Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

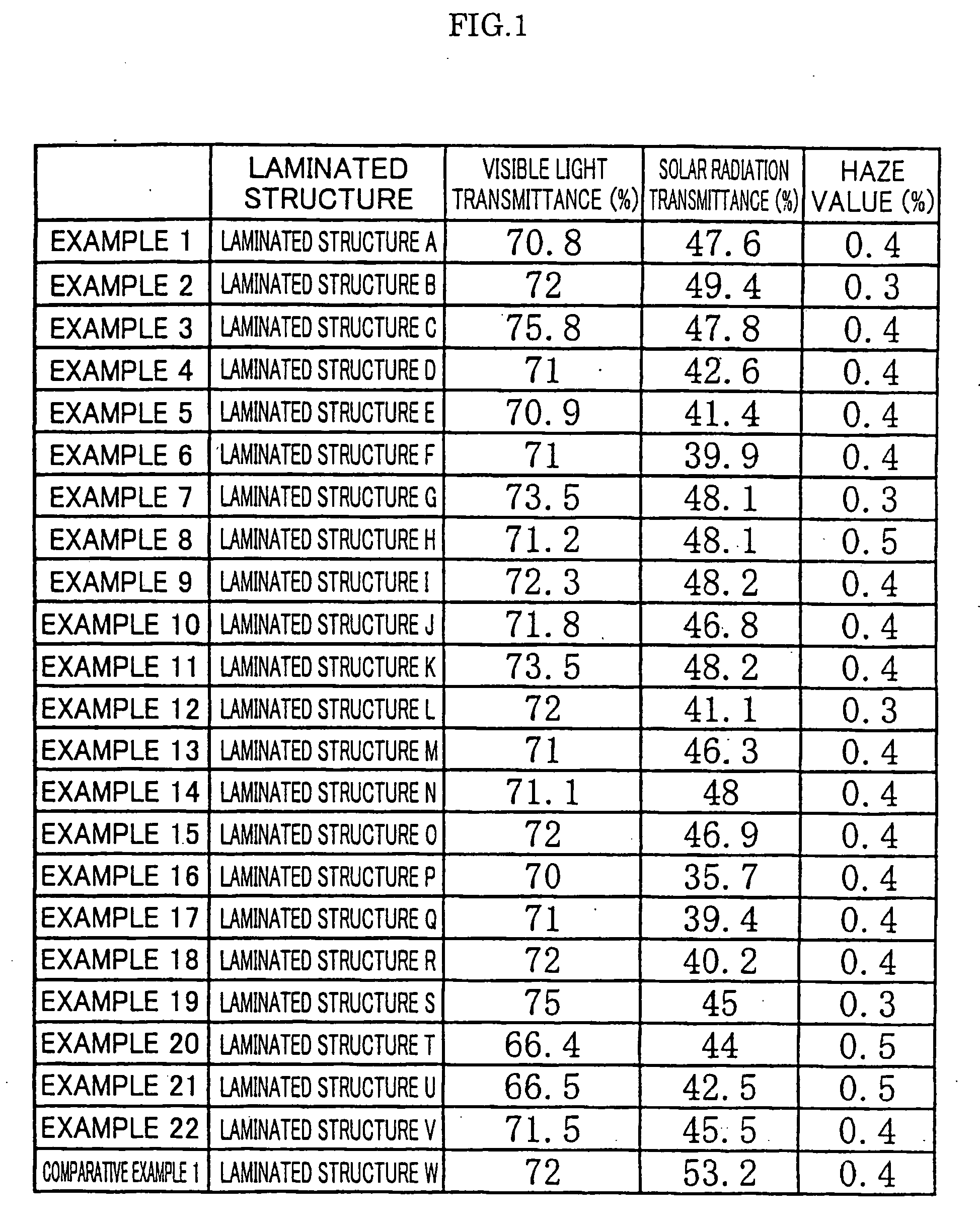

136results about How to "Low haze value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

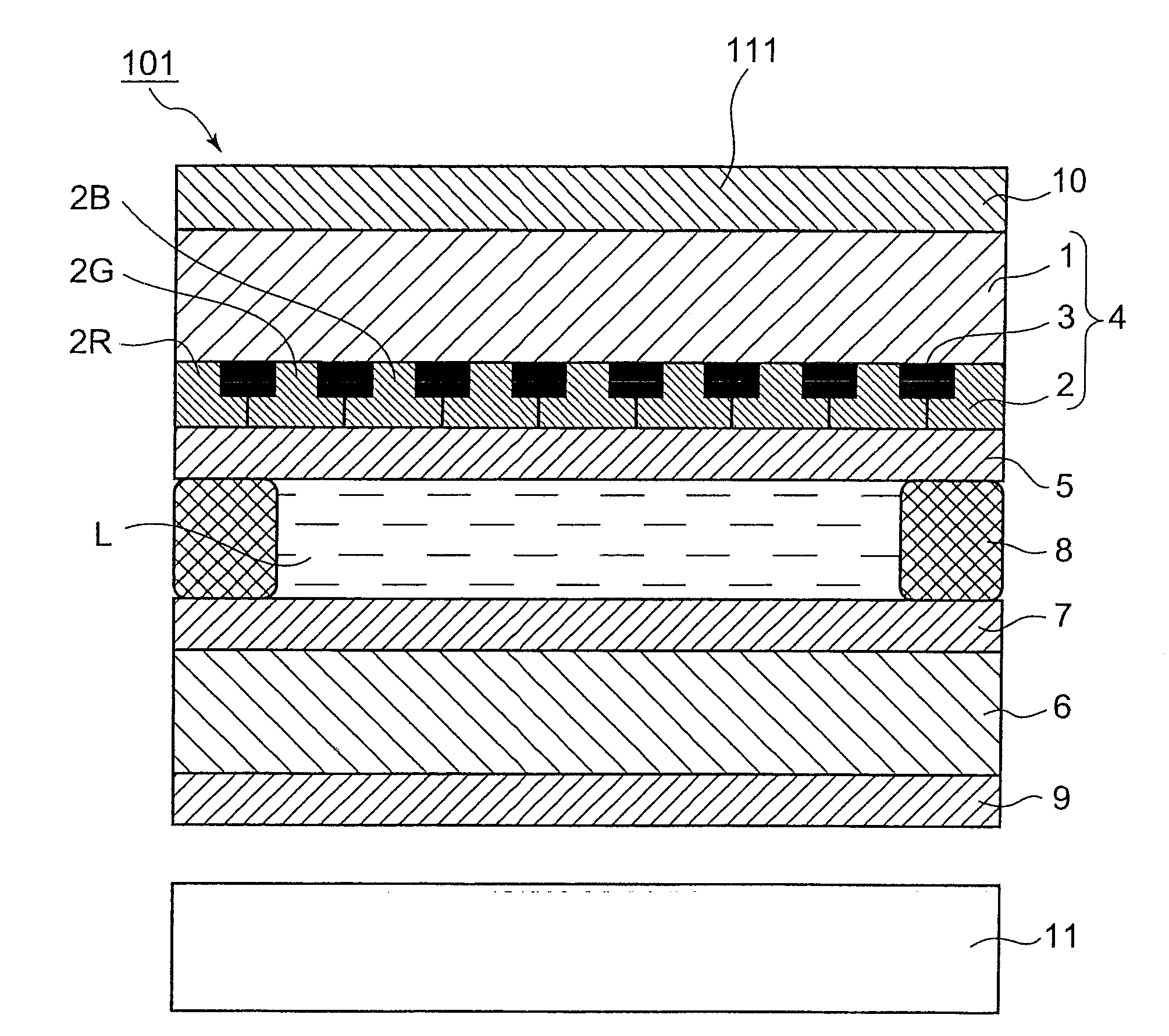

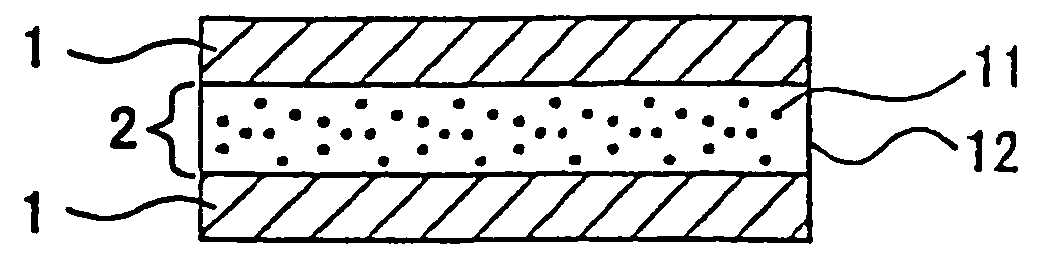

Laminated structure for shielding against solar radiation

ActiveUS20060008640A1Thin thicknessEasy to addTungsten oxides/hydroxidesSynthetic resin layered productsOptoelectronicsReducing atmosphere

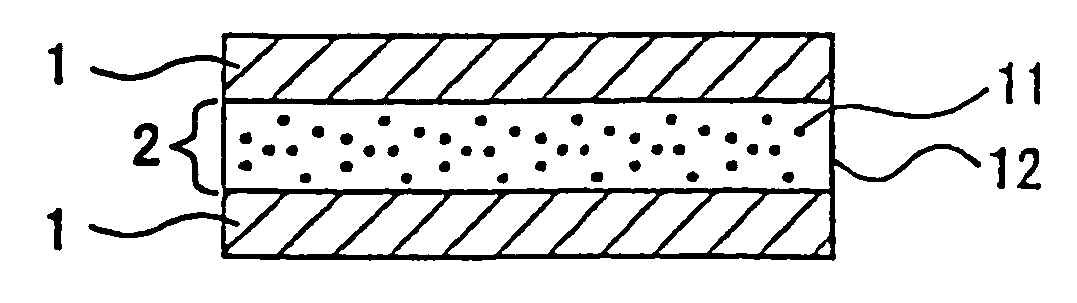

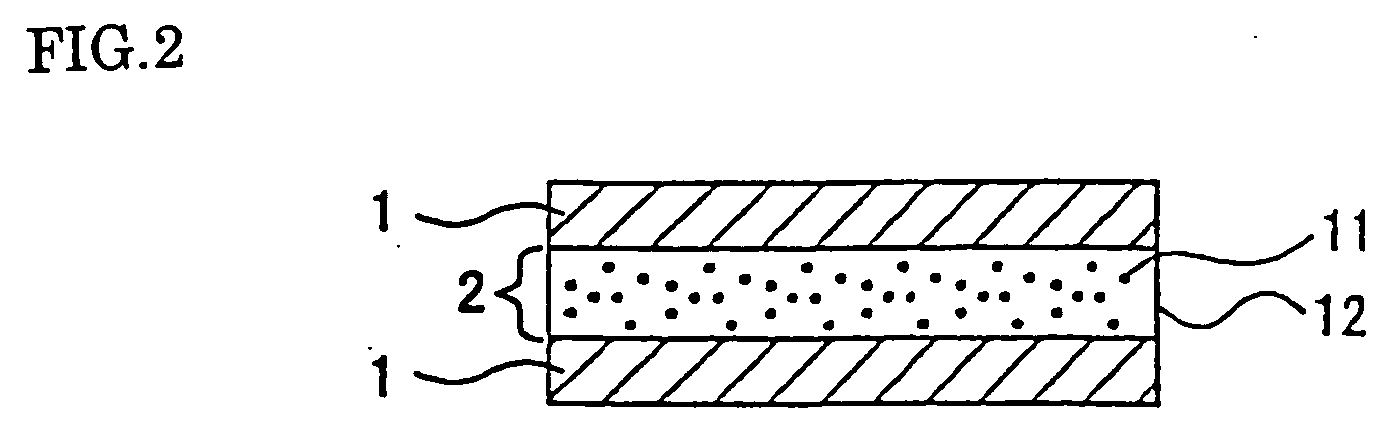

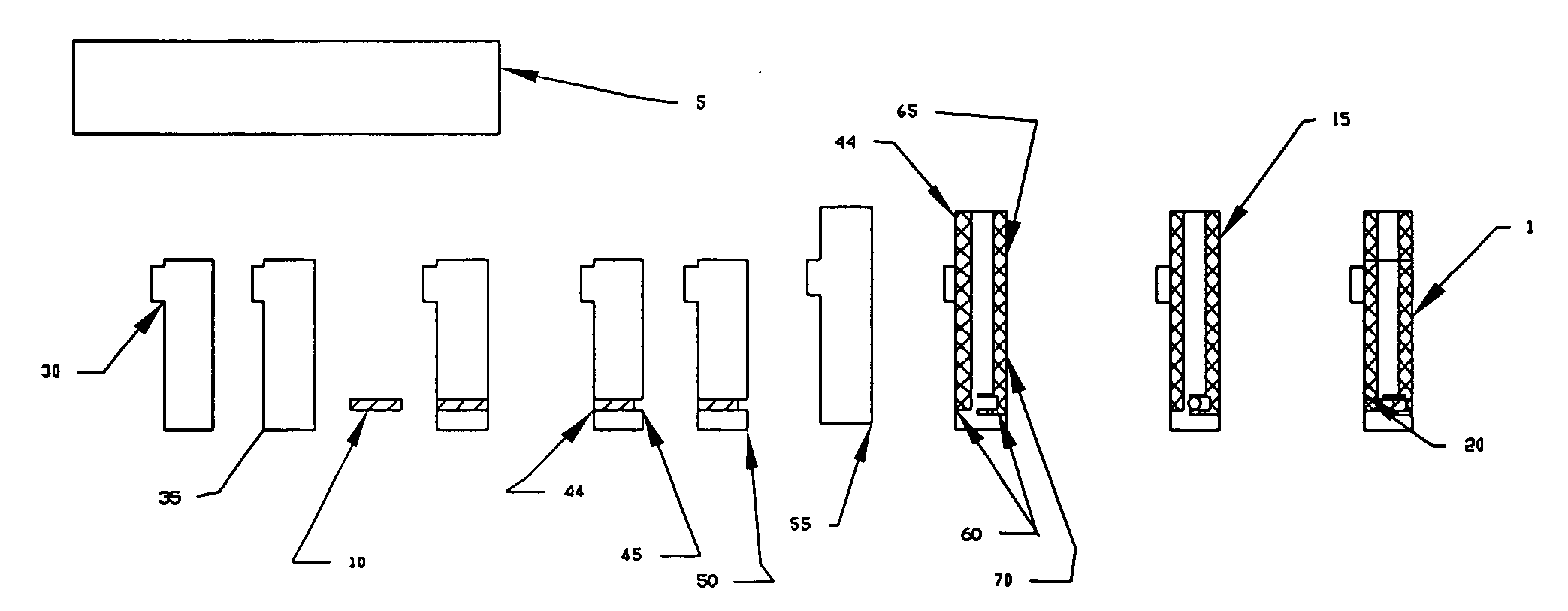

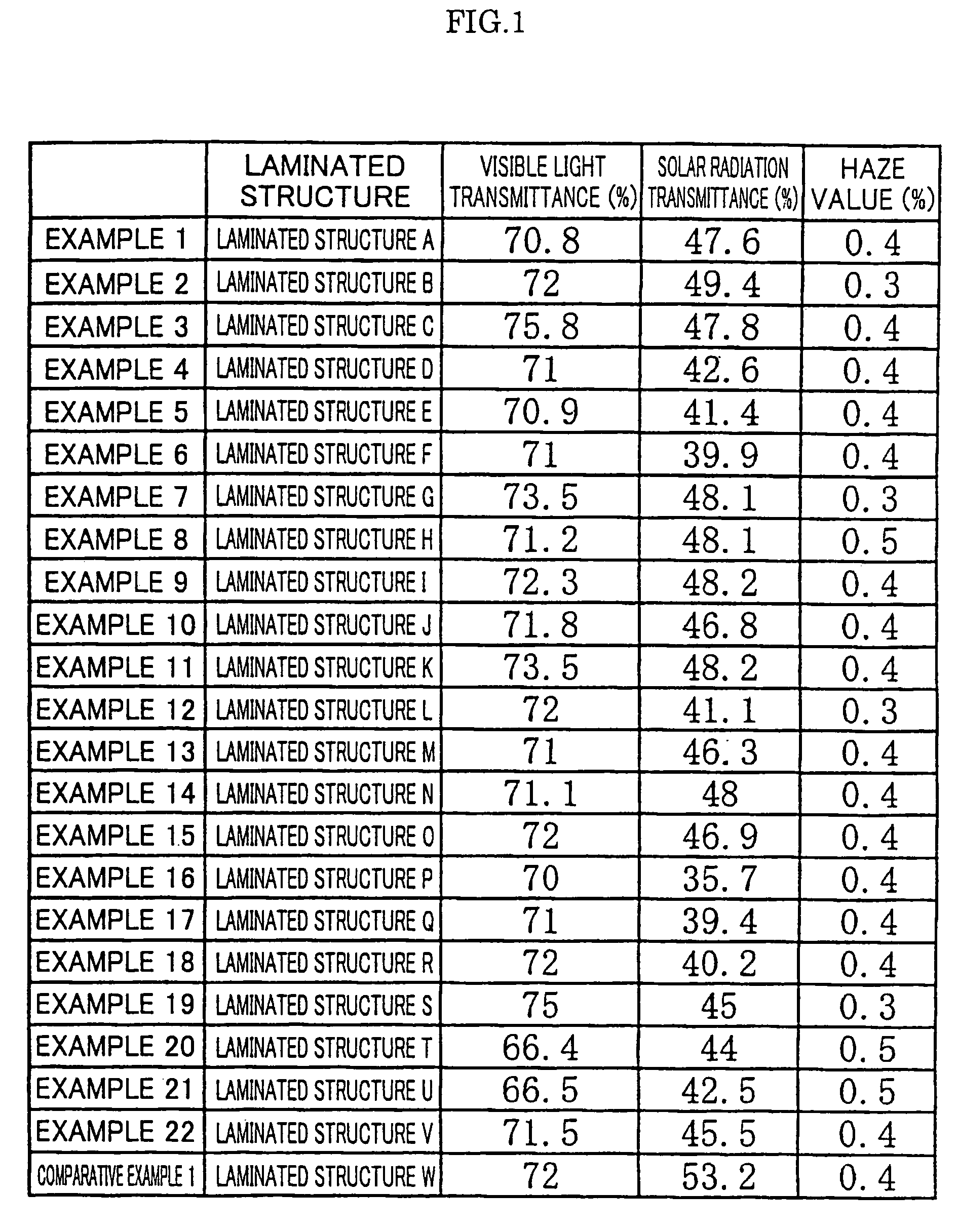

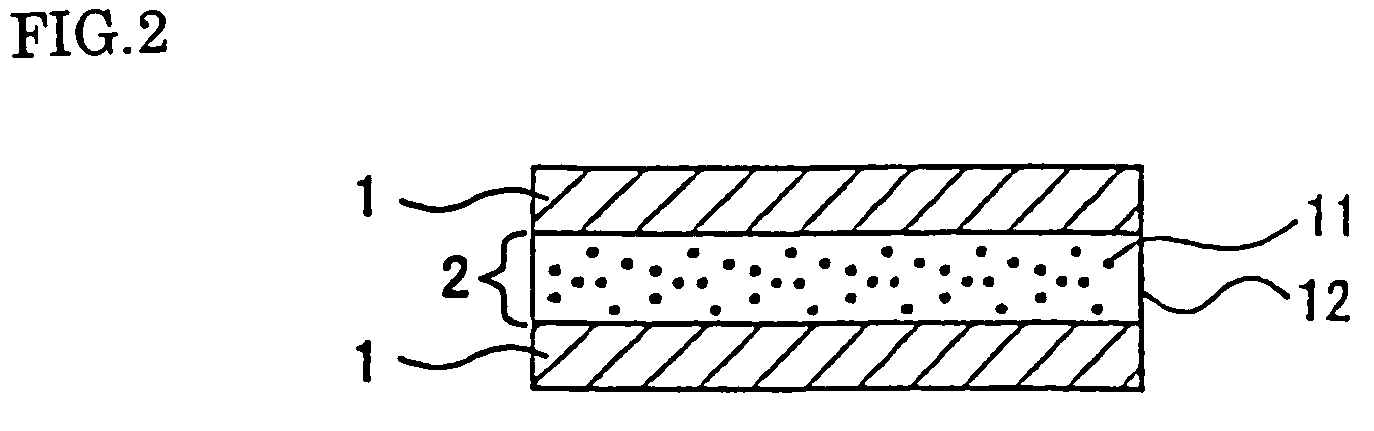

To provide a laminated structure for shielding against solar radiation having high solar radiation blocking characteristics with low manufacturing costs. Fine particles 11 functioning to block solar radiation are obtained by firing tungstic acid under a reductive atmosphere, a liquid dispersion to form a solar radiation blocking material is prepared by crashing and dispersing treatment of the fine particles, a polymer base dispersing agent, and solvent, and thus prepared liquid dispersion to form a solar radiation blocking material is added to vinyl resin, which is molded into a sheet shape to obtain an intermediate film 12. Thus obtained intermediate film 12 is sandwiched between two sheets to be laminated selected from sheet-glass or plastic to obtain an intermediate layer 2, which is heated and bonded each other to prepare a laminated structure for shielding against solar radiation.

