Preparation method of diffuse reflection colored glass

A technology of colored glass and diffuse reflection, applied in the field of preparation of diffuse reflection colored glass, can solve the problems of color film not considering color difference and complicated process, and achieve the effect of minimizing color difference and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention provides a method for preparing diffuse reflection colored glass, comprising the following steps:

[0035] S1. Take the float glass and clean it with 10% surfactant (sodium dodecylbenzenesulfonate) first, then clean it with deionized water; put it into 10% sodium hydroxide solution Soak for 5 minutes, then soak in 10% dilute hydrochloric acid solution for 5 minutes, wash with water and ethanol in turn, and dry;

[0036] S2. Carry out single-sided packaging on the A side of the cleaned float glass (paste the anti-corrosion film on the A side), and do anti-acid corrosion protection treatment;

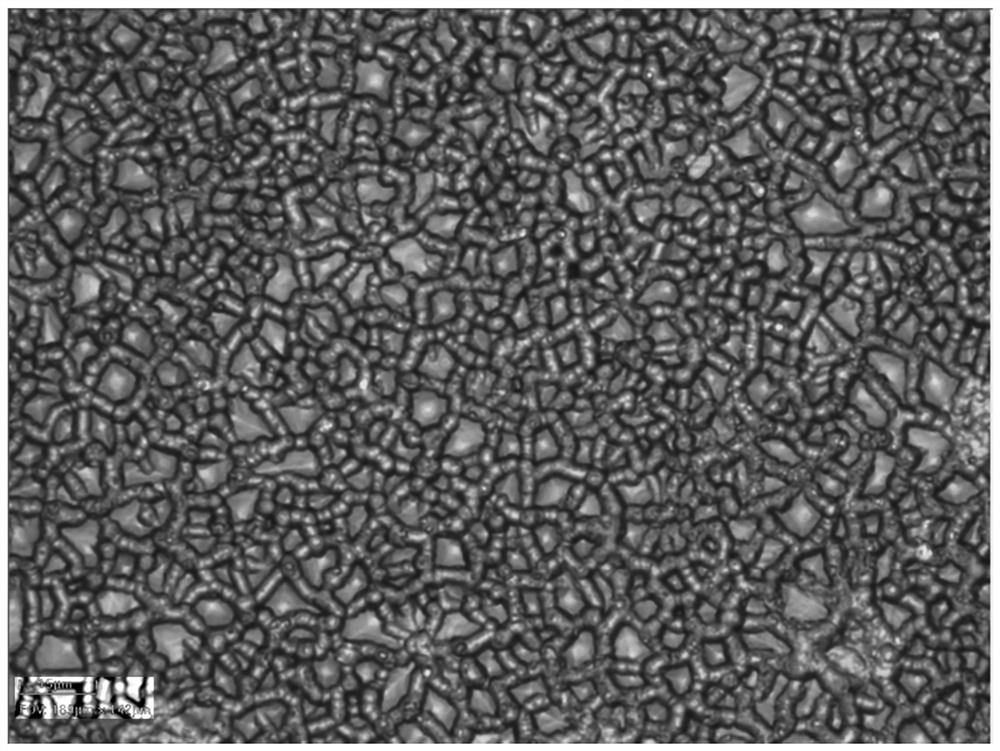

[0037] S3. Immerse the encapsulated float glass in the first acid etching solution, and perform acid etching treatment on the B surface. The first acid etching solution contains 18% hydrofluoric acid (concentration 40%) and 15% sulfuric acid in weight percentage (concentration 98%), 13% ammonium bifluoride, 13% potassium chloride, 5% ammonium sulfate, 3% zinc acetate...

Embodiment 2

[0042] The invention provides a method for preparing diffuse reflection colored glass, comprising the following steps:

[0043] S1. Take the float glass and clean it first with 10% surfactant (fatty alcohol polyoxyethylene ether) and then with deionized water; soak in 10% sodium hydroxide solution for 5 Minutes, then soaked in 10% dilute hydrochloric acid solution for 5 minutes, washed with water and ethanol in turn, and dried in the air.

[0044] S2. Encapsulate the cleaned float glass on the A-side and single-side to prevent acid corrosion protection.

