Polymer microspheres, preparation method and application thereof, composition, light diffusion plate or light diffusion film, lamp and backlight module

A technology of light diffusion plate and light diffusion film, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of inability to obtain light diffusion effect, poor compatibility between hydroxyl and resin matrix, etc., and achieve low refractive index and good transparency. Optical, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

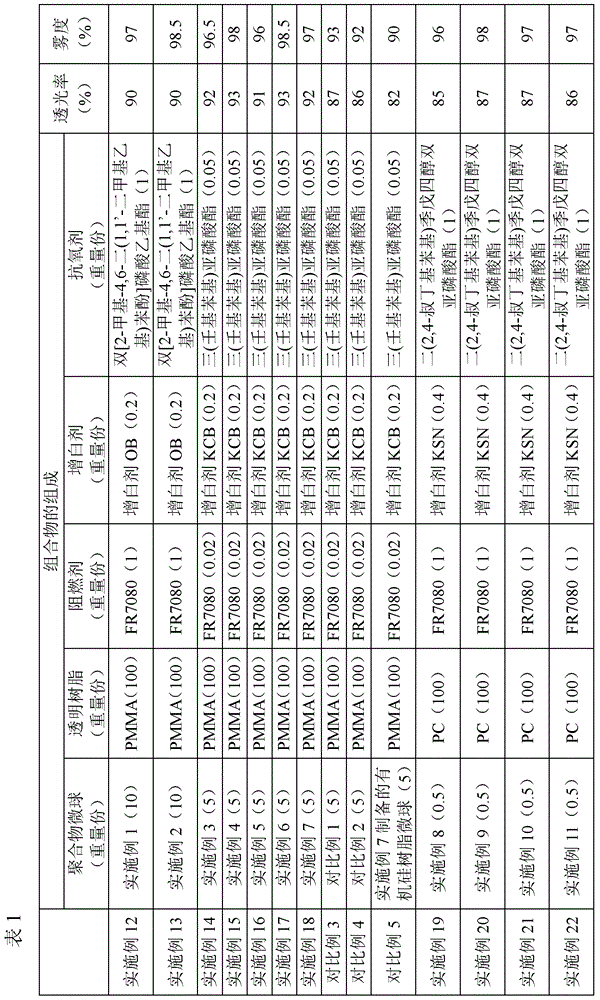

Examples

preparation example Construction

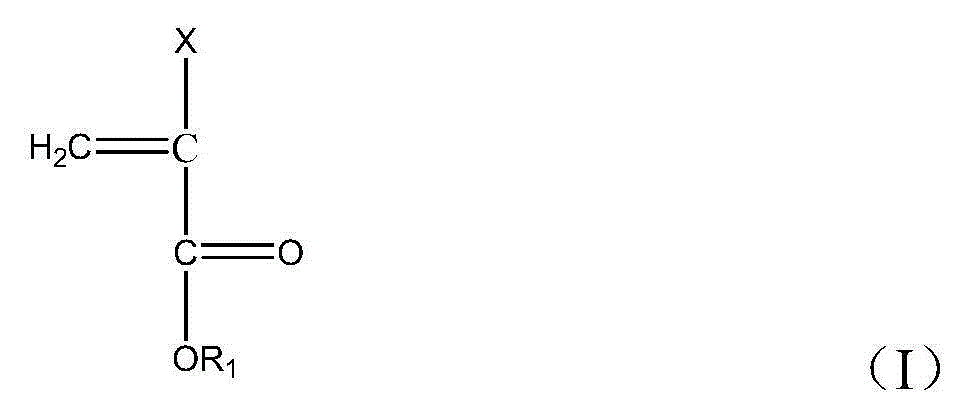

[0055] The present invention also provides a method for preparing polymer microspheres according to the present invention, the method comprising: under olefin polymerization conditions, contacting acrylate-based monomers with silicone resin microspheres having vinyl groups on the surface and an initiator , to form the polymer microspheres.

[0056] According to the method of the present invention, the ratio between the acrylate monomer and the silicone resin microspheres can be properly selected according to the specific application of the final prepared polymer microspheres. When the final prepared polymer microspheres are used as a light diffusing agent to prepare a light diffusion plate or a light diffusion film, the weight ratio of the acrylate monomer to the silicone resin microspheres can be such that the final prepared polymer microspheres In the spheres, the weight ratio of silicone resin microspheres (ie, inner core) to polymer microspheres is 0.5-0.98:1, preferably 0...

Embodiment 1

[0114] (1) Mix 30 g of vinyltrimethoxysilane and 200 g of ethanol evenly, then adjust the pH value of the mixture to 5 with hydrochloric acid, and stir and react at a temperature of 20° C. for 3 hours. Then, ammonia water with a concentration of 37% by weight was added to the above mixture, the pH of the mixture was adjusted to 9, and the mixture was reacted at a temperature of 10° C. for 3 hours. The reaction mixture is subjected to centrifugation to obtain silicone resin microspheres with vinyl groups on the surface. The amount of vinyl groups on the surface of the silicone resin microspheres was 0.1 mol / g. The silicone resin microspheres had an average particle diameter of 1.0 μm.

[0115] (2) Under the protection of nitrogen, 5 grams of silicone resin microspheres obtained in step (1) were dispersed in 90 grams of deionized water, and 1 gram of methyl methacrylate was added, and allowed to stand for 2 hours. Then, 0.05 g of an azobisisoheptanonitrile initiator was added ...

Embodiment 2

[0117] Adopt the same method as Example 1 to prepare polymer microspheres, the difference is that step (2) is:

[0118] 5 grams of silicone resin microspheres obtained in step (1) were dispersed in 90 grams of deionized water, and 0.5 grams of methyl methacrylate and 0.5 grams of trimethylolpropane trimethacrylate (commercially purchased from Hangzhou Zhejiang University) were added. Fanke Chemical Co., Ltd.), and let stand for 2 hours. Then, 0.05 g of an azobisisoheptanonitrile initiator was added to the above mixture, and the temperature of the mixture was raised to 70° C. with stirring, and maintained at this temperature for 6 hours. The obtained mixture was subjected to centrifugal separation, and the obtained solid microspheres were washed 3 times with deionized water, and dried in a vacuum oven at 60° C. for 2 hours, thereby obtaining 5.85 g of polymer microspheres according to the present invention. The average particle diameter of the polymer microspheres was 1.1 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com