Owner:SUMITOMO METAL MINING CO LTD

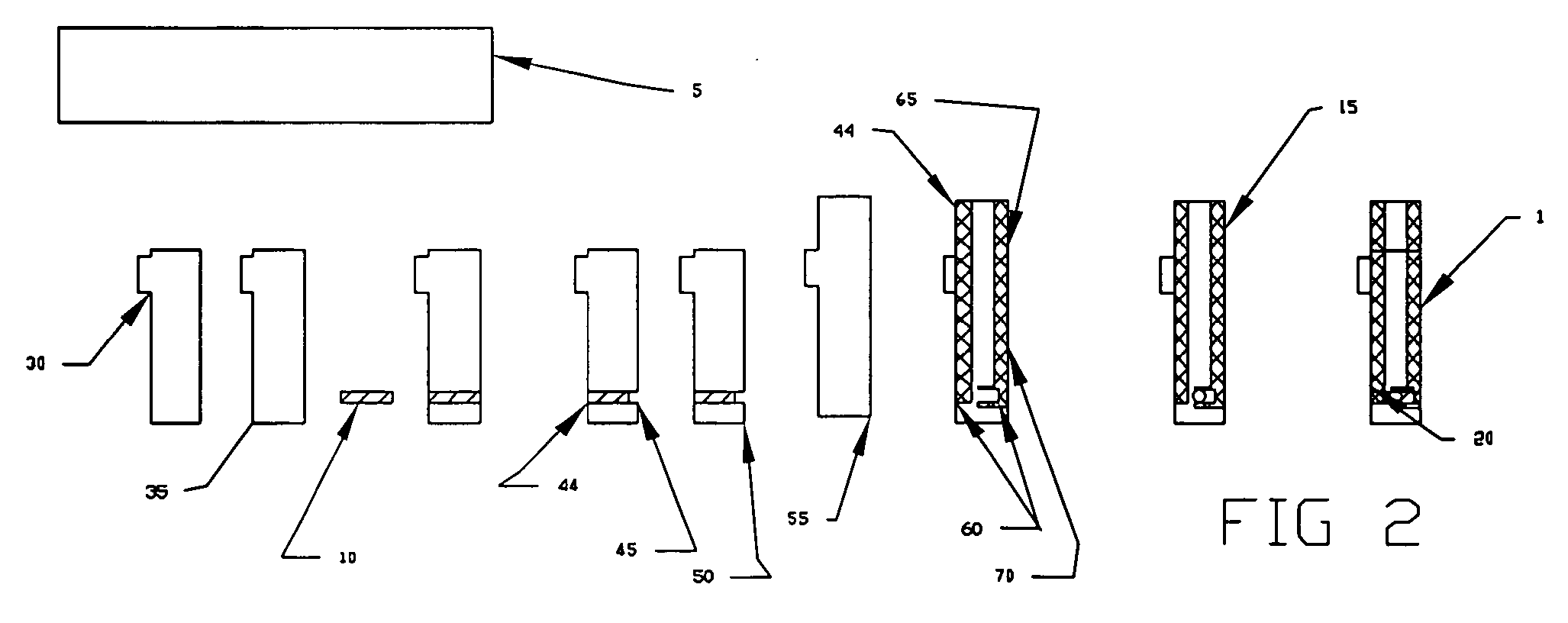

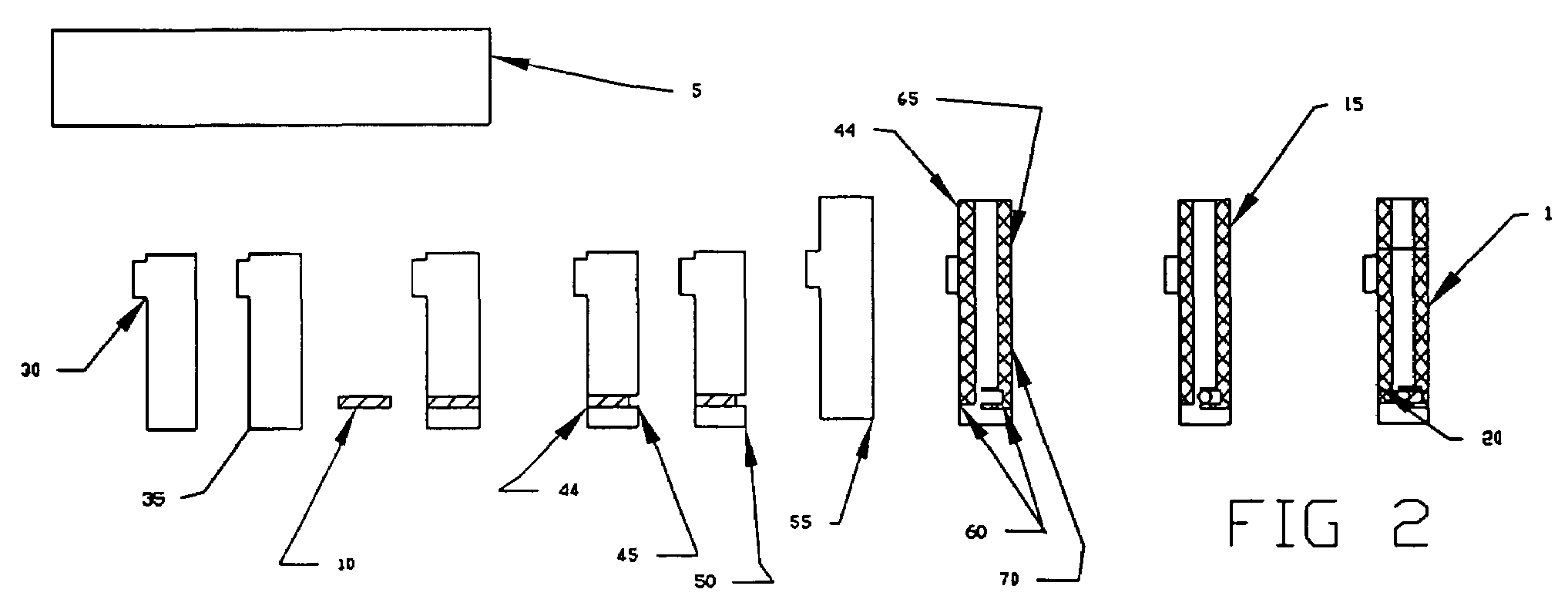

Strip electrode with conductive nano tube printing

InactiveUS20050186333A1Accurate electronic readoutMinimizing strip to strip variationImmobilised enzymesBioreactor/fermenter combinationsSilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:DOUGLAS JOEL S MR

Antiglare laminate

InactiveUS20050255291A1Good anti-glare effectIncrease contrastLayered productsDiffusing elementsOptoelectronicsEngineering

Owner:DAI NIPPON PRINTING CO LTD

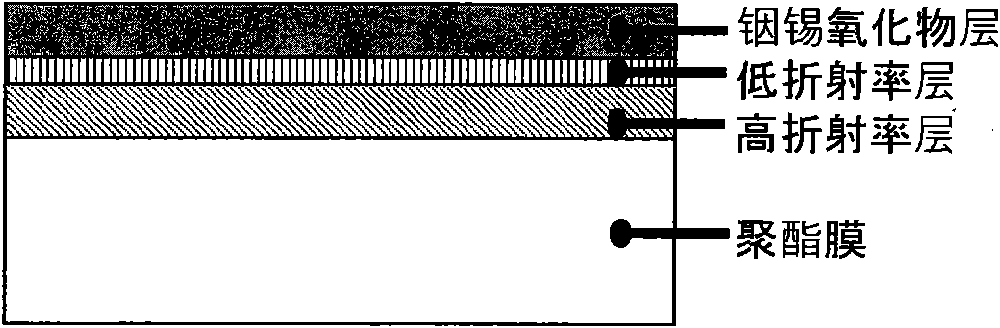

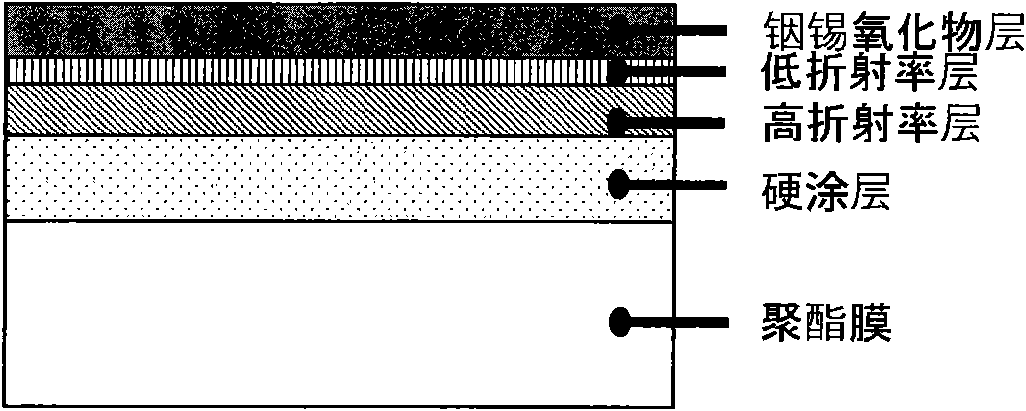

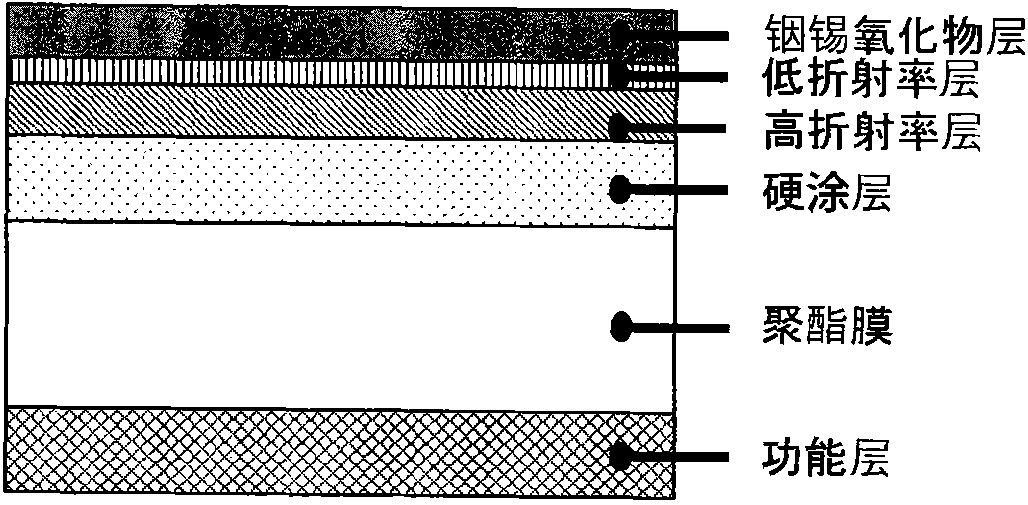

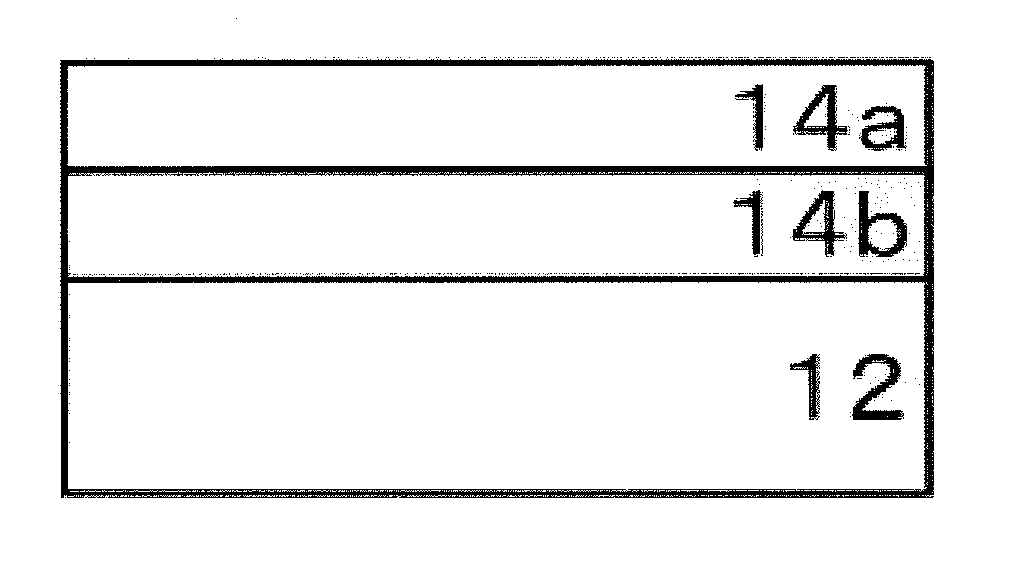

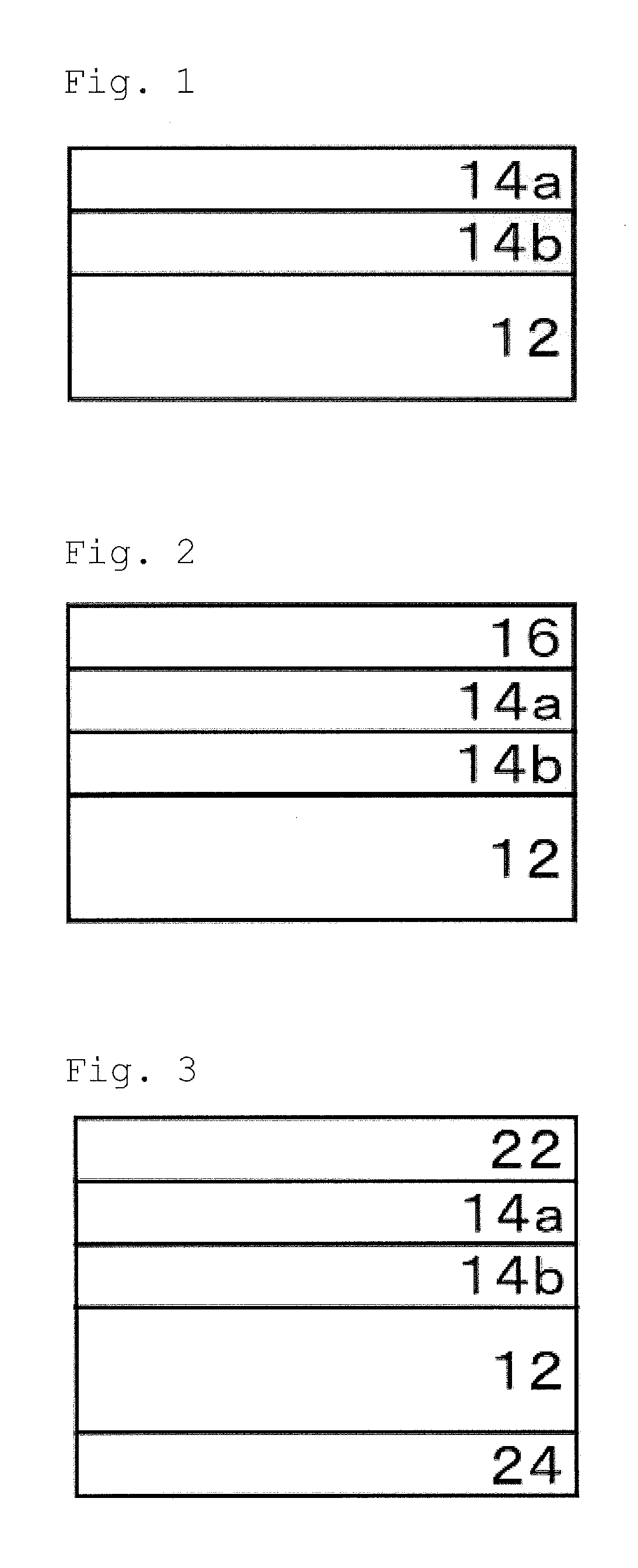

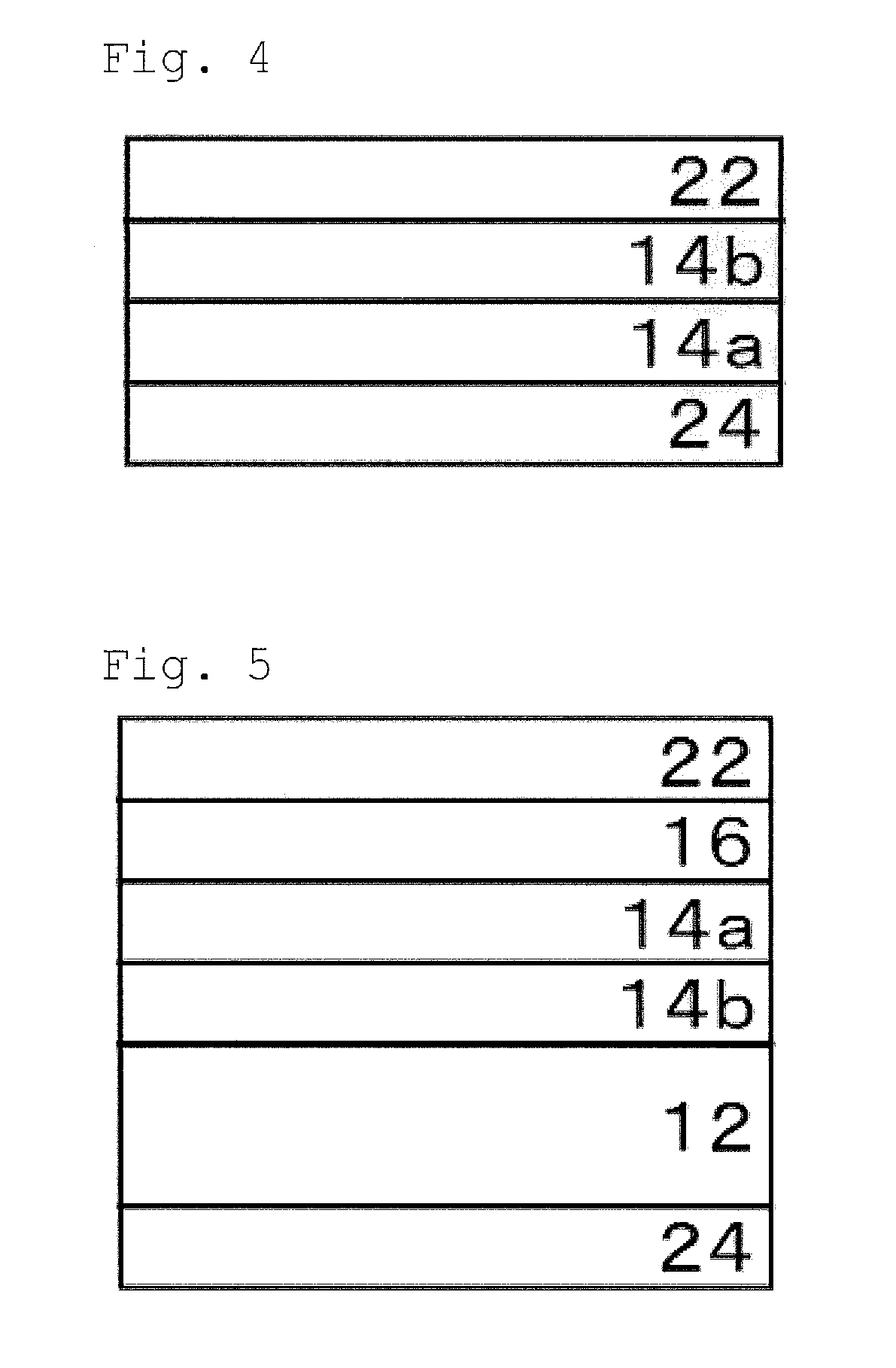

Transparent conductive film

ActiveCN102034565AInhibit coloringImprove transmittanceConductive layers on insulating-supportsInput/output processes for data processingPolyesterIndium

A transparent conductive film has a high-refractive index layer, a low-refractive index layer and a tin-doped indium oxide layer (ITO layer) which are laminated in order on a first main surface of a polyester film. The high-refractive index layer is composed of metal oxide particles and ultraviolet curing adhesives. When the wavelength is 400nm, the refractive index of the high-refractive index layer is 1.63-1.86, and the thickness of the high-refractive index layer is 40-90nm. When the wavelength is 400nm, the refractive index of the low-refractive index layer is 1.33-1.53, and the thickness of the low-refractive index layer is 10-50nm. When the wavelength is 400nm, the refractive index of the ITO layer is 1.85-2.35, and the thickness of the ITO layer is 5-50nm.