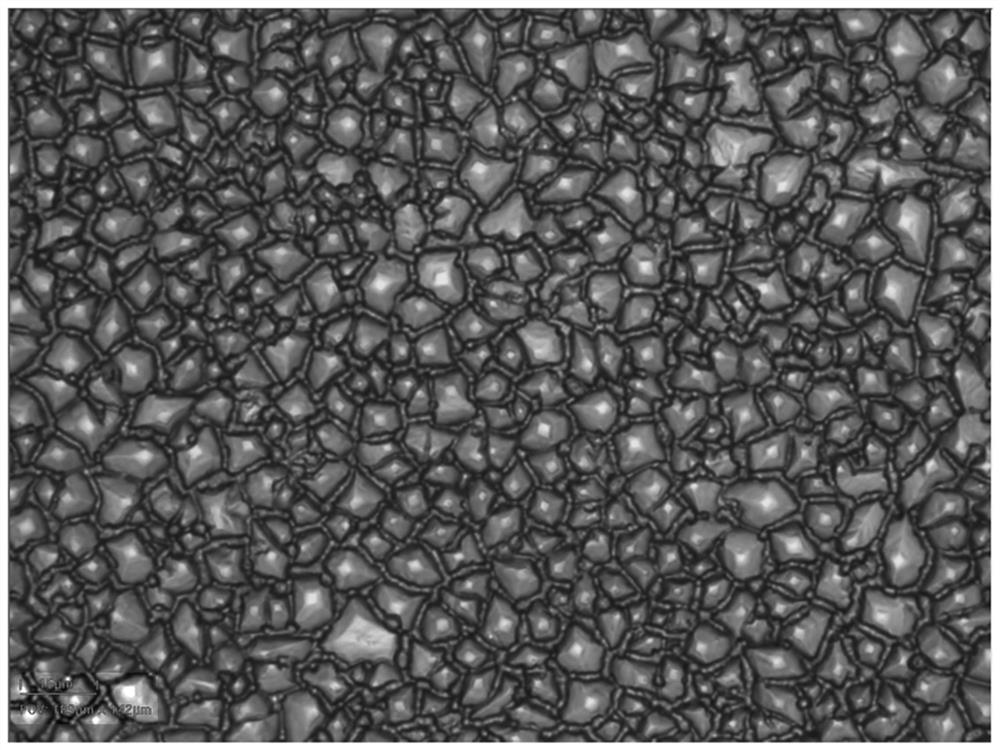

[0045] S3. Immerse the encapsulated float glass in the first acid etching solution for acid etching treatment. The acid etching solution contains 16% hydrofluoric acid (concentration 40%) and 15% sulfuric acid (concentration 98%) by weight percentage , 12% ammonium bifluoride, 15% potassium chloride, 5% ammonium sulfate, 3% zinc acetate, 3% aluminum nitrate, 4% sodium chloride, and 27% water, soak for 30 minutes.

[0046] S...

Embodiment 3

[0050] The invention provides a method for preparing diffuse reflection colored glass, comprising the following steps:

[0051] S1. Take the float glass and clean it. When cleaning, first use 10% surfactant to clean it, and then clean it with deionized water; put it into 10% sodium hydroxide solution for 5 minutes, and then put it into 10% sodium hydroxide solution. % dilute hydrochloric acid solution for 5 minutes, washed with water and ethanol in turn, and dried in the air.

[0052] S2. Encapsulate the cleaned float glass on the A-side and single-side to prevent acid corrosion protection.

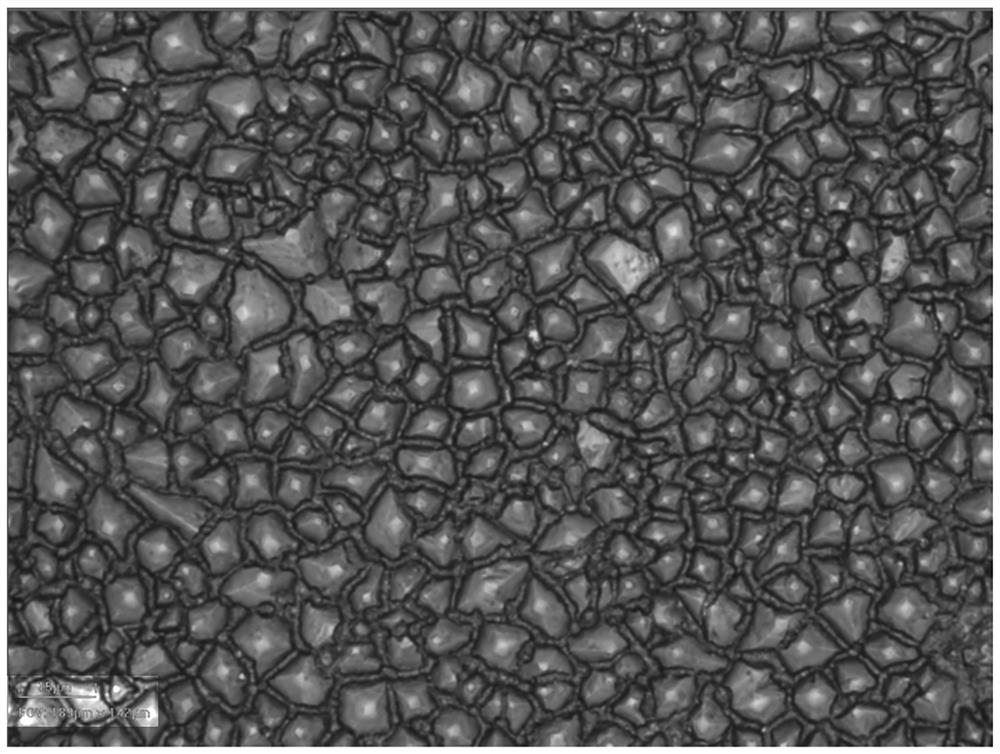

[0053]S3. Immerse the encapsulated float glass in an acid etching solution for acid etching treatment. The acid etching solution contains 15% hydrofluoric acid (concentration 40%), 15% sulfuric acid (concentration 98%), 11 % ammonium bifluoride, 15% potassium chloride, 6% ammonium sulfate, 4% zinc acetate, 4% aluminum nitrate, 3% sodium chloride, and 27% water, soak for 40 minutes.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com