Use of quaternaries compound in floating silicate mineral

A technology of salt compounds and silicate minerals, applied in flotation, solid separation, etc., can solve problems in the field of flotation of silicate minerals that have not been seen, and achieve excellent collection capacity, good flotation desilication efficiency, The effect of strong harvesting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

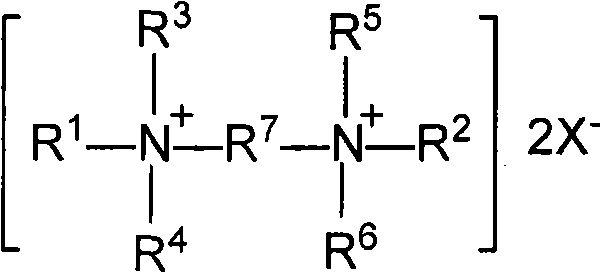

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Silicate minerals (kaolinite, illite, pyrophyllite and quartz) with a particle size of -0.074mm were respectively placed in a 50mL flotation cell, 30mL of distilled water was added, stirred for 1min to make it evenly mixed, and the pH The value is 8.0, and the flotation is carried out under the condition that the amount of collector is 150g / t. Table 1 shows the flotation comparison test results of four kinds of double quaternary ammonium salt cationic collectors in the present invention and two commonly used collectors dodecylamine and dodecyltrimethylammonium chloride. It can be seen from the table that the collector ability of diquaternary ammonium compound to kaolinite, illite, pyrophyllite and quartz is obviously stronger than that of two commonly used cationic collectors.

[0025] Table 1 Collector comparison experiment results

[0026]

Embodiment 2

[0027] Example 2: a bauxite ore sample in Henan, the raw ore contains Al 2 o 3 62.63%, SiO 2 10.68%, the ratio of aluminum to silicon is 5.86; the ore is ground to -0.074mm to account for 80%, the concentration of the flotation pulp is 27%, and the pH of the pulp is adjusted to 10 with sodium carbonate; Starch 300g / t, adding collector butyl-α, ω-bis(dimethyl dodecyl ammonium chloride) 200g / t, adding collector 20g / t, can obtain Al 2 o 3 68.51%, SiO 2 6.09% flotation concentrate, the aluminum-silicon ratio of the concentrate reaches 11.36, Al 2 o 3 The recovery rate is 82.48%.

Embodiment 3

[0028] Example 3: A certain magnetite ore in Northeast China is ground to -0.074mm, accounting for 78%, adding water to adjust the slurry to a mass concentration of 25%, adding sodium carbonate to adjust the pH value of the slurry to about 9.0, and then adding dodecylamine and dodecane Base trimethylammonium chloride and the double quaternary ammonium compound compound of the present invention, obtain the result as shown in table 2 through one crude one refined reverse flotation open-circuit test twice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com