Owner:NOF CORP

Strip electrode with conductive nano tube printing

InactiveUS7285198B2Flat surfaceImprove consistencyImmobilised enzymesBioreactor/fermenter combinationsContact padAnalyte

An electrochemical test device for determining the presence or concentration of an analyte in an aqueous fluid sample comprises a substrate comprising a non-conductive material; a working electrode comprising a conductive film formed at least with carbon nanotubes, the working electrode having a first electrode area, a first lead and a first contact pad; a counter electrode comprising a conductive film formed at least with carbon nanotubes; a reagent capable of reacting with the analyte to produce a measurable change in potential which can be correlated to the presence or concentration of the analyte in the fluid sample, the reagent overlaying at least a portion of the first electrode area of the working electrode; and a reference electrode comprising a conductive coating formed at least with carbon nanotubes, the reference electrode having a third electrode area at least a portion of which is overlaid with a reference material.

Owner:DOUGLAS JOEL S MR

Hard-coated antiglare film, and polarizing plate and image display including the same

ActiveUS20090244710A1Improve bright-dark contrastImprove contrastDiffusing elementsPolarising elementsPlastic filmDisplay device

A hard-coated antiglare film, comprising a transparent plastic film substrate and a hard-coating antiglare layer containing fine particles on at least one surface of the transparent plastic film substrate, wherein an arithmetic average surface roughness Ra (μm) that is defined in JIS B 0601 (1994 version) is in the range of 0.05 to 0.15 μm in an uneven shape of a surface of the hard-coating antiglare layer, and the hard-coated antiglare film includes at least 80 convexities that exceed a roughness mean line of a surface roughness profile in a 4-mm long portion at an arbitrary location of the surface of the hard-coating antiglare layer.

Owner:NITTO DENKO CORP

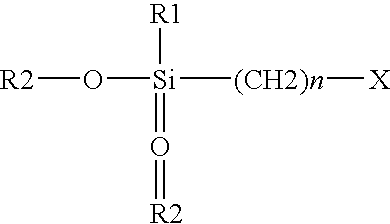

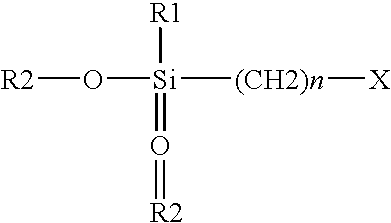

Coating composition and optical mar-resistant tintable coating

A coating composition and coating for ophthalmic lenses and other polymeric substrates having a unique combination of excellent solution stability, rapid cure rate, improved mar resistance, rapid dye absorption, and improved receptivity towards antireflective coatings. The coating comprises an abrasion resistant polymer and a dye-absorption-enhancing oligomer. The coating is tinted after curing with a dye to provide light absorbency in the coating.

Owner:COBURN TECH INT

Coating composition and optical mar-resistant tintable coating

ActiveUS20080047468A1Improve clarityHigh transparencyFibre treatmentPretreated surfacesDye absorptionOligomer

A coating composition and coating for ophthalmic lenses and other polymeric substrates having a unique combination of excellent solution stability, rapid cure rate, improved mar resistance, rapid dye absorption, and improved receptivity towards antireflective coatings. The coating comprises an abrasion resistant polymer and a dye-absorption-enhancing oligomer. The coating is tinted after curing with a dye to provide light absorbency in the coating.

Owner:COBURN TECH INT

Coating Composition, Its Coating Film, Antireflection Film, and Image Display Device

ActiveUS20080187732A1Lowering in strengthReducing and eliminating activityGlass/slag layered productsWood layered productsCoated membraneElectron hole

This invention provides a coating composition that can form a coating film having an eliminated or reduced photocatalytic action-derived deterioration and can form a coating film having a lowered haze value, has excellent dispersibility and dispersion stability in a coating liquid form, has excellent storage stability, and also has excellent coatability. The coating composition is characterized by comprising at least the following four components (1) to (4): (1) titanium dioxide fine particles with eliminated or reduced photocatalytic activity which is obtained by surface treating titanium dioxide fine particles doped with cobalt capable of capturing free electrons and / or holes, with a zinc chelate compound capable of capturing free electrons and / or holes, (2) a binder component, (3) a dispersant, and (4) an organic solvent.

Owner:DAI NIPPON PRINTING CO LTD

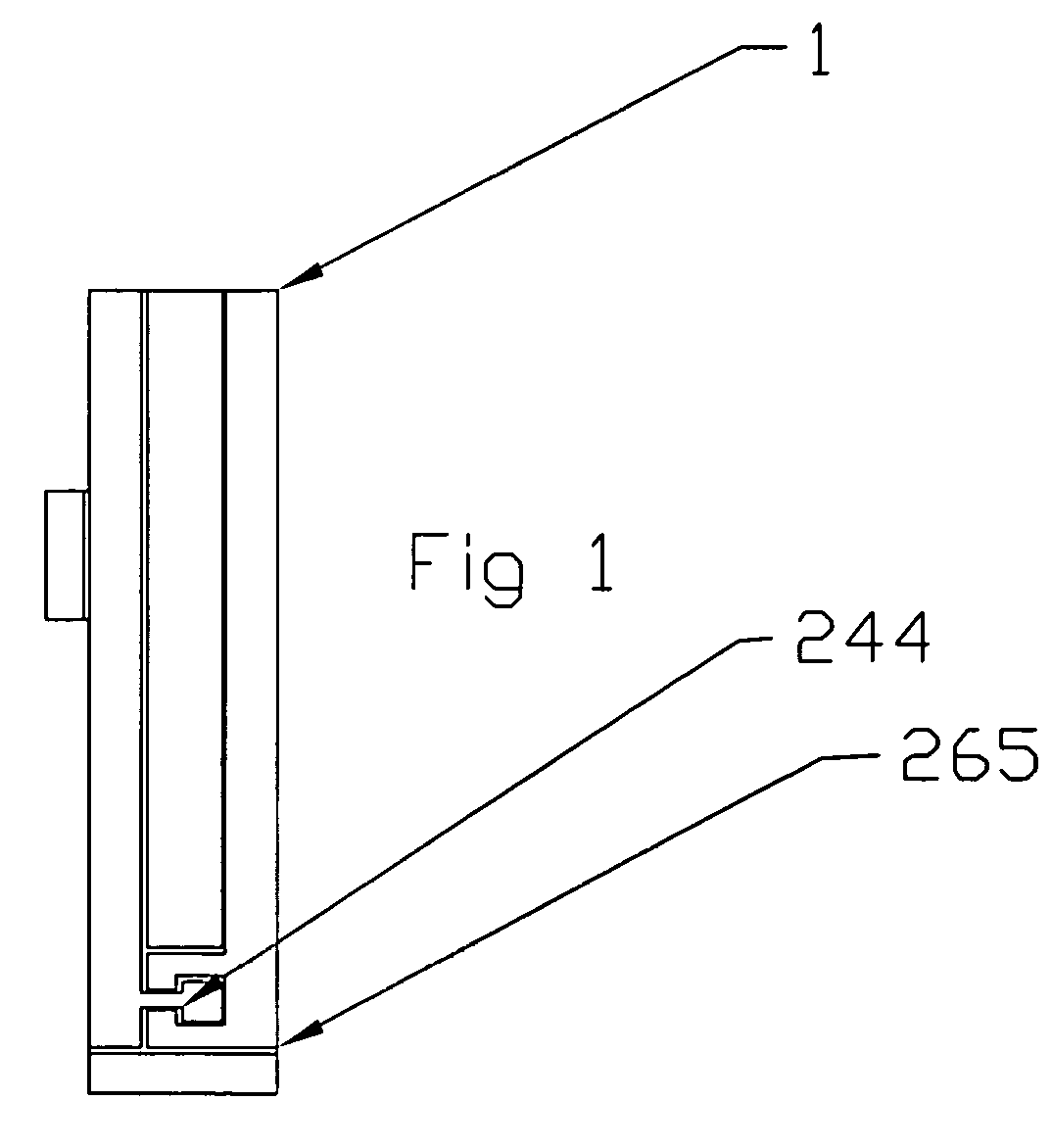

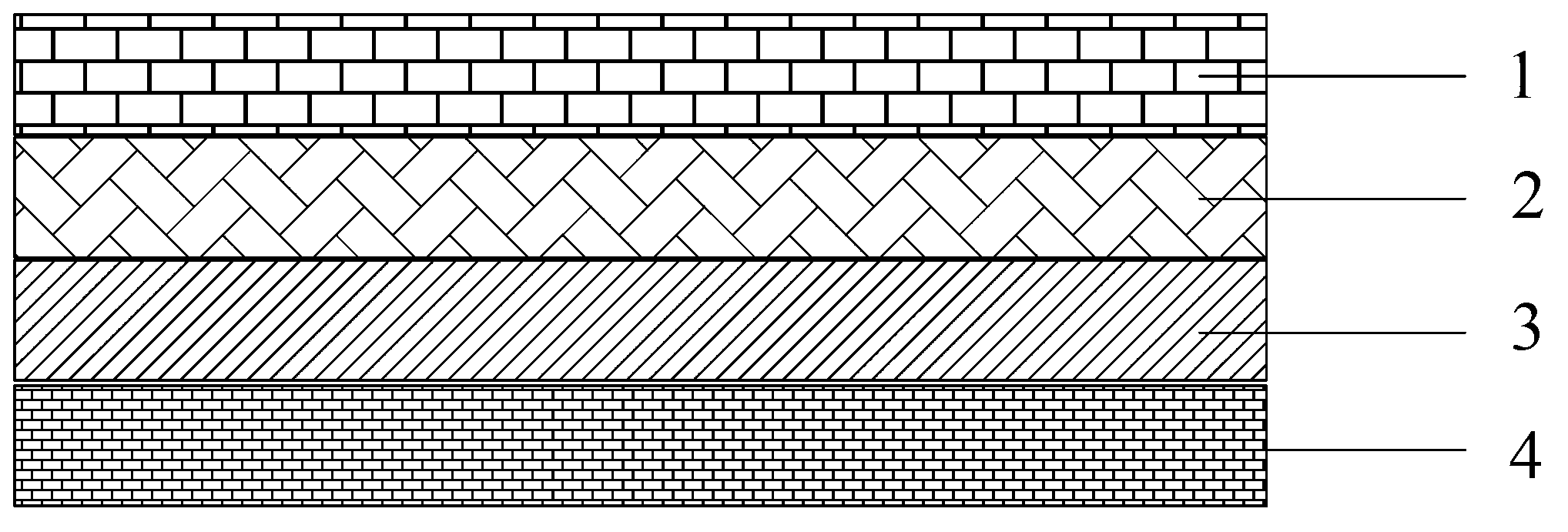

Laminated structure for shielding against solar radiation

ActiveUS7655301B2Improve featuresLow haze valueTungsten oxides/hydroxidesSynthetic resin layered productsOptoelectronicsSolvent

To provide a laminated structure for shielding against solar radiation having high solar radiation blocking characteristics with low manufacturing costs. Fine particles 11 functioning to block solar radiation are obtained by firing tungstic acid under a reductive atmosphere, a liquid dispersion to form a solar radiation blocking material is prepared by crashing and dispersing treatment of the fine particles, a polymer base dispersing agent, and solvent, and thus prepared liquid dispersion to form a solar radiation blocking material is added to vinyl resin, which is molded into a sheet shape to obtain an intermediate film 12. Thus obtained intermediate film 12 is sandwiched between two sheets to be laminated selected from sheet-glass or plastic to obtain an intermediate layer 2, which is heated and bonded each other to prepare a laminated structure for shielding against solar radiation.

Owner:SUMITOMO METAL MINING CO LTD

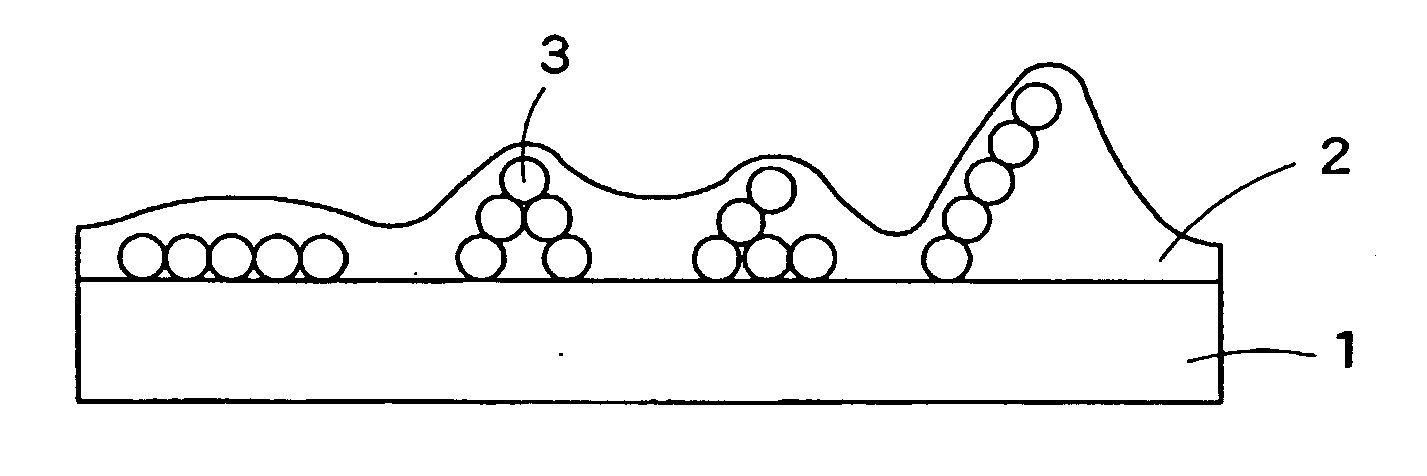

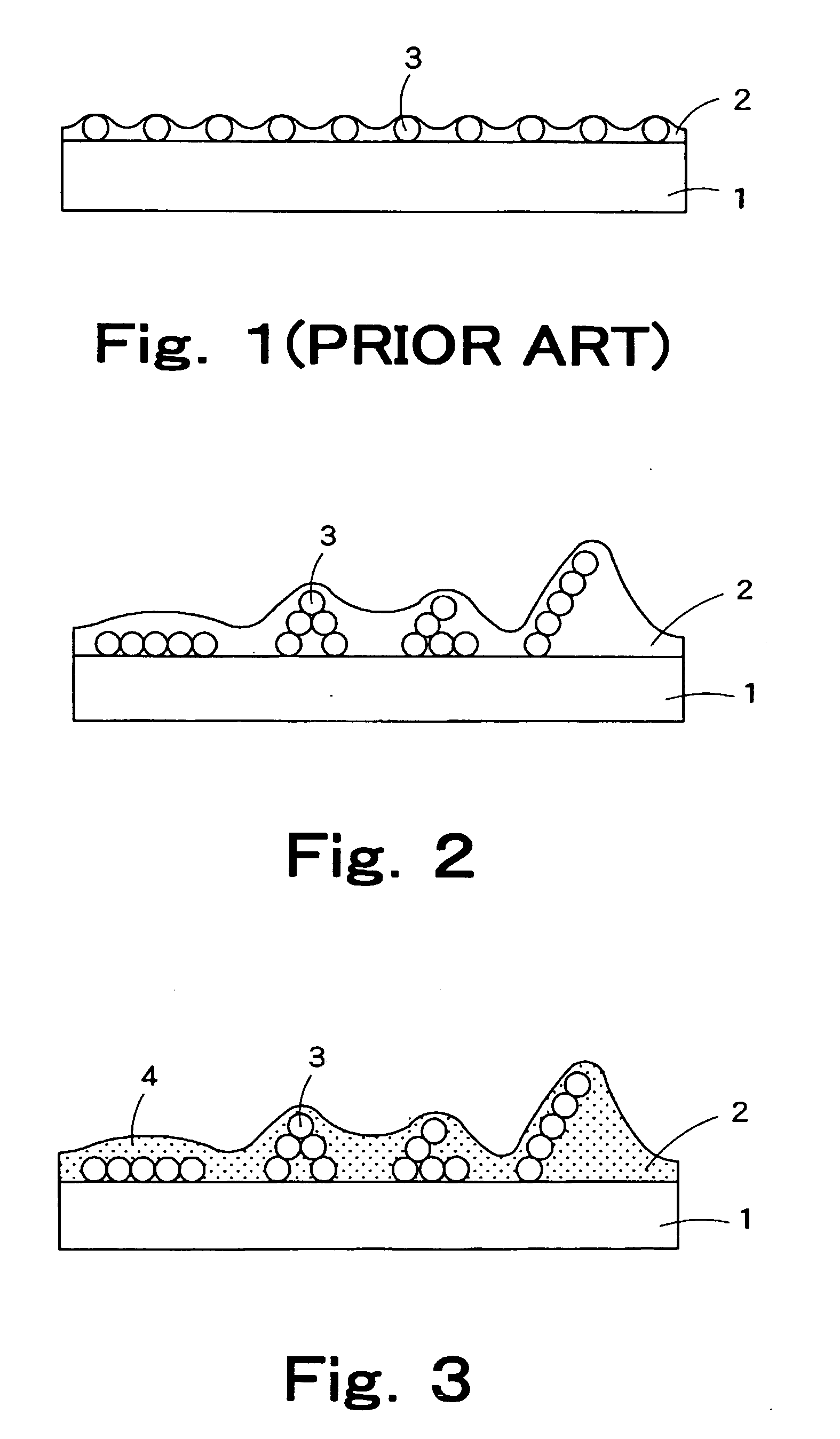

Glare-Proofing Optical Laminate

ActiveUS20090002831A1Low surface haze valueImprove clarityDiffusing elementsLayered productsImage resolutionOptoelectronics

An anti-dazzling laminate made of an optical laminate including a light transparent base material and an anti-dazzling layer having a concavoconvex shape provided on the material. The laminate simultaneously satisfies formulae: 0≦G100≦15 (I), 0.1≦Hs≦5.0 (II), 0.3≦Rz≦1.8 (III) wherein G100 represents a scintillation value which is a standard deviation of a variation in brightness distribution at a resolution of 100 ppi measured on the surface of the laminate; Hs represents the surface haze value of the laminate; and Rz represents the average roughness of the concavoconvex shape of the anti-dazzling layer.

