High-brightness shielding and low-deformation quantum dot diffusion plate and preparation method and application thereof

A technology of quantum dots and diffusion plates, applied in the field of display and lighting, can solve the problems of display problems, display distortion, difficult industrialized continuous production, etc., to reduce the linear expansion coefficient, improve the deformation resistance, high brightness and haze value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

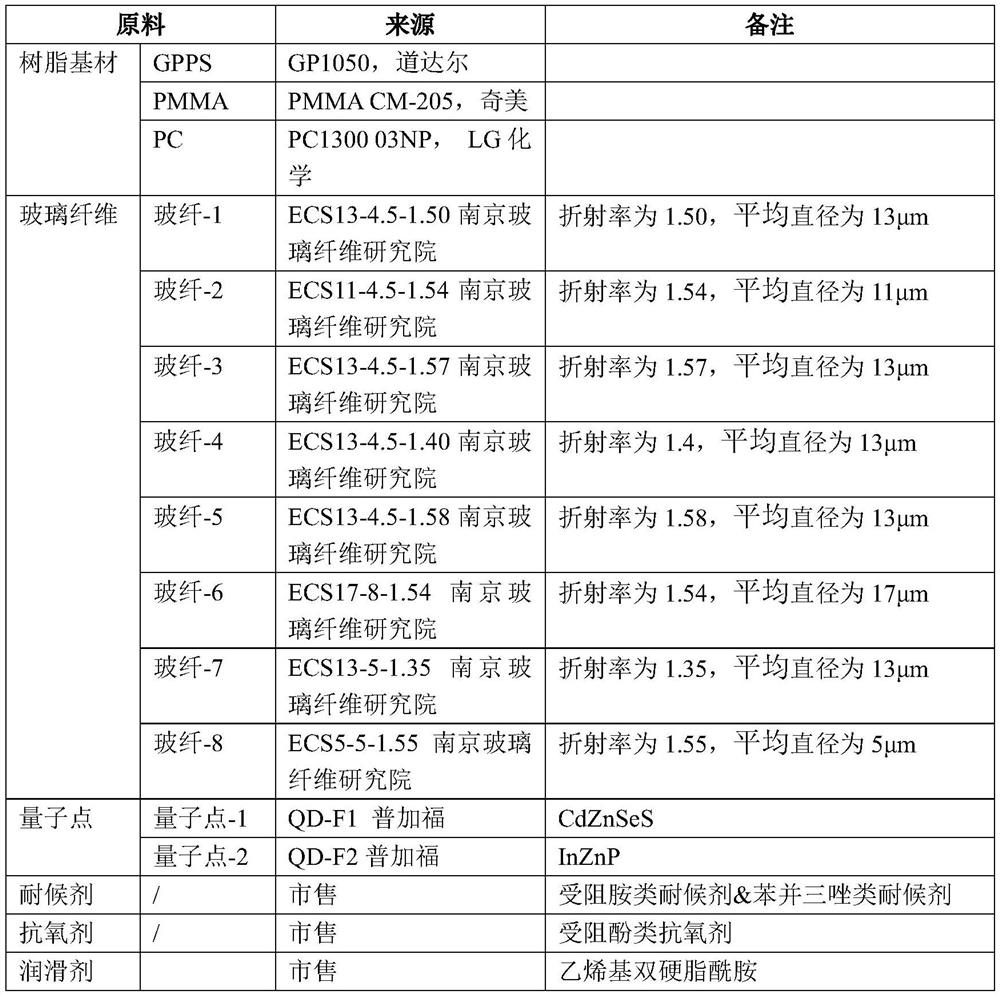

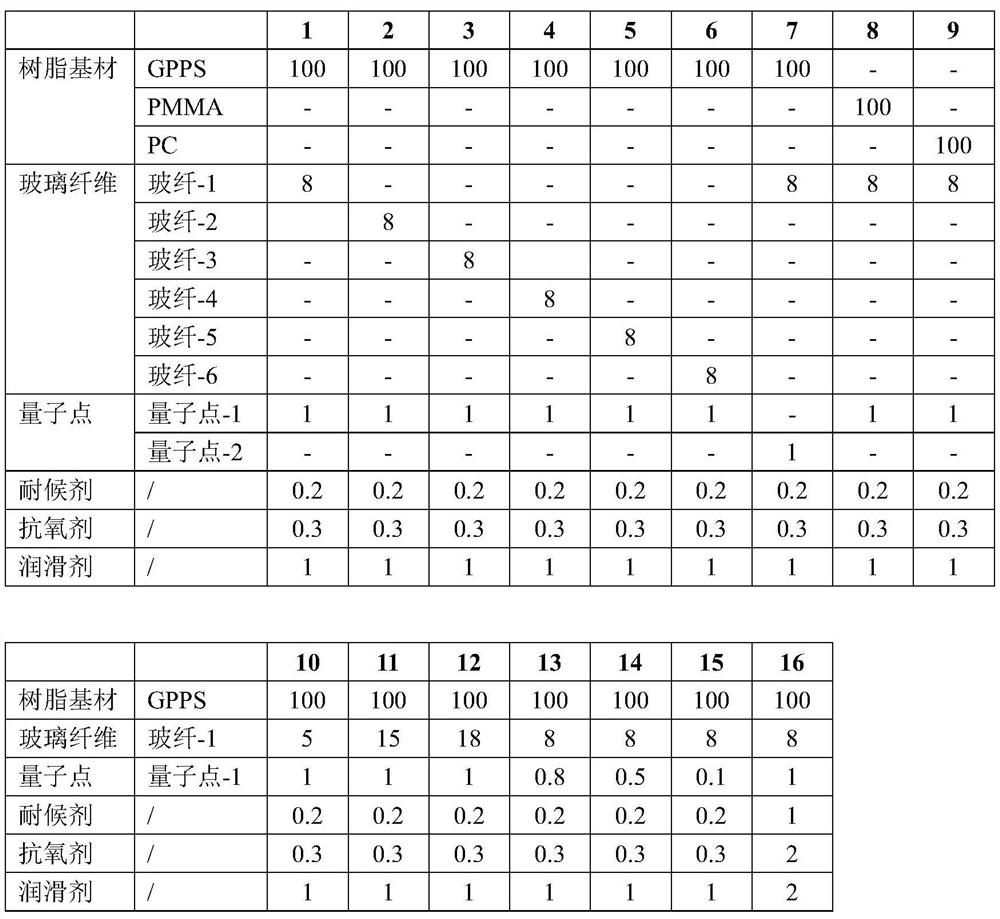

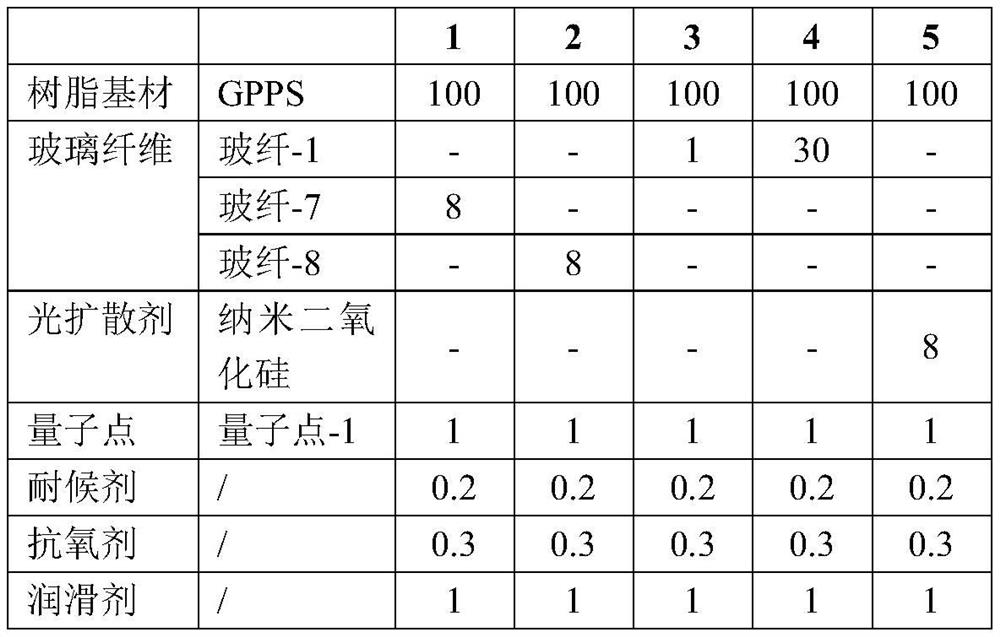

Embodiment 1~16

[0053] Examples 1 to 16 provide a quantum dot diffusion plate, the component content is shown in Table 1, the preparation method is as follows:

[0054] S1. The quantum dots and part of the resin substrate are dissolved in an organic solvent (styrene), mixed evenly, heated and stirred in a vacuum environment, the solvent is removed, and the solid product obtained is the quantum dot masterbatch;

[0055] Among them, the mass ratio of quantum dots to some resin substrates is 5:100;

[0056] S2. The remaining resin substrate, quantum dot masterbatch prepared by step S1, glass fiber, weathering agent, antioxidant and lubricant are mixed, added to the single screw extruder, melted and mixed, extruded to obtain a quantum dot diffusion plate, the size specification is 85 inches, the thickness is 1.5mm;

[0057] Among them, the head temperature of the single screw extruder is 165 ~ 185 °C, the temperature of the first area of the fuselage is 150 ~ 160 °C, the temperature of the second zon...

Embodiment 1

[0061] Example 17 provides a quantum dot diffusion plate, the component content is the same as Example 1, the preparation method and the difference between Example 1 is:

[0062] The mass ratio of quantum dots to some resin substrates in step S1 is 3:100.

Embodiment 18

[0064] Example 18 provides a quantum dot diffusion plate, the component content is the same as Example 1, the difference between the preparation method and Example 1 is:

[0065] The organic solvent in Step S1 is toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com