Preparation method of denitration catalyst

A denitrification catalyst and solvothermal technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of small crystal grains, reduced production costs, and low oxidative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is used to illustrate the preparation method of the denitration catalyst provided by the present invention.

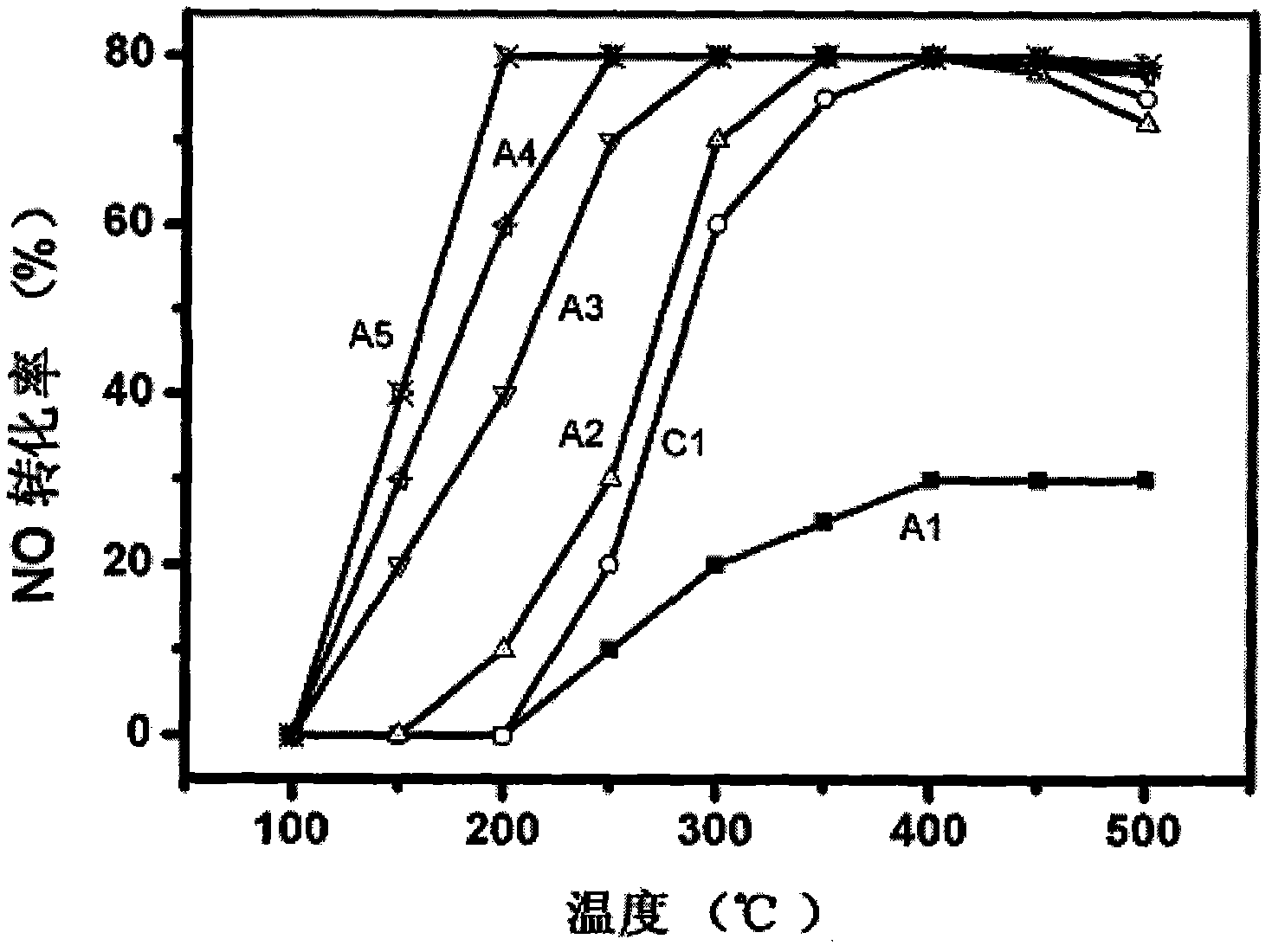

[0039] Dissolve 12g of ammonium tungstate and 200g of titanyl sulfate in 700mL of water, then conduct a hydrothermal reaction at 150°C for 10 hours, with a stirring speed of 200 rpm. After the hydrothermal reaction was completed, the sample was taken out and filtered, dried at 100°C for 10 hours, and then calcined at 450°C for 8 hours to obtain WO 3 Titanium tungsten powder with a content of 10wt.% is denoted as A1. The titanium tungsten powder has been characterized as having a surface area of 120m 2 / g, the grain size is 10-30nm, and the average particle size is 10μm.

Embodiment 2

[0041] This example is used to illustrate the preparation method of the denitration catalyst provided by the present invention.

[0042] Dissolve 1.5g of ammonium metavanadate and 5g of oxalic acid in 70mL of water, add 100g of the titanium-tungsten powder prepared in Example 1, mix and stir to form a slurry, let stand at room temperature for a period of time, dry at 100°C for 10 hours, and then dry at 400°C ℃ for 5 hours to prepare V 2 o 5 The content is 1wt.%, WO 3 The denitration catalyst with a content of 10wt.%, denoted as A2, was used for activity evaluation.

Embodiment 3

[0044] This example is used to illustrate the preparation method of the denitration catalyst provided by the present invention.

[0045] Dissolve 1.5g of ammonium metavanadate and 5g of oxalic acid in 700mL of water, add 100g of the titanium-tungsten powder prepared in Example 1 and mix them, then conduct a hydrothermal reaction at 200°C for 10 hours. After the hydrothermal reaction was completed, the sample was taken out and filtered, dried at 100°C for 10 hours, and then calcined at 600°C for 4 hours to obtain V 2 o 5 The content is 1wt.%, WO 3 The denitration catalyst with a content of 10wt.%, denoted as A3, was used for activity evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com