Owner:DAI NIPPON PRINTING CO LTD +1

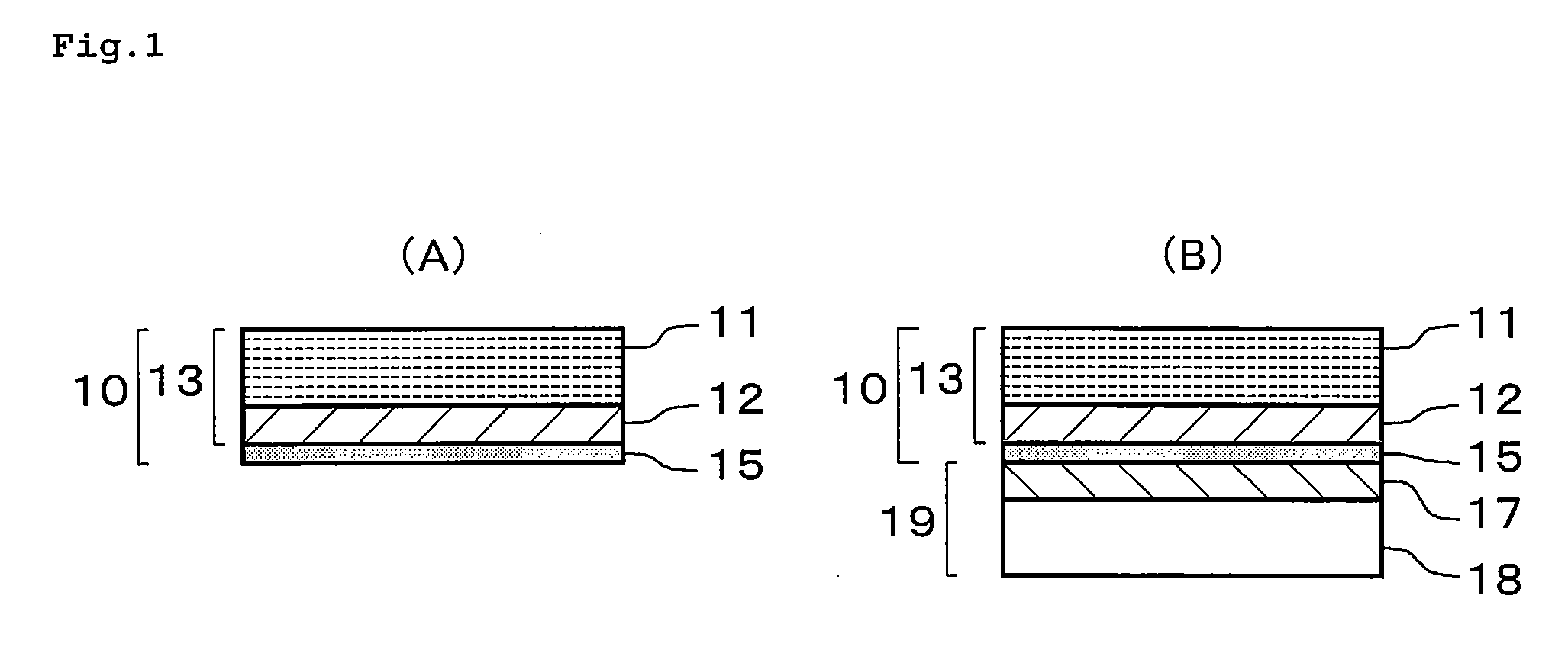

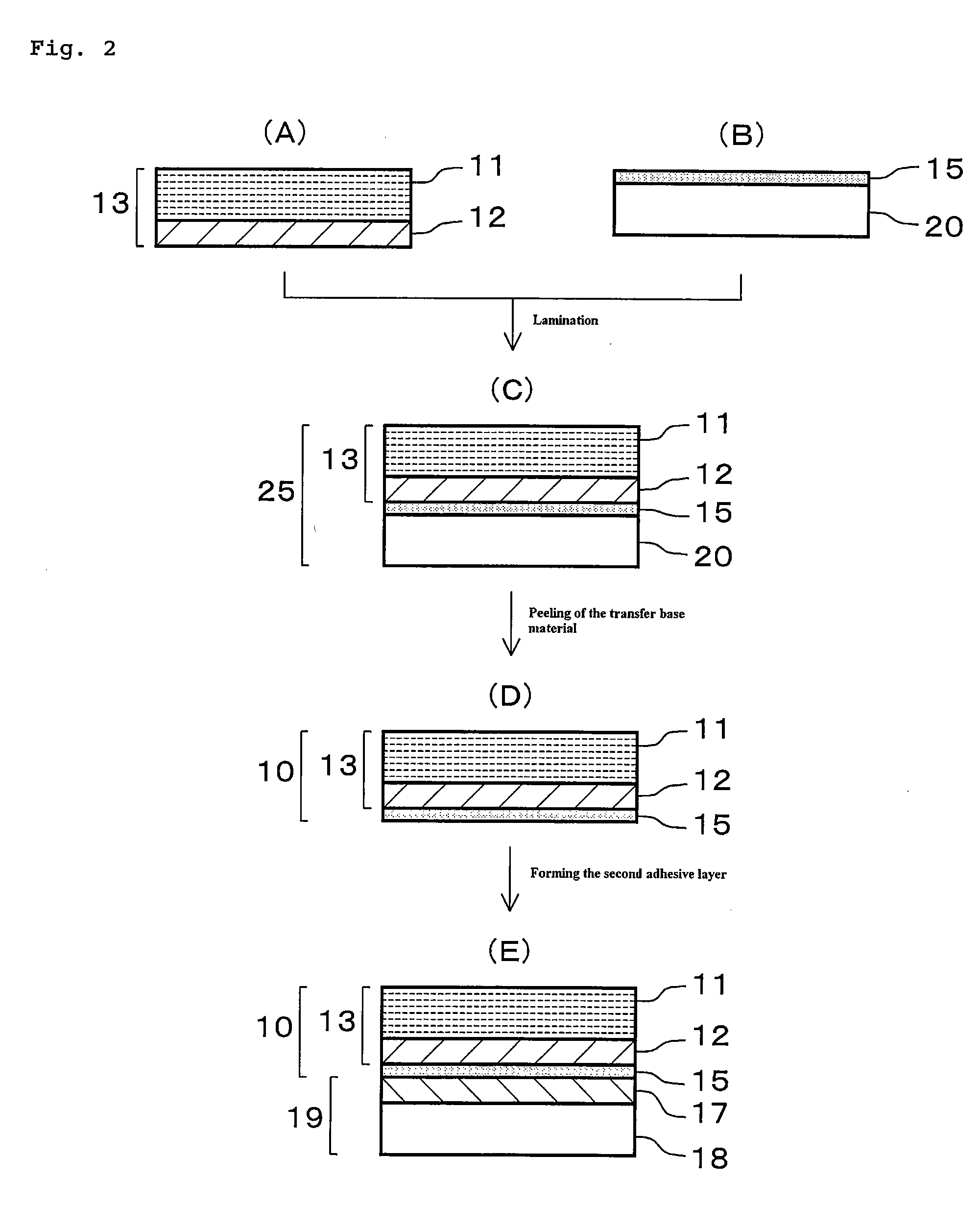

Light reflection layer, light reflection plate, laminated interlayer film sheet for laminated glass, laminated glass, and method of manufacturing these

InactiveUS20150116649A1Improve insulation performanceGood coating performanceLiquid crystal compositionsMirrorsLight reflectionCholesteric liquid crystal

A light reflection layer, comprising a first liquid crystal layer obtained by fixing a first curable liquid crystal composition through curing in a state of a cholesteric liquid crystal phase, wherein the first curable liquid crystal composition contains a polymerizable liquid crystal compound, a fluoroalkyl group-containing alignment control agent, and a hydrophilic group-containing coating property imparting agent exhibits low haze, excellent heat shielding properties and improved coating properties when the light reflection layer obtained by fixing the cholesteric liquid crystal phase on the light reflection layer is laminated and coated.

Owner:FUJIFILM CORP

Strip electrode with conductive nano tube printing

InactiveUS20080023327A1Improve consistencyFlat surfaceImmobilised enzymesMaterial nanotechnologySilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:MYSTICMD

Thermal recording material

InactiveUS20050239646A1Low haze valueHarmful effectAblative recordingThermographyCompound (substance)Heat sensitive

Disclosed is a heat-sensitive recording material comprising (a) a transparent film, (b) a heat-sensitive recording layer formed on one side of the transparent film, and containing an electron-donating compound, an electron-accepting compound, and a binder, (c) a protective layer formed on the heat-sensitive recording layer, and containing an aqueous resin as a primary component; and (d) a backside layer formed on the other side of the transparent film, and containing a pigment and a binder; the heat-sensitive recording material containing in the backside layer spherical resin particles having a mean volume particle diameter of 2 to 15 μm in an amount of 0.2 to 5.0 mass % of the backside layer.

Owner:OJI PAPER CO LTD

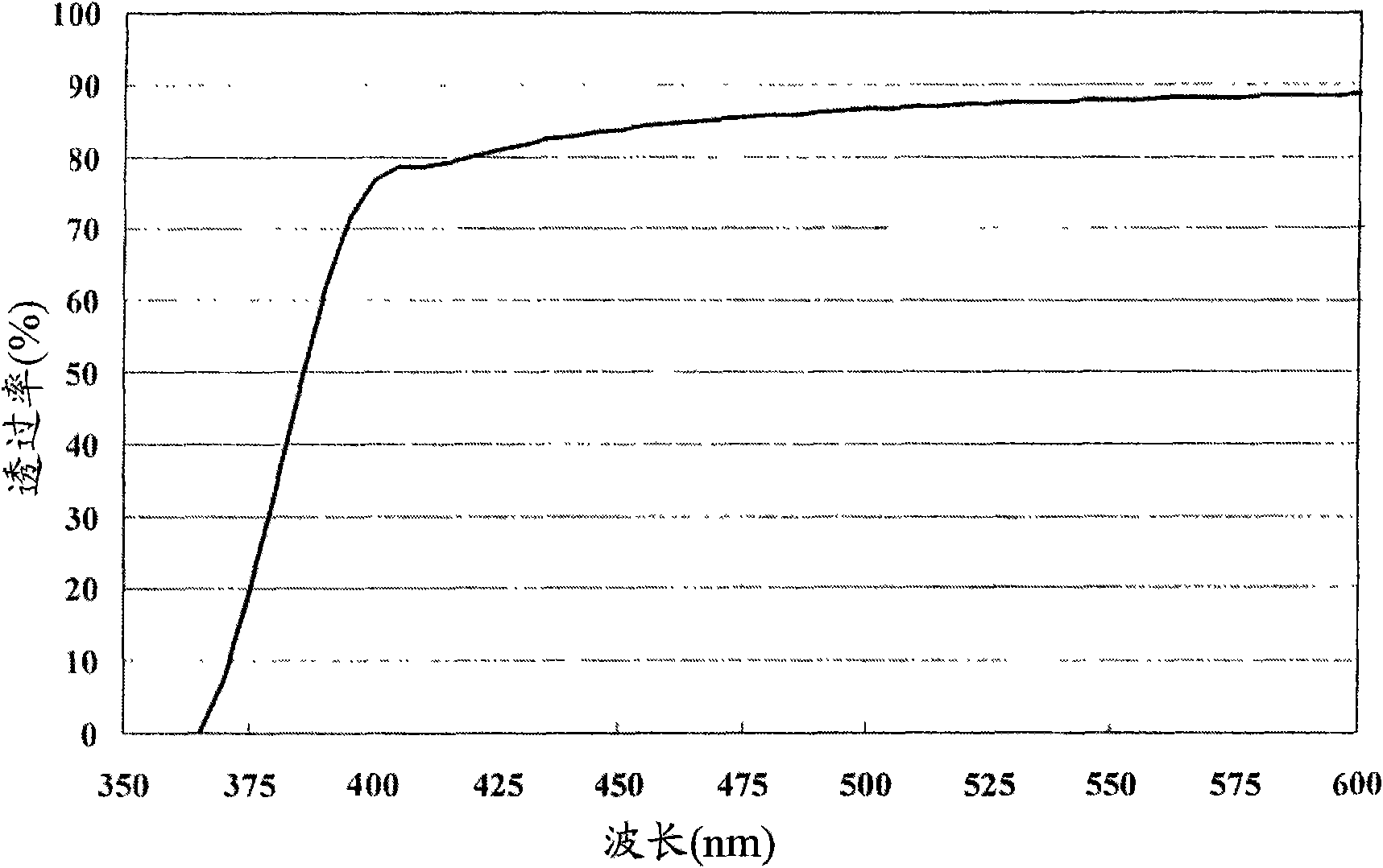

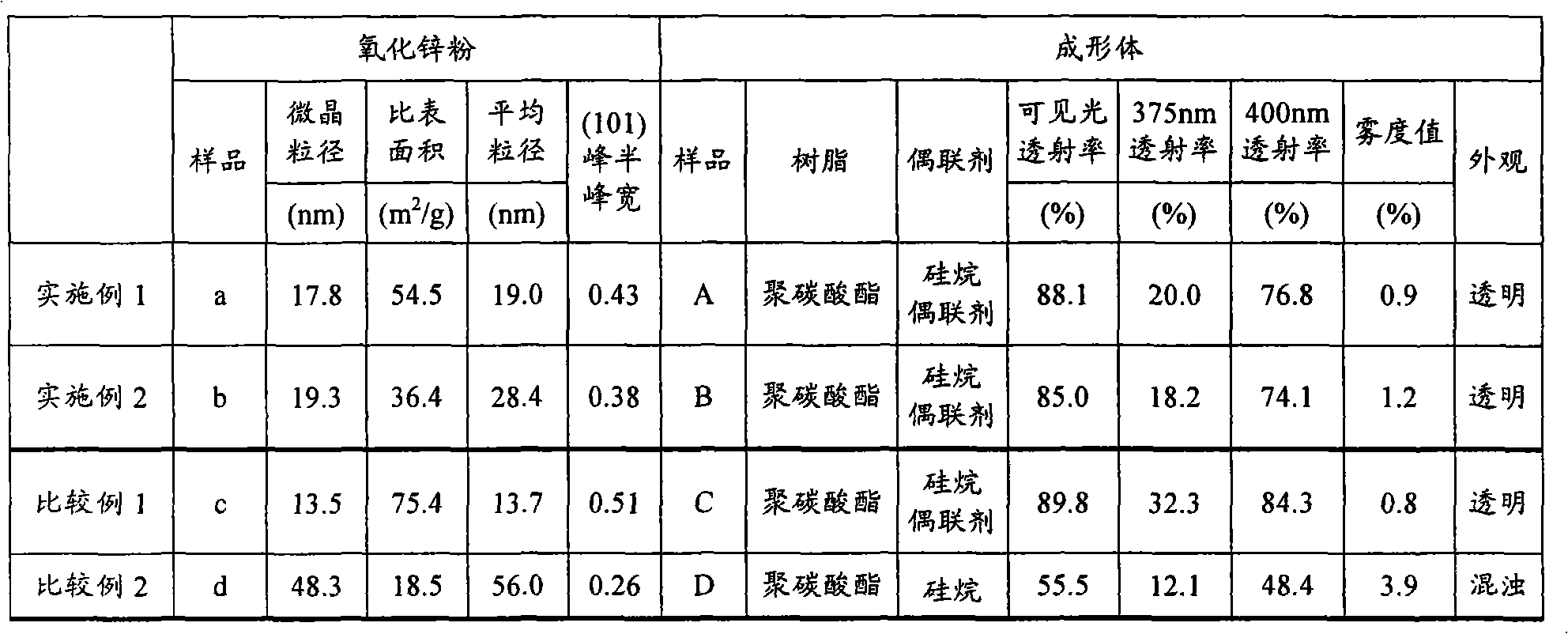

Ultraviolet-shielding transparent resin molding and manufacturing method of the same

InactiveCN101570641AHigh haze valueLow haze valuePigmenting treatmentMaterial nanotechnologyX-rayUltraviolet lights

Owner:SUMITOMO METAL MINING CO LTD

Heat ray shielding glass and manufacturing method of the same

InactiveUS20100203322A1Low haze valueExcellent heat ray shield functionGlass/slag layered productsThin material handlingLaminated glassFlat glass

A heat ray shielding laminated glass is provided, with an intermediate layer having a heat ray shielding performance interposed between opposed two plate glasses. Wherein an intermediate layer having the heat ray shielding performance is obtained by being cured by irradiation of ultraviolet ray, after a dispersion of composite tungsten oxide particles is dissolved into an ultraviolet ray curing resin precursor (E) and thereafter is filled in a gap between the opposed two plate glasses.

