Ultraviolet-shielding transparent resin molding and manufacturing method of the same

A technology of transparent resin and manufacturing method, applied in the direction of nanotechnology, zinc oxide/zinc hydroxide, fibrous filler, etc. for material and surface science, which can solve the problem that the ultraviolet shielding ability of ultra-fine zinc oxide particles is reduced and cannot be completely removed. Impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

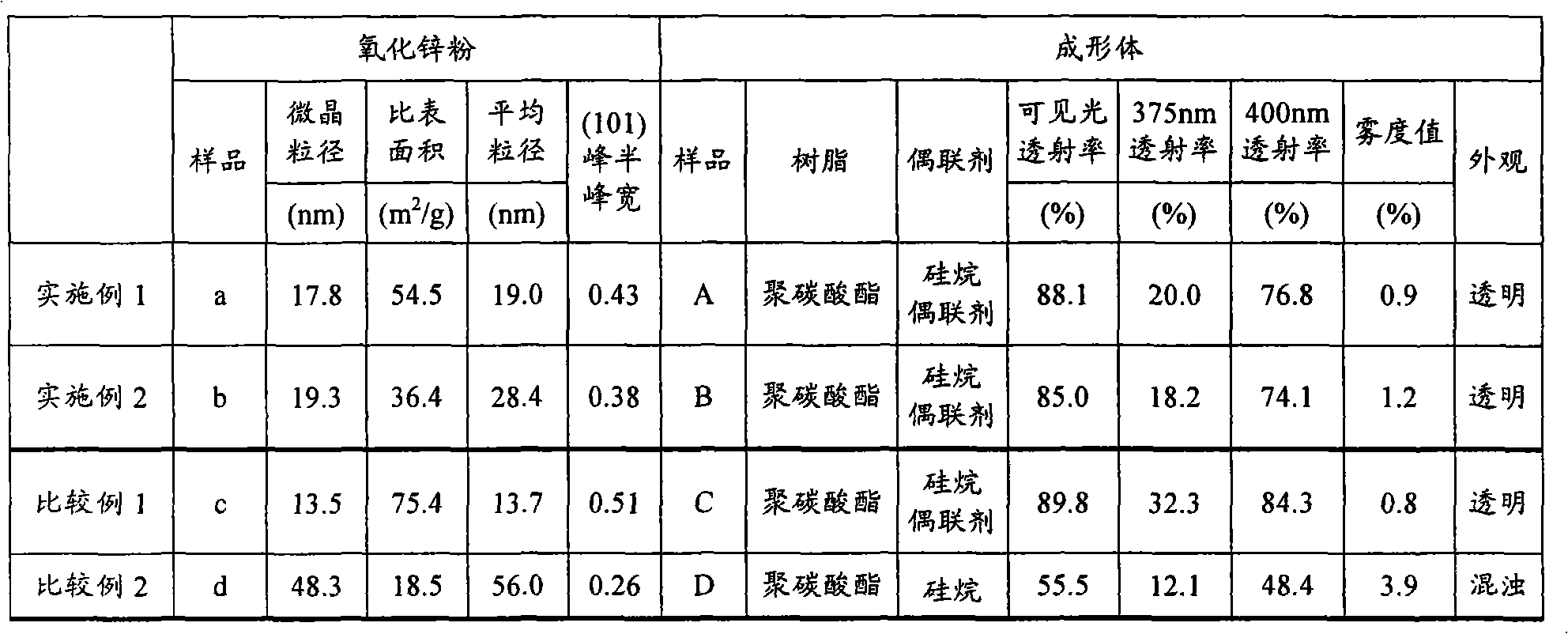

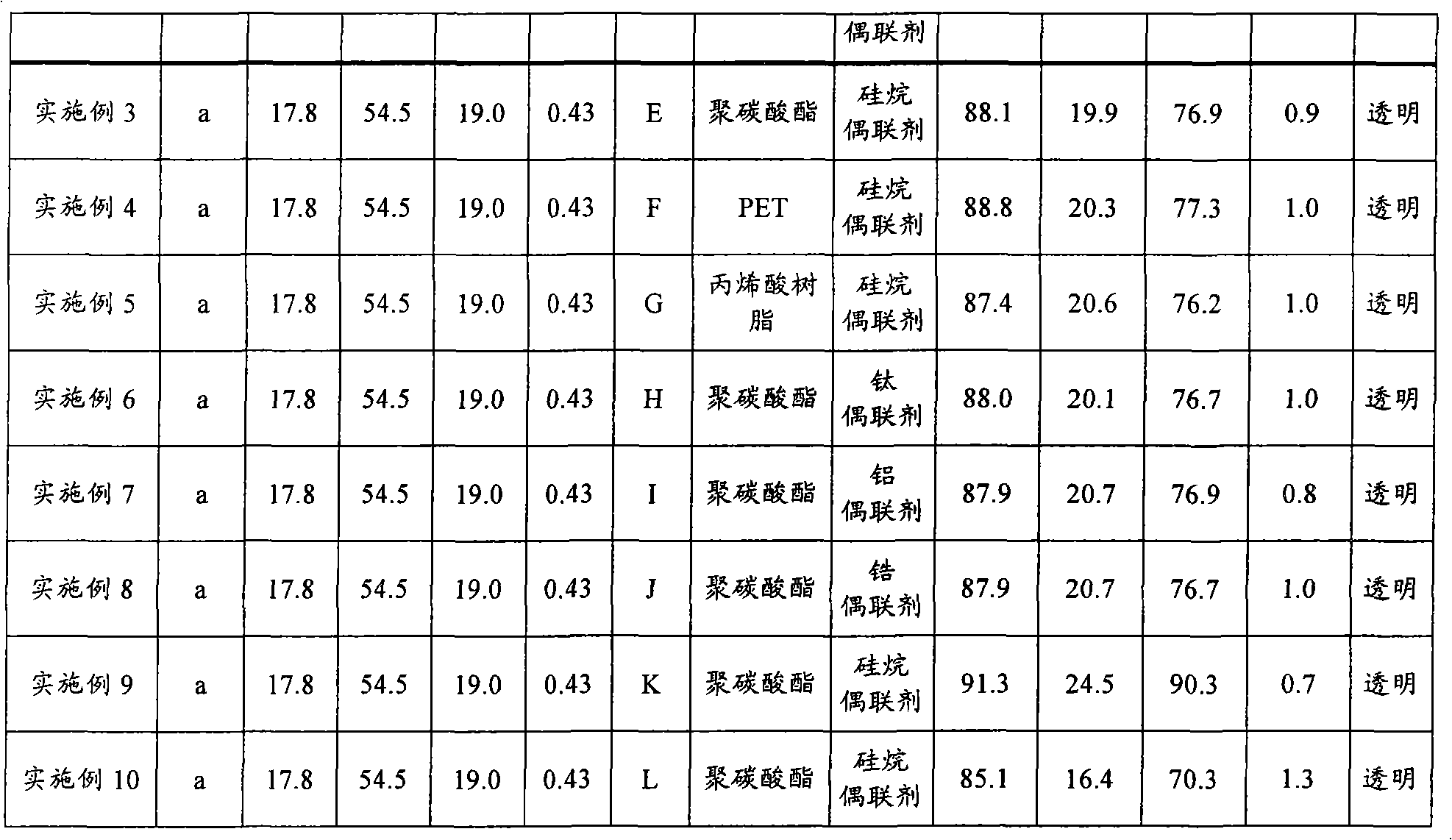

[0083] According to the preparation method of the zinc oxide microparticles used in the present invention, by dropping the solution of the zinc compound into the alkali solution, the zinc compound solution can instantly reach supersaturation and form a precipitate, so that uniform microparticles with uniform particle size can be obtained. Zinc oxide particles. Furthermore, decantation was performed using pure water to wash the generated precipitate. Repeat the decanting operation until the conductivity of the cleaning solution after cleaning reaches 1 mS / cm or less, so that impurities are sufficiently removed, thereby avoiding the ultraviolet shielding properties of the ultraviolet shielding transparent resin molded body of the present invention in which the zinc oxide particles are dispersed. reduce. Thereby, it is possible to provide a transparent resin molded article that shields ultraviolet rays and exhibits not only transparency but also excellent ultraviolet shielding p...

Embodiment 1

[0138] 1100 g of an aqueous solution containing 86.9 g of ammonium bicarbonate (special grade) was prepared.

