Paraxylene adsorbent and preparing method thereof

A technology for p-xylene and an adsorbent, which is applied in the field of adsorbent and preparation of p-xylene in the adsorption and separation of mixed xylene, can solve the problem of difficulty in conveniently preparing small spherical adsorbents, high cost, and complicated oleyl amine column forming process. problems, to achieve the effect of reasonable pore distribution, good crushing strength and high bulk density of the adsorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Specifically, the preparation method of the adsorbent of the present invention comprises the following steps:

[0017] (1) Prepare masterbatch: mix X zeolite or Y zeolite with kaolin to make a masterbatch with a particle size of 0.180-0.190 mm, and the content of kaolin in the masterbatch is less than 5% by mass;

[0018] (2) Rolling ball forming: put the masterbatch in the rolling plate of the rolling machine, and prepare the powder of X zeolite or Y zeolite and kaolin in batches for rolling ball forming. The content of kaolin in the powder used in the initial stage of rolling is 5-7 % by mass, the content of kaolin in the powder used in the middle stage of rolling is 8-10% by mass, the content of kaolin in the powder used in the later stage of rolling is 11-13% by mass, and the amount of water sprayed into each stage of rolling is 15% of the quality of the powder used ~20%, the mass ratio of powder used in the initial, middle and late stages of ball rolling is 1:1.5~1...

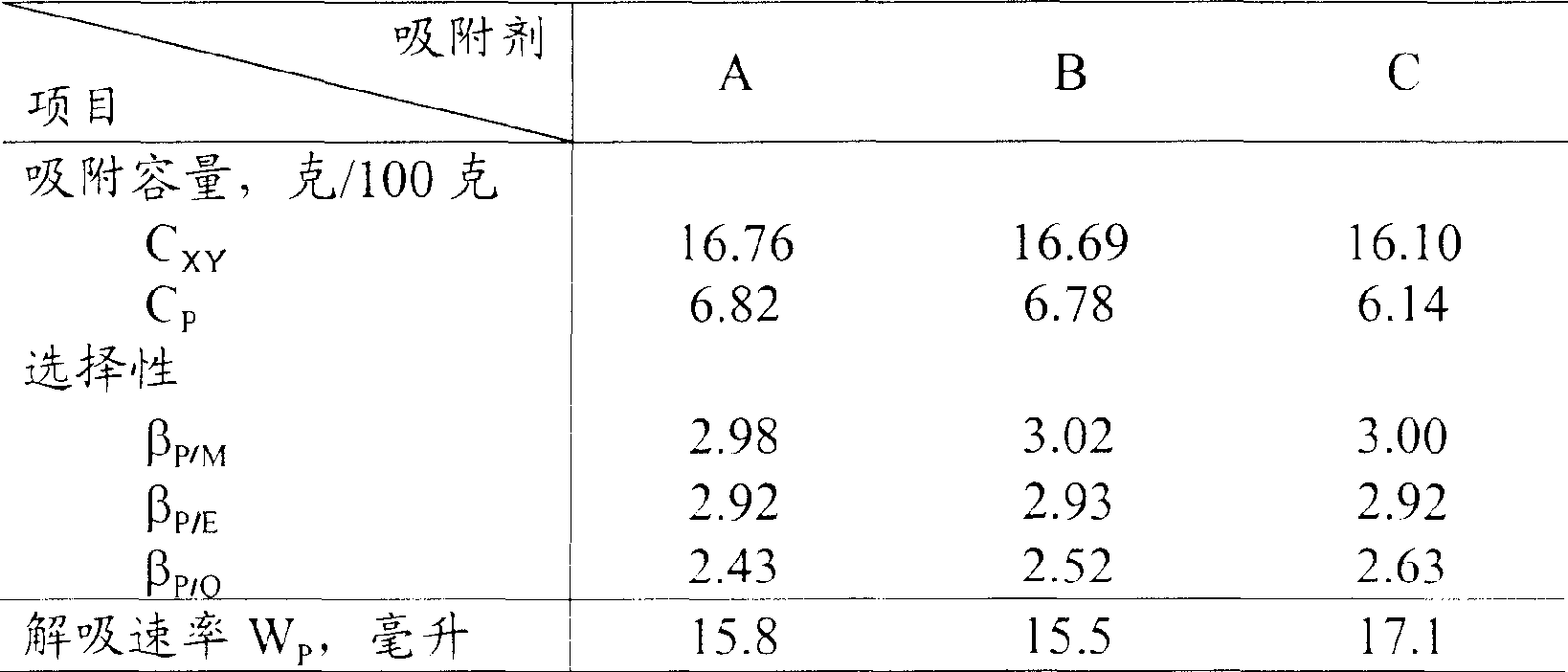

example 1

[0038] Prepare the adsorbent of the present invention.

[0039] Mix NaX with kaolin (produced in Linfen, Shanxi) to make powder. Among them, the relative crystallinity of NaX is 101%, the ratio of silicon to aluminum in the skeleton is 2.36, the grain size is 1 micron, and the mass fraction of chemical element composition analysis is as follows:

[0040] Na 2 O 15%, SiO 2 52%, Al 2 o 3 32%, K 2 O 0.59%, Fe 2 o 3 0.27%

[0041] The average particle diameter of kaolin is 57 microns, and the kaolinite content is 80% by mass, and the halloysite content is 10% by mass.

[0042] (1) Preparation of masterbatch: Mix the above-mentioned NaX and kaolin at a dry basis mass ratio of 95:5 to make powder, and roll them into small balls with a particle size of 0.180 to 0.190 mm in the rolling plate of a rolling ball machine as a masterbatch , The amount of deionized water added when rolling the ball is 5% of the powder mass.

[0043] (2) Rolling ball molding: prepare kaolin and N...

example 2

[0046] Adsorbent B was prepared according to the method of Example 1, except that the kaolin used contained 90% kaolinite. The composition and physicochemical properties of adsorbent B are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com