Owner:SUMITOMO METAL MINING CO LTD

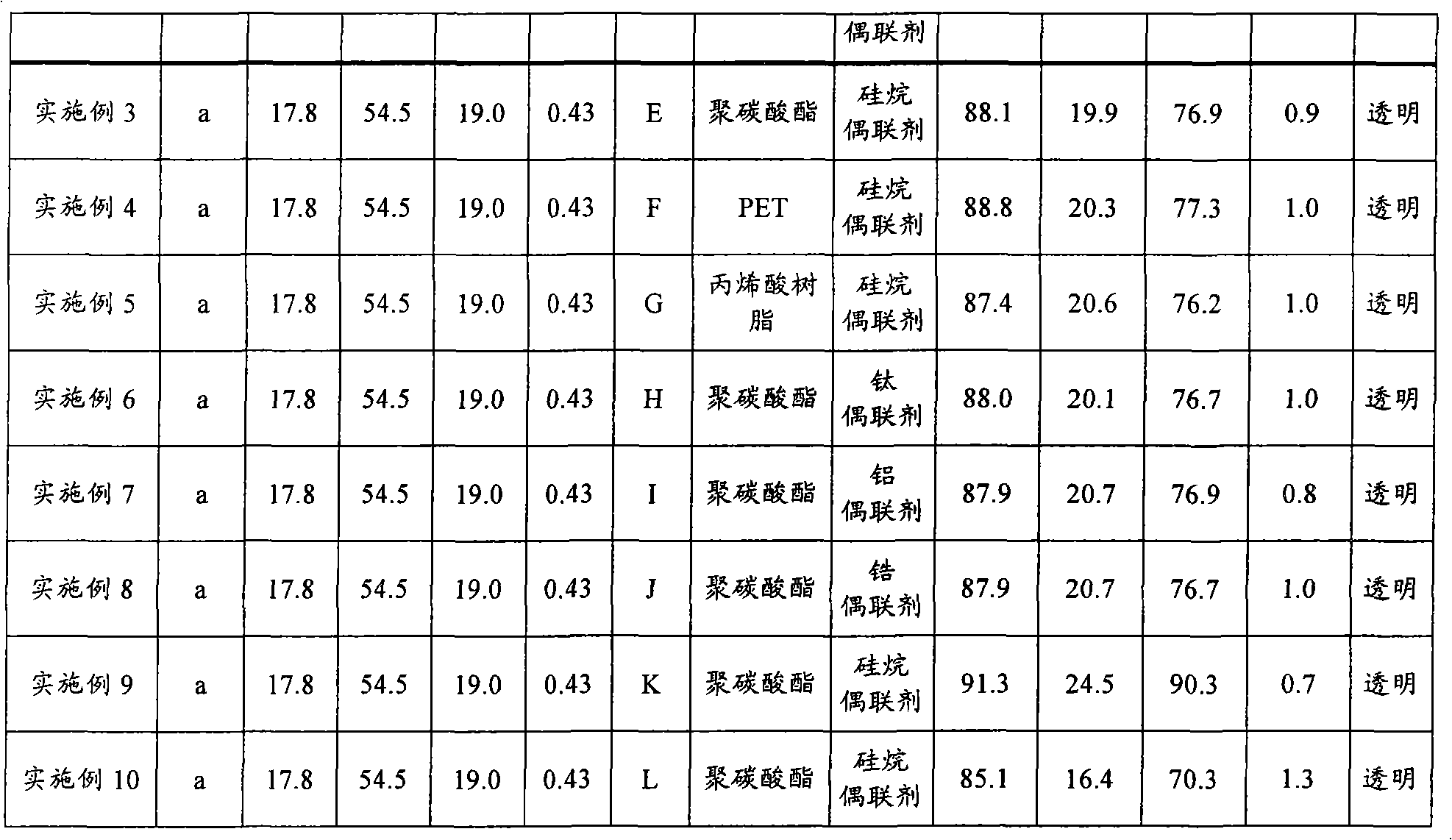

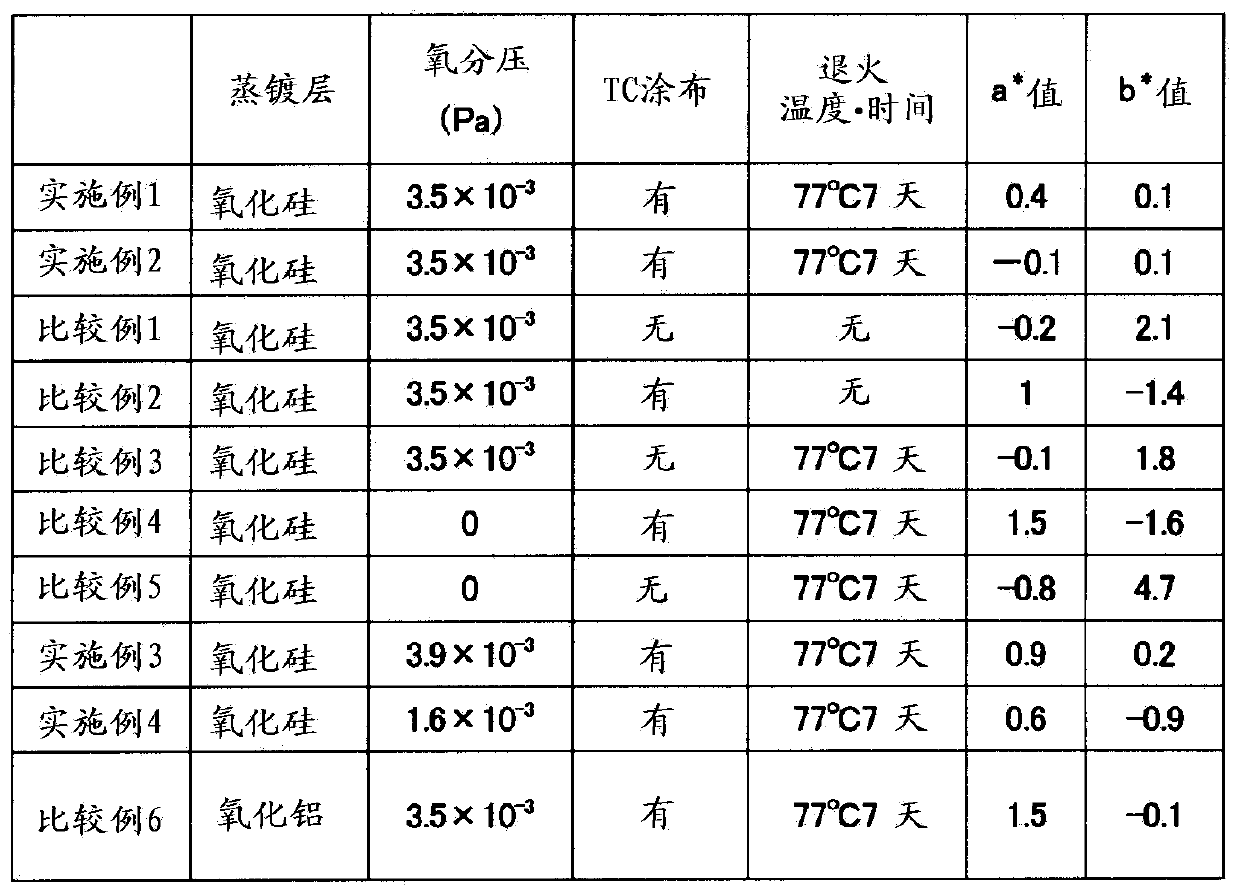

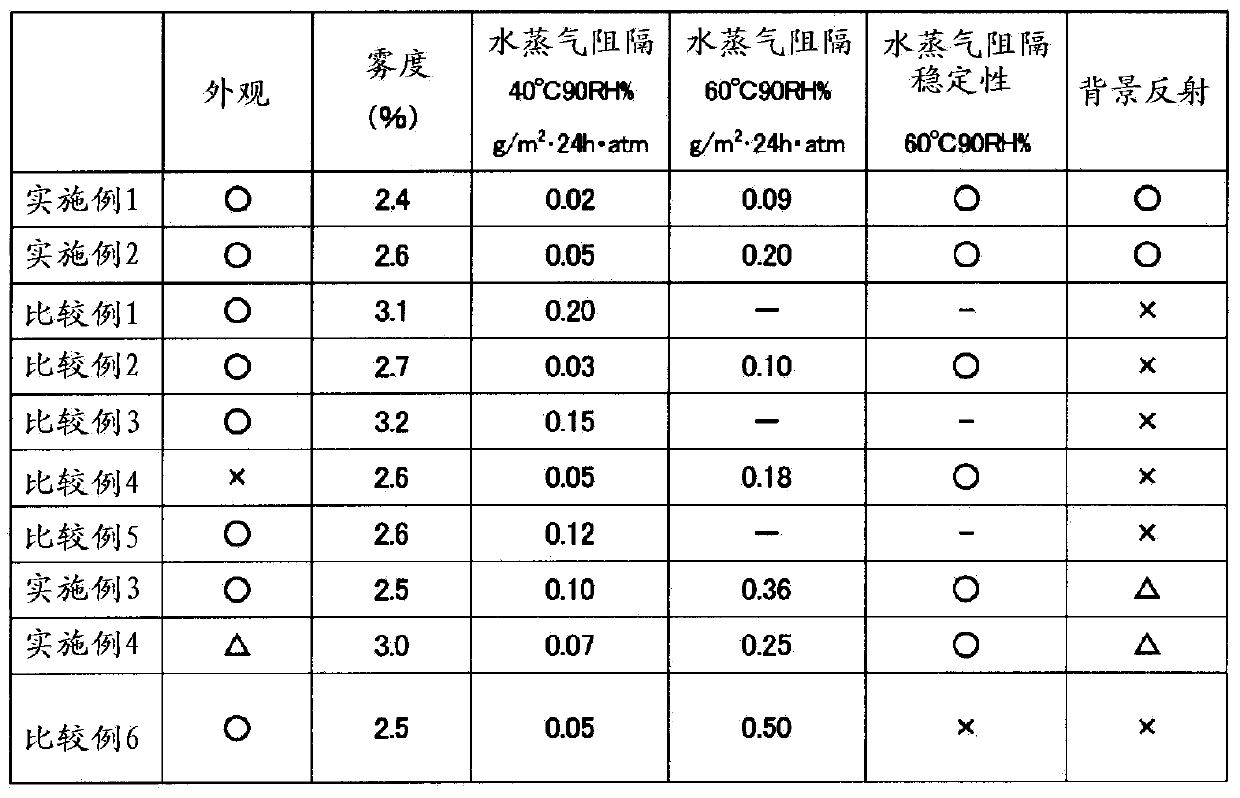

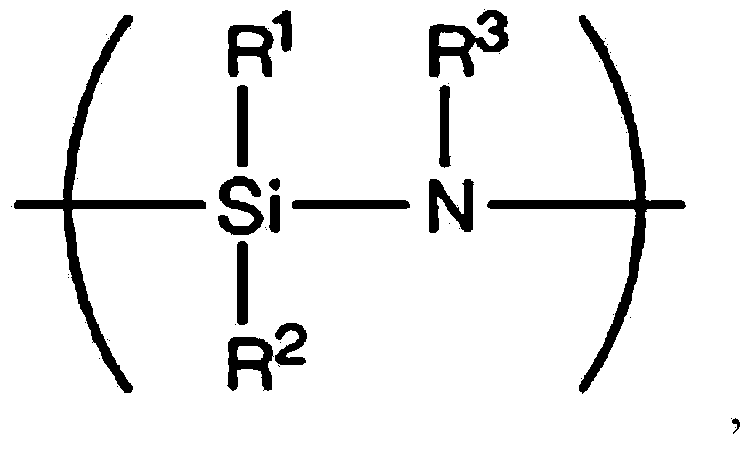

Gas-barrier film and process for producing same, and gas-barrier laminate

ActiveCN104185548AImprove barrier propertiesNo appearance defectSynthetic resin layered productsVacuum evaporation coatingWater vaporPolyvinyl alcohol

Provided are a gas-barrier film, etc. which have a low haze and excellent transparency, cause no appearance failure, and are effective in inhibiting reflection, and which have excellent impermeability to water vapor. The gas-barrier film comprises a base film, an inorganic layer formed on at least one surface thereof, and a resin layer formed on the inorganic layer and comprising polyvinyl alcohol and a silicon compound. The film has values of b* and a*, determined in accordance with JIS Z8722, of -1.0 to 1.0 and -1.0 to 1.0, respectively.

Owner:MITSUBISHI CHEM CORP

Antiglare hard coat film

ActiveUS20140254020A1High transparencySuppression of of imageDiffusing elementsCoatingsMaterials scienceOptical comb

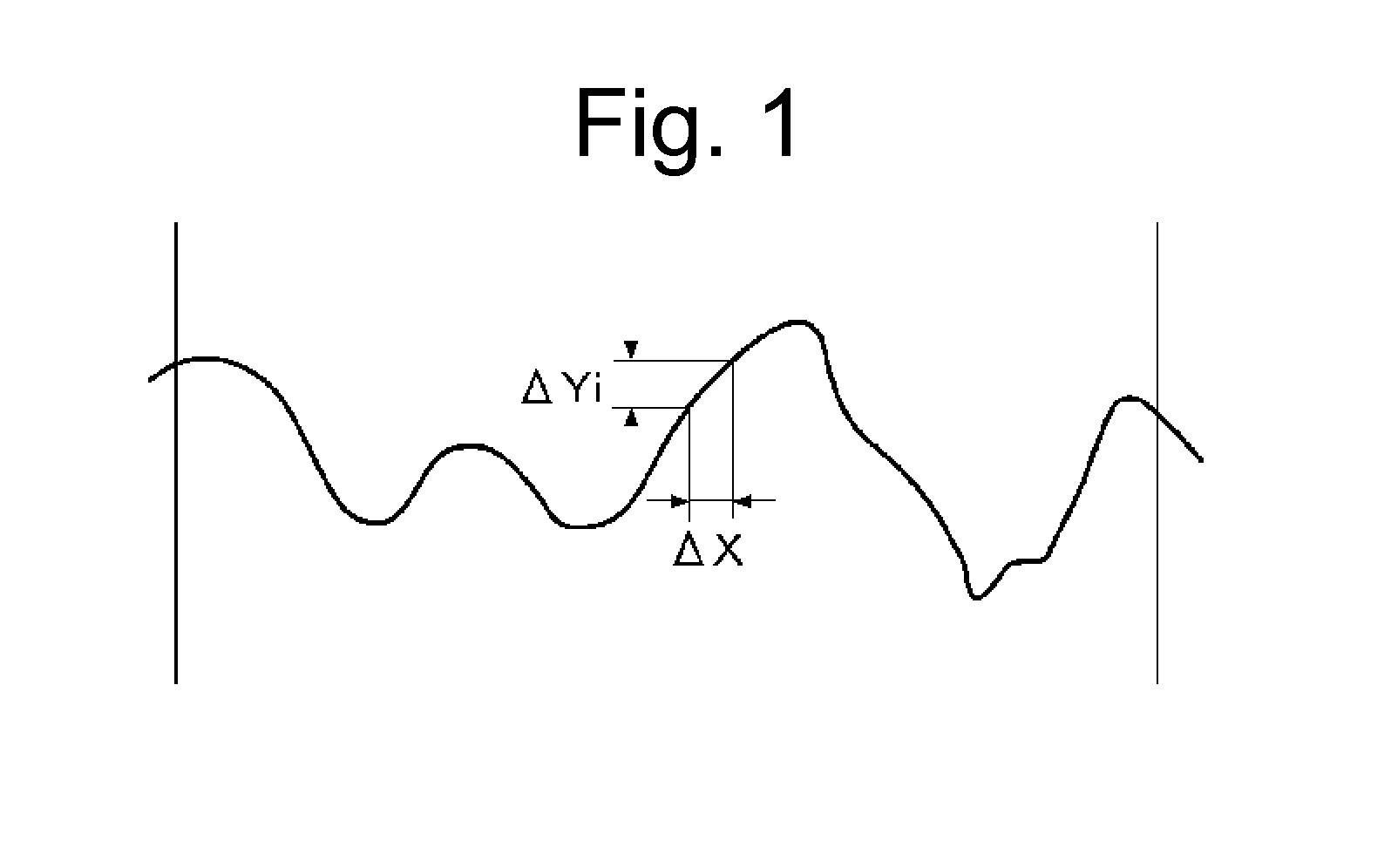

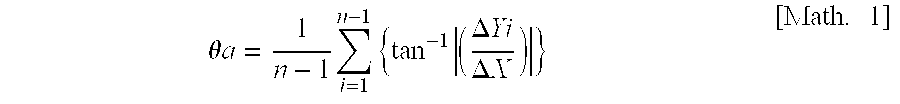

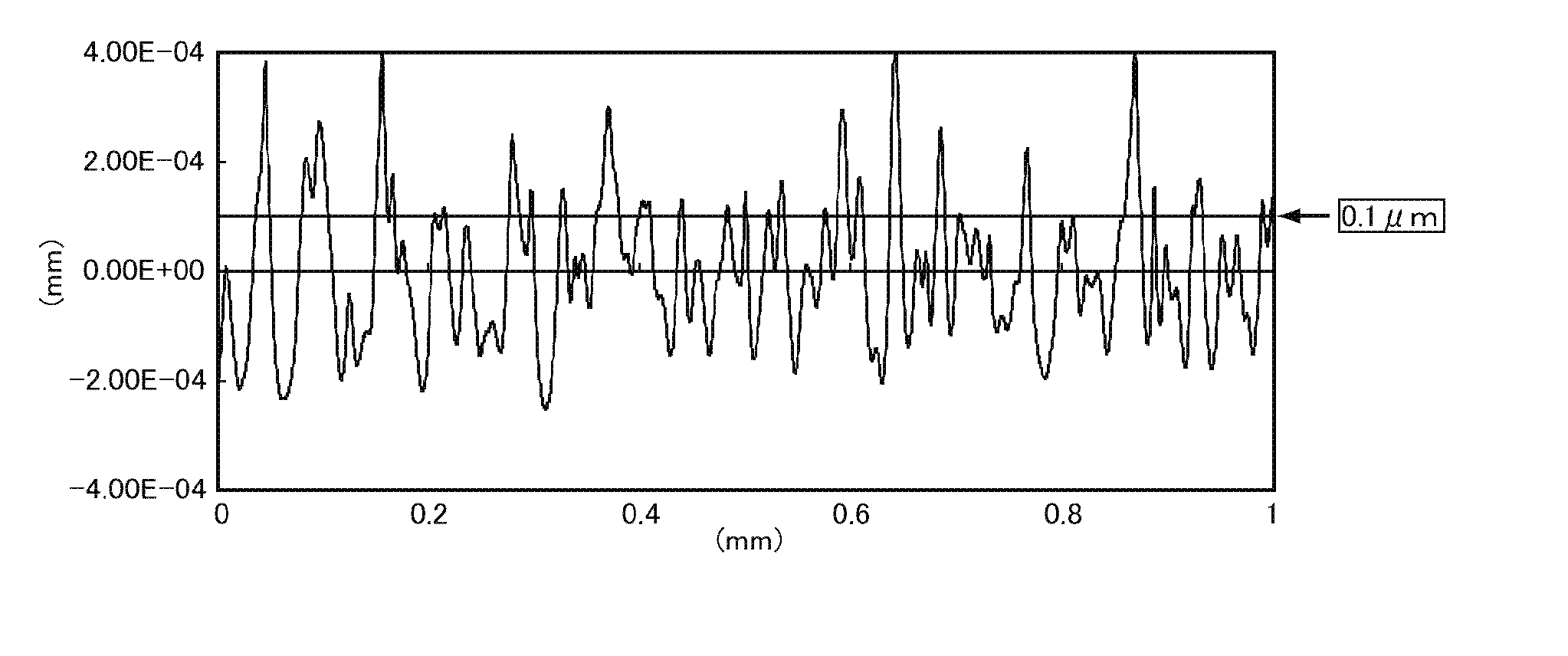

An antiglare hard coat film formed by providing an antiglare hard coat layer containing fine particles and a resin on a transparent film. When an average value of height in an evaluation region on a surface of the antiglare hard coat film is set at zero (0), a maximum cross sectional height represented by a difference between a height maximum value in the evaluation region and a height minimum value in the evaluation region is from 1.0 to 3.0 μm, and an average inclination angle of unevenness on the surface of the antiglare hard coat film is 1 degree or less. The total value of the transmissive clarity measured through four optical combs using a transmissive clarity measuring device according to JIS K 7105-1981 is 280% or more, and the value of the transmissive clarity measured through each optical comb is 70% or more, respectively.

Owner:NIPPON PAPER IND CO LTD

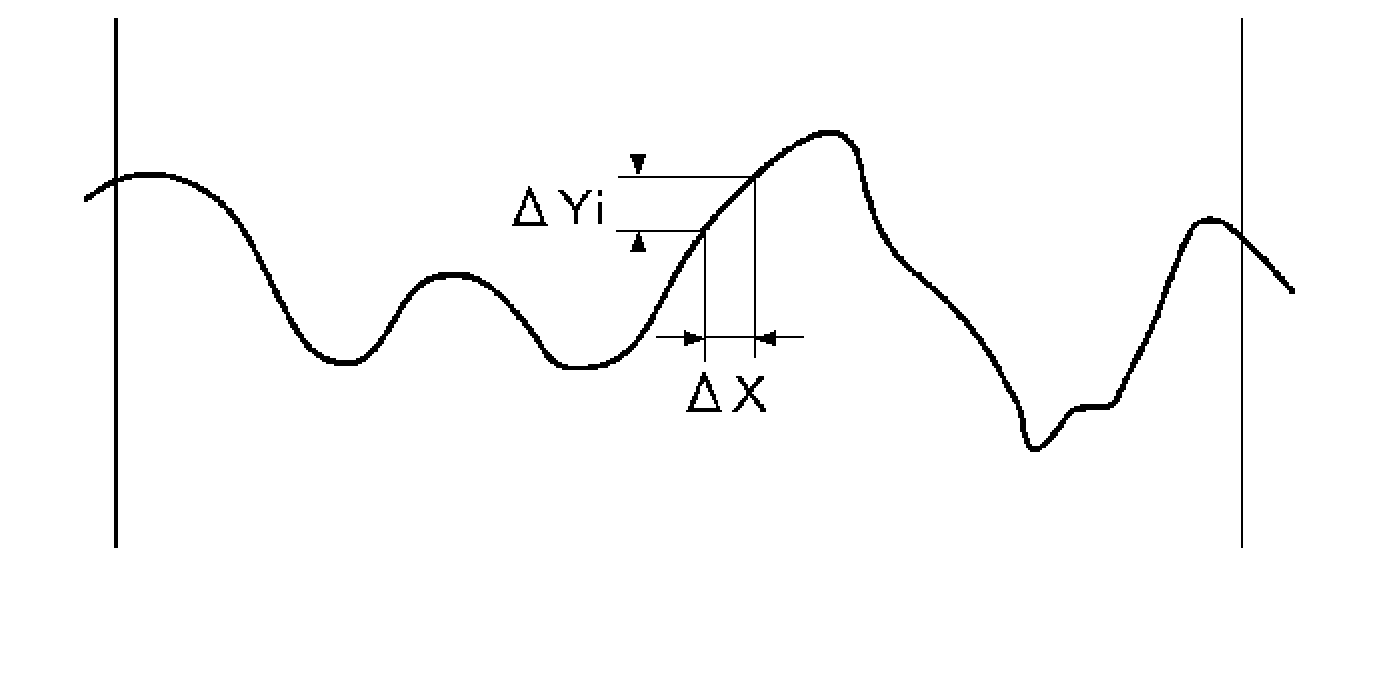

Hard-coated antiglare film, polarizing plate and image display including the same, method for producing the same, and method for evaluating the same

ActiveUS20110080645A1Improve bright-dark contrastHaze value be decreaseDiffusing elementsLayered productsPolarizerLine segment

A hard-coated antiglare film that has superior antiglare properties, allow high definition to be provided even in the case of a low haze value, can prevent white blur in an oblique direction from occurring and, and can improve the depth of black in black display, as well as a polarizing plate, and the like. The hard-coated antiglare film includes a transparent plastic film substrate and a hard-coating antiglare layer containing fine particles, which is on at least one surface of the transparent plastic film substrate. The hard-coated antiglare film has a total haze value Ht in the range of 10% to 35%. The total haze value Ht and an internal haze value Hin satisfy a relationship of 0.5≦Hin / Ht≦0.9. The surface of the hard-coating antiglare layer has an uneven shape and an arithmetic average surface roughness Ra in the range of 0.1 to 0.3 μm. The hard-coated antiglare film includes: convexities that exceed a roughness mean line of a surface roughness profile; no convexities in which line segments of portions of the mean line that cross the convexities each have a length of 80 μm or longer, and convexities that exceed a standard line that is in parallel with the mean line and is located at a height of 0.1 μm; and at least 50 convexities in which line segments of portions of the standard line that cross the convexities each have a length of 20 μm or shorter in 4-mm long portion at an arbitrary location of the surface of the hard-coating antiglare layer.

