-based PbO 2 The catalytic electrode is the anode, the stainless steel is the cathode, and the phenol-containing wastewater is the electrolyte. By electrolyzing the water in it, a strong oxidizing group is generated at the anode—hydroxyl radical·OH, and the cathode obtains electrons to generate H. 2 o 2 , the synergistic effect of the negative and positive poles realizes the deep oxidation and decomposition of phenol pollutants, so as to achieve the purpose of electrolytic oxidation treatment of phenol-containing wastewater; among them, the number of anode plates is 1 and 2, and the number of cathode plates is 2 and 3 respectively. block, the anode and cathode are arranged alternately, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com