[0139] This ammonium bicarbonate aqueous solution was stirred at 25°C, and 946.1 g of an aqueous solution containing 148.4 g of zinc nitrate hexahydrate (special grade) was added dropwise thereto over 6 minutes to form a precipitate. After the above-mentioned dropwise addition was completed, the stirring was continued for another 10 minutes to ripen the precipitate. The final pH at this point was 7.5.

[0140] Next, the precipitate was repeatedly washed by decantation using pure water until the conductivity of the washing liquid after washing became 1 mS / cm or less.

[0141] The washed precipitate was dried at 105°C to obtain a dry powder. Containing 8.2g colloidal silicon dioxide (SiO 2 Content 20% by weight) modified alcohol (Nippon Alcohol Sales (Nippon Alcoll Sales) Co., Ltd., SOLMIX (Solmix) AP-2 (trade name): hereinafter sometimes abbreviated as "AP-2") solut...

Embodiment 2

[0146] Zinc oxide fine particles b were obtained in the same manner as in Example 1 except that the amount of ammonium bicarbonate was 79 g and colloidal silica was not added when producing zinc oxide fine particles.

[0147] The specific surface area of zinc oxide particle b is 36.4m 2 / g, the average particle diameter is 28.4nm, the half width of the X-ray diffraction (101) peak is 0.38, and the crystallite particle diameter is 19.3nm.

[0148] A transparent resin molded body B that blocks ultraviolet rays was obtained in the same manner as in Example 1 except that zinc oxide fine particles b were used instead of zinc oxide fine particles a. Table 1 shows the optical properties of the ultraviolet-blocking transparent resin molded body B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com