Owner:NITTO DENKO CORP

Fine particles of antimony tin oxide for sunscreen, dispersion thereof for sunscreen material formation, sunscreen material and transparent base material for sunscreen

ActiveUS20050163999A1Sufficient transparencyHigh visible light transmittancePigmenting treatmentMaterial nanotechnologyTransmittanceAntimony

Physical characteristics of ATO fine particles capable of exhibiting such optical properties as a high visible light transmittance, a low solar radiation transmittance, and a low haze value when the ATO fine particles are formed on a transparent substrate or in the substrate are clarified, and the ATO fine particles having the physical characteristics thereof are manufactured. The ATO fine particles having such physical characteristics that a size of a crystallite constituting the ATO fine particles is 4 to 125 nm, and that a specific surface area of the fine particles of 5 to 110 m2 / g can exhibit the above-described optical properties, and an example of a method for manufacturing thereof is to parallel-drop an antimony chloride alcoholic solution and an ammonium hydrogen carbonate aqueous solution in a tin chloride aqueous solution, thoroughly wash generated precipitates, dry and calcinate them in an atmosphere, thereby the ATO fine particles are manufactured.

Owner:SUMITOMO METAL MINING CO LTD

Transparent conducting film and preparation method thereof

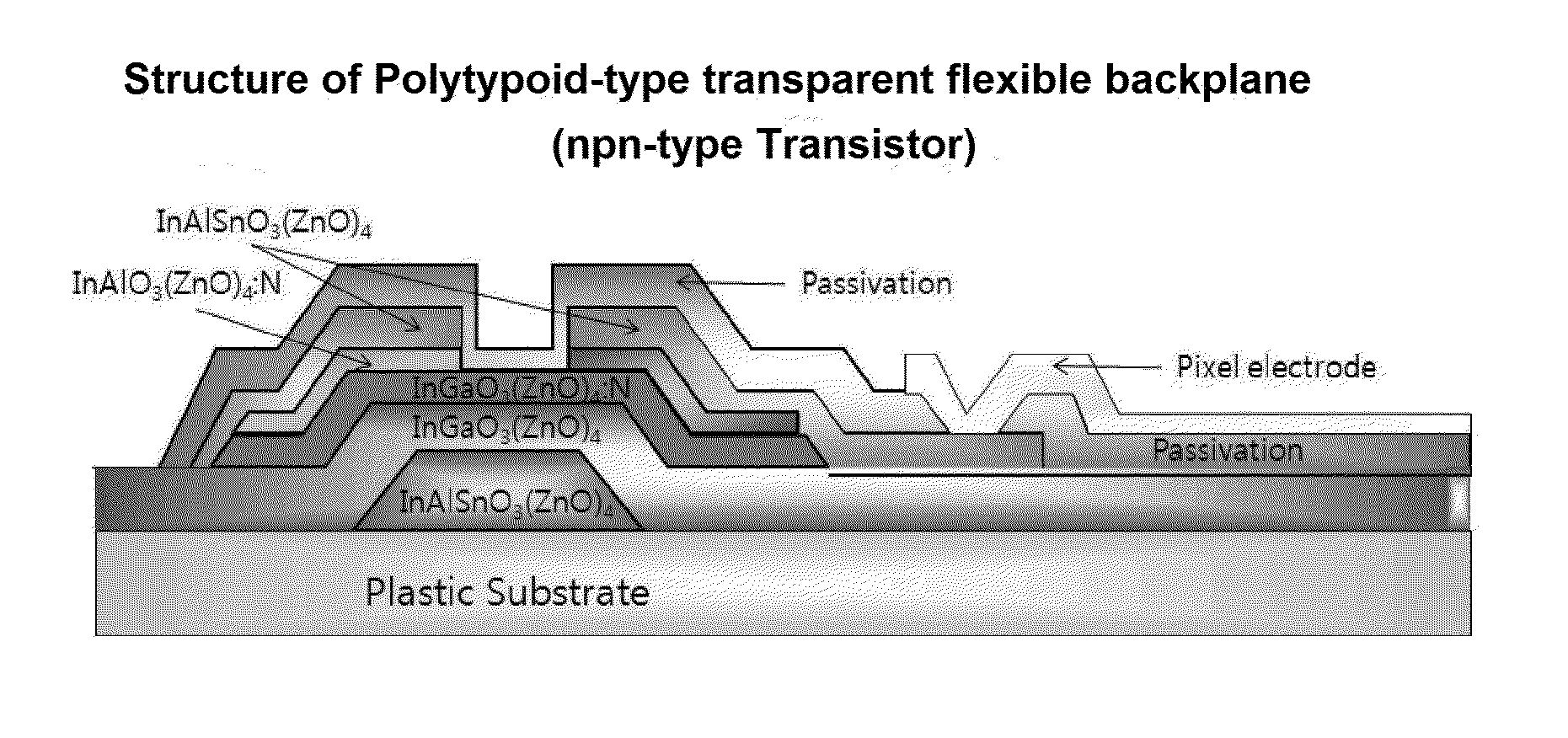

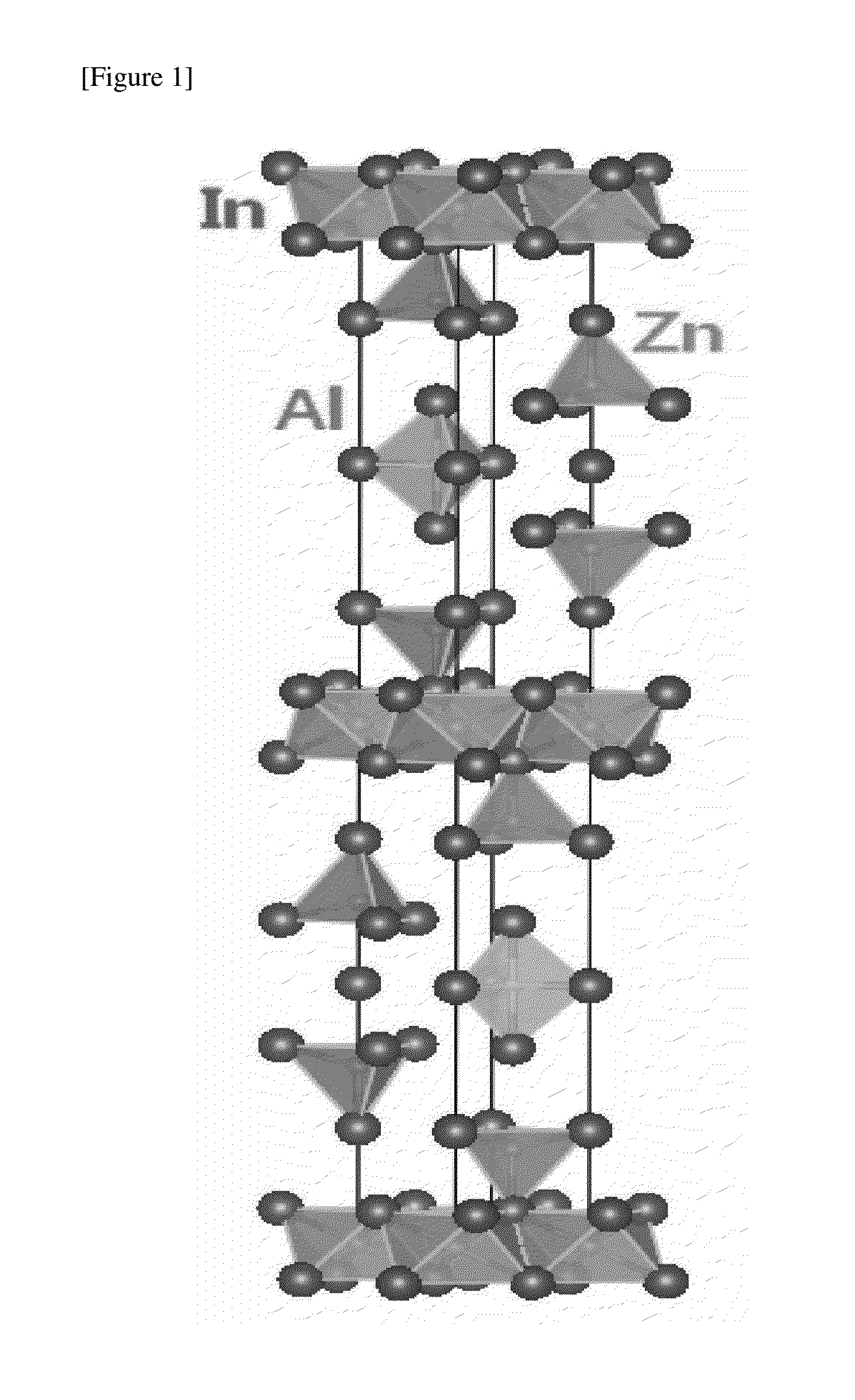

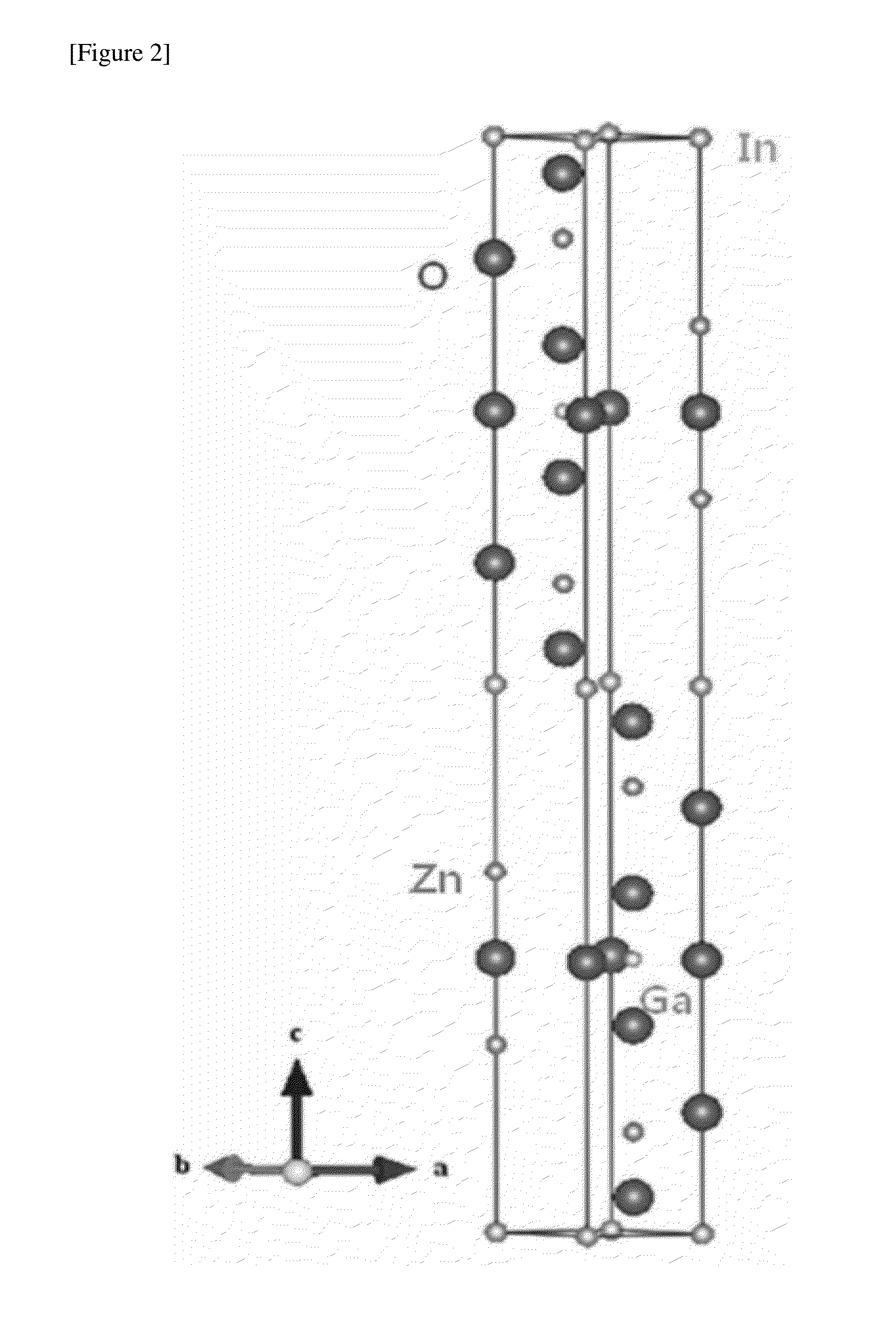

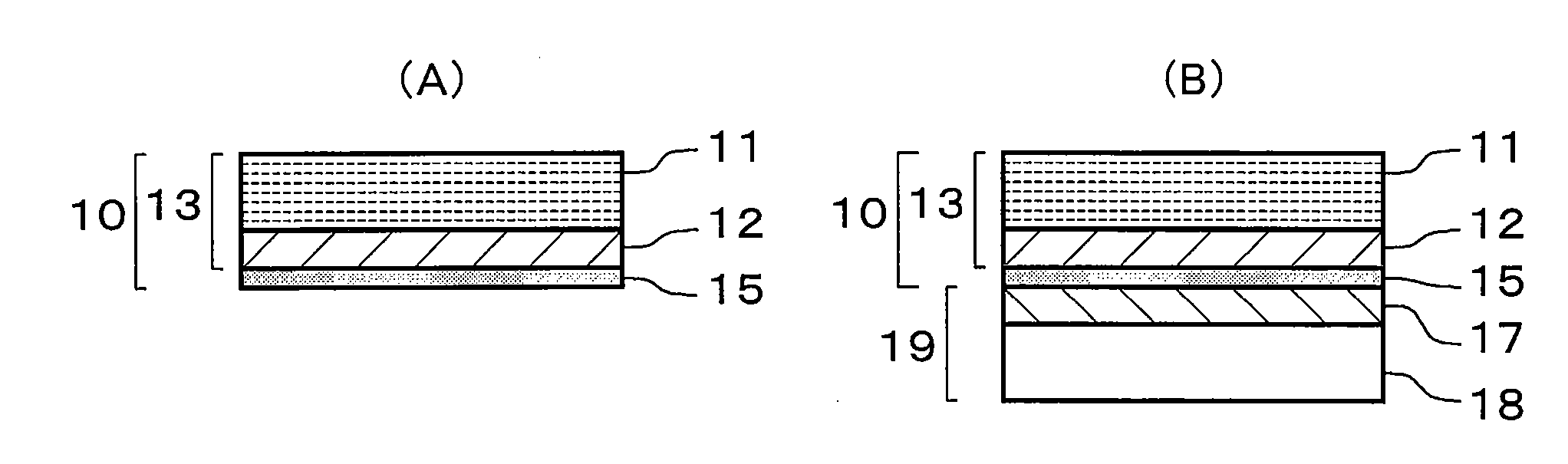

ActiveUS20150194531A1Improve conductivityImprove transmittanceAluminium compoundsConductive layers on insulating-supportsCrystal structureTransparent conducting film

There are provided a transparent conductive film and a method for preparing the same. The transparent conductive film of the present application comprises a compound having a crystalline structure and represented by Chemical Formula 1 and thus can be applied as a technology substituting for conventional ITO conductive films.

Owner:LG CHEM LTD

Coating liquid for coating a retardation film, retardation film and composite polarizing plate using the coating liquid and method for producing retardation film, and liquid crystal display device

InactiveUS20060292314A1Thin and simple structureExcellent optical propertiesLiquid crystal compositionsThin material handlingHigh contrastPolarizer

The invention provides a coating liquid containing an organic modified clay complex, being able to reduce the haze value when formed into a coating retardation film and to maintain a high contrast ratio of the liquid crystal display device. The coating liquid is formed into a retardation film and composite polarizing plate, and the composite polarizing plate is applied to a liquid crystal device. The invention also provides a coating liquid for coating a retardation film containing an organic modified clay complex and a binder resin in an organic solvent and having a moisture content in the range from 0.15 to 0.35% by weight as measured with a Karl Fischer moisture meter. A retardation film is formed from the coating liquid for coating the retardation film by forming a composition obtained by removing the organic solvent and water from the coating liquid into a film. A composite polarizing plate is prepared by laminating the polarizing plate, adhesive layer and retardation film in this order. A liquid crystal display device is produced by disposing this composite polarizing plate at one surface of a liquid crystal cell, and another retardation film and polarizing plate on the other surface of the liquid crystal cell.

Owner:SUMITOMO CHEM CO LTD

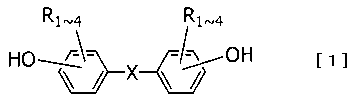

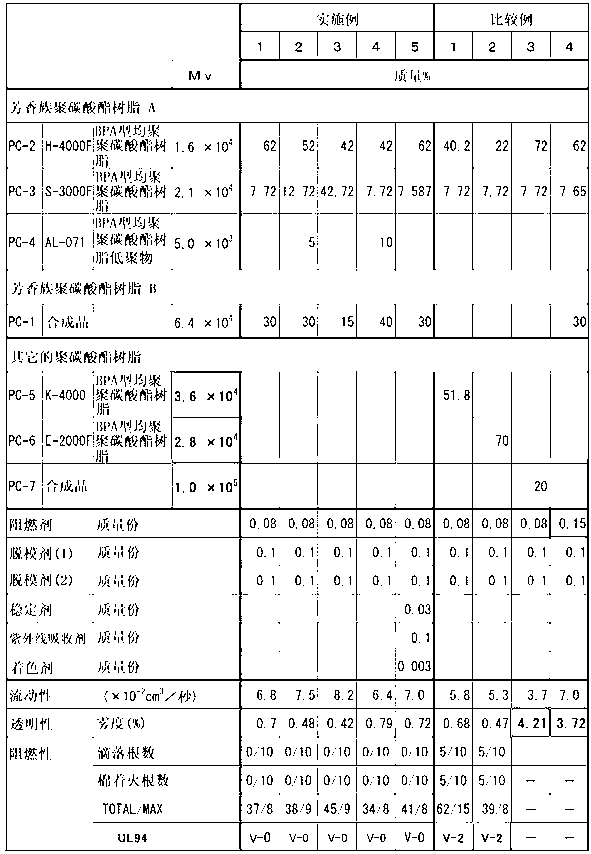

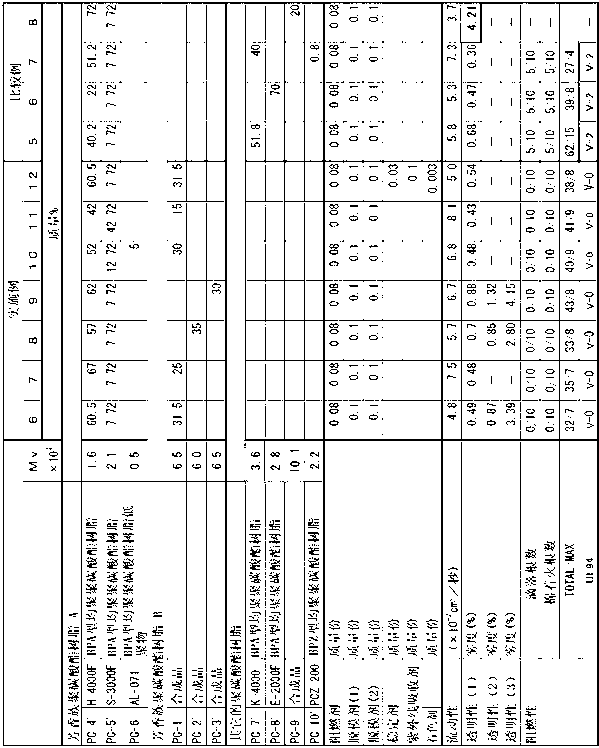

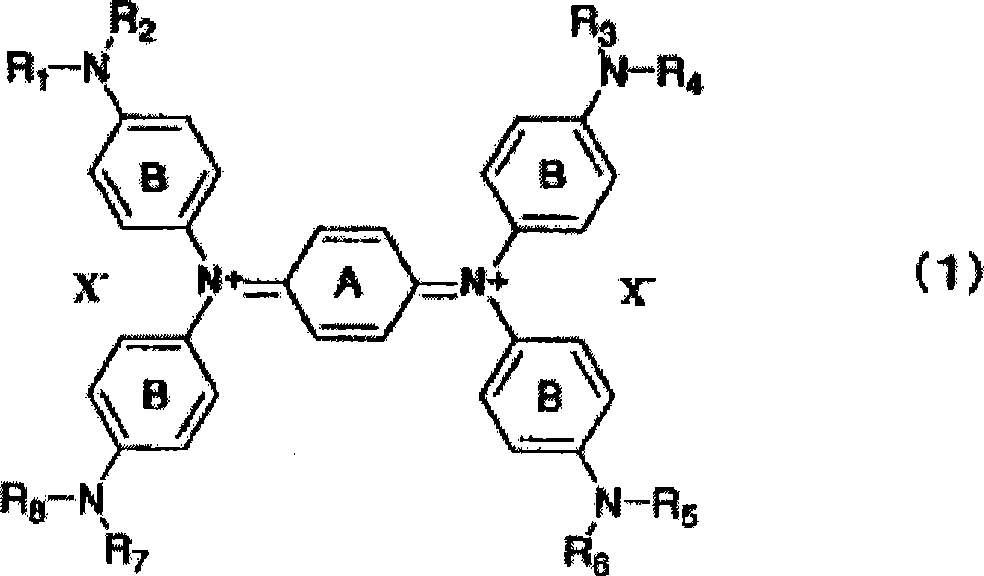

Transparent, fire-retardant aromatic polycarbonate resin composition and molded product

ActiveCN102844377AImprove flame retardant performanceLow haze valueOrganic sulfonic acidPolymer science

Disclosed is a fire-retardant aromatic polycarbonate resin composition with high transparency. The transparent, fire-retardant aromatic polycarbonate resin composition is formed from (A) 100 parts by mass of a transparent aromatic polycarbonate resin comprising 50 mass% to 99 mass% of an aromatic polycarbonate resin-A having a viscosity average molecular weight (Mv) of 3103 to 2.5104 and 1 mass% to 50 mass% of an aromatic polycarbonate resin-B having a viscosity average molecular weight (Mv) of 5104 to 9104, and (B) 510-3 parts by mass to 910-2 parts by mass of a fire retardant comprising the alkali metal salt of an organic sulfonic acid, wherein the Q value is no more than 0.1 cm3 / second, a molded product with a thickness of 2.0 mm that was molded from said aromatic polycarbonate resin composition meets the UL94V-0 standard, and the haze value of a molded product with a thickness of 3.0 mm is no more than 2%.

