Transparent, fire-retardant aromatic polycarbonate resin composition and molded product

A polycarbonate resin, aromatic technology, applied in the field of aromatic polycarbonate resin composition, can solve the problems of limited use, impact resistance, heat resistance reduction, molding mold corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

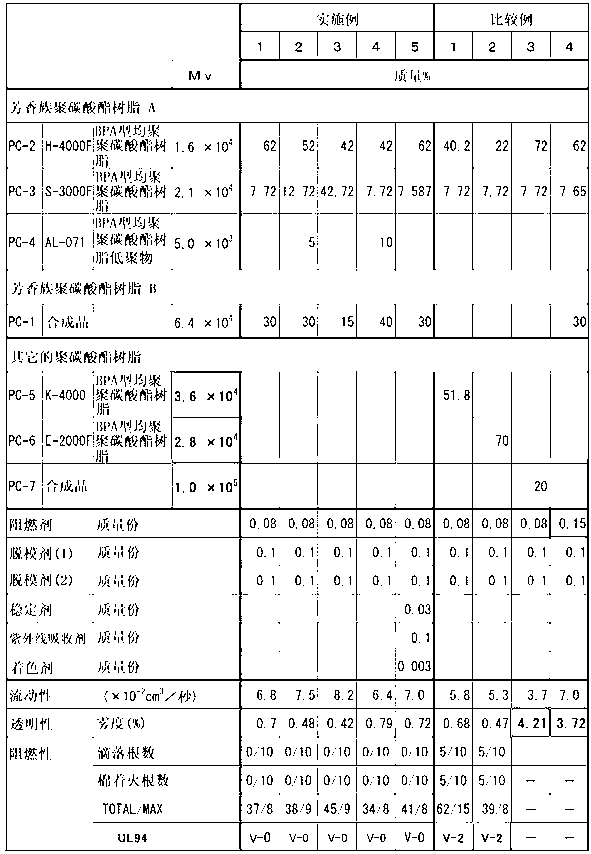

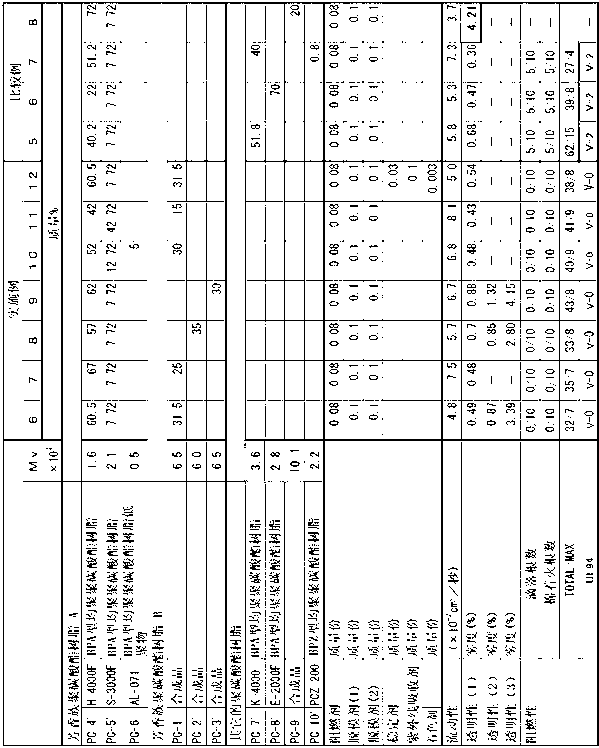

[0072] The polycarbonate resin composition used in Example 1-Example 5, Comparative Example 1-Comparative Example 4, Example 6-Example 12, Comparative Example 5-Comparative Example 8 was prepared by the following method. That is, each component was mixed with a tumbler for 20 minutes at the contents (addition ratio, mass %) shown in Table 2 and Table 3, and then supplied to a twin-screw extruder manufactured by Nippon Steel Works Co., Ltd. with one vent hole. In the extruder (TE×30×CT), the screw rotation speed is 200rpm, the discharge rate is 20kg / hour, and the barrel (barrel) temperature is 310°C. Medium quenching and granulation using a granulator to obtain granules of the polycarbonate resin composition.

[0073] Then, in the transparency test, after drying the obtained pellets at 120° C. for 5 hours, they were molded at a cylinder temperature of 290° C. and a mold temperature of 80° C. Injection molding was performed under the conditions of a molding cycle of 50 seconds,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com