Owner:MITSUBISHI GAS CHEM CO INC

Method of compositing nanocellulose with nano silver wires to prepare transparent conductive fiber

ActiveCN106222773ASmall coefficient of thermal expansionHigh strengthElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentFiberAcrylic resin

The invention discloses a method of compositing nanocellulose with nano silver wires to prepare transparent conductive fiber. The method includes: a), extracting nanocellulose from wood powder; b), preparing a nanocellulose / nano silver wire compound c), performing miscible compositing on the nanocellulose / nano silver wire compound and acrylic resin; d), adopting a wet mixing extrusion method to prepare the transparent conductive composite fiber. The method has the advantages that the nanocellulose is low in coefficient of thermal expansion, high in strength and Young modulus and excellent in thermochemical stability; a transparent conductive material made from the nano silver wires is high in transparency, low in haze, high in bending resistance and low in impedance, and a simplified preparation process is adopted; nanocellulose / nano silver wire composite conductive wires are high in light transmittance and low in haze value.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

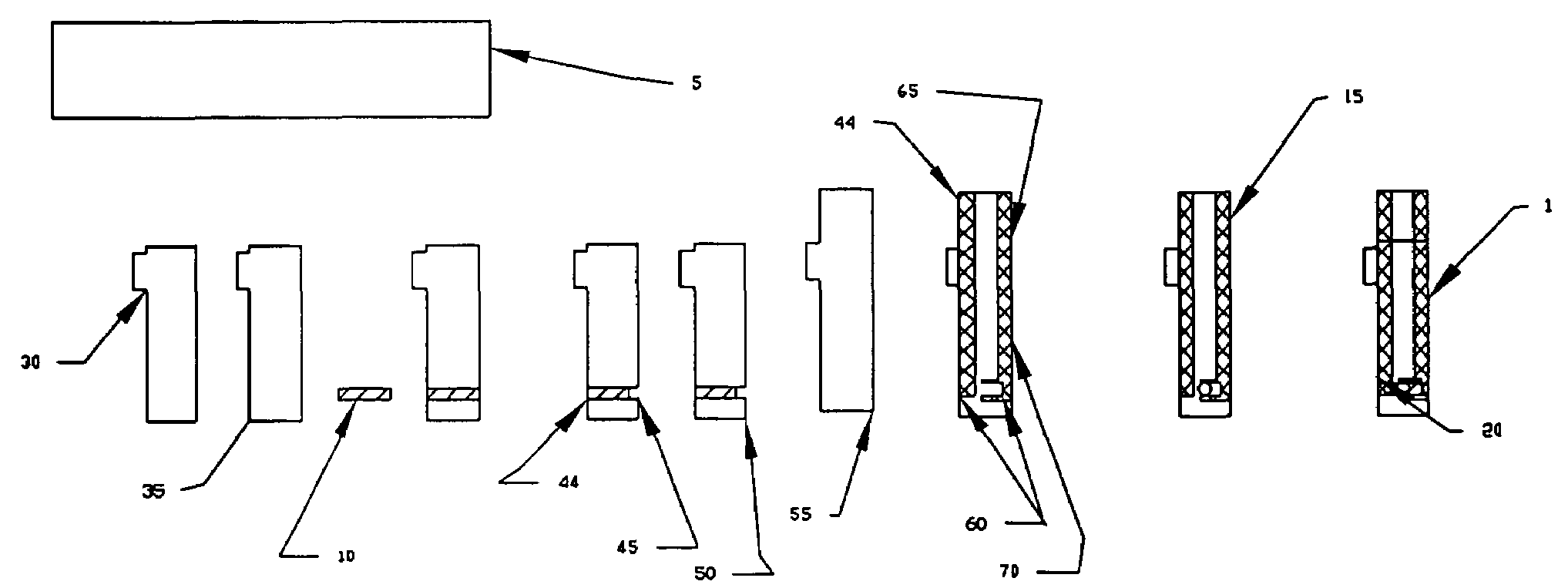

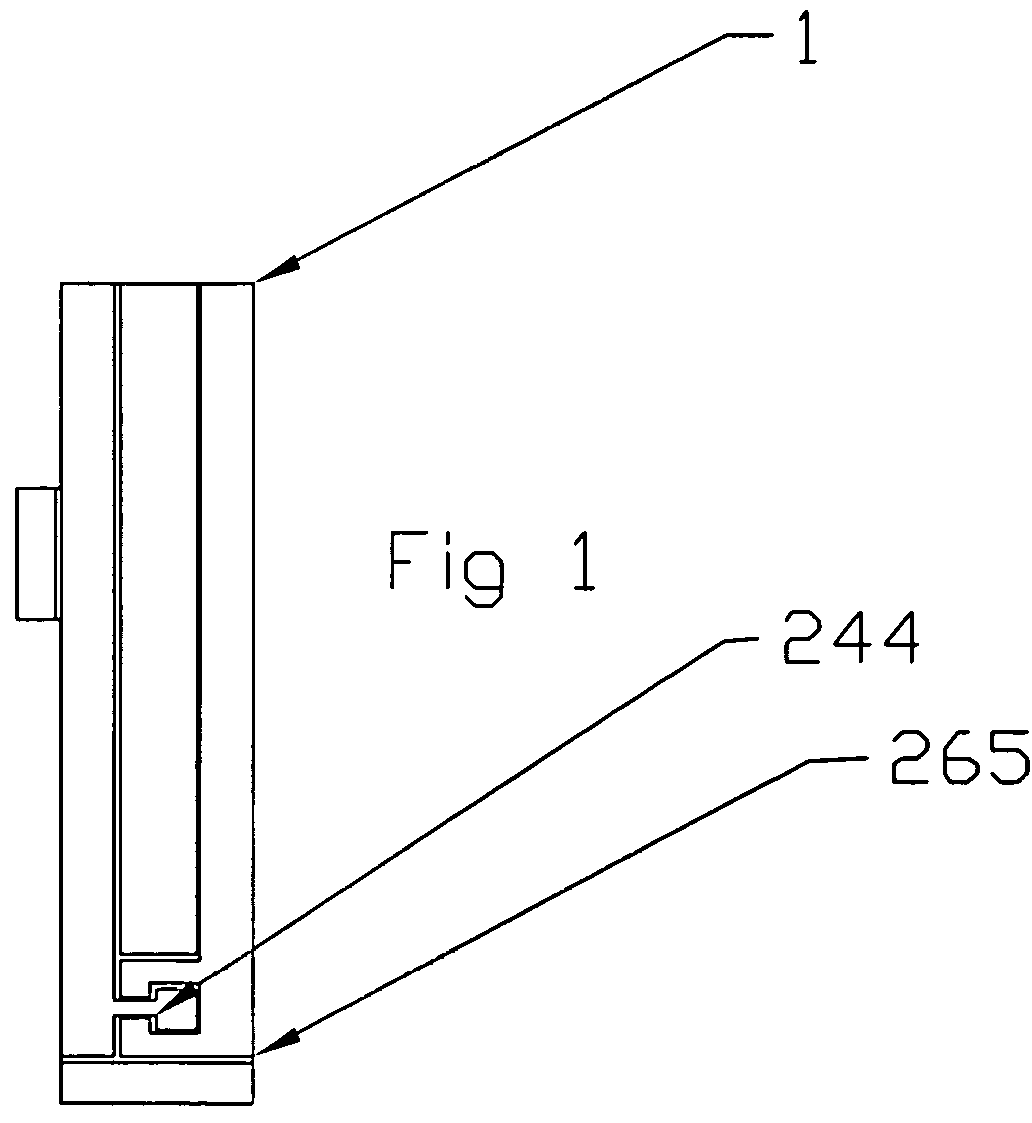

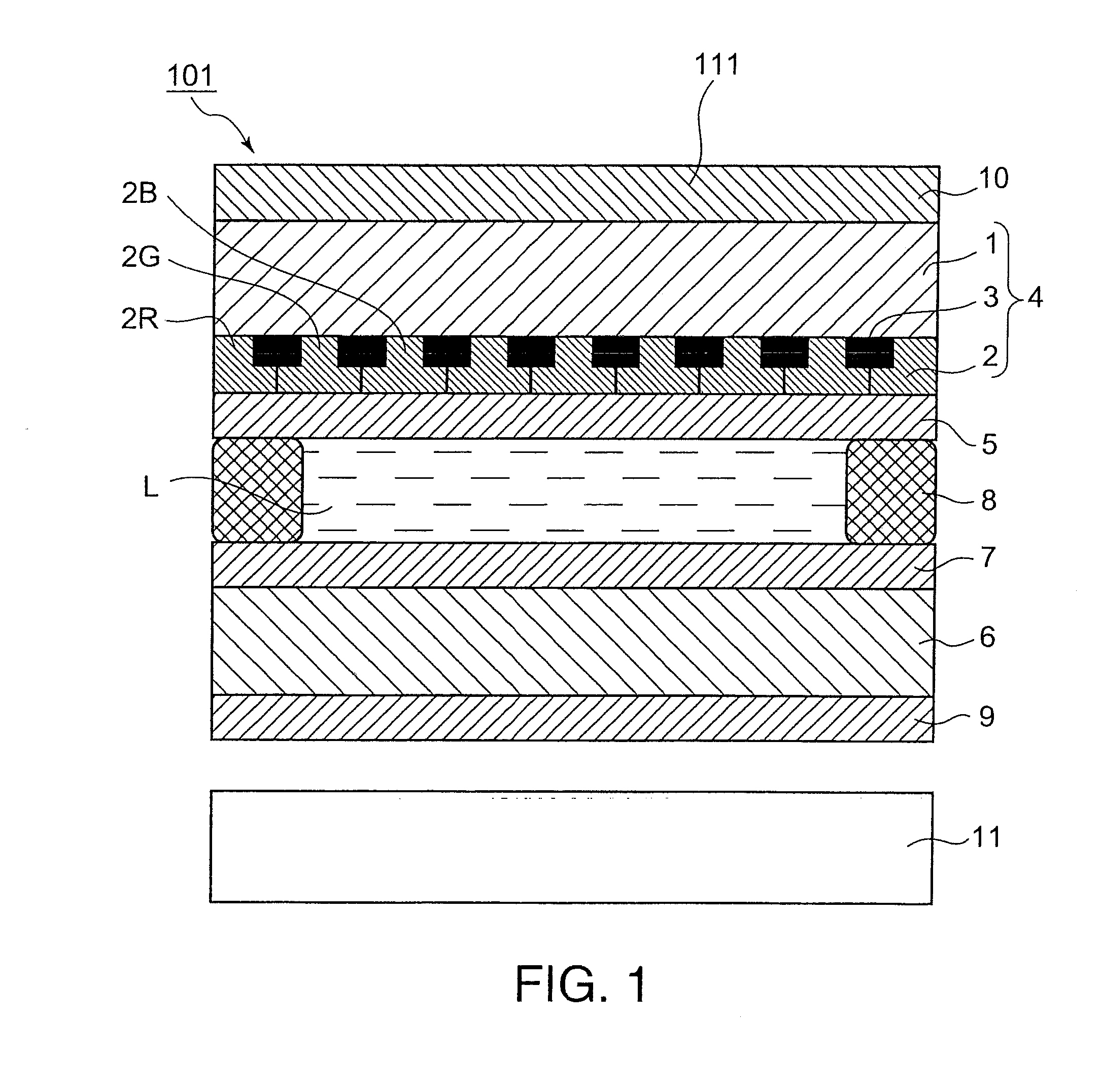

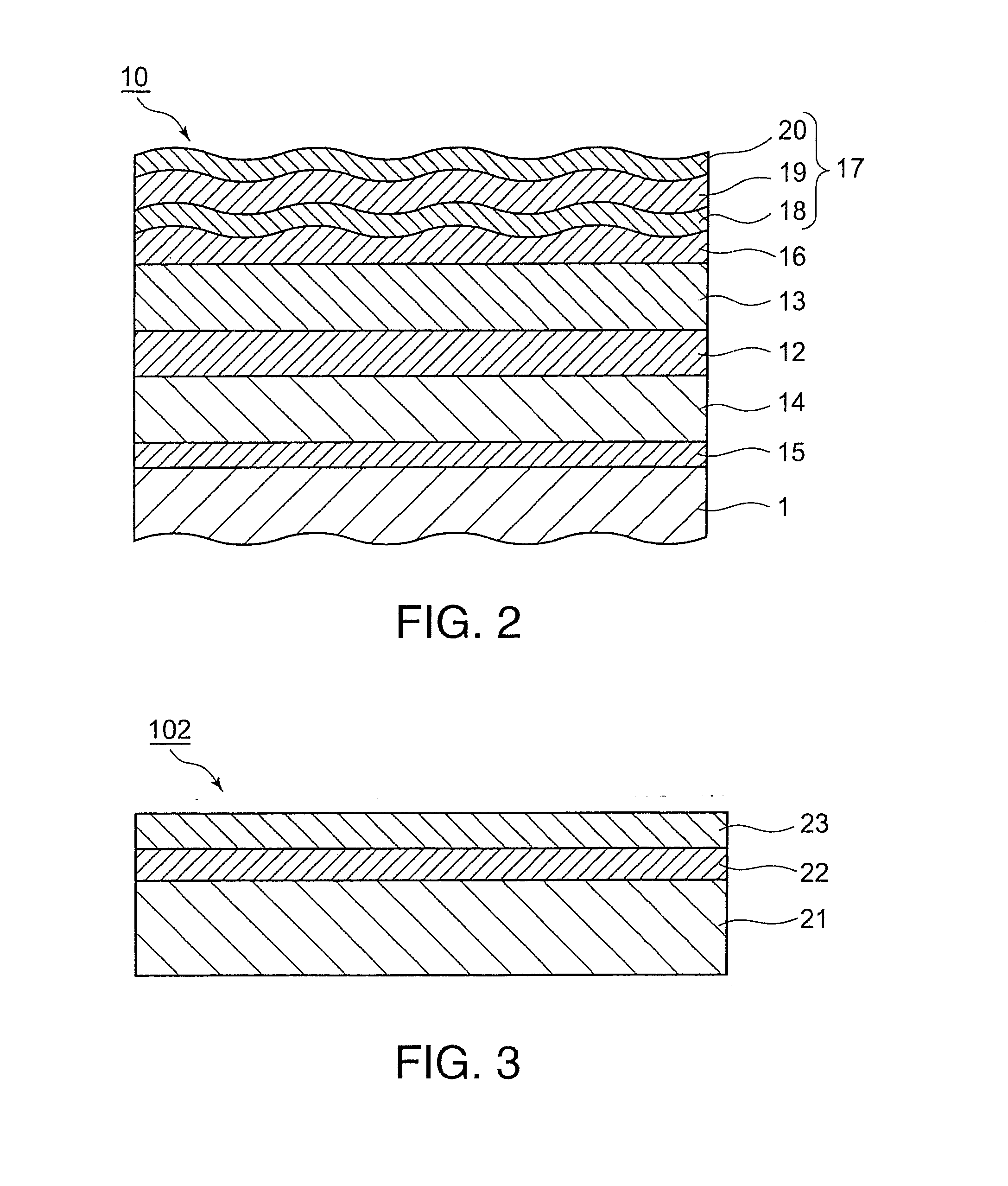

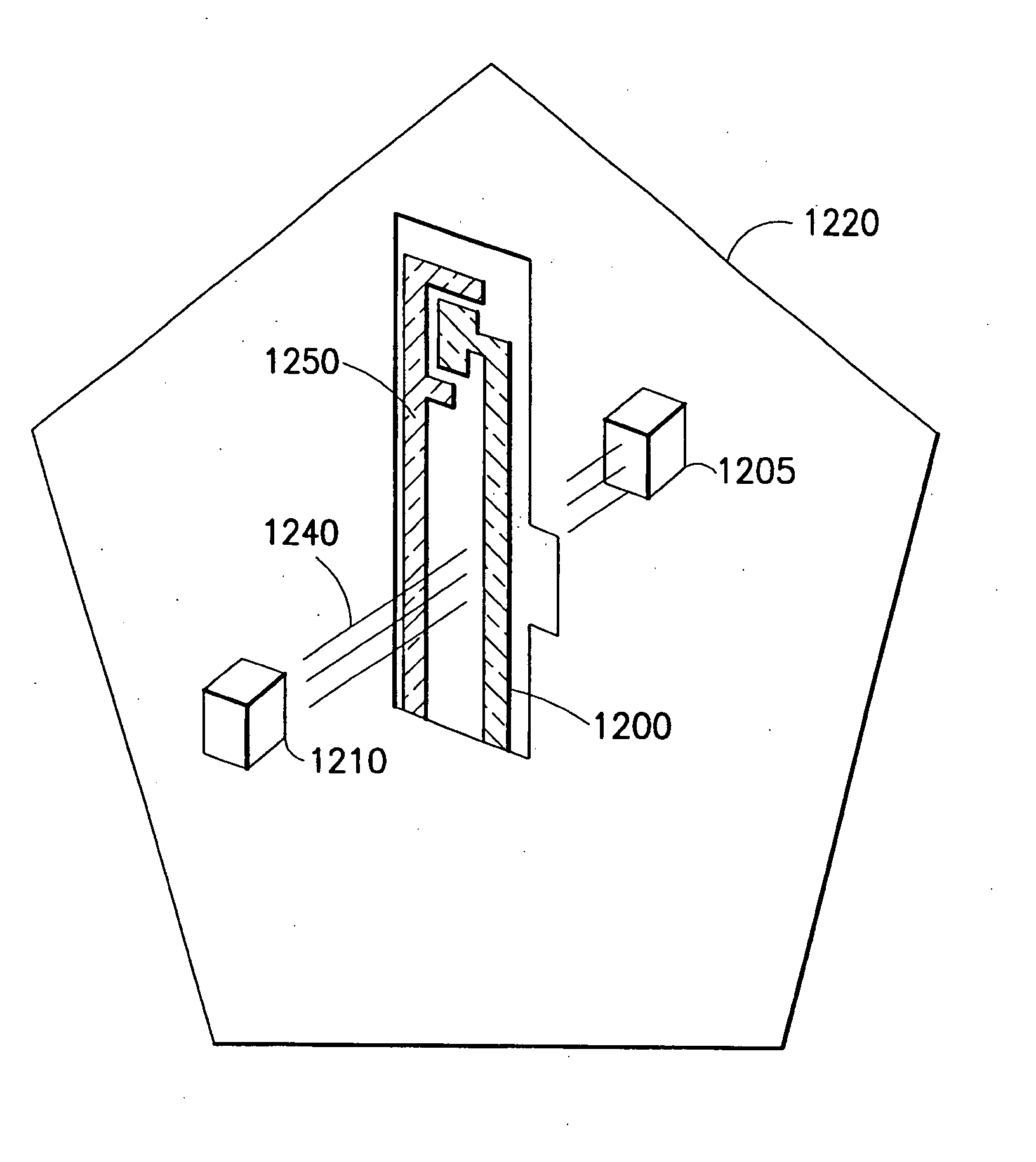

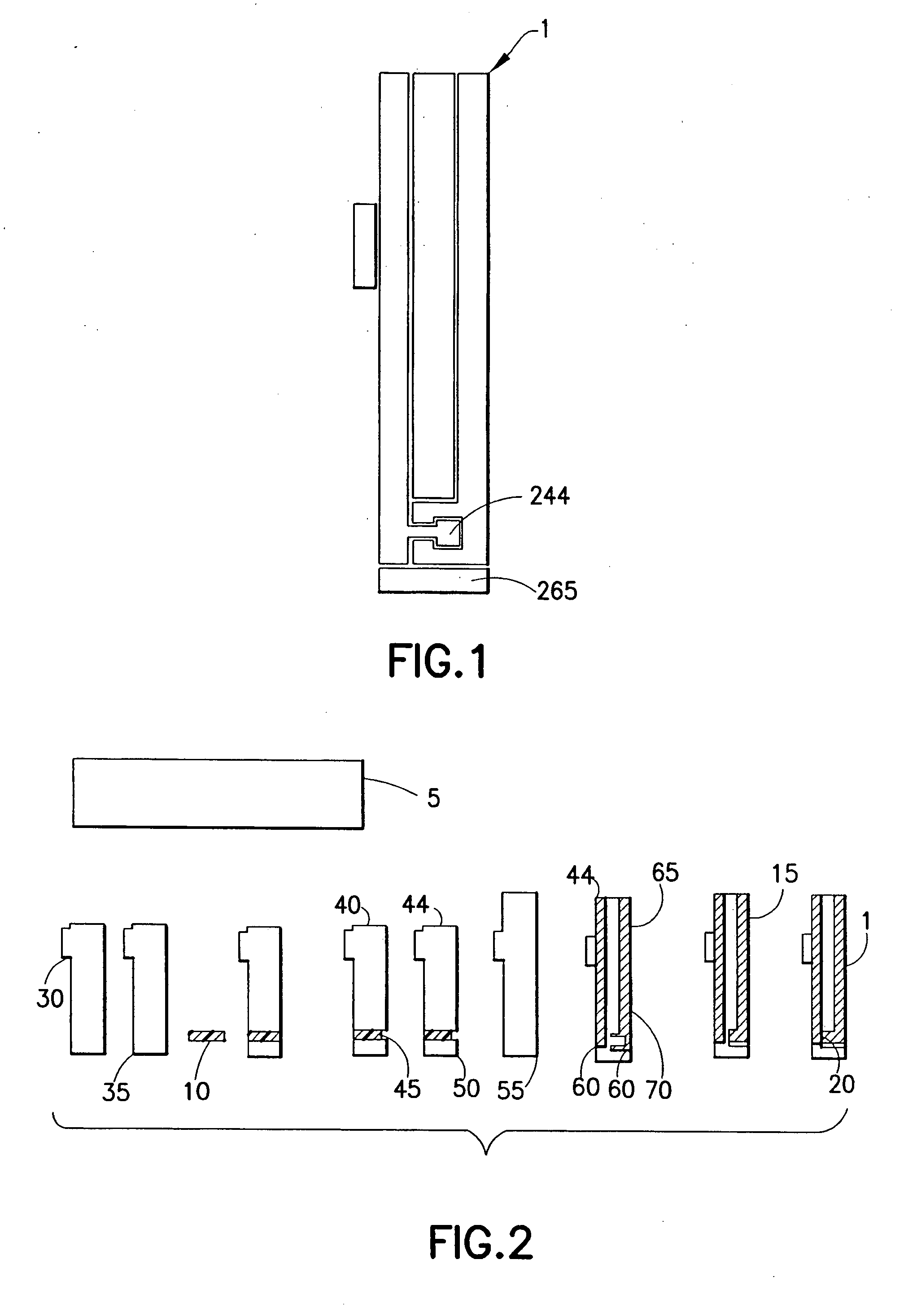

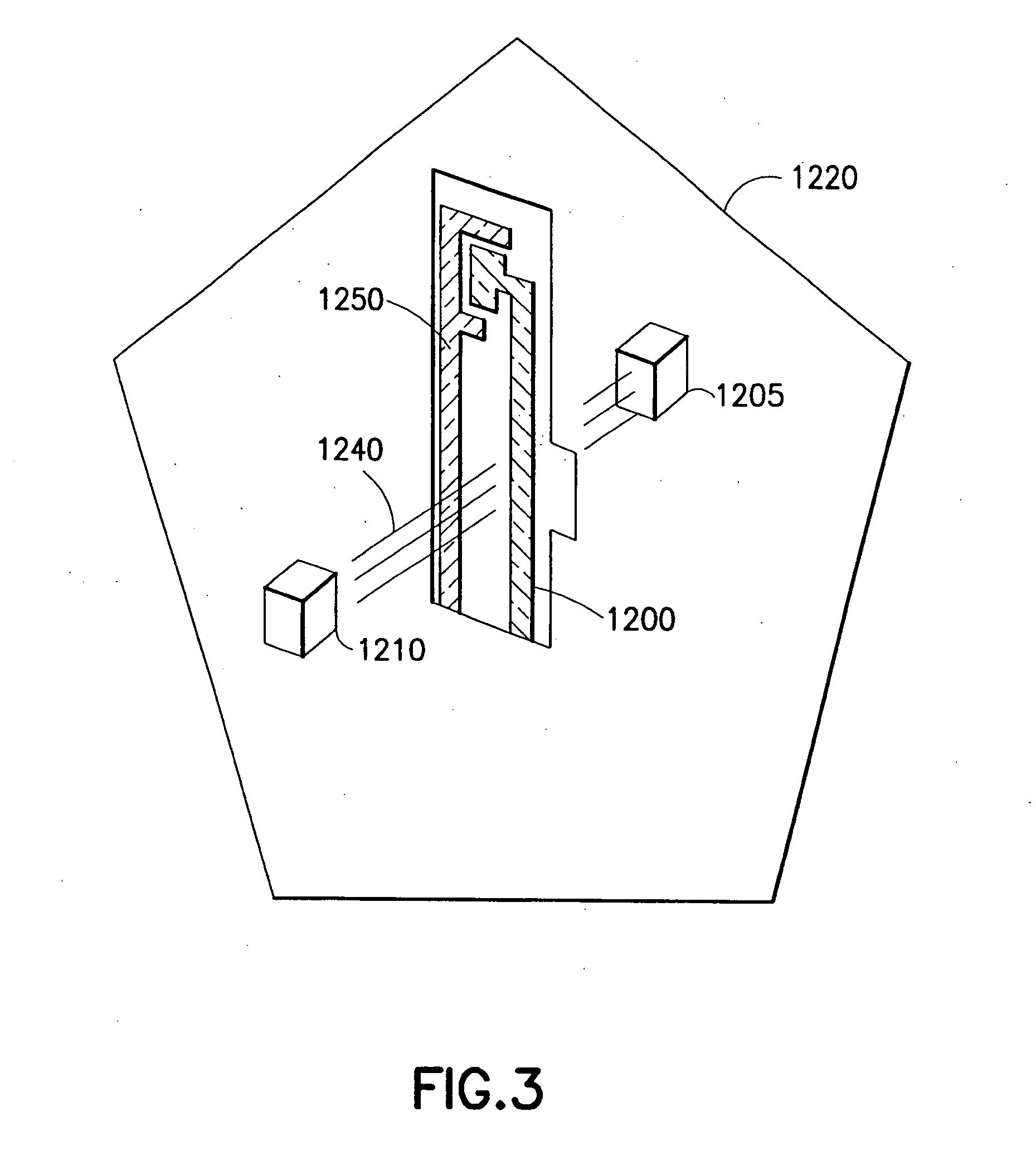

Liquid crystal optical device and process for its production

InactiveUS20090147211A1Low haze valueExcellent characteristicsLiquid crystal compositionsNon-linear opticsRotatory powerProduction rate

To provide a liquid crystal optical device showing a low haze value in the transparent state, further an excellent stability in the transparent-scattering characteristics and productivity, and to provide a production process thereof.The liquid crystal optical device in the embodiment 1 of the present invention is a liquid crystal optical device 1 comprising a pair of insulating substrates 11 and 21, of which at least one is transparent, electrodes 12 and 22 formed on respective inner faces of the substrates, and a composite 50 comprising nematic liquid crystal and a cured material, interposed between the inner faces of the substrates. The composite 50 is obtained by curing the following curable compound in the following chiral nematic liquid crystal composition in a state where the liquid crystal composition is interposed between the inner faces of the insulating substrates and the liquid crystal is aligned:chiral nematic liquid crystal composition: a liquid crystal composition showing a chiral nematic phase, comprising nematic liquid crystal and a curable compound, wherein at least a part of the curable compound is an optically active material having an optical rotatory power, and the optically active material having an optical rotatory power consists substantially solely of the curable compound.

Owner:ASAHI GLASS CO LTD

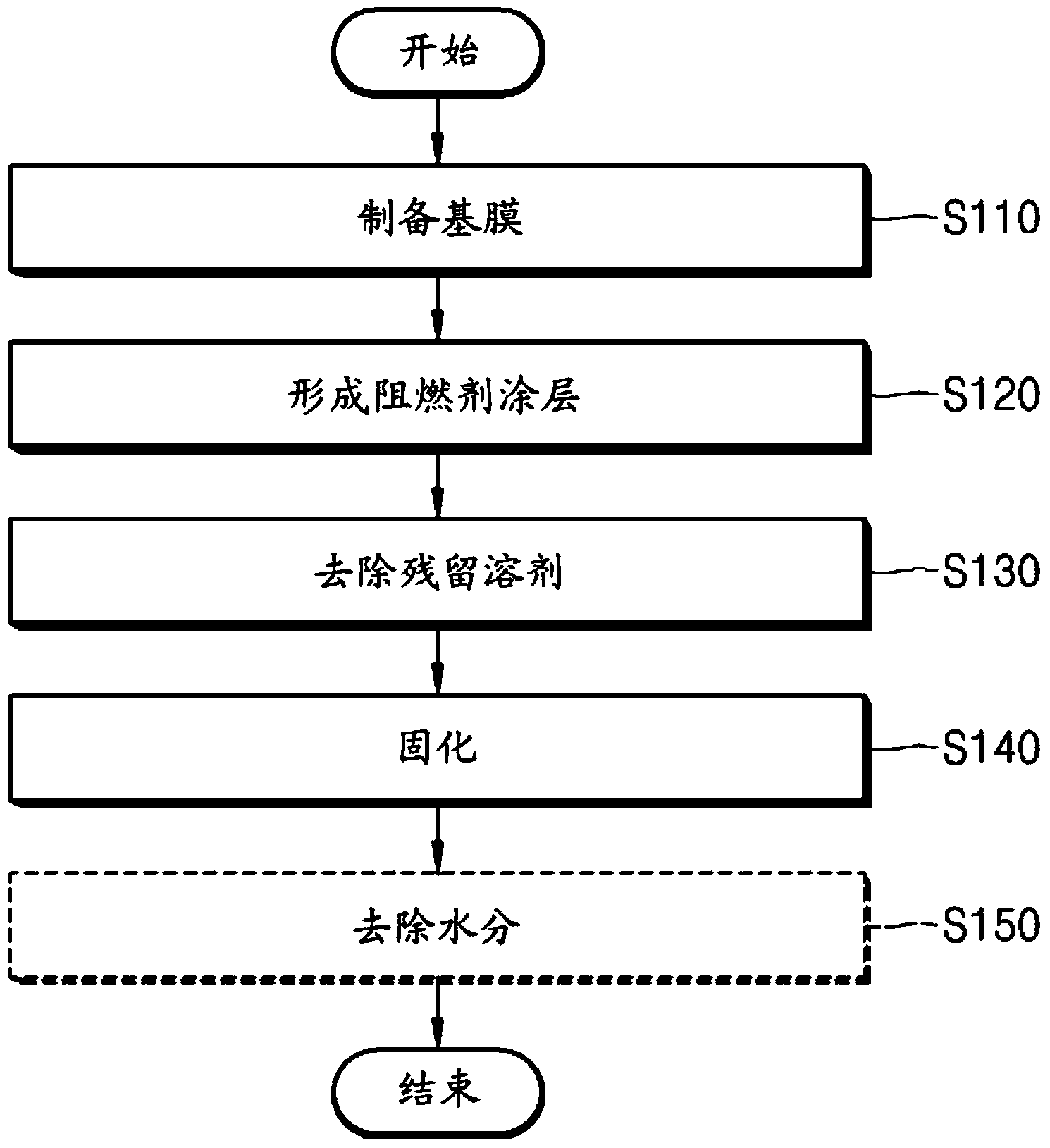

Method for manufacturing a flame-resistant and transparent film, and flame-resistant and transparent film manufactured using same

InactiveCN103415555AHigh transparencyLow haze valueFireproof paintsThin material handlingOptical propertyPolysilazane

Disclosed is a method for manufacturing a flame resistant and transparent film having a high transparency after imparting flame resistance through flame resistance treatment. The method for manufacturing the flame resistant and transparent film according to the present invention comprises the steps of: (a) preparing a transparent base film; (b) forming a flame resistant coating layer by coating a flame resistant material comprising a polysilazane onto at least one surface of the base film; (c) drying the flame-resistant coating layer so as to remove residual solvents in the flame-resistant coating layer; and (d) curing the flame-resistant coating layer under a humid environment. The present invention is characterized by the flame-resistant coating layer and a laminated body of the base film having an optical property in which a measured haze value is less than 0.3.

Owner:LG HAUSYS LTD

Electromagnetic wave shielding laminate and production method therefor

InactiveCN101194543AHigh light transmittanceHigh transparencyMagnetic/electric field screeningIdentification meansInfraredScattering function

The present invention relates to a method for producing an electromagnetic wave shielding laminate, comprising the following steps: a step of forming a geometrically shaped electromagnetic wave shielding material on a peelable support; peeling the electromagnetic wave shielding material from the peelable support; The process above the support for transfer, wherein the support for transfer has one or more layers having conductivity, anti-reflection, reduced reflectivity, hard coat properties, anti-glare properties, anti-glare properties on one side or both sides of the film. A functional layer with one or more functions among contamination function, near-infrared absorption function, ultraviolet absorption function, color correction function, heat dissipation function, de-neon function, scattering prevention function, and shock-resistant buffer function.

Owner:TOPPAN PRINTING CO LTD

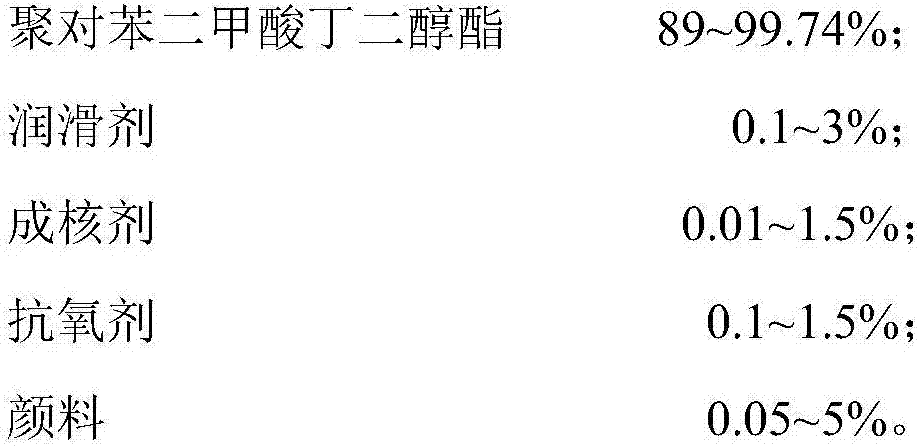

Low haze, high heat resistant and base coat-free PBT composite material and preparation method thereof

InactiveCN106867211AImproves surface fogging and bloomingExpand the scope of applicationHeat deflection temperatureThermal deformation

The invention discloses a low haze, high heat resistant and base coat-free PBT composite material and a preparation method thereof, and aims to solve the problem that the thermal deformation temperatures of existing PBT base coat-free products are all below 160DEG C and cannot meet the high heat resistance requirements of car light decorating parts. One purpose of the invention is to provide the low haze, high heat resistant and base coat-free PBT material, and another purpose is to provide a preparation of the PBT composite material. Determination shows that the prepared PBT composite material has very good surface smoothness, and injection molded parts prepared by the PBT composite material can be subjected to vacuum aluminizing directly. At the same time, the invention effectively solves the surface haze phenomenon during long-term use of aluminized products under a high temperature environment. In addition, the product prepared by the method provided by the invention has very high thermal deformation temperature, can meet higher use requirement, and has significant progress relative to the prior art.

Owner:SICHUAN COREMER CO LTD

Silica gel composite membrane for collecting biological texture image, preparation method and purpose thereof

ActiveCN103057229APlay a supporting roleHigh light transmittanceSynthetic resin layered productsPalm printImaging quality

The invention discloses a silica gel composite membrane for collecting a biological texture image and a preparation method thereof. The preparation method comprises the following steps: coating a liquid silica gel on the surface of a surface-treated substrate film by using coating technologies such as spin coating or blade coating, controlling the thickness of the silica gel membrane through adjusting a coating process, and finally curing the silica gel membrane so as to form the silica gel composite membrane. The silica gel composite membrane disclosed by the invention has the advantages of high light transmittance, low haze, high hydrophobicity, scratch resistance and high rebound elasticity; and through an electrostatic effect, the silica gel composite membrane is adsorbed to the surface of a glass window of a fingerprint (or palm print) image collector; therefore, the image collecting sensitivity is enhanced, the imaging quality is improved, the image analysis difficulty of image processing software is reduced and the identification rate of the fingerprints (or palm prints) is increased; and in a dry or wet environment, the silica gel composite membrane is especially effective for improving the fingerprint (or palm print) image collecting quality.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Anti-dazzle hardened film for liquid crystal display

InactiveCN112480454AAvoid smearingImprove clarityPolyurea/polyurethane coatingsIdentification meansMicron scaleSilicon dioxide

The invention relates to the technical field of thin films, and particularly relates to an anti-dazzle hardened film for liquid crystal display. The anti-dazzle hardened film comprises the following substances in parts by weight: 15-45 parts of urethane acrylate resin, 5-30 parts of an active diluent, 0.01-5 parts of a leveling agent, 3-20 parts of micron-sized organic particles, 3-10 parts of a photoinitiator, 5-35 parts of modified nano silicon dioxide, and 30-60 parts of an organic solvent. The anti-dazzle hardened film has low haze and improves light transmittance and friction resistance without losing display characteristics such as high definition and anti-dazzle performance.

Owner:HEFEI LUCKY SCI & TECH IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com